- Which chimney is best for a gas boiler

- Chimney installation steps

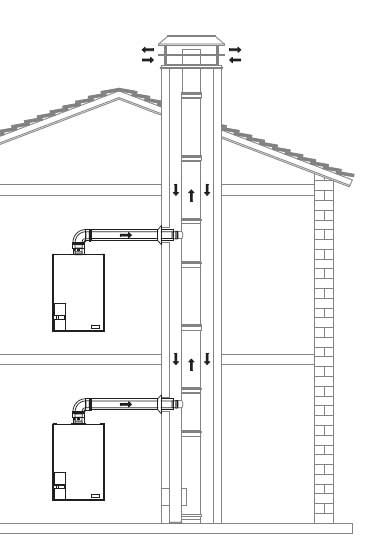

- Internal version of the chimney

- External chimney device

- Step-by-step instructions for building a smoke exhaust system

- outside the building

- Inside the house

- Smoke extraction structure insulation

- Requirements for chimneys for gas boilers

- Gas chimneys

- What materials are suitable for gas chimneys?

- Does the type of boiler affect the choice of chimney?

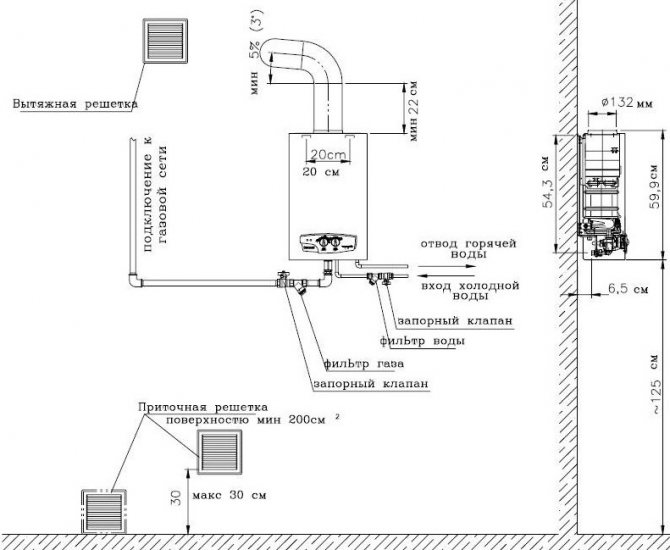

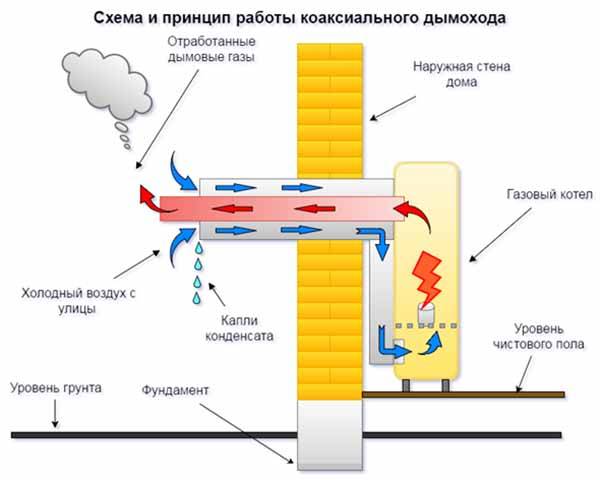

- How to install a coaxial chimney?

- Is it possible to change the chimney?

- Chimney Requirements

- Coaxial chimney installation technology

- Installation of the internal system

- Installation of an external structure

- About installation rules

- Features of installation and connection of chimneys

- Chimney materials for solid fuel boilers

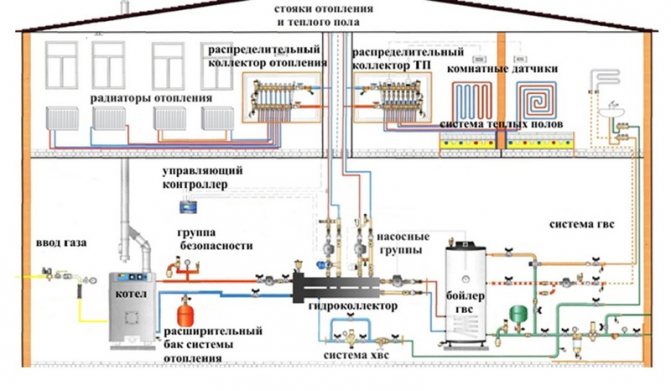

- Options for gas ducts for a country house

- Selection Guide

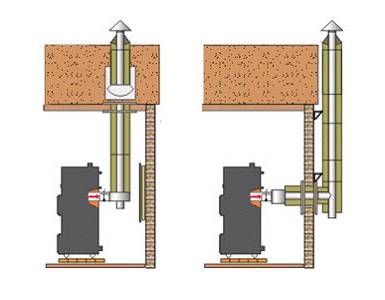

- Chimney of solid fuel boiler

Which chimney is best for a gas boiler

The durability of the channel depends on the material. It must withstand high temperatures, moisture and acid produced during the combustion of gas. The material must be chosen light enough so that it is not necessary to strengthen the walls and foundation of the building. For the manufacture are used:

- Stainless steel - resistant to most types of corrosion, lightweight, is considered the best option. Provides reliable traction for 15 years.

- Aluminum is also durable, but due to its low mechanical strength, it is used only for interior decoration.

- Enamelled pipes - are produced with built-in thermal insulation, which simplifies the installation of the chimney.

- Galvanized steel - will last a maximum of 5 years, as it will lose its tightness under the influence of fumes of high acidity.

- Ceramics - the service life of such products reaches 30 years. European manufacturers reinforce them with a beautiful steel frame. However, due to the heavy weight, it is sometimes necessary to take measures to strengthen the walls and foundation. Such designs provide maximum traction only in a vertical position, which is not always possible to implement.

- Sandwich chimneys - consist of two pipes inserted one into the other, with a heater between them. Due to 2 layers of metal, they are highly reliable. Durability depends on the material of the inner tube. During installation, additional insulation is not required.

- Coaxial chimneys - also consist of two pipes, but the space between them is used to supply air to closed-type gas boilers from the street. Produced in modules that are convenient for quick assembly.

- Brick chimneys are heavy, so they require a foundation. Due to the rough walls, the traction is not up to par, which leads to the accumulation of soot on them. Therefore, the pipe will have to be cleaned twice a year. In addition, the brick is hygroscopic, absorbs the resulting condensate and quickly collapses. But the preserved chimney can be used as a protective frame if you insert a stainless steel pipe with a condensate trap at the bottom into it.

- Asbestos-cement channels are cheap, but rarely used, as they are prone to cracking and releasing carcinogens when overheated.

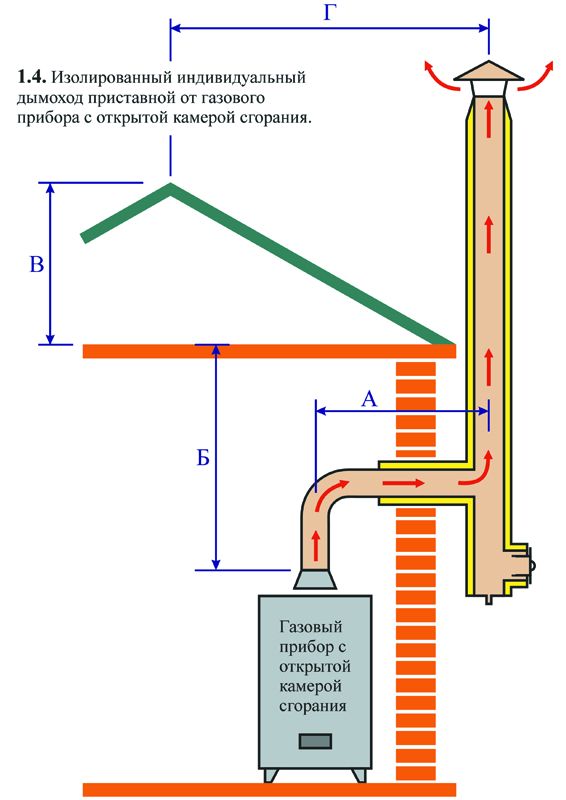

Depending on the installation method, chimneys are external and internal. Which one is better to choose depends on the type of building and the location of the boiler. External channels are horizontally brought out into the street and attached to the outer wall. They are easier to install, you just need to follow the fire rules when arranging the hole, if the house is built from combustible materials. However, careful insulation and installation of a condensate trap will be required.

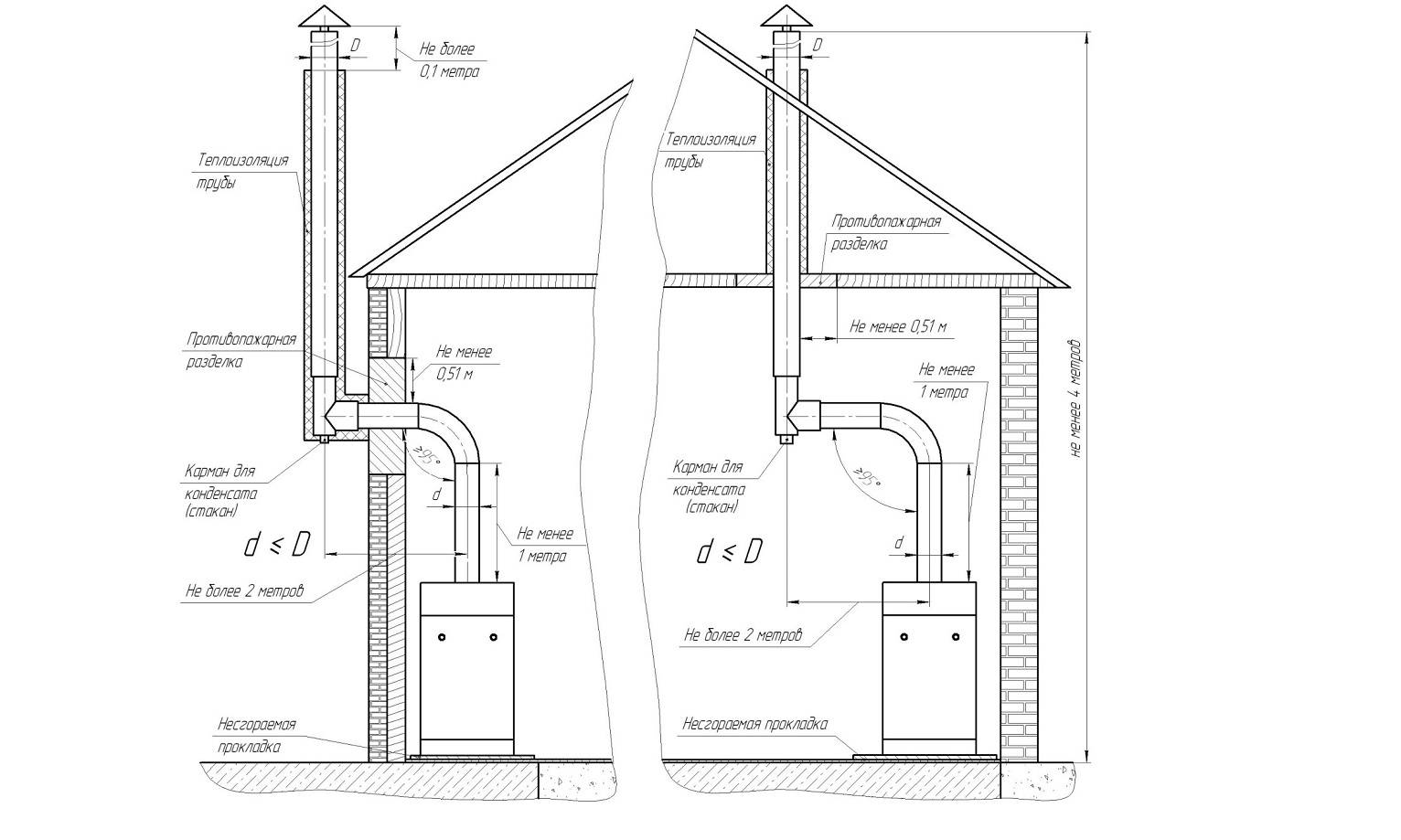

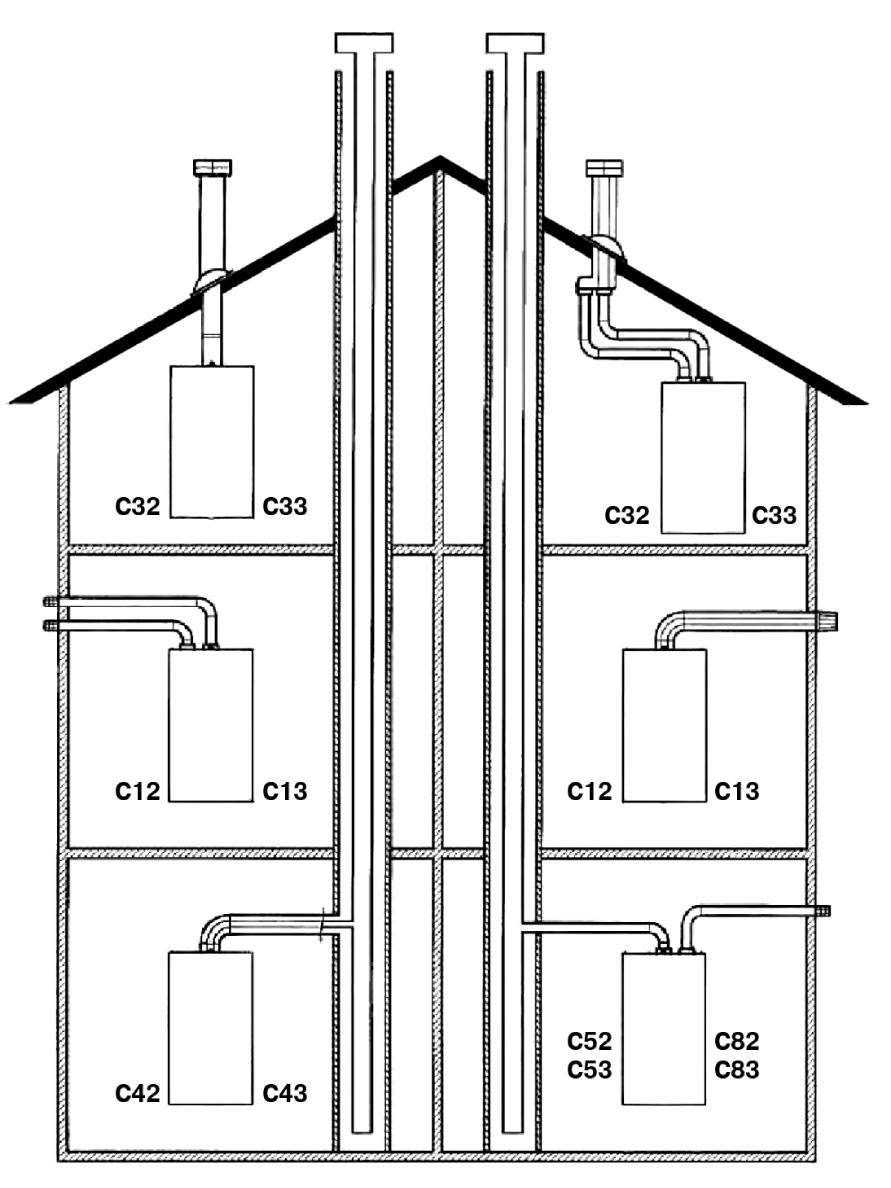

The internal chimney is discharged through the ceilings and the roof, which is not always acceptable in multi-storey buildings. Installation is complicated by the installation of several special passage units that ensure fire safety.

Chimney installation steps

The selection of the chimney should be started only after the purchase of the boiler, otherwise it is impossible to select its cross section and calculate the dimensions. In terms of shape, a round section is best, although a rectangle is also acceptable. The useful area should be calculated by multiplying the internal size by the length of the chimney:

S=π x d ext. X L

The proportion must be observed: the entire useful section of the pipe is greater than the area of \u200b\u200bthe boiler inside.

The height of the chimney is chosen depending on its location in relation to the roof ridge.

The chimney height given in the table is the minimum. You can increase it, but you cannot decrease it. Therefore, if during the calculation it turns out that the condition is not met under which the useful cross-section of the pipe must be greater than the internal area of \u200b\u200bthe heating unit, you should take a pipe of a smaller cross-section, but of greater length

Under the internal chimney it is necessary to build a foundation. If you also add a protective brick channel, this will minimize the amount of condensate.Sometimes chimneys are attached outside to the wall behind which the unit is located.

Internal version of the chimney

Before proceeding with the installation of the chimney, a place is chosen for it. Then mark the places where it will pass through the ceiling and roof. Carefully check the accuracy of the markup and make openings. The next step is to connect the boiler pipe to the chimney, and then mount the revision and the tee.

A sheet of steel is fixed, the main bracket is installed, the pipe is increased, if necessary, “knees” are used. Branch pipes are used in the area of contact with the overlap. They take a sheet of galvanized steel with a hole so that a pipe passes freely through it, attach it to the ceiling. Clamps are used to reinforce the joints. Every 2 m the chimney is fixed with clamps, and every 4 m with brackets.

The work is completed by checking the seams for tightness. To do this, take a soap solution, apply it to all joints. If everything is done qualitatively, then when the unit is connected to the chimney, bubbles will not appear in these places.

External chimney device

For a remote chimney in a blank wall, a hole is made of such a diameter that a pipe with insulation passes freely through it. Having installed the first element of the future chimney in the hole, fix it, wrap it with insulation. The next sections are added from the side of the street, controlling the verticality with a plumb line.

An outdoor chimney is safer, but it needs to be well insulated. In the purchased design, all the elements fit well, so the assembly will not create problems

The pipe is fixed to the wall with brackets until it reaches the desired height. The process is completed by attaching the pipe to the boiler nozzle and sealing the joints.In order for the external chimney to warm up quickly, it is insulated along its entire length with basalt wool.

Step-by-step instructions for building a smoke exhaust system

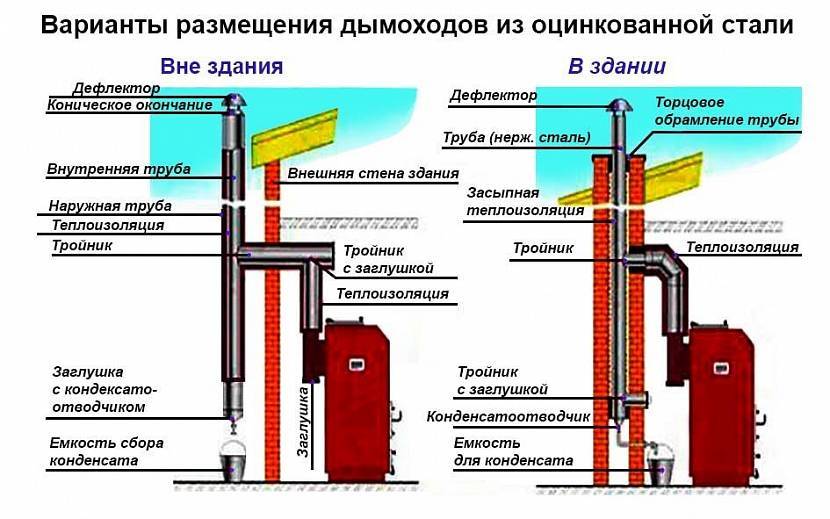

Chimney location options for a gas boilerHow to install a sandwich chimney

The procedure for arranging a chimney will be considered using the example of building a sandwich system from pipes. This is the most optimal and universal solution. There are 2 methods of assembling a similar structure: in the house and outside. Explore both options and choose the one that suits you.

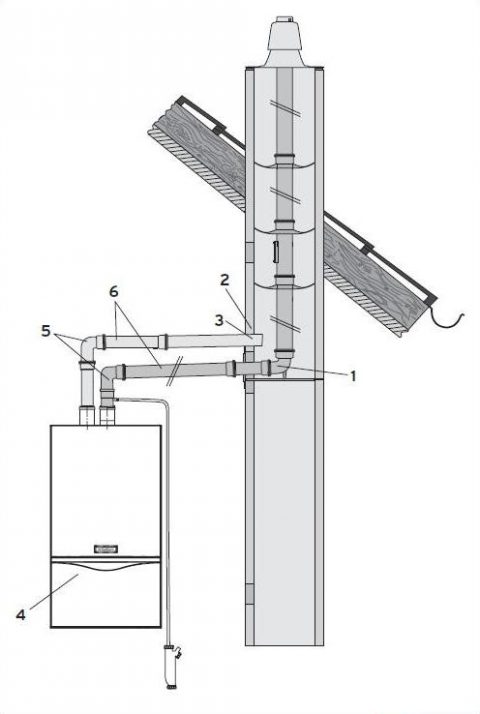

outside the building

Scheme of installation of a gas chimneyLocation chimney for gas boiler

First step. We connect a passage element designed for laying through the wall to the branch pipe of the heating unit.

Elements for connecting a gas boiler to a chimneyConnecting a gas boiler to a chimney

Second step. We apply markings on the surface of the wall in accordance with the dimensions of the passage element and cut out the opening.

hole in the wall

Third step. We remove the chimney from the room.

Pipe exit through the opening

Fourth step. We carry out a thorough insulation of the hole and the pipe passing through it.

How to make overlay plates

Fifth step. We attach a tee with a revision to the pipe, then put a plug

Sandwich teeInspection capConnecting a tee with an inspectionConnecting a tee with an inspection (bracket and clamp)

Sixth step. We build up the chimney by attaching new links until the required length is reached. Having gained the planned height, we install a cone-shaped tip on the pipe. It will protect the system from rain and wind. We use brackets to fasten the pipe to the wall of the building.The step of placing the fixing elements shouldn't be less than 200 cm.

Assembling the chimney of a gas boiler

Seventh step. We strengthen all joints of the structure with the help of clamps. We tighten them with wire or bolts.

Eighth step. We paint the chimney with a special heat-resistant paint and varnish composition. It will provide proper protection of the material from rust.

Inside the house

Inside the house

We start with preparation:

- we outline holes for the pipe in the ceilings and roof;

- after checking the marks with the dimensions of the pipe, we make an opening for the chimney.

Next, we deal directly with the installation of the chimney.

First step. We connect the adapter to the branch pipe of the unit.

Second step. We install a tee and revision.

Third step. Let's start building the chimney.

Do-it-yourself installation and installation of a chimney

If necessary, we perform work using the so-called. knees. In places where the pipe overlaps, we use a special protective pipe.

Docking

Fourth step. We put a sheet of stainless steel on the chimney. We cut a hole in the sheet in advance, slightly larger than the diameter of the pipe. Such a sheet should be on both sides of each overlap.

Scheme of arranging a hole in the ceiling

Fifth step. We strengthen the joints of the structure with the help of clamps.

Sixth step. If necessary, we attach the pipe to the attic beams. To do this, we use brackets (every 400 cm) and wall clamps (every 200 cm).

Fixing the chimney with a bracket Roofing element 20/45 degrees diameter 300 mm (sandwich)

Seventh step. We mount a tip (deflector) in the form of a cone on the chimney outlet.

Assembly diagram of the hood for a gas boilerChimney elements

Smoke extraction structure insulation

Smoke extraction structure insulation

At the points of contact of the elements of the chimney with flammable materials, it is necessary to equip reliable thermal insulation. To ensure it, cover the passage pipe with basalt wool with a foil layer. Fasten the insulation with fire-resistant mastic. Additionally, lay mineral wool around the perimeter of each opening in partitions and ceilings.

At the end of the installation activities, be sure to check the tightness of each seam of the system. To do this, it is enough to apply a simple soapy solution to the seams. The appearance of soap bubbles indicates a violation of the tightness of the system. Fix any issues you find as soon as possible.

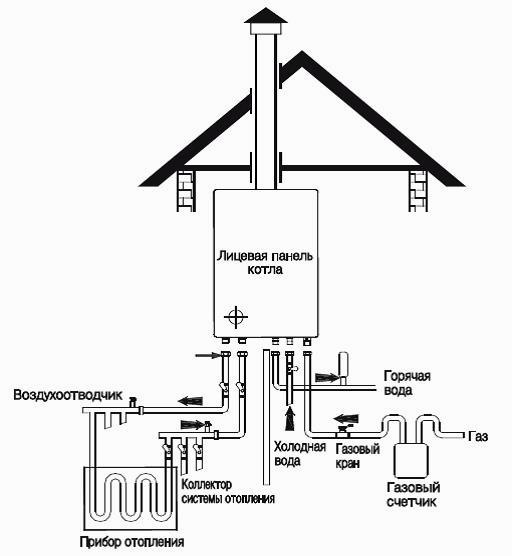

Boiler connection diagramFloor gas boiler

Successful work!

Requirements for chimneys for gas boilers

Design, assembly, installation and other activities aimed at installing a smoke channel are regulated by regulatory documents that clearly and clearly spell out the basic requirements for these structures.

For floor and wall-mounted gas boilers, a steel chimney is most often mounted

For floor and wall-mounted gas boilers, a steel chimney is most often mounted

On the basis of these documents, for smoke exhaust structures that will be used in conjunction with heating boilers, the following requirements apply:

- section of the chimney - cannot be less than the outlet pipe of the gas boiler.For example, if the branch pipe has a cross section of Ø150 mm, then the minimum diameter of the chimney must also be at least 150 mm. Throughout the length of the chimney, the pipe should not have narrowed sections and curvature;

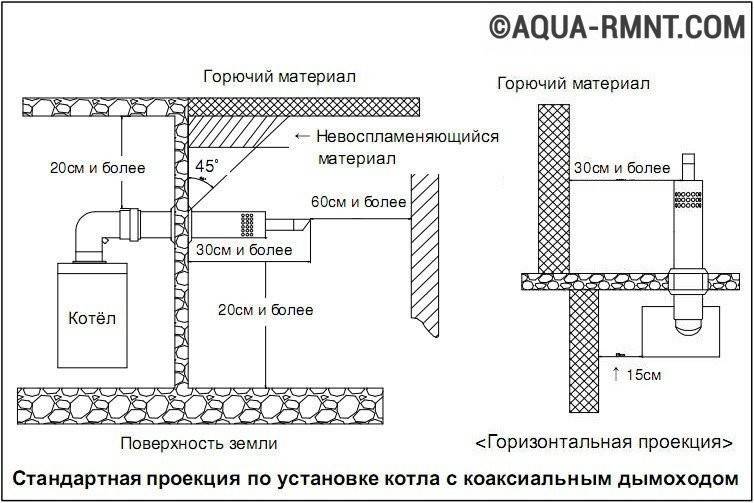

- the location of the smoke channel - the chimney must go straight up. If necessary, a slope of 30o is possible. In this case, the length of the bends can be no more than 100 cm, and their maximum number is no more than 3. If it is required to turn the pipe, then the radius of curvature must be greater than or equal to the diameter of the pipe used;

- the height of the chimney above the ridge is at least 0.5 m in cases where the pipe is located at a distance of up to 1.5 m from the roof ridge. If this distance is from 1.5 to 3 m, then the pipe is allowed to be flush with the level of the ridge. In other cases, a conditional line is drawn from the level of the ridge at an angle of 10o. The head of the pipe must "touch" this line. The distance from the roof overhang to the chimney is at least 1.5 m;

- materials - for the manufacture of the chimney, only non-combustible gas-tight materials are used. When building up the structure, the upper part of the pipe must be put on the lower link. In this case, the contact point must be treated with a non-combustible sealant;

- device - the minimum distance from the chimney to objects and surfaces made of flammable materials must be at least 25 cm. In other cases, at least 5 cm. When the chimney passes through ceilings and roofs, there should not be direct contact between the chimney and these structures . At the bottom of the chimney, a revision module with a dripper must be mounted.

The above requirements are general and must be met in all cases without exception.When installing the chimney, it should be remembered that even small deviations from the values required by regulatory documents can reduce the life of the chimney, and in some cases lead to more serious consequences.

Gas chimneys

What materials are suitable for gas chimneys?

Due to the characteristics of the chemical composition of the smoke that appears during the combustion of gas, the main requirement for the material is resistance to chemical aggressive environments and corrosion. Thus, there are the following types of gas chimneys:

1. Stainless steel. The best option. Their advantages are light weight, resistance to various corrosions, excellent traction, operation up to 15 years.

2. Made of galvanized steel. Not the best option compared to stainless steel. Provides poor traction, more prone to corrosion. Operation no more than 5 years.

3. Ceramics. Gaining popularity. Operation up to 30 years. However, the high weight of the chimney must be taken into account when laying the foundation. The maximum thrust is only possible with vertical installation without errors.

4. Coaxial chimney. It has increased efficiency and safety, but at the same time a high price. It is a pipe within a pipe. One is for smoke removal, the other is for air supply.

5. Brick chimney. Shows negative qualities when using gas heating. Operation is short. It is permissible to use a brick chimney left over from stove heating only as an outer casing for an insert made of a more suitable material.

6. Asbestos cement. Outdated variant. Of the positive aspects - only low price.

There are a lot of options for holding a gas chimney.When choosing a material, it is worth starting from its quality characteristics. Do not save on your health and the safety of your loved ones.

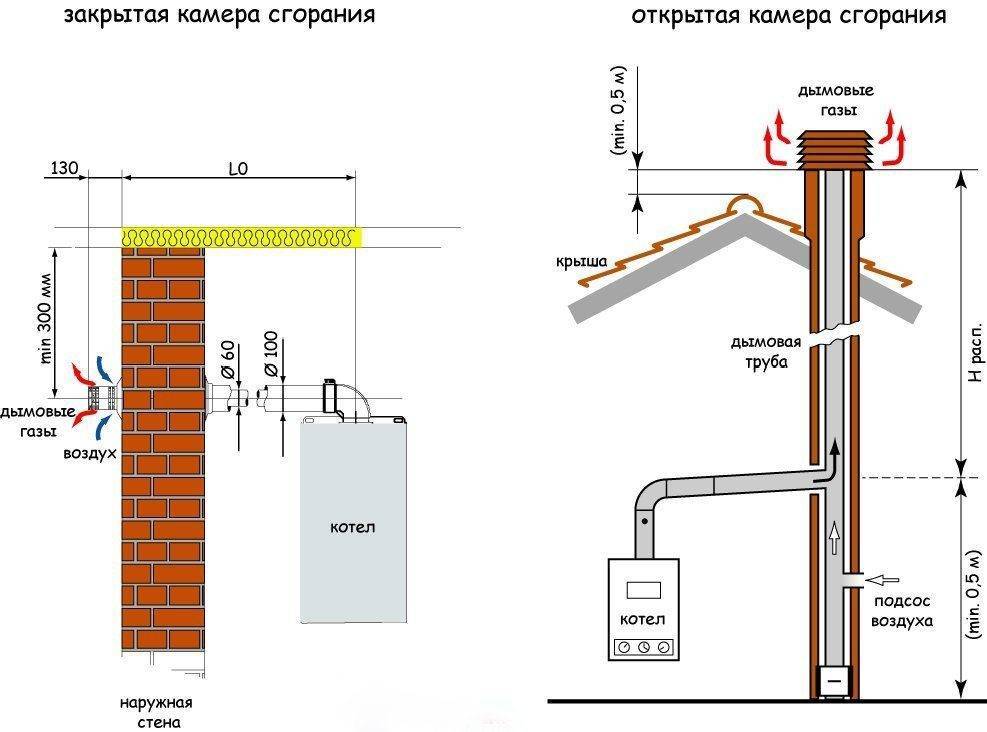

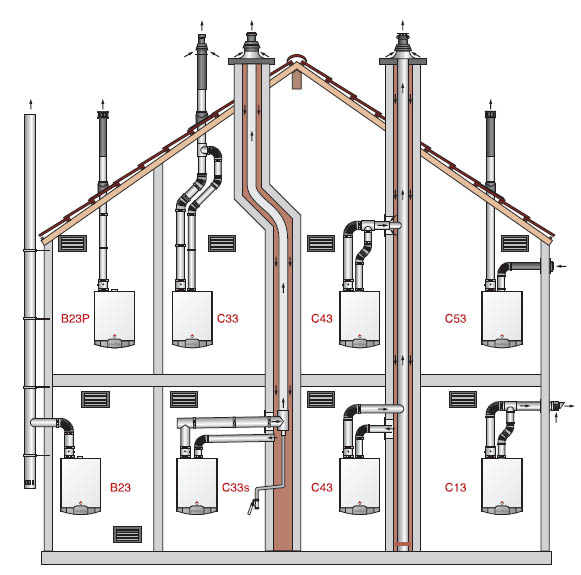

Does the type of boiler affect the choice of chimney?

The design of the chimney depends entirely on which boiler will be used - closed or open type. This dependence is explained by the different principle of operation of the boilers.

The open type is a burner with a heat carrier coil located on it. Air is needed to operate. Such a boiler requires the best possible traction.

Installation is carried out:

- Outside way. When conducting a chimney, you can use the external installation method by bringing a straight horizontal pipe through the wall, and then lifting it up to the required height. This method requires a high-quality heat-insulating layer.

- In an internal way. It is possible to pass the pipe internally through all the partitions. In this case, 2 slopes of 30° are acceptable.

The closed type is a chamber with a nozzle where air is injected. The blower blows the smoke into the chimney. In this case, the best solution would be to choose a coaxial chimney.

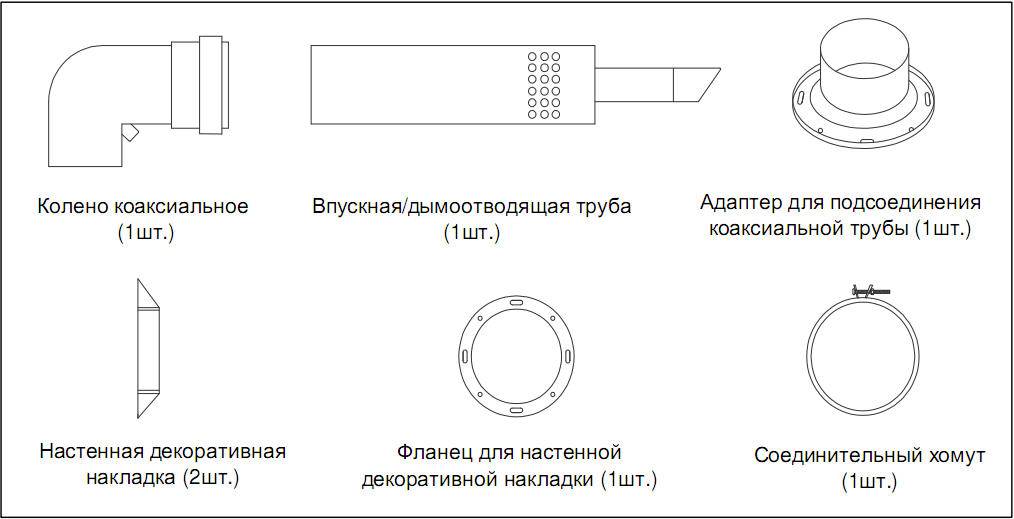

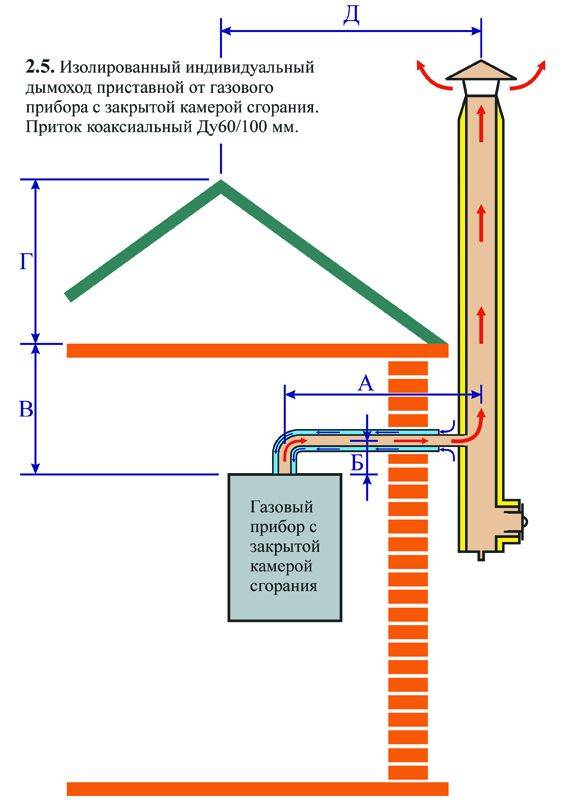

How to install a coaxial chimney?

The main positive characteristics of this type of chimney are:

- Easy installation;

- Safety;

- Compactness;

- By heating the incoming air, it cools the smoke.

Installation of such a chimney is permissible both in a vertical position and in a horizontal one. In the latter case, a slope of no more than 5% is required to protect the boiler from condensate. It should be borne in mind that the total length should not be more than 4 m.For installation, you will need to purchase special adapters and umbrellas.

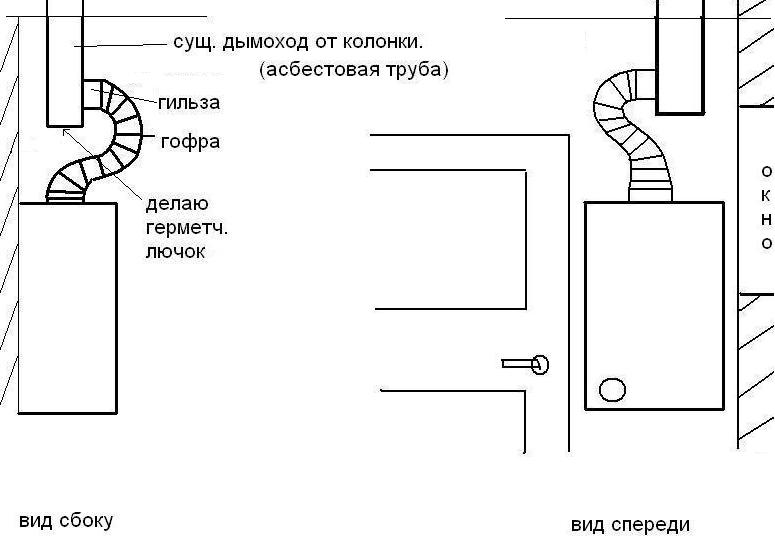

Is it possible to change the chimney?

Often there are cases when the owner decides to switch from solid fuel to gas. Gas equipment requires a suitable chimney. But do not completely rebuild the chimney. It is enough to sleeve it in one of the ways:

1) Use of a stainless steel pipe. A stainless steel pipe of suitable length is installed inside the existing chimney. Its diameter must be no less than the boiler pipe, and the distance between the pipe and the chimney is filled with insulation.

2. Furanflex technology is more expensive, but more durable. An elastic pipe under pressure is installed in the chimney, where it takes shape and hardens. Its advantages are in a seamless surface that provides complete tightness.

Thus, you can significantly save on materials, while complying with all regulatory requirements.

Chimney Requirements

Appropriate technical support is used for the efficient and safe removal of fuel combustion products, as well as air supply to a certain section of gas equipment that ensures an efficient combustion process. In appearance, this is a mine with a pipe installed inside. The mounted structure must meet all the established requirements:

The chimney shaft is installed in a vertical position. There should be no expansion or contraction in this case. Only a slight slope (up to 30 degrees) from the vertical and a side deviation of no more than 1 meter are allowed. It is also allowed to set up to three turns, if the radius of their rounding is equal to the diameter.

The material of manufacture must be non-combustible and non-melting, and the structure must be free of cracks and any other damage to prevent fire. The best option among the numerous range of types is the use of stainless steel pipes, since they are light, easy to install and maintain, versatile and affordable.

The height and diameter of the pipe must fully comply with all the established output parameters of the gas equipment

This is necessary to ensure sufficient traction and efficient operation of the equipment.

Laying chimneys indoors is prohibited.

At the bottom of the connection of the outlet pipe from the boiler to the chimney, it is important to make a so-called pocket for cleaning from accumulated condensate.

If pipes are laid through rooms without heating, then it is important to cover them with thermal insulation.

Coaxial chimney installation technology

The process of installing an external and internal coaxial chimney is different. Let's consider both options.

Installation of the internal system

First of all, we check the conformity of the diameters of the outlet pipe of the boiler and the chimney. Then we proceed to prepare a hole in the wall through which the chimney will go outside.

Its diameter must exactly match the dimensions of the coaxial pipe. After making the hole, you can proceed to the installation of the structure. It begins with the outlet pipe of the boiler, to which the corresponding chimney element is attached.

The resulting connection is fixed with a clamp and fixed on both sides with bolts. Next, the entire structure is sequentially assembled.Each element is inserted into place and secured with special clamps to give the system additional reliability. Decorative overlays are installed on top of the fasteners, so an attractive appearance of the structure is preserved.

Chimney output through the wall to street. If necessary, a deflector or additional wind protection. The section of the passage in the wall is sealed. At the same time, fire safety requirements are observed. A special protective casing is put on the pipe. The joints of the passage are sealed and covered with an apron.

Outer coaxial chimney vertical orientation. Such systems are quite simple to install.

Installation of an external structure

Before it begins, the exit point of the coaxial chimney is determined and its location is marked on the wall of the building. Then a hole is made in the wall with a diameter corresponding to the cross section of the smoke channel.

Further, all internal work is carried out. Start by connecting the pipe to the heater. For this, a single-circuit elbow and a double-circuit tee are used.

The latter is needed to fix the structure in a vertical position. The resulting structure is fixed on the wall surface with special brackets.

Further, all work is carried out in the same way as described above. The chimney exit section is sealed and the pipe assembly continues to the desired height. The design is fixed to the wall with clamps. To connect double-circuit pipes, transition nodes are used.

About installation rules

To build the right chimney, you need not only to comply with the general requirements, but also adhere to the specific rules governing its laying:

The connection of gas-using equipment to the chimney system is made with a steel pipe or corrugation in such a way that at the outlet a vertical section with a length of at least 15 cm is obtained;

- the distance from this connector to non-combustible structures - 50 mm, to combustible - at least 250 mm

- the maximum length of a horizontal section laid with a slope of 0.01 towards the boiler is 3 m;

- the number of turns along the entire length of the gas duct - no more than three;

- deviation from the vertical up to 30° at a distance of up to 1 m is allowed without reducing the channel cross section;

- the minimum depth of a pocket with an inspection door is 25 cm;

- the flue pipe of the heat generator must be equipped with a damper;

- when crossing ceilings made of combustible materials with a ceramic pipe or sandwich, it is necessary to maintain a distance of 380 mm from the inner wall to the wooden structure;

- caps or umbrellas are not placed on chimneys from gas boilers in order to avoid icing and fumes in the premises.

Despite the impressive list of requirements, it is not so difficult to meet them. Chimney channels inside the walls are laid out during the construction process, when you have a project in your hands and the opportunity to correct flaws at any time. If a private house has already been built, it is more convenient to organize the removal of combustion products with sandwich chimneys, you just need to decide whether to lay the pipe inside or take it outside the building. The second option is most preferable, provided that the boiler is located near the outer wall.

As for the installation of coaxial pipes, the same requirements apply to it. The horizontal section should not be longer than 3 m, and the distance to combustible structures should not be 25 cm.So that in severe frosts the end of the gas duct does not freeze from condensate, the inner channel must be released 5-10 cm further than the outer one.

Features of installation and connection of chimneys

Installation of a metal chimney is carried out in the following ways:

- along the smoke - the assembly of elements is carried out by inserting the lower pipe into the socket of the upper one;

- according to the condensate drain - in the reverse order, the higher one is inserted into the socket of the lower pipe.

The chimney is made of steel with a thickness of at least 1 mm and is installed vertically.

Permissible deviations in individual sections are not more than 30o. It is obligatory to have a special accelerating section with a length of at least 1 m after the boiler nozzle. It is permissible to have horizontal sections with a length of not more than 0.5 m.

The elevation of the pipe head above the roof is set within 50 cm. The joints are sealed with a heat-resistant sealant.

At wall mounting mount produced in increments of at least 1.5 m.

When installing the pipe indoors, contact with combustible materials is unacceptable, the distance to walls and wooden floor structures is at least 0.25 m. A special protective screen must be installed on the chimney.

Chimneys are connected to the boiler with a slope of at least 0.02 towards the boiler.

Chimney materials for solid fuel boilers

Modern ceramic block chimneys - reliable and easy to install

There are few choices in this section. There are a lot of materials, but in practice you have to work with only three of them:

- brick;

- ceramics;

- iron.

Brick pipes for the chimney of a solid fuel boiler are familiar to everyone who has seen a stove at least once in their life. Their maximum operating temperature is 1000 degrees. Even in modern premium-class cottages, you can see a beautiful eurobrick chimney proudly towering over the roof of the house. And this does not at all indicate that the heating in this estate was done according to the old grandfather methods. No, it's more about aesthetics. If you look closely, you can see that metal or ceramic pipes are inserted into the brick chimney. Since the brick itself is not suitable for arranging the chimney of a solid fuel boiler. It also happens that in old houses you have to upgrade brick chimneys. An insert is inserted into them, and a heater is laid in the formed cavities.

Ceramic sandwich pipes have just a gigantic margin of operating temperature. This indicator reaches 1200 degrees, which is one and a half times higher than the maximum temperature of the smoke formed as a result of coal combustion. Pipe device:

- inner ceramic layer;

- insulation layer;

- rigid shell made of expanded clay concrete.

Now about the unpleasant. They are rustic in appearance, perhaps for someone it matters. They are also slightly more expensive than iron ones. And finally, installation will require some skills. But at the same time, this material has become widespread among middle-income consumers.

Iron chimney. The most used material. It is able to withstand +800 degrees without changing its physical and chemical qualities. It consists of three layers: inner and outer steel, and basalt wool between them. For production, stainless steel with the addition of molybdenum is used.This element increases the resistance of the metal to corrosion and acids.

It is already known how to calculate the diameter of a chimney for a solid fuel boiler, and the characteristics of materials are also described. It remains to deal with the techniques installation and design features. If you stop at metal pipes, then you can assemble it yourself, for this you need to follow some rules.

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.