- Tank capacity calculation

- What is it and how is it different from conventional water systems

- System elements

- Service life and scope

- How to turn an open system into a closed system

- Pump selection rules

- Characteristics of Leningradka

- What is the system and how does it work

- Types of open heating schemes

- Natural circulation in heating

- Forced system with pump

- Answers to frequently asked questions about the beam system

- Requirements for the arrangement and operation

- The principle of operation of the heating system without a pump

- Selection of pipes, boiler and radiators

- Installation of the heating structure "Leningradka"

- What is the best material for the pipeline?

- Connection of radiators and pipes

- Starting the heating structure

- Features of the device and operation

Tank capacity calculation

This element of the heating network should not be too bulky or unacceptably small. There are special formulas for calculating its capacity.

However, such techniques are so complex that only a specialist, a heat engineer, can master them. You can do it easier and perform the necessary calculation in a more accessible way, since it is necessary to choose an expansion tank for a closed heating system based on several factors.

The volume of coolant in the heating network increases by 5-10 percent when heated - this is a well-known fact.There are two ways to determine the initial amount of water in the circuit:

- practical - to measure the amount of water during test injection into the circuit;

- calculated - calculate how much coolant is placed in the boiler heat exchanger, in radiators and pipes. Such data on the boiler and batteries are in the passports for the equipment. The internal volume of pipes is determined by multiplying the cross-sectional area of \u200b\u200beach pipe by its length.

The resulting volume of coolant is multiplied by 10 percent (for a guarantee). The result obtained is the capacity of the expansion tank, which is suitable for a particular heating system.

In addition to determining the volume of the expansion tank, it is important to correctly assign its location. There is an opinion that in a closed system it can be installed anywhere in the heating circuit

This is not entirely true. There are some nuances, and they must be remembered. The expansion tank must not be installed:

- behind the pump, which creates pressure in the system;

- immediately after the boiler in the direction of hot water flow.

The most convenient is the location of the tank on the return pipe, in front of the boiler. It’s a good idea to mount a pressure gauge nearby to control the pressure, at this point it is always stable.

What is it and how is it different from conventional water systems

Many people believe that steam and water heating are one and the same. This is an erroneous opinion. With steam heating, there are also batteries and pipes, there is a boiler. But it is not water that moves through the pipes, but water vapor. The boiler is required completely different. Its task is to evaporate water, and not just heat it to a certain temperature, respectively, its power is much higher, as well as the requirements for reliability.

Several steam boilers

System elements

With steam heating, water vapor moves through the pipeline. Its temperature is from 130°C to 200°C. Such temperatures impose special requirements on the elements of the system. First, pipes. These are only metal pipes - steel or copper. Moreover, they should be seamless, with a thick wall.

Simplified scheme of steam heating

Secondly, radiators. Only cast iron, registers or finned pipe are suitable. Cast iron under such conditions is less reliable - in a heated state, from contact with a cold liquid, they can burst. More reliable in this regard are pipe registers, coils or a pipe with ribs attached to it - a convector-type heater. Steel is more tolerant of cold water entering its heated surface.

Service life and scope

But do not think that a steel steam heating system will last a very long time. Very hot and humid steam circulates in it, and these are ideal conditions for steel to corrode. Elements of the system quickly fail and fail. Usually they burst in the most corroded places. Despite the fact that steam with a temperature above hundred degrees is under pressure inside, the danger is obvious.

Structural diagram of a boiler for steam heating

Therefore, steam heating is recognized as dangerous and is prohibited for heating public places and apartment buildings. It is also used in some private houses or for heating industrial premises. In production, it is very economical if steam is a derivative of the technological process. In private houses, steam heating is used mainly in seasonal residences - in dachas.All due to the fact that it normally tolerates freezing - there is little water in the system and it cannot harm, and also because of its efficiency at the device stage (compared to water systems) and the high speed of heating the premises.

How to turn an open system into a closed system

An open expansion tank contributes to the natural evaporation of the coolant and its saturation with oxygen from the air masses. To get rid of these problems and extend the life of the system, it is enough to perform a simple conversion of an open heating circuit into a closed one. At the same time, the principle of circulation can be quite preserved, and water will move due to its physical properties, but the best option would be to purchase and install a circulation pump.

The main stages of modernization are as follows:

- dismantling and replacement of an open expansion tank;

- setting up a security group;

- expansion mat installation.

Pump selection rules

The device is selected according to two main characteristics: power and pressure. These parameters directly depend on the area of the heated building. In most cases, the following values \u200b\u200bare taken as a guideline:

- For a system heating an area of 250 m2, a pump with a capacity of 3.5 m3 / h and a pressure of 0.4 atmospheres is required.

- For an area up to 350 m2, it is better to choose equipment with a capacity of 4.5 m3 / h and a head of 0.6 atm.

- If the building has a large area, up to 800 m2, then it is recommended to use a pump with a capacity of 11 m3 / h with a pressure of more than 0.8 atmospheres.

If you take a more careful approach to the choice of pumping equipment, then additional parameters are taken into account:

- Pipeline length.

- Type of heating devices and their quantity.

- The diameter of the pipes and the material from which they are made.

- Type of heating boiler.

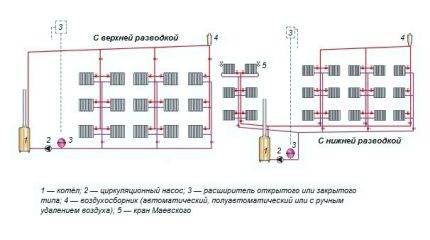

Characteristics of Leningradka

When choosing an installation, you should pay attention to the fact that it differs in the way the coolant circulates:

- Water moves forcibly. Leningradka with a pump increases circulation, but at the same time consumes electricity.

- Water moves by gravity. The process is carried out due to physical laws. Cyclicity is provided by the temperature difference and under the action of gravity.

The technical characteristics of Leningradka without a pump are inferior to forced ones in terms of the speed of movement of the coolant and the speed of heating.

To improve the properties of the equipment, it is equipped with various devices:

- Ball valves - thanks to them, you can adjust the temperature level for heating the room.

- Thermostats direct the coolant to the desired zones.

- Valves are used to regulate the circulation of water.

These add-ons allow you to upgrade even a previously installed system.

Advantages and disadvantages

The advantages of using include:

- Profitability - the cost of the elements is low, installation can be carried out independently. During operation, energy is saved.

- Availability - parts for assembly are available at any hardware store.

- The heating system of a private house in Leningradka is easily repaired in case of breakdowns.

Among the shortcomings are:

- Installation features. To equalize heat transfer, it is necessary to add several sections to each radiator located far from the boiler.

- Inability to connect to a horizontal installation of underfloor heating or heated towel rails.

- Since pipes with a large cross section are used when forming an external network, the equipment looks unaesthetic.

How to mount correctly?

Installing Leningradka is quite feasible with your own hands, for this, 1 of the methods is selected:

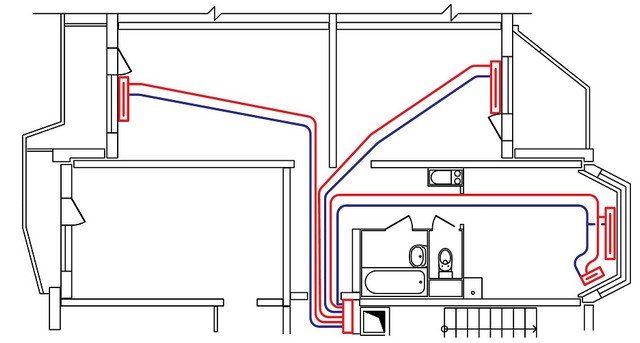

1. Horizontal. A prerequisite is the laying of a floor covering in the structure or on top of it, it is necessary to choose at the design stage.

The supply network is installed at a slope to ensure the free movement of water. All radiators must be located on the same level.

2. Vertical is used in case of using forced type equipment. The advantage of this method lies in the rapid heating of the coolant even when installing pipes with a small cross section. Functioning occurs due to the installation of a circulation pump. If you want to do without it, then you should purchase pipes with a large diameter and place them under a slope. The Leningradka vertical water heating system is mounted with bypasses, which allow repairing individual elements of the equipment without shutting it down. The length must not exceed 30 m.

Features of the installation of the Leningradka heating system are reduced to following the sequence of work:

- Install the boiler and connect it to a common line. The pipeline must run around the entire perimeter of the building.

- The expansion tank is a must. To connect it, a vertical pipe is cut. It should be located near the heating boiler. The tank is installed above all other elements.

- Radiators are cut into the supply network. They are supplied with bypasses and ball valves.

- Close the equipment on the heating boiler.

A video review of the Leningradka heating distribution system will help you understand the order of work and follow their sequence.

“A few years ago we moved to live outside the city. We have a single-pipe heating system installed in a two-story house similar to Leningradka. For normal circulation, I connected the equipment to the pump. There is enough pressure for heating the 2nd floor, it is not cold. All rooms are well heated. Easy to install, no expensive materials required.

Grigory Astapov, Moscow.

“When choosing heating, I studied a lot of information. According to reviews, Leningradka approached us due to the savings in materials. Radiators chose bimetallic. It works smoothly, fully copes with the heating of a two-story house, but the equipment should be cleaned periodically. After 3 years, our radiators stopped working at full capacity. It turns out that garbage was clogged on the approaches to them. After cleaning, the operation resumed.

Oleg Egorov, St. Petersburg.

“The Leningradka heating distribution system has been working with us for more than a year. Generally satisfied, easy installation and easy maintenance. I took polypropylene pipes with a diameter of 32 mm, the boiler runs on solid fuel. We use antifreeze diluted with water as a coolant. The equipment fully copes with the heating of a house of 120 m2.

Alexey Chizhov, Yekaterinburg.

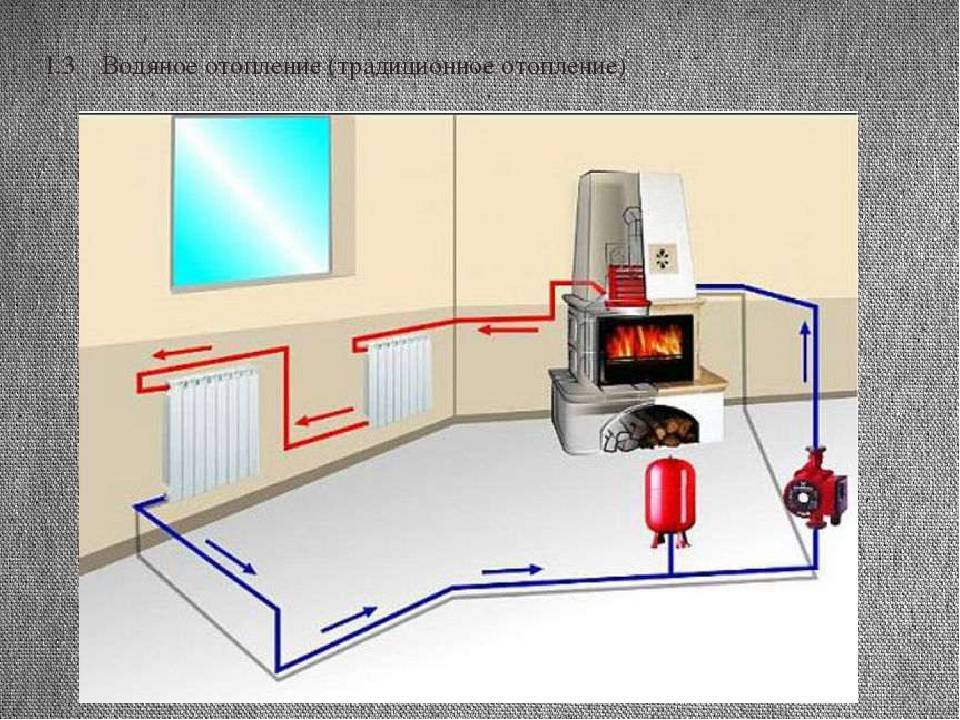

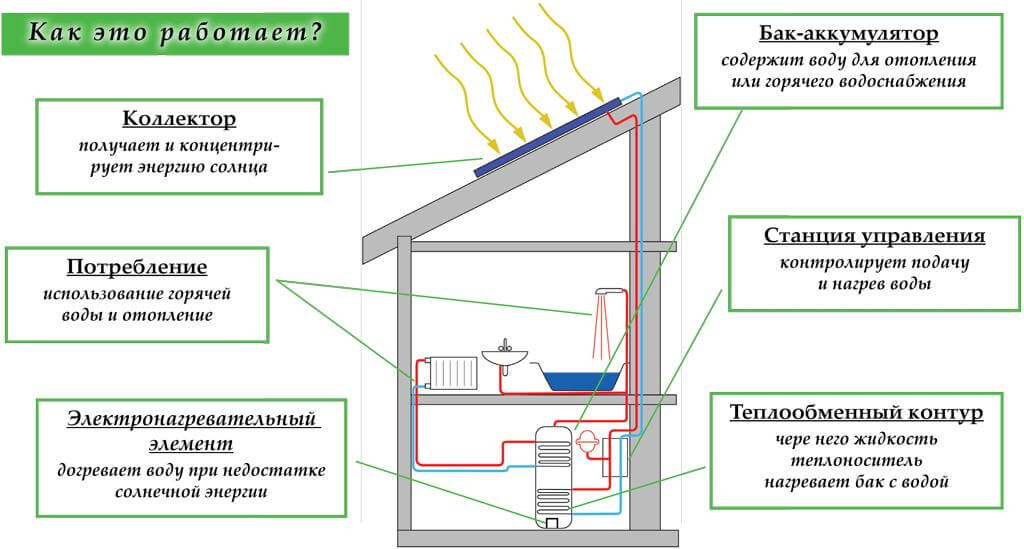

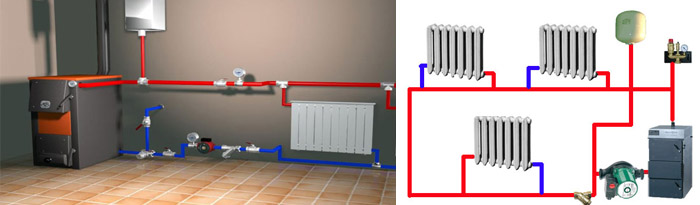

What is the system and how does it work

In order for heat to flow from the boiler room to the heating devices, an intermediary is used in the water system - a liquid. This type of coolant moves through the pipeline and heats the rooms in the house, and all of them can have a different area. This factor makes such a heating system popular.

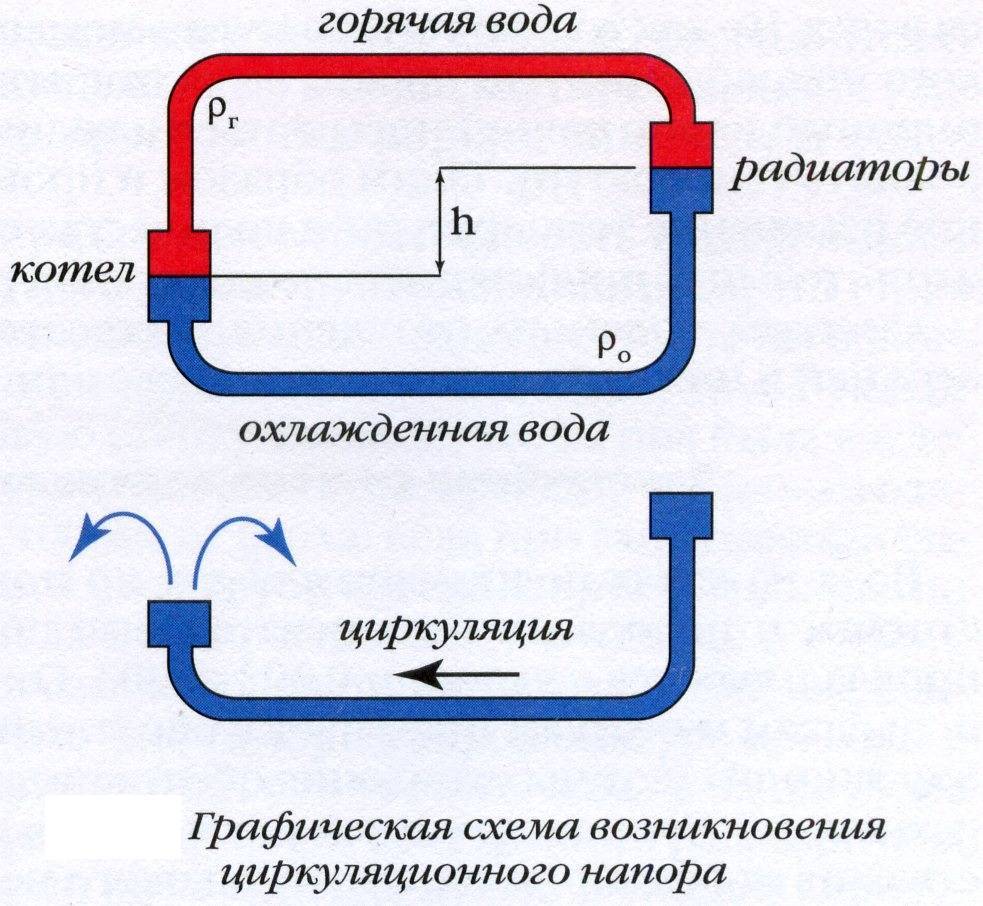

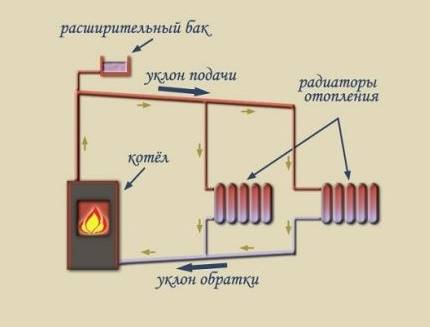

The movement of the coolant can be carried out in a natural way, the circulation is based on the principles of thermodynamics.Due to the different density of cold and heated water and the slope of the pipeline, water moves through the system.

Open heat supply operates according to the following scheme:

- Water is heated in the boiler and supplied to the heating devices in each room of the house.

- On the way back, excess liquid goes into an open-type expansion tank, its temperature drops, and the water returns to the boiler.

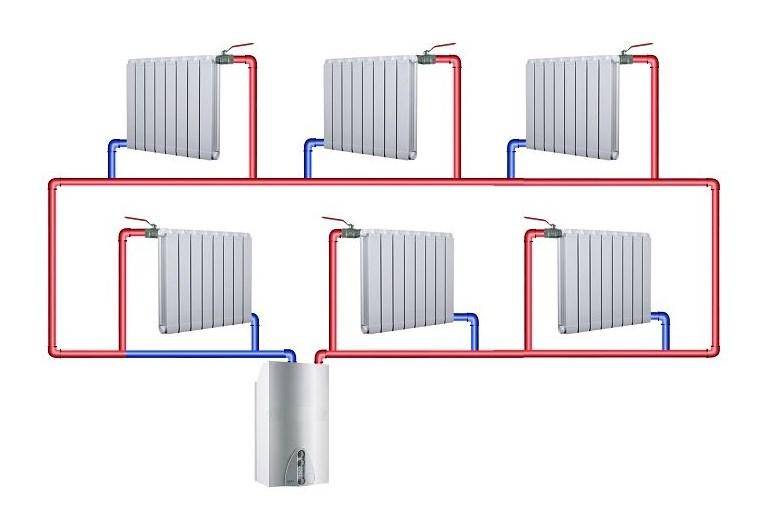

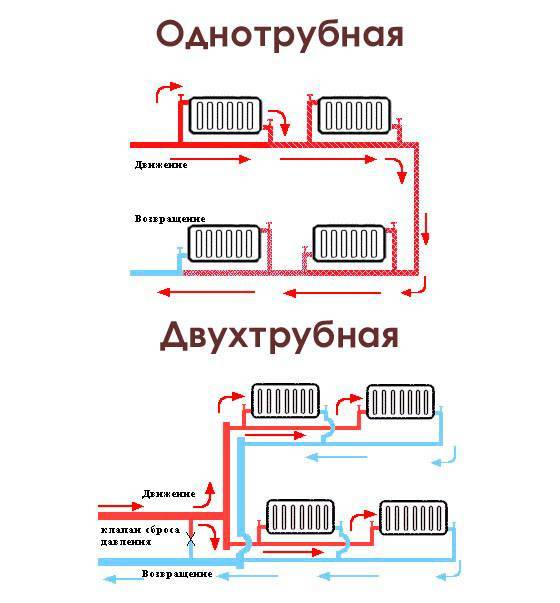

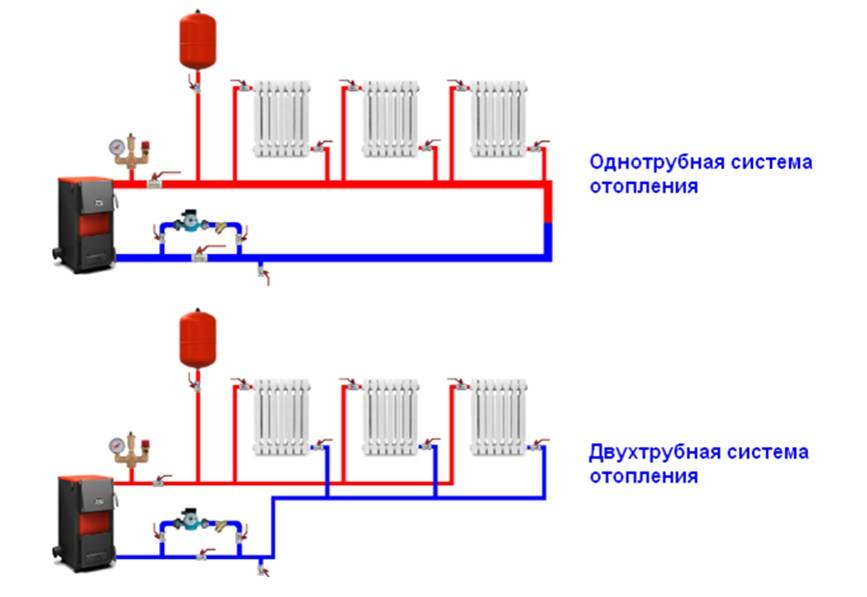

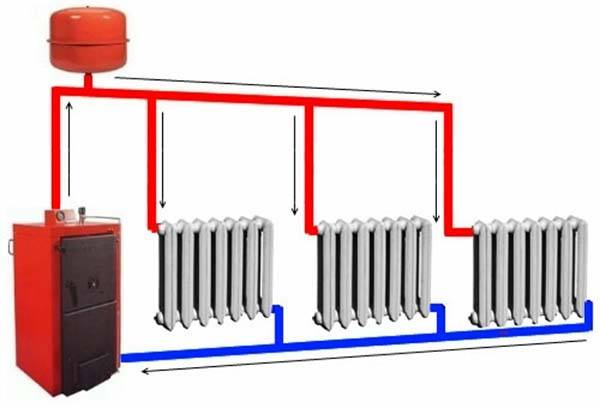

One-pipe type heating systems involve the use of one line for supply and return. Two-pipe systems have an independent supply and return pipe. When deciding to independently install a dependent heating system, it is better to choose a one-pipe scheme, it is simpler, more affordable and has an elementary design.

Single-pipe heat supply consists of the following elements:

- Heating boiler.

- Batteries or radiators.

- Expansion tank.

- Pipes.

A simplified scheme implies the use of pipes with a cross section of 80-100 mm instead of radiators, but it should be borne in mind that such a system is less efficient in operation.

Types of open heating schemes

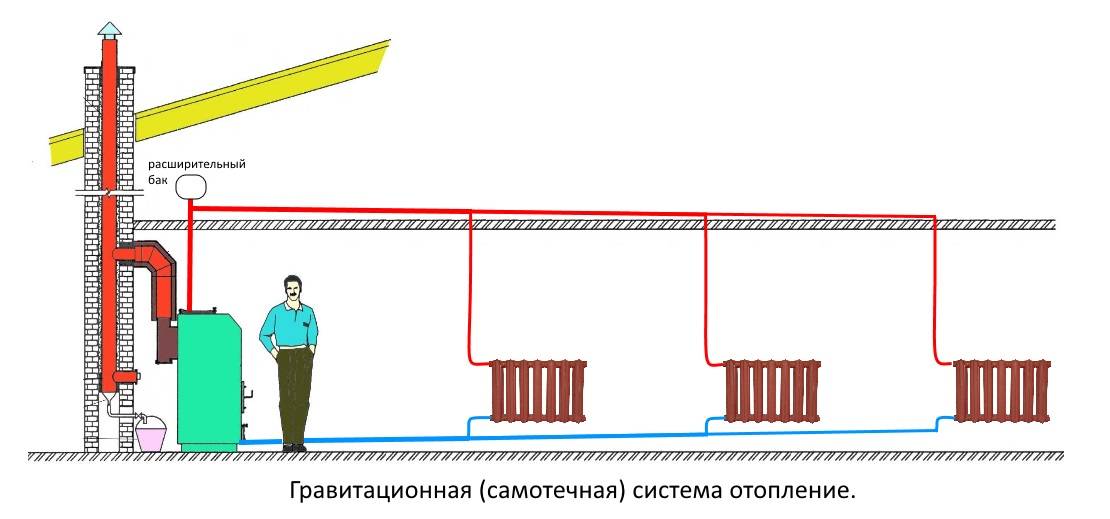

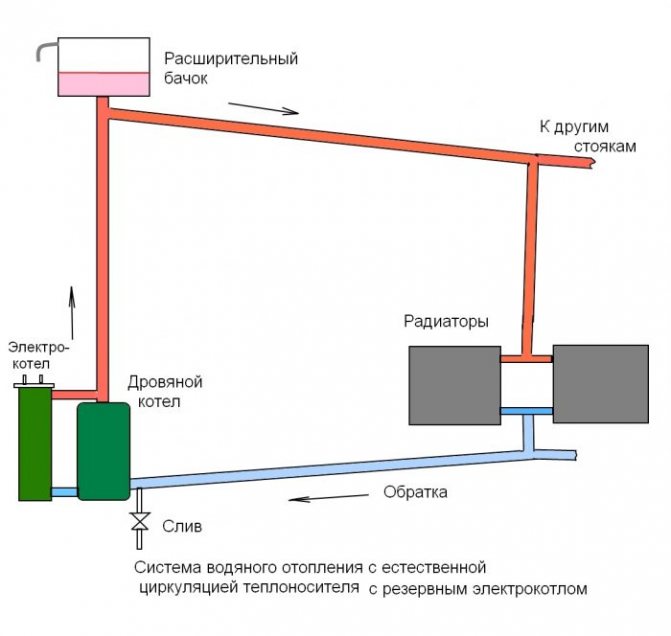

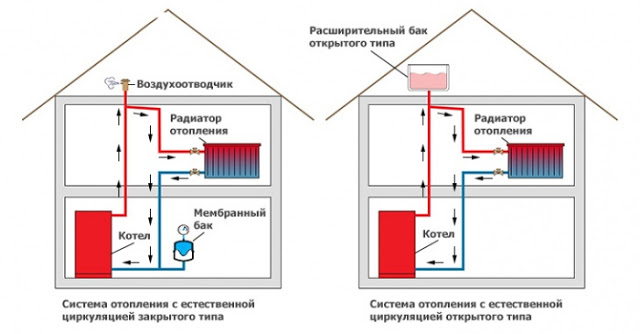

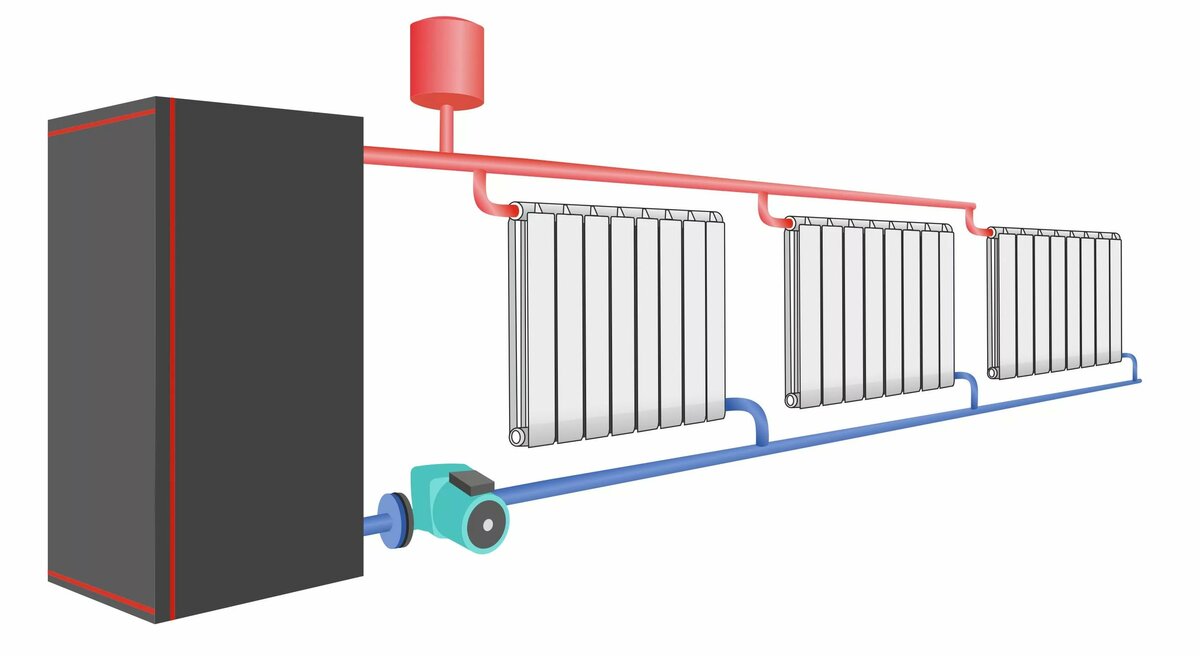

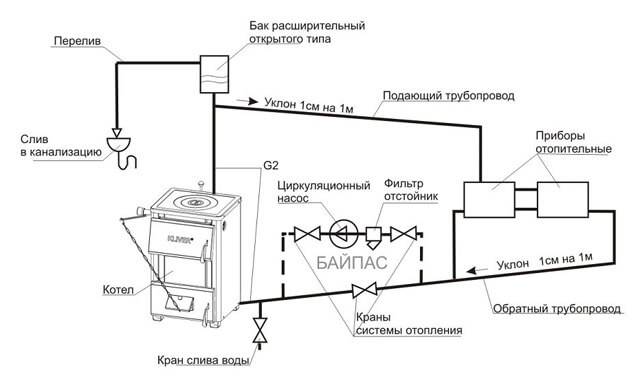

In the open circuit of the heating system, the movement of the coolant is carried out in two different ways. First option - natural or gravity circulation, the second is forced or artificial inducement from the pump.

The choice of scheme depends on the number of storeys and the area of \u200b\u200bthe building, as well as on the expected thermal regime.

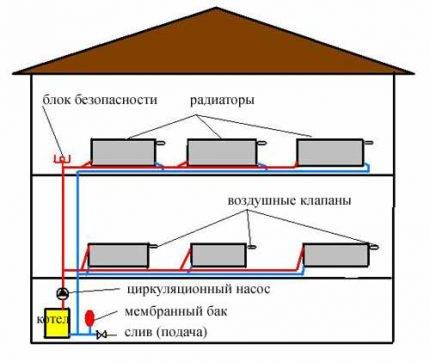

Natural circulation in heating

In the gravitational system, there is no mechanism for ensuring the movement of the coolant. The process is carried out solely by the expansion of hot water. For the operation of the scheme, an accelerating riser is provided, the height of which is at least 3.5 m.

If we neglect the installation of a vertical transit riser, then there is a high probability that the coolant coming from the boiler will not develop sufficient speed

If we neglect the installation of a vertical transit riser, then there is a high probability that the coolant coming from the boiler will not develop sufficient speed

The natural circulation type heat supply system is optimally suited for buildings up to 60 square meters. m. The maximum length of the circuit that can provide heat is considered to be a highway of 30 m. An important factor is the height of the building and the number of storeys of the house, which allows you to mount an accelerating riser.

The natural circulation scheme is not suitable for low temperature applications. Insufficient expansion of the coolant will not create the proper pressure in the system.

Gravity scheme features:

- Connection to underfloor heating. A circulation pump is mounted on the water circuit leading to the floor. The rest of the system functions normally. In the event of a power outage, the house will continue to heat.

- Boiler work. The heater is mounted at the top of the system - slightly below the expansion tank.

To ensure uninterrupted operation, a pump can be installed on the boiler. Then the scheme of heat supply and production of hot water automatically goes into the category of forced options. Additionally, a check valve is installed to prevent the recirculation of the coolant.

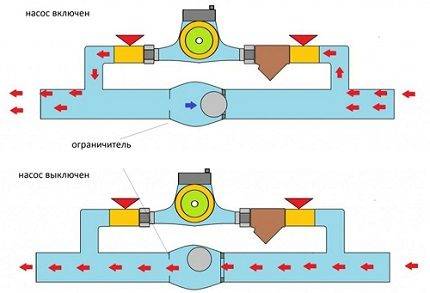

Forced system with pump

In order to increase the speed of the coolant and reduce the time for heating the room, a pump is built in. The movement of the water flow increases to 0.3-0.7 m/s. The intensity of heat transfer increases, and the branches of the main line are heated evenly.

Pumping circuits are constructed both open and closed.In open circuits, the expansion tank is installed at the highest point in the system. The presence of the pump allows you to increase the pipeline between the heating boiler and batteries, both in height and in length

Pumping circuits are constructed both open and closed.In open circuits, the expansion tank is installed at the highest point in the system. The presence of the pump allows you to increase the pipeline between the heating boiler and batteries, both in height and in length

- The circuit with a built-in pump is volatile. So that the heating of the room does not stop when the electricity is turned off, the pumping equipment is placed on the bypass.

- The pump is installed before entering the boiler on the return pipe. The distance to the boiler is 1.5 m.

- When installing the pump, the direction of water movement is taken into account.

Two shut-off valves and a bypass elbow with a circulation pump are mounted on the return. In the presence of current in the network, the taps are closed - the movement of the coolant is carried out through the pump. If there is no voltage, then the valves must be opened - the system will be rebuilt for natural circulation.

A non-return valve must be installed on the supply line. The element is located immediately after the boiler and prevents the recirculation of the coolant when the pump is running

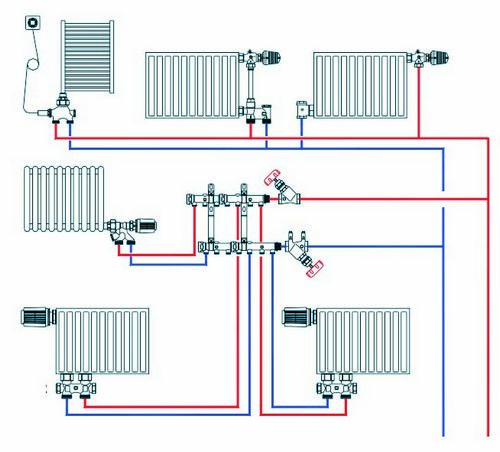

Answers to frequently asked questions about the beam system

What pipe diameter to choose?

Most often, when installing a beam system, pipes of 16 diameters are enough for the eyes. In rare cases, a larger diameter is used. Now we are talking of course about the diameter of the pipes from the collector.

How to do in a two-story house?

Many are wondering how to make a beam system in a two-story house. We can make a beam system even in a skyscraper. The main thing is to use your own heating collector on each floor.

Is it possible to make a beam system in an apartment?

Yes, you can. It is unlikely that this can be done directly from the CHP. But if you have your own heating system or connect to the CHP through a heat exchanger, then everything will work.

Better two-pipe system or beam?

Requirements for the arrangement and operation

- To ensure normal circulation, the boiler is installed at the lowest point of the line, and the expansion tank at the highest point.

- The best place to place the expansion tank is the attic. In the cold season, the container and the supply riser within the unheated attic must be insulated.

- The laying of the highway is carried out with a minimum number of turns, connecting and shaped parts.

- In a gravity heating system, water circulates slowly (0.1-0.3 m / s), so heating should also occur gradually. Boiling should not be allowed - this accelerates the wear of radiators and pipes.

- If the heating system is not used in winter, then the liquid must be drained - this measure will keep pipes, radiators and the boiler intact.

- The coolant level in the expansion tank must be monitored and replenished periodically. Otherwise, air jams will occur in the line, reducing the efficiency of the radiators.

- Water is the optimal heat carrier. Antifreeze is toxic and is not recommended for use in systems that have free contact with the atmosphere. Its use is advisable if it is not possible to drain the coolant during an unheated period.

Particular attention is paid to the calculation of the cross section and slope of the pipeline. Design standards are regulated by SNiP number 2.04.01-85

In circuits with gravitational movement of the coolant, the size of the pipe section is larger than in pump circuits, but the total length of the pipeline is almost two times less. The slope of the horizontal sections of the system, equal to 2 - 3 mm per linear meter, is suitable only for the installation of heat supply with natural movement of the coolant.

Failure to comply with the slope when installing systems with natural movement of the coolant leads to airing of the pipes and insufficient heating of radiators remote from the boiler. As a result, the heat efficiency is reduced.

The principle of operation of the heating system without a pump

The principle of operation of such a system is based on the elementary laws of physics. During heating, the density and mass of the liquid decreases. As the water in the circuit cools, it becomes heavier and more dense. Any pressure in the circuit is completely absent in this case. In the developed heat engineering formulas, there is a ratio of 1 atm per 10 m of head.

When determining a pumpless system in a two-story house, the hydraulic performance will not be higher than 1 atm. One-story structures are equipped with systems with a pressure of 0.5-0.7 atm.

Since the volume of liquid increases during the heating process, an expansion tank will have to be equipped for normal circulation. The liquid passing through the installed water circuit will heat up, this will significantly increase the volume. The expansion tank must be placed on the coolant supply in the uppermost part of the heating circuit. The main functional purpose of such a buffer tank is to compensate for the increase in the volume of liquid.

A heating device in private housing construction without a pump can be installed if these types of connections are suitable for installation:

- Connection to a floor heating system will always require the installation of a pumping device. The distribution of the coolant to the radiators will not require any pumps. When the electricity is turned off, the living space will be heated by equipped radiators.

- Interaction with an indirect water heating boiler.Interaction with the natural circulation system can always be organized without a pump. To make this possible, the boiler is mounted at the highest point of the equipped system. If this is difficult to do, a storage tank can be equipped with a pump with the additional installation of a check valve to eliminate hot water recirculation.

In mechanisms with hydraulic circulation, the flow of the coolant is organized by gravity. Due to the process of natural expansion of water, the heated liquid will tend up the so-called accelerating section, and then it will drain through the radiators and move towards the boiler for subsequent heating.

Selection of pipes, boiler and radiators

The operation of the entire system depends on the correct choice of the boiler.

For example, if water heating requires the installation of a boiler, then you can get by with the option of a single-circuit gas boiler.

Making a choice in favor of gas heating, it is better to purchase a boiler made of cast iron or a special durable metal. Although they are heavy, they will last much longer.

But pipes for such a heating system are suitable for polypropylene or metal-plastic. as a budget option, and copper, if the wallet allows it.

With radiators, you also have to decide in advance. Today, bimetallic heating radiators have gained great popularity among consumers.

Which ones are actually better for an apartment can be determined by the amount of their heat transfer, for example:

Before buying radiators, it is necessary to calculate in advance how many sections will be required for each room. To do this, the heat transfer of the material must be divided by 100.For example, for a bimetallic radiator, it is 199 W / 100, which equals 1.99 W per 1 m2.

There are several nuances that should be taken into account when choosing radiators and calculating their number:

- If the installation of batteries is supposed to be in a corner room, then 2-3 sections must be added to the results that were obtained in the calculations.

- When decorative panels are installed that hide the batteries behind them, the heat transfer is reduced by 15%, which should be taken into account before calculations.

- Insulated walls or metal-plastic windows can reduce heat loss.

- Installing a meter will allow you to independently regulate gas consumption.

Having made all the calculations and adding to them the cost of the autonomous gas heating system itself, you can make a decision to buy it, or you can compare these figures with electric types of heating.

Installation of the heating structure "Leningradka"

Before you start building the heating system of a private house with your own hands, you need to perform a competent and accurate calculation. It will be problematic to do this on your own, so it is better to turn to professionals in this industry. Using the calculation, you can determine the list of equipment and materials necessary for the work.

The main elements of "Leningradka" include the following:

- boiler for heating the coolant;

- metal or polypropylene pipeline;

- radiators (batteries);

- expansion tank or tank with a valve (for an open system);

- tees;

- a pump for circulating the coolant (in the case of a forced design scheme);

- Ball Valves;

- bypasses with needle valve.

In addition to calculations and the acquisition of materials, one should also take into account the location of the pipeline.If it is planned to be carried out in a wall or in the floor, it will be necessary to prepare special niches - strobes, which should be located around the entire perimeter of the contours. In addition, all pipes must be wrapped with heat-insulating material in order to prevent the temperature of the liquid from dropping before entering the radiators.

What is the best material for the pipeline?

Most often, polypropylene is used as a pipeline for installing Leningradka in a private house. This material is quite simple to install and inexpensive. However, experts do not recommend installing polypropylene pipes in regions where the air temperature drops too low, meaning the Northern Territories.

Polypropylene begins to melt if the coolant temperature rises above 95 degrees, which can lead to pipe ruptures. In such cases, it is more advisable to use metal counterparts, which are rightfully considered the most reliable and durable.

In addition to the material, when choosing a pipeline, it is important to choose its cross section correctly. In this case, the number of radiators used in the circuit is of no small importance. For example, if there are 4–5 elements in the circuit, then the diameter of the pipes for the main line should be 25 mm, and for the bypass this value changes to 20 mm

Thus, the more radiators in the system, the larger the cross section of the pipes. This will make it easier to balance when starting the heating structure.

For example, if there are 4-5 elements in the circuit, then the diameter of the pipes for the main line should be 25 mm, and for the bypass this value changes to 20 mm. Thus, the more radiators in the system, the larger the cross section of the pipes.This will make it easier to balance when starting the heating structure.

Connection of radiators and pipes

Installation of Mayevsky's crane.

Bypasses are manufactured together with bends and then mounted in the main. At the same time, the distance observed when installing the taps must have an error of 2 mm, so that during the connection of the structural elements, the battery fits.

The backlash that is allowed when pulling up an American is usually 1–2 mm. The main thing is to stick to this value and not exceed it, otherwise it can go downhill and a leak will appear. To obtain more accurate dimensions, you will need to unscrew the valves located at the corners in the radiator and measure the distance between the couplings.

Starting the heating structure

Before starting the Leningradka heating system, it is necessary to open the Mayevsky taps installed on the radiators and let the air out. After that, a control inspection of the structure for the presence of flaws is done. If they are found, they should be eliminated.

After starting the equipment, all connections and nodes are checked, and then the system is balanced. This procedure means equalizing the temperature in all radiators, which is regulated using needle valves. If there are no leaks in the structure, unnecessary noise and the rooms heat up quickly enough, the equipment is installed correctly.

The Leningrad heating system of a private house, although outdated over time, has changed, but is still common, especially in buildings with small dimensions. It is easy to install it yourself, while saving money on attracting specialists and the equipment necessary for the construction.

Features of the device and operation

When choosing an open heating circuit, in a circuit with an expansion tank and a circulation pump, when installing the system, it is necessary to take into account:

For efficient operation of an open heating circuit with proper water circulation, it is necessary to place the boiler at the bottom of the circuit, the tank at the top.

For an expansion tank, the best place in the house is the attic

If there is no heating, the tank, pipes need to be insulated.

It is desirable that the heating circuit has a minimum of turning sections, junctions of contours, shaped elements.

It is important to exclude boiling of the liquid, circulation does not occur quickly. If the water temperature in the circuits is too high, wear is accelerated, the service life of heating radiators is reduced.

It is necessary to drain the water from an open system if it will not start in winter

Otherwise, when the air temperature drops, the liquid in the circuits will increase in volume, break pipes, batteries, and damage the boiler.

It is important that there is always water in the expansion barrel. If not followed, the pipes may become airy, the open circuit will become ineffective.