- Protection of a solid fuel boiler against overheating

- Scheme of connecting a solid fuel boiler to a closed heating system

- Installation Features

- About the features of using the device

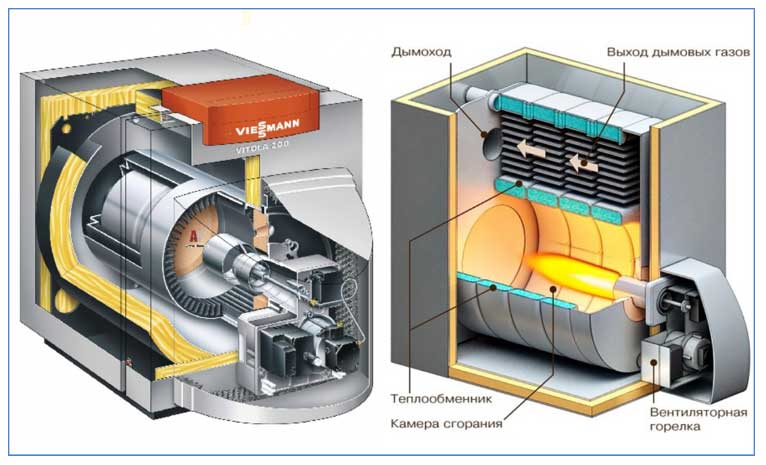

- About liquid fuel

- The best pyrolysis solid fuel boilers

- Buderus Logano S171

- Ecosystem ProBurn Lambda

- Atmos DC 18S, 22S, 25S, 32S, 50S, 70S

- Kiturami KRH-35A

- General installation instructions

- Installation procedure

- How can I fill the heating system in an apartment building

- boiler room requirements

- Boiler room in a private house in a separate room (built-in or attached)

- Special requirements for attached boiler rooms

- When filling with coolant

- Basic rules for arranging heating make-up

- Installing a gas boiler

- Preparation and connection

- Conclusions and useful video on the topic

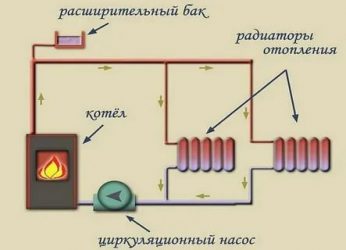

Protection of a solid fuel boiler against overheating

In a solid fuel boiler, burning fuel, and the boiler itself, have a rather large mass. Therefore, the process of heat release in the boiler has a large inertia. The combustion of fuel and the heating of water in a solid fuel boiler cannot be stopped instantly by cutting off the fuel supply, as is done in a gas boiler.

Solid fuel boilers, more than others, are prone to overheating of the coolant - boiling water if the heat is lost, for example, when the water circulation in the heating system suddenly stops, or more heat is released in the boiler than is consumed.

Boiling water in the boiler leads to an increase in temperature and pressure in the heating system with all serious consequences - the destruction of the heating system equipment, injury to people, damage to property.

Modern closed heating systems with a solid fuel boiler are especially prone to overheating, as they contain a relatively small volume of coolant.

Heating systems usually use polymer pipes, control and distribution manifolds, various taps, valves and other fittings. Most elements of the heating system are very sensitive to overheating of the coolant and pressure surges caused by boiling water in the system.

The solid fuel boiler in the heating system must be protected against overheating of the coolant.

To protect the solid fuel boiler from overheating In a closed heating system that is not connected to the atmosphere, two steps must be taken:

- Shut off the combustion air supply to the boiler furnace in order to reduce the combustion intensity of the fuel as soon as possible.

- Provide cooling of the heat carrier at the outlet of the boiler and prevent the water temperature from rising to boiling point. Cooling should take place until the release of heat is reduced to a level at which boiling water becomes impossible.

Consider how to protect the boiler from overheating, using the heating circuit as an example, which is shown below.

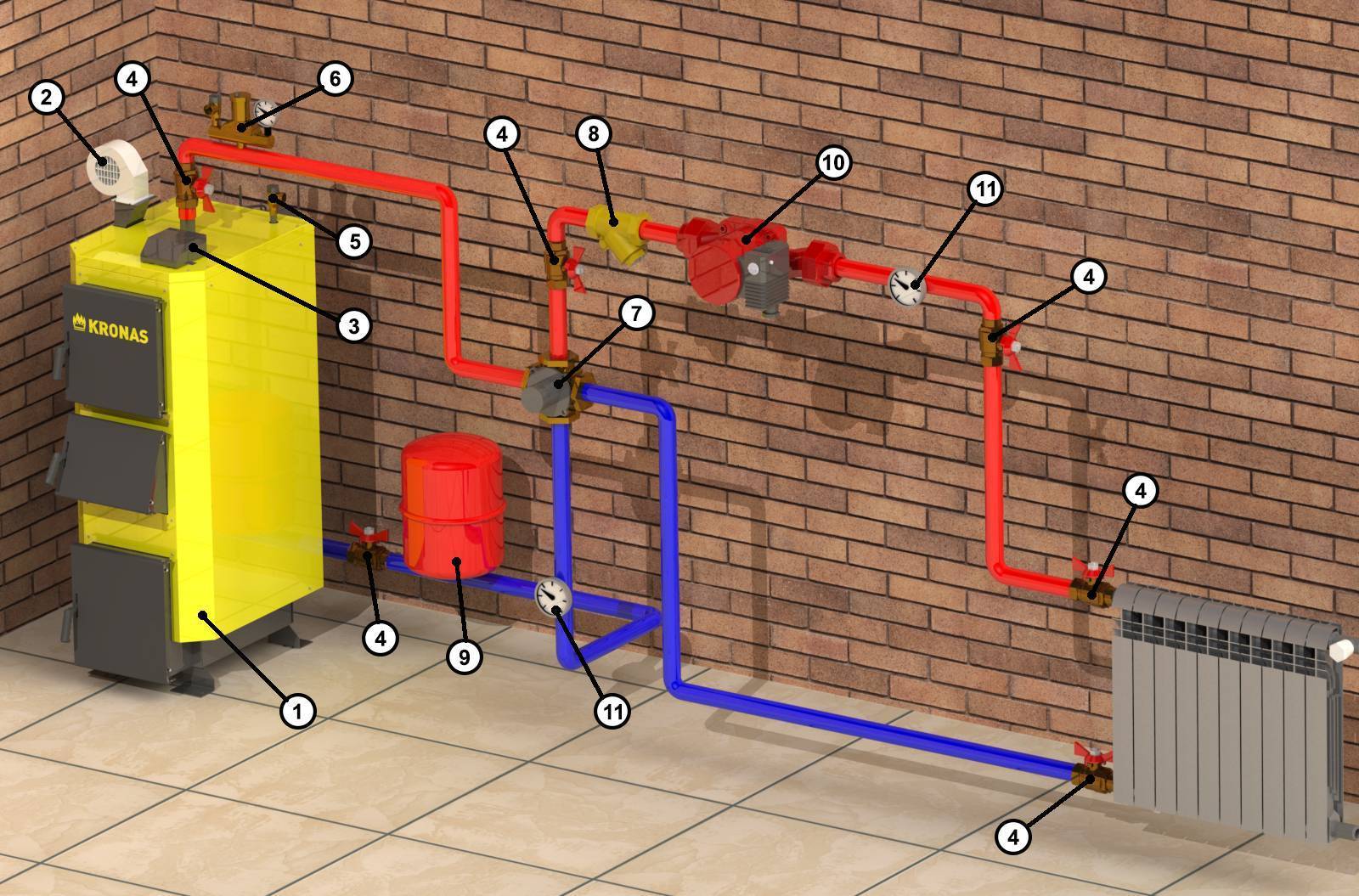

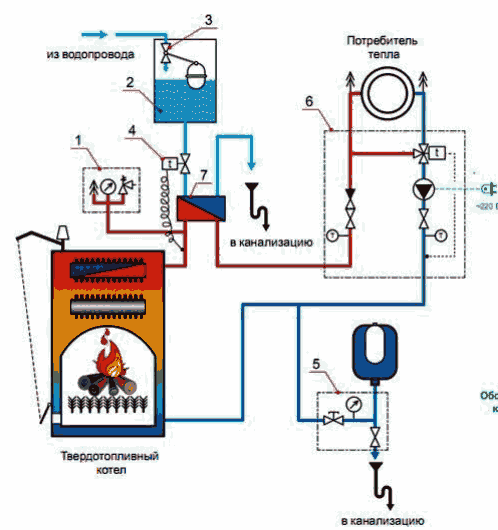

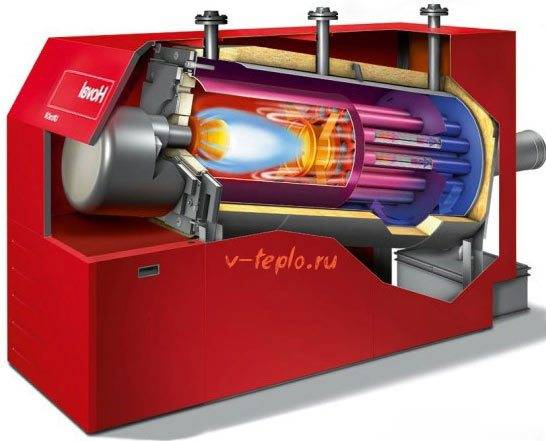

Scheme of connecting a solid fuel boiler to a closed heating system

Scheme of a closed heating system with a solid fuel boiler.

1 - boiler safety group (safety valve, automatic air vent, pressure gauge); 2 - a tank with a supply of water for cooling the coolant in case of boiler overheating; 3 - float shut-off valve; 4 - thermal valve; 5 - group for connecting an expansion membrane tank; 6 - coolant circulation unit and boiler protection against low-temperature corrosion (with a pump and a three-way valve); 7 - heat exchanger protection against overheating.

Boiler protection against overheating works as follows. When the temperature of the coolant rises above 95 degrees, the thermostat on the boiler closes the damper for supplying air to the combustion chamber of the boiler.

Thermal valve pos.4 opens cold water supply from the tank pos.2 into the heat exchanger pos.7. Cold water flowing through the heat exchanger cools the coolant at the outlet of the boiler, preventing boiling.

The supply of water in the tank pos.2 is necessary in case of lack of water in the water supply, for example, during a power outage. Often a common storage tank is installed in the water supply system of the house. Then the water for cooling the boiler is taken from this tank.

A heat exchanger to protect the boiler from overheating and coolant cooling, pos.7 and a thermal valve, pos.4, are usually built into the boiler body by boiler manufacturers. This has become standard equipment for boilers designed for closed heating systems.

In heating systems with a solid fuel boiler (with the exception of systems with a buffer tank), thermostatic valves and other automatic devices that reduce heat extraction must not be installed on heating devices (radiators).Automation can reduce heat consumption during the period of intensive fuel burning in the boiler, and this can cause the overheating protection to trip.

Another way to protect a solid fuel boiler from overheating is described in the article:

Read: Buffer tank - protection of a solid fuel boiler from overheating.

Continued on next page 2:

Installation Features

As we already said in one of the previous paragraphs of the article, a liquid fuel boiler provides for the arrangement of a separate room for itself. Thus, a miniature boiler room will appear in your house, in which, in addition to the boiler itself, the following should be located:

- chimney;

- a tank for storing fuel;

- exhaust system.

You can find out about the requirements and norms of SNiP for a boiler room in a private house here

By the way, the reservoir should be as large as possible (ideally, it should be enough for the entire heating season) so that you do not bother to constantly fill it. You should also take care of fittings for the pipeline and a pump that would distill liquid fuel from the tank directly to the boiler. If you have the relevant experience and skills, you can independently perform the entire range of work - from drafting project to actual installation heat generator.

But it is recommended, of course, to resort to the help of professionals. A trained person will take everything into account when working, taking into account the features of your home, so he will do everything right and in record time. After all, such a heating system is a serious thing that requires a special approach.

Another important point is that the installation of the boiler can be carried out in one of two existing ways, and the choice of one or another of them is based solely on the features of the device itself.

- Mounted boilers are lighter, but at the same time less powerful and productive. In other words, they are compact and convenient, but the area of the building that they can heat is often limited to 300 square meters. There are such devices infrequently, which cannot be said about gas appliances, perhaps due to the fact that they are not so popular among the population.

- And floor boilers are more powerful and, accordingly, more massive.

Heating boilers of industrial type

If the heating system has a significant scale, then the boiler, of course, must correspond to these scales. Of course, ordinary household appliances have ten times less power than industrial ones. In the role of fuel at large industrial enterprises is fuel oil or diesel fuel, sometimes mining is also used.

With regards to the use of oil, this is rather the lot of those states that pay special attention to the cleanliness of the environment. This option has two advantages at once:

- liquid fuel boilers have something to work on;

- solves the problem of waste disposal.

The heating system, which is used together with industrial appliances, is often steam, that is, the heat carrier in this case is heated water vapor, which is often necessary for the needs of the enterprise. Each boiler has its own economizer and fully autonomous blowdown. Condensate is removed during operation, and thanks to the use of economizers, the efficiency increases significantly. In general, if you need to heat a workshop or other large room, it is advisable to additionally install a boiler.

About the features of using the device

The fan burner needs power supply. Therefore, a liquid fuel boiler is also dependent on electricity. Moreover, the fuel tank must be large enough, ideally such that it is enough for the entire heating season.

To do this, you need to calculate the approximate fuel consumption (it is measured in liters per hour). This can be done like this:

Consumption - a tenth of the power of the device; if the boiler is 150 kilowatts, then its consumption is 1.5 liters per hour.

To determine the burner flow rate, multiply its power by 0.1. It turns out that for an average house of 300 square meters, a boiler with the same capacity is needed. If you use the above formula, it turns out that approximately 3 tons of diesel fuel will be required for the heating season.

With regards to the number of circuits, single-circuit devices are more popular.

Important information! Single-circuit devices can only heat the room, they are not designed to heat water.

For heating, in this case, it is better to use an indirect heating water heater, which will use hot water from the heating system in operation.

About liquid fuel

Oil boilers can use the following types of fuel:

- diesel fuel;

- mining (used engine oil);

- fuel oil.

We mentioned the cost of diesel fuel at the beginning of the article - it is the most expensive of the listed options. The price of oil will be approximately 1/5 of this figure, and fuel oil - ?. It is characteristic that each type of fuel needs a special, if not its own, burner.And then a paradox pops up: the cost of the burner increases inversely with the cost of fuel! But there are also universal burners (very expensive) that can operate on any liquid fuel.

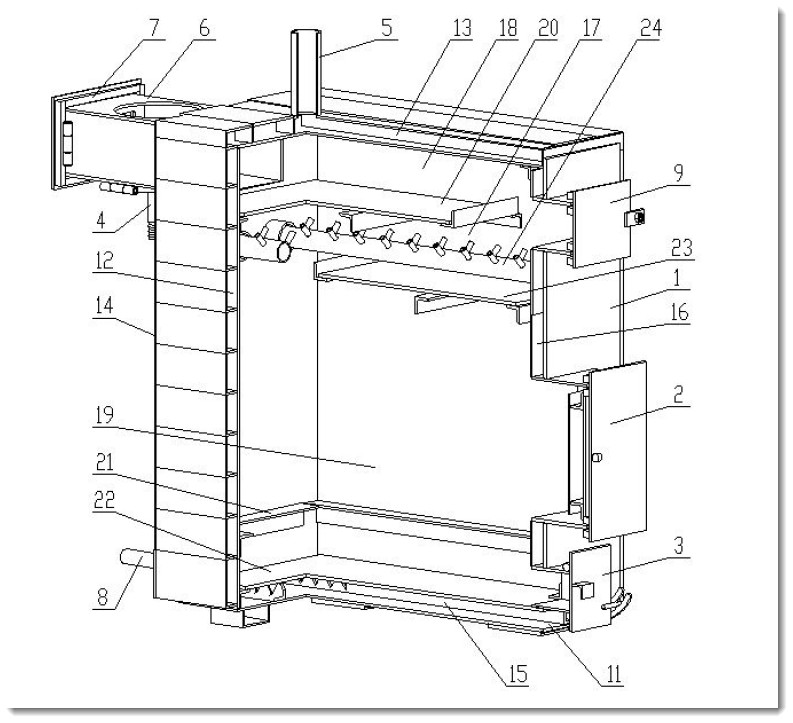

The best pyrolysis solid fuel boilers

Buderus Logano S171

The lineup

Floor-standing pyrolysis boilers of German production Buderus Logano S171 are available in four modifications with a capacity of 20, 30, 40 and 50 kW. They work automatically and do not require constant human supervision. Their performance is enough to heat low-rise buildings of various sizes. Equipment efficiency reaches 87%. For normal operation, a 220-volt electrical connection is required. Electricity consumption does not exceed 80 watts. The unit is reliable and easy to operate. Manufacturer's warranty 2 years.

Watch product video

Design features

The boiler has a spacious open-type combustion chamber with a two-stage air supply scheme. Exhaust gases are removed through a chimney with a diameter of 180 mm. Wide doors facilitate the process of loading fuel and revision of internal devices. The design pressure in the heating circuit is 3 bar. The temperature of the heat carrier is 55-85o C. Protection against overheating is provided.

Fuel used. The main source of energy is dry firewood up to 50 cm long. The burning time of one bookmark is 3 hours.

Ecosystem ProBurn Lambda

The lineup

Bulgarian single-circuit pyrolysis boilers are available in two versions with a capacity of 25 and 30 kW. Their performance is sufficient to heat a medium-sized private house. The automatic control system requires a connection to a standard electrical network.

The unit is designed to heat the circulating water up to 90 ° C. The maximum pressure in the circuit is 3 atmospheres. There is protection against overheating of the coolant. The boiler is easy to maintain and highly efficient. A 12 month warranty is provided.

Watch product video

Design features

There is a branch pipe with a diameter of 150 mm for connecting the chimney and fittings 1 ½” for the circulation circuit. In the exit zone of the flue gas furnace, a probe is installed that measures the oxygen concentration. It gives control signals to the damper that regulates the air supply.

Fuel used. Regular wood is used as fuel.

Atmos DC 18S, 22S, 25S, 32S, 50S, 70S

The lineup

The range of elegant pyrolysis boilers of this brand includes a range of models with a capacity of 20 to 70 kW. They are designed for floor installation in residential, industrial and warehouse premises. The equipment is highly efficient and reliable. For the correct operation of the automatic control system, the unit requires power from the 220 volt network. The maximum power consumption is 50 W.

The system of intelligent regulation of the flow of air entering the combustion chamber ensures the efficiency of each model at the level of 91%.

Watch product video

Design features

The devices are distinguished by spacious fireboxes of a special configuration, wide doors and a convenient control panel. The design of the heat exchanger is designed for a maximum pressure of 2.5 bar. Maximum heating of the coolant is 90 ° C. In case of overheating, a protective blocking is triggered. The flue gas outlet is adapted to connect chimneys of various diameters.

Fuel used.To load the furnace, firewood with a relative humidity of not more than 20% should be used.

Kiturami KRH-35A

The lineup

This floor Korean brand boiler is designed for heating of residential and industrial premises up to 280 sq.m. It has two heat exchange circuits, working on heating and heating hot water for household needs. They are designed for working pressures of 2 and 3.5 bar respectively. For the correct operation of the equipment, it is necessary to connect to the electrical network.

This model has a remote control unit with a choice of several operating modes. Automation protects equipment from overheating and freezing of the coolant. Unit efficiency 91%.

Watch product video

Fuel used. The main difference of the presented brand is versatility. The boiler is able to work not only on solid, but also diesel fuel. When loading coal, its power reaches 35 kW. With the liquid fuel version, it is reduced to 24.4 kW.

General installation instructions

Before buying a heating unit, you must determine the location of its installation. A furnace is intended for this, but often there is not enough free space in it, since it is occupied by an existing gas or other heater. Then the installation of a solid fuel boiler in a private house can be done behind the wall of the furnace room, in an annex. A frame of metal structures is installed and sheathed with sandwich panels or profiled sheets with insulation. The option is convenient for those who are going to heat with coal, there will be no dirt inside the house.

All inexpensive solid fuel boilers for a low-power house can be placed directly on a rough floor screed.They are light in weight and do not exert vibration loads on the base, since they are not equipped with a fan or screw conveyor for feeding pellets. For units with a capacity of more than 50 kW, it is recommended to arrange a concrete foundation, which should rest on the ground and compacted gravel bedding. The foundation is carried out 80-100 mm above the level of the screed, while it should not be associated with it. Base devices also require long-burning boilers, which have a mechanism for lifting and lowering a heavy load.

Projects for private houses usually provide for the installation of a chimney shaft in the thickness of the wall with a pipe exiting through the roof. If the shaft is missing or occupied by an existing gas heater, it will be necessary to install a chimney for a solid fuel boiler. To do this, it is better to use metal double-walled chimneys with insulation. They are lightweight, assembled from sections of the desired length and easily attached to the wall of the house. For bends and branches, the same double-walled tees and bends are made. Methods for installing chimneys with and without an exhaust shaft can be seen in the figure.

Natural exhaust ventilation is required in the furnace room. When heating boilers are installed in a private house, the hood is provided through a shaft in the wall. The shaft is parallel to the chimney, only of a smaller section. In its absence, an overflow grate is placed in the outer wall, it should be located under the ceiling of the room. The role of the hood is as follows:

- A vacuum is created in the furnace, as a result of which supply air from other rooms is sucked in and used for combustion. Boiler plants with a capacity of 50 kW and above require the organization of a separate supply ventilation.

- Removal of combustion products that accidentally got into the room.

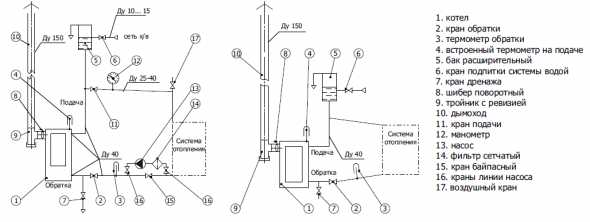

The approximate layout of the equipment and the installation diagram of a solid fuel heating boiler is shown in the figure.

Scheme of installation of a solid fuel boiler

Often in the boiler rooms of country houses there is no sewer outlet. This is not entirely correct, as sometimes it is necessary to empty the system or the water jacket of the boiler. The relief valve is sent to the same drain.

Installation procedure

To perform the work, the following installation instructions for solid fuel boilers are proposed:

- Release the product from its original packaging.

- If there is not enough space in the furnace room, then it is better to assemble the product on the street. Install all doors and ash drawer, as well as other items supplied separately. The fan and automation devices do not need to be installed, this is done after the installation of the boiler.

- Move the unit indoors and install it on a foundation or floor in such a way that the gas outlet pipe is on the same axis as the chimney pipe. At home, do-it-yourself installation of a solid fuel boiler must be done with an assistant; the weight of the equipment is rarely less than 50 kg.

- Fix the boiler on the foundation or screed so that there are no distortions.

- Connect the chimney, install a fan with a control unit and a safety group.

- Connect the boiler to the heating system according to the selected scheme.

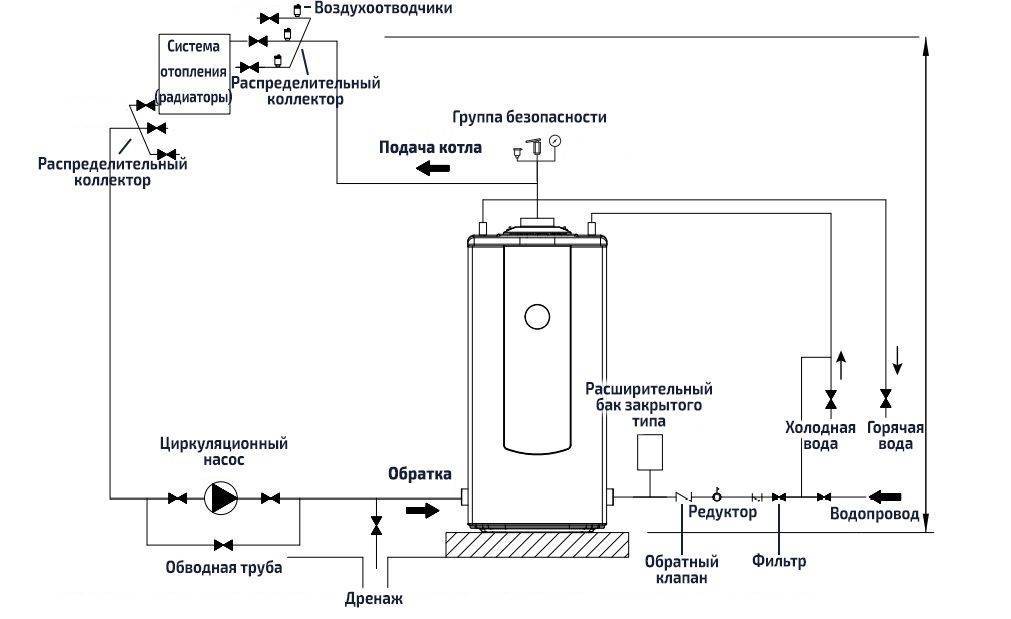

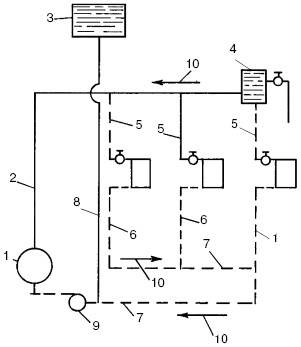

How can I fill the heating system in an apartment building

Scheme of water heating with associated water movement: 1 - boiler; 2 - main riser; 3 - expansion tank; 4 - air collector; 5 - supply risers; 6 - reverse risers; 7 - return line; 8 - expansion pipe; 9 - pump; 10 - pipe slope direction.

The water valve located in the house should be closed, and the water discharge is gradually opened on the coolant supply pipeline. At this time, the discharge on the return line is blocked. Then you need to very slowly open the shutter on the return pipeline until it is fully open.

Caution must be exercised, because if the high pressure water supply of the general heating system is abruptly opened, this can lead to sudden pressure drops that cause water hammer. The push can be so powerful that one will be enough to break the system in the most vulnerable places. It will take some time for the heating system to fill up.

Reset should be constantly monitored. When water flows without the admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, the discharge valve is closed. Now it's time to open the valve for supplying water to a particular room. At the final stage, it remains to bleed air from all heating circuits. This method of filling the system with water is provided for heating with a lower wiring.

It will take some time for the heating system to fill up. Reset should be constantly monitored. When water flows without the admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, the discharge valve is closed. Now it's time to open the valve for supplying water to a particular room.At the final stage, it remains to bleed air from all heating circuits. This method of filling the system with water is provided for heating with lower wiring.

A system with top piping looks much easier to handle.

In this case, simultaneously, with the same caution, both dampers should be opened at once, while the discharge should be closed. To bleed air, go up to the attic of the building and open the air valves provided for by the design

boiler room requirements

Gas equipment belongs to the category of explosion and fire hazard. Therefore, special requirements are imposed on the room in which it will be installed.

First of all, it should have natural light. At the same time, for each cubic meter of the room there should be at least 0.03 square meters. m of window opening without a frame, that is, only glazing. The window must be equipped with a window.

The wall on which the gas boiler is installed must be finished with non-combustible materials

Another prerequisite is the presence of forced ventilation, which can provide a change in the air volume of the room within 3 times in one hour. In this way, gas pollution in the room can be minimized.

In addition, the volume of the room in which it will be installed depends on the power of the selected boiler. Equipment with a capacity of 30 kW and below can be placed in 7.5 cubic meters. m boiler room.

For heaters, the power of which varies from 30 to 60 kW, a furnace with a volume of 13.5 cubic meters will be required. m and above. If the heater is placed in the apartment, it is usually installed in the kitchen.

This is possible if all the requirements of SNiPs are met.An important nuance: in this case, the total heat output from all heating appliances located in the kitchen should not exceed 150 kW.

According to the installation standards for wall-mounted gas boilers, to improve air exchange in the kitchen door, it is necessary to make a hole with an area of at least 0.02 sq.m and close it with a grate.

Experts recommend for installation in an apartment building only equipment with a closed firebox equipped with a coaxial chimney. In kitchens with a volume of 7.5 cubic meters. m and less, it is forbidden to install more than one heating device.

Requirements for the installation of gas heating equipment are regulated by SP-41-104-2000 and SNiP 42-01-2002. Compliance with installation standards guarantees safe operation

In private houses for gas boilers, it is recommended to allocate a room separated from the living rooms by refractory durable partitions.

It is optimal that the materials with which the room is finished have a time limit of fire resistance of at least 45 minutes. It is desirable that the layout of the premises prevent the rapid spread of flames to living rooms.

Fixing the gas boiler can only be done on a solid foundation. Partitions made of plywood or drywall are not suitable for these purposes. The wall on which the heater will be placed must be finished with refractory materials.

If this is not the case, a non-combustible substrate is mounted under the boiler. The minimum distance from the device to supporting structures is 0.5 m to the ceiling or walls and 0.8 m to the floor.

In the photo one of the options for connecting a wall-mounted gas boiler

In the photo one of the options for connecting a wall-mounted gas boiler

Boiler room in a private house in a separate room (built-in or attached)

Separate boiler rooms for the installation of gas boilers with a power of up to 200 kW must be separated from the rest of the rooms by a non-combustible wall with a fire resistance limit of at least 0.75 hours. These requirements are met brick, cinder block, concrete (light and heavy). The requirements for separate furnaces in a built-in or attached room are as follows:

- The minimum volume is 15 cubic meters.

- Ceiling height :

- with power from 30 kW - 2.5 m;

- up to 30 kW - from 2.2 m.

- There must be a window with a transom or window, the glass area is not less than 0.03 square meters per cubic meter of volume.

- Ventilation should provide at least three air exchanges in one hour.

If the boiler room is organized in the basement or basement, the minimum size of the boiler room will be larger: 0.2 m2 is added to the required 15 cubic meters for each kilowatt of power that goes to heating. A requirement is also added to walls and ceilings adjacent to other rooms: they must be vapor-gas-tight. And one more feature: when installing equipment with a capacity of 150 kW to 350 kW, a furnace in the basement or basement must have a separate exit to the street. Access to the corridor leading to the street is allowed.

It is not the area of \u200b\u200bthe boiler room that is normalized, but its volume, the minimum height of the ceilings is also set

In general, it is advisable to choose the size of a boiler room in a private house based on the convenience of maintenance, which, as a rule, far exceeds the standards.

Special requirements for attached boiler rooms

There are not very many of them. Three new requirements are added to the points above:

- The extension should be located on a solid section of the wall, the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-combustible material with a fire resistance of at least 0.75 hours (concrete, brick, cinder block).

-

The walls of the extension must not be connected to the walls of the main building. This means that the foundation must be made separate, incoherent and not three walls should be built, but all four.

What to keep in mind. If you are going to arrange a boiler room in a private house, but there is no room of a suitable volume or the ceiling height is slightly lower than the requirements, you may be met and demanded in return to increase the glazing area. If you are planning to build a house, then you must meet all the requirements, otherwise the project will never be approved for you. They are also tough on the construction of attached boiler houses: everything must comply with the standards and nothing else.

When filling with coolant

There are only two situations that require the implementation of this technological operation:

- putting heating into operation (at the beginning of the heating season);

- restart after repair work.

Usually, the heat carrier water is drained in late spring for two reasons:

- Water is inevitably polluted by corrosion products (inside radiators, metal-plastic and polypropylene pipes are not subject to it). Leaving the old water for the new season, you risk breaking the circulation pump with solid contaminants.

- Non-launched flooded systems of country houses can “thaw out” during a sudden cold snap - such cases are not uncommon. In this sense, antifreeze coolant is preferable.The high-quality composition has high anti-corrosion properties, which increase the “drainage” interval up to 5-6 years. There are cases of uninterrupted operation of heating on the same volume of antifreeze for 15-17 years. Low-quality antifreeze is recommended to be drained after 2-3 years.

Pumping antifreeze into the heating system.

Basic rules for arranging heating make-up

Example of a heating system make-up unit

Example of a heating system make-up unit

What is the reason for the decrease in the volume of water in the pipes? The main source of its leakage is the excess of the operating temperature. As a result of this, a critical expansion of the liquid occurs, after which its excess in the form of steam leaves through an air vent (closed circuit) or an open expansion tank (gravitational).

The installed heating system replenishment machine compensates for the lack of water by adding the required volume to the line. But this is not the only case when it is necessary to quickly add a coolant to the system:

- Removal of air pockets. As a result of opening the Mayevsky tap or air vent, some of the liquid will inevitably leave the system. In a closed circuit, in this case, a pressure drop will occur, to which the automatic replenishment of the heating system must respond;

- Micro leaks. Loose fitting of pipeline joints and loss of sealing even at a small level will lead to a gradual decrease in the volume of water. It is difficult to identify such defects, but it is necessary. The automatic heating system make-up valve will work only after the pressure drops to a minimum level;

- Carrying out repair or maintenance work;

- The formation of corrosion on the walls of metal pipes, which leads to their thinning and, as a result, an increase in the internal volume.At first glance, this is a minor factor. But if the recharge of a closed heating system is not installed, the pressure will gradually decrease and air jams will begin to form.

What should the heating system feed device consist of? It all depends on the type of heating scheme. Also, the design of adding a coolant to the system is influenced by its characteristics: pressure, temperature regime of operation, line layout, number of heating circuits, etc.

Installing a gas boiler

As a rule, the installation of heating boilers of this type in a private house requires a separate non-residential premises (boiler room). This is necessary for the removal of combustion products, that is, for the installation of a chimney. The boiler room must be equipped with inlet and outlet ventilation. A hole is made under the ceiling for air to escape, and for its inflow - 30 cm from the floor level. Installation of floor-standing boilers is carried out using:

- welding machine;

- drills and a set of drills;

- keys, including gas;

- a set of screwdrivers;

- scissors for metal;

- building level;

- tape measure and marker.

Preparation and connection

The mounting surface must be solid and level, and ideally the foundation must be poured. To ensure safety during the operation of the equipment, it is necessary to lay a sheet of iron on the foundation. The first step is to bring the chimney and check for draft. Then connect the boiler to the internal heating system: before the return pipe inlet, install a filter that protects the heat exchanger from blockage, and the tie-in to the water supply should be placed as close as possible to the water pipe inlet into the room.

This scheme will provide high pressure in the system and a constant supply of water.

This is necessary for dismantling equipment without discharging water. It should be noted that the installation of gas equipment is carried out only after agreement with the supervisory authorities with the involvement of certified gas service specialists. Don't skimp on safety!

Conclusions and useful video on the topic

Watching video materials will help you understand the device and the principle of operation of liquid fuel heating units.

Comparison of a diesel boiler and a unit operating on a "working out":

The rules for choosing liquid fuel heating equipment will be discussed in the following video:

Liquid fuel boilers are characterized by a high level of automation. Heating based on diesel devices allows you to achieve autonomy, and the absence of rigid frameworks for documenting makes them an attractive proposition. However, a number of significant shortcomings in the maintenance of the boiler plant keeps the demand for diesel units.

If you are concerned about the choice of an oil-fired boiler, please leave your questions in the box below. There you can also write practical advice on the topic of the article or share your experience in using such heating equipment.