- No. 4. Porcelain tile for facade

- Sheathing of a frame house

- Facade decoration: specifics and varieties

- The task of exterior cladding of a wooden house

- Why do we need wooden wall cladding, requirements for finishing materials

- How to sheathe a wooden house with corrugated board

- Types of facade structures

- Criteria for choosing facade finishing materials

- Painted facade board

- Vinyl siding

- fiber cement siding

- Plaster

- Brick

- wood paneling

- Siding for house cladding

- Option number 1 - vinyl panels

- Option number 2 - metal siding

- Wood

- Overview of materials for interior wall decoration

- Conclusion

No. 4. Porcelain tile for facade

Porcelain stoneware, obtained from clay, quartz sand, feldspars and water by semi-dry pressing, is one of the most durable materials for finishing the facade of a private house, and in terms of operational properties it is practically not inferior to stone. For facing a private house, porcelain tiles with a thickness of at least 12 mm, and preferably 14-16 mm, are suitable.

Advantages:

- durability and strength, resistance to abrasion and mechanical damage;

- absolute moisture resistance. Porcelain stoneware does not absorb moisture, has high frost resistance;

- resistance to extreme temperatures and temperature changes;

- preservation of the original appearance during the entire period of operation;

-

great variety, the presence of many shades and textures, the possibility of imitation of stone, wood and other noble materials. Matte, polished (with a waxy sheen), glazed, polished, semi-polished, structured and mosaic porcelain tiles are produced, so there will be plenty to choose from.

Flaws:

- big weight;

- high price;

-

specific installation. Due to the weight and low hygroscopicity, it will not work to use a cement mortar for the installation of porcelain tiles - you will need either a special glue or a metal frame.

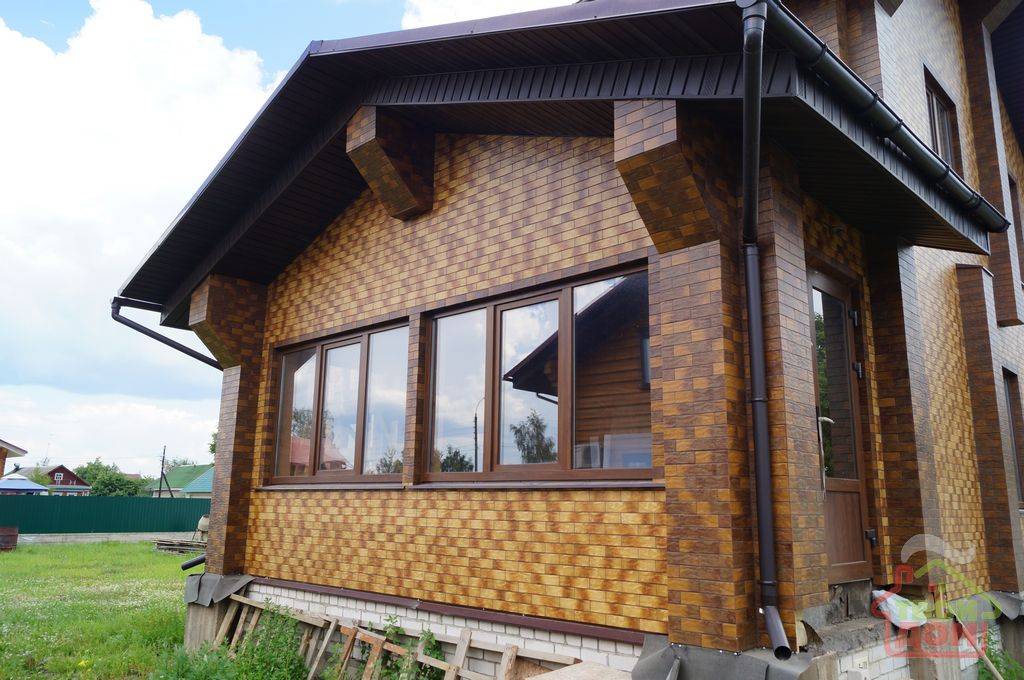

Sheathing of a frame house

Frame houses are becoming more and more popular, such a house is built quite quickly and the materials for its construction are inexpensive. However, this structure cannot be considered capital, because sometimes a frame house does not even have a foundation as such, they are built on the so-called sand cushion. Therefore, it is desirable to use the lightest materials for its lining. The brick is too heavy for sheathing a frame house. And for this, it is required to lay a foundation of increased width in advance, which will make the frame house more capital. But this option can no longer be considered economical.

How to sheathe a frame house? Here are some economical options.

As in the case of a wooden house, all types of siding are suitable for cladding a frame. It seems to be asking for this type of house. Vinyl siding imitating stone is especially good in the case of facing a frame house, because it will give the building solidity. However, other types of siding can significantly decorate such a house.But you should not choose too colorful and bright colors of siding, if they are suitable, then in exceptional cases as separate elements, or to a certain landscape design of the site, and here you can’t do without a designer (if you don’t have your own design skills).

The process of sheathing a frame house with vinyl siding

The process of sheathing a frame house with vinyl siding

Block house is also a good option for a frame. You should know that the block house is not only wooden, but also plastic and even metal. These materials are more stable and durable than wood. However, metal, as already mentioned, can make the structure heavier, which may be undesirable in the case of a frame house.

A variant of the pie sheathing with wooden clapboard or block house

A variant of the pie sheathing with wooden clapboard or block house

Natural wood is also a good way to sheath a frame house. This option is especially good for craftsmen who are ready to decorate their home with wood carvings and some kind of skillful ornament. But it should be remembered that wooden boards require timely painting and maintenance.

Of course, there are other ways of sheathing a frame house. For example, clinker tiles, which exactly imitate brick, while being much lighter than it. However, what is called “cheap” can hardly be attributed to it.

Facade decoration: specifics and varieties

The façade is as important a part of the structure as the roof or foundation. Facade finishing technologies are constantly evolving. For an apartment, private or country house, there will always be the best ways to clad the walls from the outside. The market offers many solutions with which to finish the outer walls. You can choose them yourself or with an experienced specialist. When choosing finishing materials, it is necessary to take into account several important points.The building should harmoniously fit into the local area, look attractive. And the material should not only play the role of decor, but also insulate the object. The load-bearing structures of a construction site must be reliably protected from negative external influences. Methods for finishing the facades of private houses should be chosen deliberately and consciously by experienced craftsmen. Combined cladding methods remain popular.

The task of exterior cladding of a wooden house

The facade of a wooden house cannot be left without protection, otherwise the material will simply lose its appearance or suffer from the destructive actions of rodents and insects.

Facing a wooden house is carried out to solve the following tasks:

- increase resistance to rodents, insects and fire;

- improve the appearance of the structure;

- protect the structure from heat loss;

- increases the sound insulation of the building.

The materials used for facing the building must meet certain requirements:

- the minimum level of moisture absorption and hygroscopicity, this helps to prevent the process of wood decay;

- the material must pass air and remove excess steam inside the structure, these requirements directly affect the internal microclimate and the atmosphere of the house;

- the thermal conductivity of the material should be minimal, this will keep the heat inside the building and significantly reduce heating costs;

- the product must have high fire resistance, in the event of a fire, ignition will be minimized;

- have high resistance to chemical aggressive substances;

- be highly resistant to bacteria, insects, mold and mildew;

- the material must be environmentally friendly;

- soundproofing, i.e.products must contain noise.

Why do we need wooden wall cladding, requirements for finishing materials

The centuries-old practice of using wooden residential buildings in Russia shows their fairly acceptable performance. In modern conditions, finishing the outside of a house with wooden walls has several goals:

- Protection of walls from adverse climatic factors - precipitation, wind, icing, sudden temperature changes. The outer layers of the sheathing material must not be impregnated with sedimentary moisture and condensate.

- Creation of reliable thermal insulation and waterproofing of residential premises. The lower the material's thermal conductivity and vapor permeability, the better.

- Protection of walls from mechanical damage such as cracks, chips.

- Additional sound insulation of the interior of the house.

- Protection of the wooden part of the house from dampness, rot, fungi.

- Decoration of the facade of the building in a certain architectural and artistic style. In order for the appearance of the building to remain unchanged for as long as possible, it is desirable to select a material that is resistant to direct sunlight and ultraviolet radiation. This reduces the chance of fading/discoloration of the skin.

- Protecting the house from open fire, ensuring the fire safety of the building.

The surface can be protected and reinforced in various directions

An important requirement for cladding is ease of installation when sewing walls, which minimizes the need for special equipment.

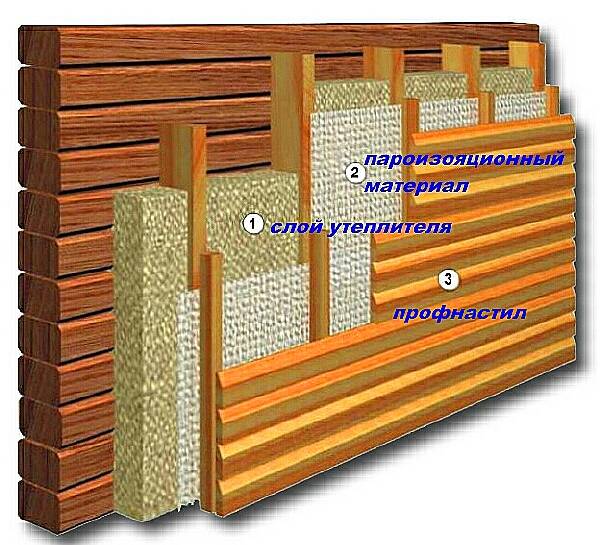

How to sheathe a wooden house with corrugated board

When choosing corrugated board for finishing a wooden house, you need to know that the finishing material is only one layer of the five layers required for exterior wall cladding. The correct order of their installation will provide the building with the necessary protection and an attractive appearance.

The correct procedure for using materials when finishing with corrugated board guarantees high-quality heat preservation in the house

- The first stage of work will be the installation of the frame. For this purpose, you can use both a metal profile and wooden bars. When choosing bars, they are pre-impregnated with an antiseptic. The use of wooden bars when facing a wooden house greatly facilitates the work process.

- Initially, markings are made on the wall surface to fix the brackets, and then the bars are attached to them. It should be noted that the distance between the bars should be at least 1 meter, and the bars should be installed as evenly as possible. To check the installation of the bars, a plumb line and a level are required.

- The next step will be the installation of a thermal insulation layer. The best choice for creating this layer would be mineral wool. The insulation is cut into pieces of the required size, inserted between the bars, and then fixed with plastic dowels.

- A vapor barrier layer is laid on top of the insulation and fastened with fasteners with wide caps. Laying starts from the top, the next layer is overlapped, and the seams are fixed with a special adhesive tape. Thus, maximum protection against moisture penetration is achieved.

- Completes the installation of the profiled sheet. It is attached to the bars with galvanized self-tapping screws using rubber gaskets every 40 cm. Holes for fasteners are drilled with metal drills.The installation of additional elements for windows and doors completes the work. The process of finishing with a profiled sheet will become more understandable after watching the video.

Types of facade structures

Among other things, when choosing a facade material, it is necessary to take into account what the building is built from, the principle of organizing facade decoration may depend on this. For example, for wooden houses, it is advised to equip a ventilated facade.

It is customary to divide facades into the following types:

- "wet" are created with the obligatory use of building mixtures;

-

"Dry" facades are equipped with mechanical fasteners (nails, self-tapping screws, dowels, etc.). This method is more convenient, allows installation at any time of the year, but does not provide the same holistic design as in the previous method.

Depending on whether there is a gap between the outer wall of the house and the finishing material, the facades are divided into:

- ventilated;

- non-ventilated.

Ventilated facade

Ventilated facades require a ventilation gap between the facade material and the wall or insulation, if used. The gap is necessary for free air circulation and removal of excess moisture that condenses or leaves the house through the walls. At the same time, the material of the ceiling wall remains completely protected from all atmospheric influences. It is better to equip such a facade when the walls breathe. A non-ventilated facade involves the installation of a finishing material directly to the wall. Sometimes facades are classified simply as ventilated and "wet", although this is not entirely correct.

Now we can move on to materials that are widely used in the decoration of the facade of a private house.

Criteria for choosing facade finishing materials

In order to choose the right material for finishing the facade of a frame house, you should first of all decide on the purpose of its use. If purely appearance is important to you, then you can choose the material, relying only on your taste and the thickness of your wallet.

And if the goals of improving the thermal insulation characteristics of the building are pursued, then we recommend that you opt for hinged facades or thermal panels. They have a multi-layer construction that increases thermal insulation performance and creates an optimal microclimate inside the house.

But important is not only the chosen material, but its high-quality installation. The absence of cracks and gaps, as well as reliable fastening ensures that the facade of the house will faithfully serve for years, pleasing the eyes of the owners.

Painted facade board

One of the ways to finish the facade of a frame house is to use a painted board.

This option is often found in the Scandinavian countries, where they have always paid special attention to the environmental friendliness and safety of building materials. The board has a rectangular shape, after installation it imitates the appearance of a beam

The material varies in length, can be sanded on the outside and planed on the inside. Sanding is necessary in order to ensure better absorption of the paint.

Most often, the board is supplied painted, ready for installation. At the same time, it is pre-primed and painted in two layers on the front side. This is necessary so that the surface is protected as much as possible, and the color is saturated.

If the installation was carried out without violating technological processes, then it will not be necessary to repaint the board for at least 10 years.In addition, this material provides for ventilation between the board and the walls of the house, which is provided by a special gap between the structural elements. If it is not done, then putrefactive processes and damage to the material may occur.

Vinyl siding

Vinyl (plastic, acrylic) siding is one of the most popular materials for finishing the facade of frame houses. It has a low cost, it is easy to mount it yourself. To fix it, you need to create a crate on which the siding panels will be installed.

Among the disadvantages of the material can be called its low strength. Under mechanical stress, it is easy to damage. In addition, vinyl siding burns well. It is possible to equip an additional layer of thermal insulation under its surface.

fiber cement siding

Fiber cement siding is a durable and wear-resistant material. Outwardly, it looks spectacular, and its texture resembles ceramics. The production of this material is carried out industrially in compliance with all the requirements of the technology, which sets high characteristics of wear resistance and resistance to ultraviolet radiation and fire.

The material is 90 percent cement and mineral filler that protects it from moisture. In addition, fiber cement siding has heat-insulating and noise-absorbing properties. The material is presented in the widest range of textures and colors, which allows you to find the right option for everyone.

Plaster

Finishing the facade with mineral or acrylic plaster allows you to give the house an attractive appearance.However, when choosing this type of finish, it should be borne in mind that you will first need to install a heat-insulating layer of foam or similar material, on which the plaster will be applied.

Finishing the facade with plaster will make it possible to improve the thermal insulation of the walls and the frame of the building. However, errors during the application of the material promise many problems:

- The appearance of cracks;

- swelling of the surface;

- flaking;

- The appearance of spots.

If you are not sure that you are able to do the work yourself, then it is better to turn to experienced builders. This will save time and nerves that will be spent on reworking possible flaws.

Brick

The outer skin can be made of silicate, hyperpressed or ceramic bricks. The facade of a frame house, in addition to excellent aesthetic properties, will acquire protection of the wall structure from the negative effects of external factors and increase their strength. A wide range of color solutions for the brick surface and laying methods make it possible to realize any ideas and wishes of the owners of the house.

The disadvantage of using the material is the impossibility of working with it at sub-zero temperatures. Therefore, if you have settled on the use of facade bricks as a finishing material, you will need to correctly plan the construction schedule.

wood paneling

Wood in construction and decoration has been used for centuries, and it looks like it will be relevant for a long time to come. All thanks to the excellent appearance and the ability to regulate the humidity in the room.This is perhaps the only material that will easily remove excess moisture, no matter what material the walls are built from.

Wooden sheathing can have a completely non-standard look: different colors and sizes, different directions. It's simple and the effect is amazing

The most popular wall cladding materials are block house and timber imitation. There is also a lining for exterior decoration - it has a greater thickness, compared to the one intended for interior decoration of the house, otherwise it is no different.

The block house imitates the surface of a rounded log - the front part has a rounded shape. Imitation of a bar is very similar to a planed bar. Both types of cladding are attached to the crate, then sanded and coated with protective impregnations, optionally varnished or painted.

What lumber looks like for exterior cladding of a house

If you can’t decide how to sheathe a house of foam blocks on the outside, consider wood cladding. In this case, a crate (metal or wooden) is nailed to the walls. If necessary, a heater is laid between the planks - basalt wool (styrofoam or polystyrene foam cannot be used), and then the wooden sheathing is nailed.

This building is sheathed with imitation timber. Under the skin there can be a brick, a log house, a frame or any of the building blocks

If you need the cheapest option, for most regions of Russia this is an ordinary planed board. Its thickness is from 40 mm, it is stuffed in the same way as a lining or a block house on a crate, the lower end of the upper board goes 10-20 mm onto the one located under it. It turns out the principle of the bump. So you can cheaply veneer a country house or even a residential one.With proper processing, such a lining has a very good appearance.

What is the cheapest way to sheathe a house outside? For central Russia - a planed wooden board

The disadvantages of such a finish are the same as for any wood: it can be damaged by pests, rot, without proper care it quickly loses its decorative effect, becomes dark and ugly. If you want to sheathe a house and not think about it for years, this is not your choice. Wood paneling requires maintenance, and, most often, annual maintenance.

Siding for house cladding

The most democratic option for finishing a house is siding. The material has a lower cost than wood, lumber, ceramics, has a long service life, so it is used much more often than other facade coatings.

Siding can cover walls built from any material with any type of external insulation. The facade, equipped in this way, is ventilated, since the materials are mounted on the prepared crate, so this coating is universal.

Option number 1 - vinyl panels

Vinyl siding is made from high-tech polyvinyl chloride, which is used in various climatic zones. It can be easily cut to form the correct facade of houses with uneven walls, ledges, and many decorative elements.

The material is a flat strip 10-12 mm thick, 205-255 mm wide. The siding is attached to the facade using a perforation line for fasteners and docking locks connecting the two panels to each other.

When installing siding on the facade of the house, use several shades of material, choose dark shades for corners, window sills, the foundation of the house so that the building does not look boring and monotonous

When installing siding on the facade of the house, use several shades of material, choose dark shades for corners, window sills, the foundation of the house so that the building does not look boring and monotonous

Installation of vinyl strips is carried out on a metal or impregnated wooden crate, consisting of starting and side additional beams. Self-tapping screws are screwed in such a way that there is a backlash, for possible changes in the siding, under the influence of temperatures.

A variety of vinyl panels is basement siding. Only in this case, the panels do not look like stripes, but like a square or rectangular part of the wall.

The material is thicker than vinyl panels, as it is designed to protect the roof base from precipitation and other influences. But because of its practicality, strength has become widespread when facing facades.

The basement facade is attached to the crate, which is attached more densely, due to the fact that the panels look like a square, a rectangle of shorter length.

To join the pattern, you may need additional fastening beams during direct work with the material. Keep this in mind when purchasing materials for the crate

To join the pattern, you may need additional fastening beams during direct work with the material. Keep this in mind when purchasing materials for the crate

For installation of panels, each has perforation and a connecting lock. When screwing in self-tapping screws, play should be left to compensate for possible material movements.

Basement siding imitates natural materials better than others. Therefore, with skillful installation, it is possible to distinguish an artificial facade from a stone or brick wall only by directly touching the wall.

The benefits of vinyl siding are:

- Easy installation on buildings of any configuration.

- Affordable material price.

- Installation of a vinyl siding facade is possible at temperatures from -5 to +40 °С.

The disadvantages include fast fading on the sunny side of the building, so it is better to choose light shades of panels. In addition, installation at low temperatures from -5 ° C will increase the number of trimmings, as the siding will burst with minor kinks during processing.

Option number 2 - metal siding

Metal siding is made from aluminum or galvanized steel. A dye is applied to the surface, which performs a protective function.

The material is decorated in two ways:

- Covered with a polymer shell. Such panels do not fade, are resistant to mechanical stress. When polymerizing, manufacturers use a limited number of shades.

- Powder coated. With this treatment, the paint does not fade, it is operated for a long time at any temperature without signs of peeling. The panels are available in a variety of colors and shades.

Installation of metal panels is carried out on the bearing and additional side beams using self-tapping screws and connecting locks on the strips.

Metal siding comes in a variety of textures and colors. A house made of such material can be similar to housing made of timber, shipboard, logs, wild stone, brick

Metal siding comes in a variety of textures and colors. A house made of such material can be similar to housing made of timber, shipboard, logs, wild stone, brick

The advantages of such panels include their low price, durable coloring without fading of colors on the sunny side of the building. In addition, it is easy to work with metal panels at any time of the year, they bend perfectly, do not break, and are suitable for facing rounded structures.

The disadvantage is the aesthetic simplicity of metal strips.With unsuccessful installation, the building looks more like a production workshop.

Wood

At the moment, houses made of timber are in trend. For this reason, when it becomes necessary to choose a material for cladding exterior walls, many choose edged or unedged boards.

Also, such material is welcomed by homeowners who prefer country style.

Cladding options may vary. It all depends on what kind of board the owner of a private house chooses.

Edged board is lumber, characterized by smooth edges. The unedged version is obtained as a result of sawing a log, which is not subjected to preliminary cleaning, therefore, at the end of the boards, the following are observed:

- bark;

- bast;

- sapwood.

Facing with an unedged board is carried out with a herringbone or overlap. Despite the fact that the wood paneling will need to be replaced in 15-20 years, many people still prefer this option, because the tree:

- retains heat;

- allows the walls to "breathe";

- provides a beautiful appearance to the building.

When asked how to sheathe a wooden house, we can recommend sheathing with a block house. This is a material that perfectly imitates a log, has a convex surface on one side.

Despite the fact that the cost of such material remains affordable, a house sheathed with a block house looks colorful and quite expensive.

Overview of materials for interior wall decoration

For the decoration of industrial premises, materials with a certain “set” of performance are used - vibration resistance, resistance to acid and alkaline effects, etc.Let's leave the industry alone for now and consider the properties and characteristics of materials that are most often used in such a technological process as the interior decoration of a private house.

The composition, technology of application, performance require the decoration of the walls of the room from any material and any size.

According to their design features and method of application, all finishing materials are divided into groups:

- plastering;

- paint and varnish;

- tiled;

- roll;

- rack.

It should be noted that the materials of the plastering group, with the help of which the interior decoration of a brick house is often performed, are practically not used in the decoration of wooden walls. Under the wallpaper (roll group) and painting, a pre-prepared surface is required, therefore there is a direct connection with the plaster and lath groups. Finishing the house inside is a set of activities that we will analyze into components and consider in detail.

Start decorating a room

Start decorating a room

Conclusion

In our realities, finishing the facade of a wooden house, at least at the initial stage, often becomes a search for a solution than to sheathe the house from the outside cheaply and beautifully. But the choice of a budget cladding option should not be reduced to a simple arithmetic operation showing where the least money will be spent on purchasing the material.

It is also necessary to take into account the cost of installation work, during which it becomes necessary to equip the frame and crate for thermal insulation, as well as the resource of trouble-free operation of the house. For example, the cost of wood siding is not high, but wood cladding must be periodically impregnated with special compounds to maintain antiseptic properties.Practice has shown that the most budget option is PVC siding and lining of medium quality.