- DIY drainage well

- Materials and working principle

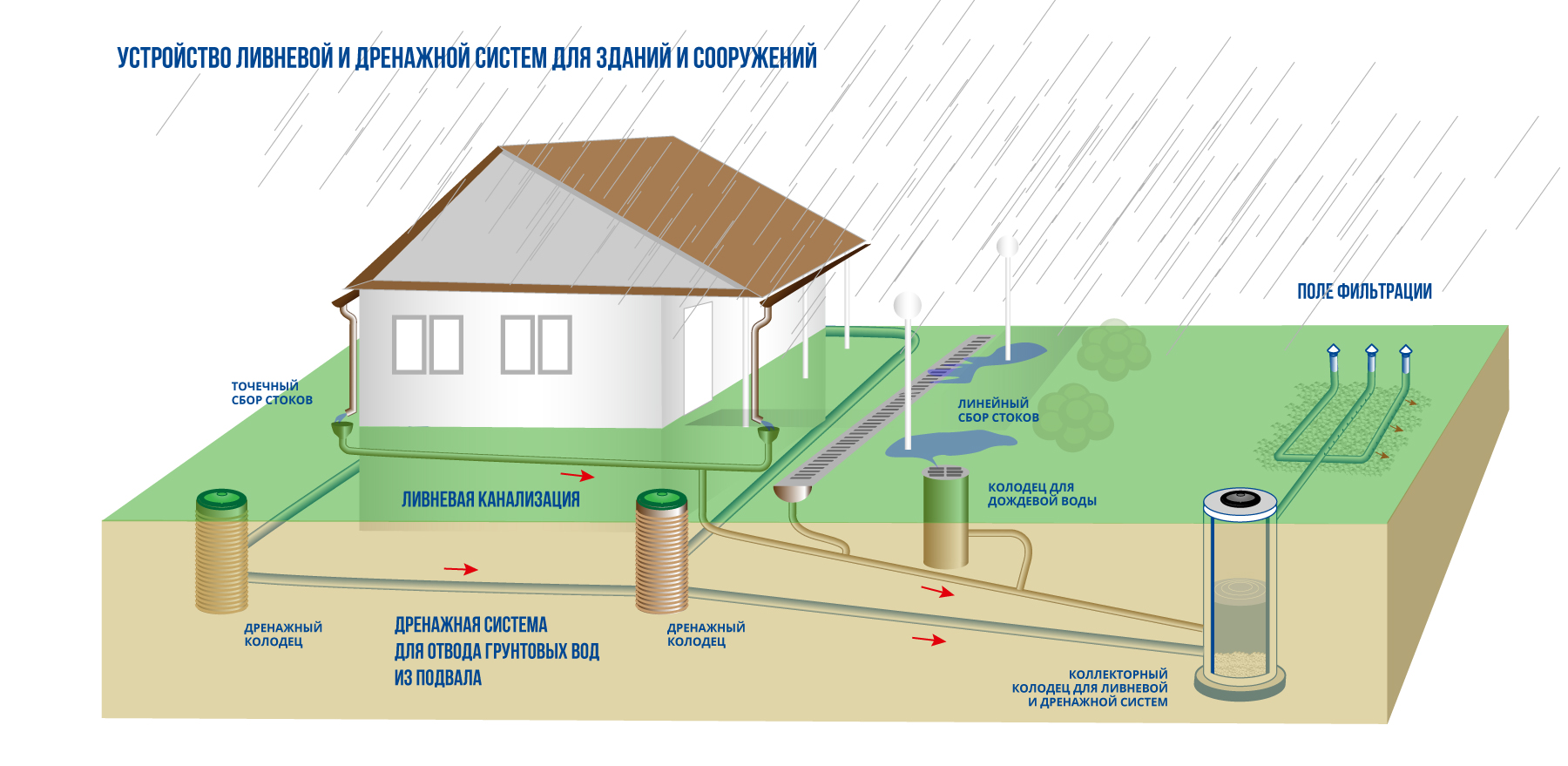

- Types of drainage systems

- Construction order

- Digging a trench

- System care and maintenance

- Regular maintenance of the drainage system

- Capital maintenance

- General information

- Is drainage always necessary?

- Consequences in the absence of drainage

- Self-assembly of the structure

- The procedure for performing work during the construction of drainage systems

- How to build an open drainage system

- How is the construction of a closed drainage

- What type of well to choose for the drainage system

- The device of the storage drainage well

- Materials used to build a well shaft

- Construction of a well from concrete rings

- Varieties

- What are drainage wells for and what are they

DIY drainage well

It is unlikely that anyone would think of building a house on a sandy area. For construction, places with groundwater are selected so that in the future there will be no problems with drinking water. But this plus of the area can turn into waterlogging of the soil, and the destruction of the foundation of the building. To protect yourself from this problem, you need to build a drainage well. This design serves to divert groundwater from the site.

Materials and working principle

The work of the well is simple. A trench is pulled out on the site to collect and drain water - a drain.One or more drains are connected to it, which drain the liquid into a reservoir located nearby with the site or into a special reservoir.

Types of drainage systems

Drainage wells are divided into four types according to the type of soil and the movement of groundwater. The principle of operation of each is different, and before you make a drainage well, decide what system you need.

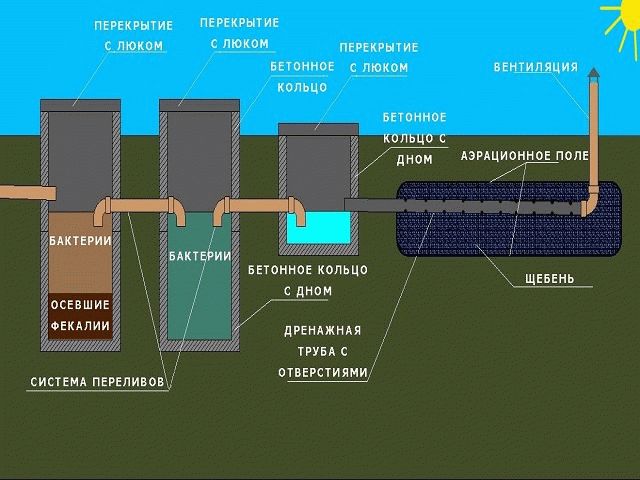

Collector well

This version of the drainage system is able to collect and accumulate moisture, which can later be dumped into a ditch or used to water plants. Its construction is appropriate in the lowest part of the terrain.

Rotary wells

They are mounted on drainage bends or in places where several sewers are connected. In such places, there is a high probability of contamination of the internal cavities.

absorption well

Such a well must be equipped in those places where it is impossible to lay pipes to drain liquid, due to the lack of a reservoir for discharge or sewerage. This is the deepest type of drainage system, and the minimum depth must be at least 3 m. The bottom in the well is made of crushed stone or sand, this will allow the liquid to be discharged into the groundwater.

manhole

This option is used to access the drainage system and possible repairs. For convenience, its width should be at least 1 m. In principle, such wells can be made in other systems, because repairs and preventive cleaning will not be superfluous.

Construction order

When choosing the size of the future well, the area of \u200b\u200bthe site is taken into account, namely the part that needs to be drained.

When all the materials are ready, work can begin.We dig a hole at least 2 meters deep, depending on the type of drainage system. At the bottom you need to equip a special pillow. Coarse sand is best suited for this. The bedding should be from 30 to 40 cm thick, in the process of arranging it must be well tamped.

On the backfill, you need to make a square formwork for arranging the foundation, which will serve as the bottom of the well. It should be laid reinforcing mesh, preferably small. This structure is filled with concrete mortar.

After the concrete has set, the inner and outer formwork is installed on the base. The walls from above must be connected with wooden planks. Concreting of the walls of the well is carried out according to the level. After 2 - 3 weeks, when the concrete is completely dry, we remove the formwork and backfill the base. It is better to use fine gravel or expanded clay for this.

Digging a trench

To drain liquid from the well, polyethylene or asbestos pipes are used. Just digging a trench and laying pipes towards the dump site will not be enough. In order for the reset to occur correctly, you need to perform the following steps.

- Fill the bottom of the trench with sand.

- Lay a layer of fine gravel on top of it.

- A drainage pipe is laid on such a pillow, which is also covered with sand and gravel.

Together, the layer of sand and gravel should be half the depth of the trench. The remaining depth is covered with loam, and a fertile layer of earth is laid on top.

When arranging drainage on an already built-up site, work should be carried out in small sections of 15–20 meters each. During operation, the soil removed from the excavated section is poured into the previous section of the trench. It is better to start work in late July - early August.At this time, the groundwater level is the lowest.

System care and maintenance

During operation, drain wells and pipe outlets must be securely closed with manholes or plugs to protect the system from contamination and debris.

Activities for the care and maintenance of the drainage system include:

- regular inspection - drainage wells and collectors after floods and heavy rains must be carefully inspected without fail and, if necessary, the drainage system must be cleaned;

- capital cleaning of pipes - removal of various deposits from the walls of drainage pipes and repair of drainage, if necessary.

Regular maintenance of the drainage system

At the bottom of the drainage well, soil particles regularly accumulate, sediment, which at some point may begin to enter the pipes. Constant monitoring of the contents of the well will help prevent the unacceptable accumulation of large soil particles and prevent them from clogging the drainage system.

If a large amount of sediment is found, the well is cleaned. This can be organized independently, you will need a pump for pumping wastewater and a hose that supplies clean water. The sand in the well is mixed with water with an ordinary stick and pumped out.

The contents of the sewer well are pumped out by a drainage pump

Capital maintenance

With an interval of 10-15 years (more often if necessary), drainage pipes are subjected to major flushing, which allows them to be freed from deposits and deposits. In this case, access should be to all pipes from both ends. That is, on the one hand, it is a connection with a drainage well, and on the other, a pipe is brought out to the soil surface with the installation of a tight cover (plug).

Pro tip:

It is possible to optimize work and reduce labor costs during major pipe cleaning by installing drainage wells at the beginning and at the end of the drainage pipeline, and also on pipe bends (with an interval through one turn).

Flushing occurs in two directions: the water driven by the pump flows through the pipes from the beginning to the end, then vice versa. Drainage cleaning is carried out using water, which is supplied from a garden hose under high pressure. Drainage cleaning is carried out only after the drainage wells are cleaned.

Cleaning the drain with a jet of water

Compliance with the rules of the drainage system and high-quality, timely work on its maintenance guarantee a long service life of the drainage. On average, this is 50 years - this is how long the polymer pipes from which the pipeline is constructed function without destruction. Further, the plastic will become unusable, but the drainage, due to the volume filter made of crushed stone, will work for another 20 years.

Proper pipe laying will help the drainage system cope with such important tasks as:

- drainage of the summer cottage in the season of even the strongest and most prolonged rains;

- prevention of harmful effects of ground and surface waters on structures and plantings on the site.

General information

Is drainage always necessary?

A drainage system is not necessarily needed in every area. Drainage is required if:

1. groundwater is located high, above the level of the foundation, or the distance from the surface is less than a meter.

1. groundwater is located high, above the level of the foundation, or the distance from the surface is less than a meter.

2.if the site is located on the territory, which runs through slope or low.

3. if the soil is clayey, and the foundation is slab or shallowly buried.

4. if the site is partially or completely waterlogged.

5. if desired, exclude the formation of puddles and dirt on the site.

6. Water often enters the basement or basement where the equipment is located, or the room is intended for other purposes.

7. If there is a clay type of soil on the site, surface-type drainage should be organized to drain water after rains and snow.

Attention! Sandy loams, chernozems do not require mandatory drainage. The drainage system is not necessary to perform if:

The drainage system is not necessary to perform if:

1. groundwater rarely and briefly rises higher than the foundation is located.

2. if water rarely and in small quantities enters the basement.

3. The site is not of a swampy type, it is not required to preserve the appearance of the site without puddles.

Signs When You Need a Drainage System

The first step is to inspect the area. If the following signs are revealed, then drainage is required:

1. cracked blind area, the appearance of cracks in the foundation and on the walls.

2.when water enters the basement.

3. puddles stagnate after rains.

4. the waters in the well are high, near the surface.

Consequences in the absence of drainage

If drainage is necessary, but it was not done, then bad consequences can be expected. Including:

1. The soil around the foundation will be saturated with water and freeze, the foundation will deform, begin to collapse, cracks will appear on the walls, the walls will deviate from the vertical.

2. if the foundation is slab, shallowly buried, and the soils in the area are clayey, then in spring, when thawing, the earth will warm up differently from the shady and sunny side of the building, this will lead to deformation of the foundation and the formation of cracks in the structure.

3.water, mold will appear in the basement.

Self-assembly of the structure

It is possible to carry out the installation of a drainage system, in particular, the installation of a manhole, with the help of specialists who are engaged in the implementation of such work. Or do it all on your own with the help of family and friends.

First of all, it is necessary to lay pipes on the territory of the site. In places where drainage wells will be located, recesses should be dug corresponding to their size and shape - they can be round or square.

Any well consists of the following parts:

- the foundation;

- tray part;

- working chamber;

- neck;

- Luke.

After the completion of the preparatory work, the finished well is lowered into the pit, pipes are connected to it, which will drain water. The gap between the walls of the pit and the container is covered with earth.

Installing a homemade well from a corrugated pipe is much harder. First of all, you should prepare the container itself - cut off the required size from the corrugated pipe of the desired diameter and make holes through which the pipeline will pass. Equip the bottom - build a gravel-sand cushion and pour cement on top. As soon as the solution has completely hardened, geotextiles should be laid on top of it.

After installing the corrugated pipe in the pit on the prepared bottom, pipes are passed through specially made holes and connected to each other.

The joints and points of penetration of pipes into the well must be smeared with mastic to ensure maximum tightness. The free space outside the well is covered with earth, rubble and other materials. Be sure to install and close the hatch.

Paying attention to the laying and installation of the drainage system and special wells at the site development stage, it is possible to ensure its effective drainage and drainage for many years.

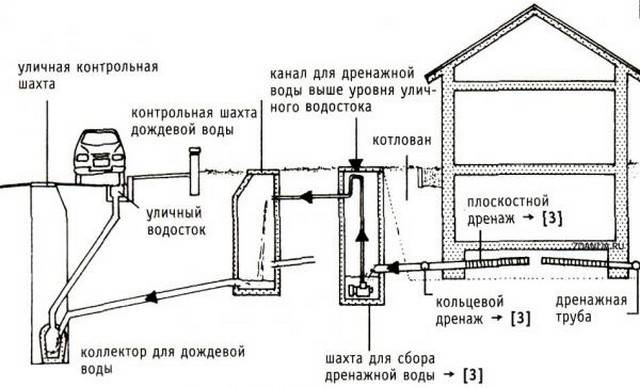

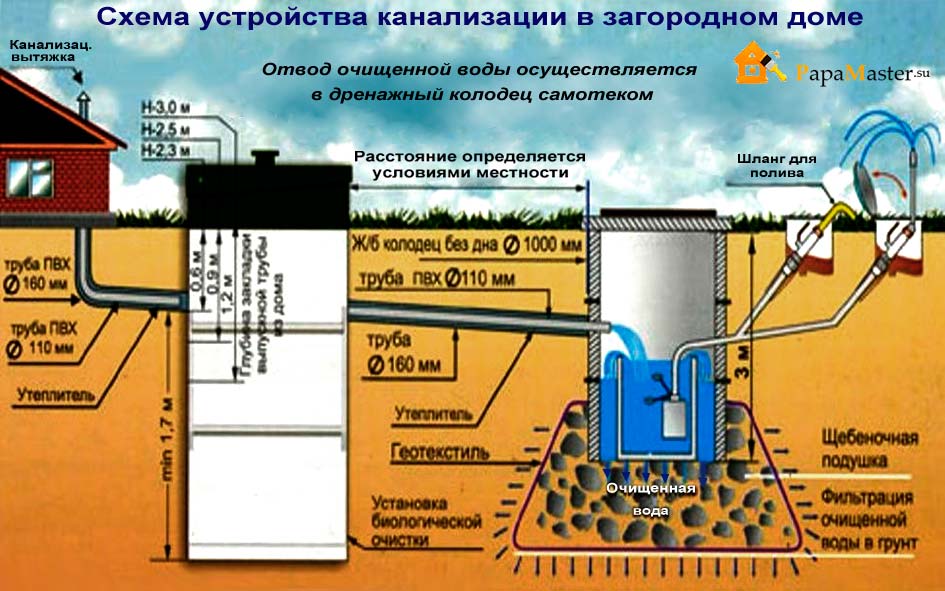

The procedure for performing work during the construction of drainage systems

In order to successfully build drainage in a summer cottage, you need to be guided by the following general considerations:

- The construction of a closed drainage system requires a large amount of earthwork. In this regard, it is necessary to build drainage even before trees are planted on the site, and even better - before the foundation of buildings is laid.

- Before work begins, a detailed system plan must be drawn up. To do this, it is necessary to study the terrain, determine the highest and lowest points on the site, set the value of the required slope.

- When designing a closed system, revision wells should be included in the plan to ensure the possibility of servicing the drainage system.

- When laying a drainage pipeline, the recommended slope is from two to ten millimeters per meter of pipe.

How to build an open drainage system

Drainage construction open systems is a much easier task than laying a closed drain, as it does not require digging deep trenches. When laying a network of trenches, a plan for their location is first drawn up. Then trenches are dug.Usually, the main ditches are laid along the perimeter of the site, and the auxiliary ditches are laid from the places of the greatest accumulation of water. In this case, the depth of the trench should be from fifty to seventy centimeters, the width should be about half a meter. Auxiliary trenches should slope towards the main ditches, and main trenches should slope towards the catchment. Walls trenches should be not vertical, but beveled. The angle of inclination in this case should be from twenty-five to thirty degrees.

The further course of work depends on which system is being built, filling or tray. During the construction of the backfill system, the ditch is first covered with rubble - 2-thirds of the depth is large, and then shallow. Sod is laid on top of the gravel. To prevent silting of crushed stone, it is desirable to cover it with geotextile.

The construction of flume drainage includes the following steps:

- Laying trenches subject to the required slope.

- Filling the bottom of the ditches with a ten-centimeter layer of sand, which must then be compacted tightly.

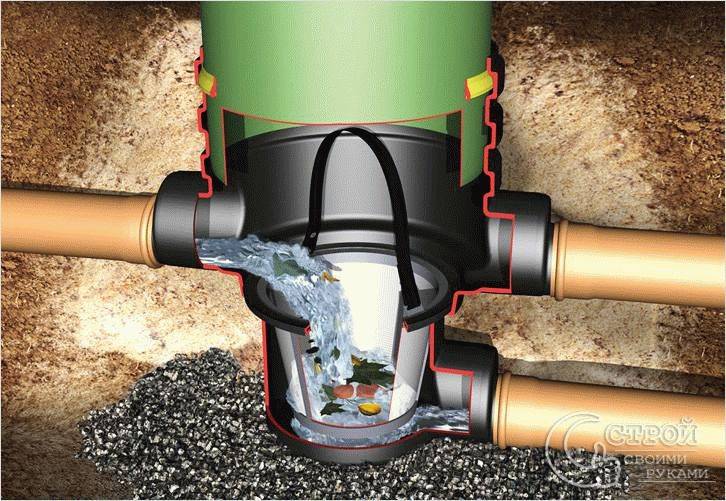

- Installation of trays and sand traps, which are plastic parts that prevent sand and debris from entering the drainage, and thereby protecting the system from silting.

- Closing the ditches from above with gratings that prevent clogging of the trenches with fallen leaves and various debris, and also perform an aesthetic function.

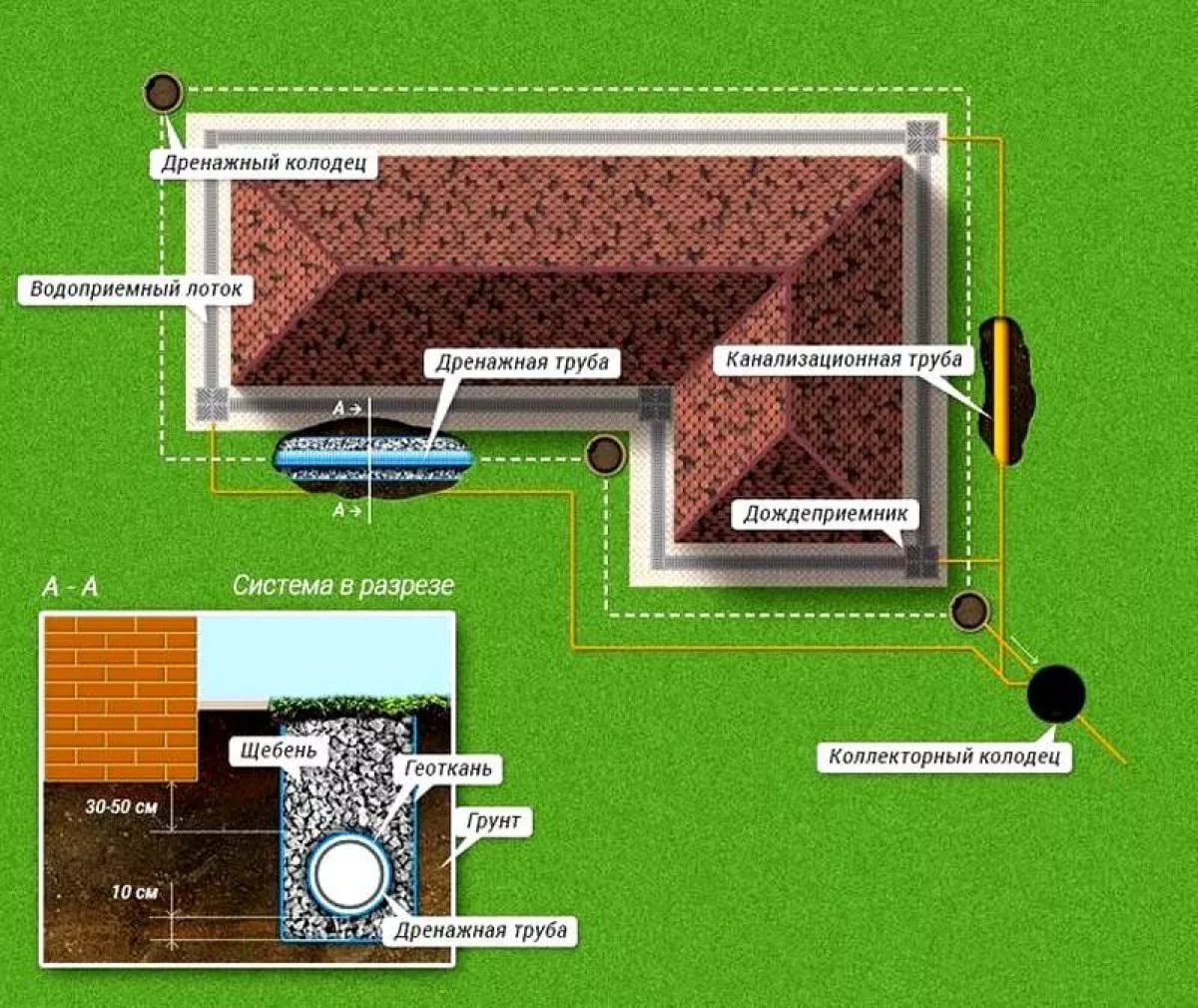

How is the construction of a closed drainage

The construction of a closed-type drainage system consists of the following steps:

- Studying the relief of the territory of the site using a level and a laser rangefinder, and building a plan for the drainage network.If surveying instruments are not available, then you should wait for heavy rain and observe the movement of rainwater flows.

- Laying trenches under the drainage pipeline.

- Backfilling the bottom of the trenches with a layer of sand seven to ten centimeters thick, followed by tamping.

- Laying geotextiles in a trench, while the edges of the fabric should protrude beyond the sides of the ditch.

- Laying a twenty-centimeter layer of gravel on top of the geotextile, which serves as a filter. In this case, limestone gravel should not be used, since this can form a salt marsh.

- Laying pipes on a layer of gravel. In this case, their holes should be directed downwards.

- Filling gravel on top of the pipes and closing it on top with the edges of a geotextile that will filter water from suspended particles, thereby preventing silting of the system.

- Burying ditches with soil, on top of which sod can be laid.

The drainage system should end with a well for collecting water, which must be dug at the lowest point of the site. From this well, water can be discharged into a natural reservoir, into a ravine, or into a general storm drain, if there is one in this settlement.

A properly constructed drainage system will prevent problems associated with excessive dampness, which is why its construction is mandatory in areas with wet soil.

And those owners of summer cottages who are not sure that they can cope with the construction of drainage on their own should contact specialists and pay the required amount, but you should not try to save on such an important functional element of a summer cottage as drainage

Well, that's all guys - I hope I was able to give you an answer to the question: "How to make do-it-yourself drainage". All success!

What type of well to choose for the drainage system

Before self-installation of drainage wells, it is recommended that you familiarize yourself with the disadvantages and advantages of these structures. Among the main advantages of the design are the following:

- Excavation work is carried out simultaneously with the installation of a drainage well during the day.

- The tightness of the structure is ensured by waterproofing and the use of reinforced concrete rings.

- The cost of doing the work on the device of this design with your own hands is relatively low.

- The strength of reinforced concrete structures is greater than that of brick wells.

Before you make a drainage well with your own hands, you should choose its size. It should allow flushing the entire drainage system, if necessary, with a pressure of water under pressure. Manholes for drainage are usually mounted at the places where drains turn in conditions of elevation changes. An acceptable distance between them in straight sections is 40 m. The maximum distance should be 50 m. Such wells usually have a diameter of 300-500 mm.

Access to the system through the drainage well is through the hatch. The optimal diameter of the structure for descending a person through it should be increased to 1 m.

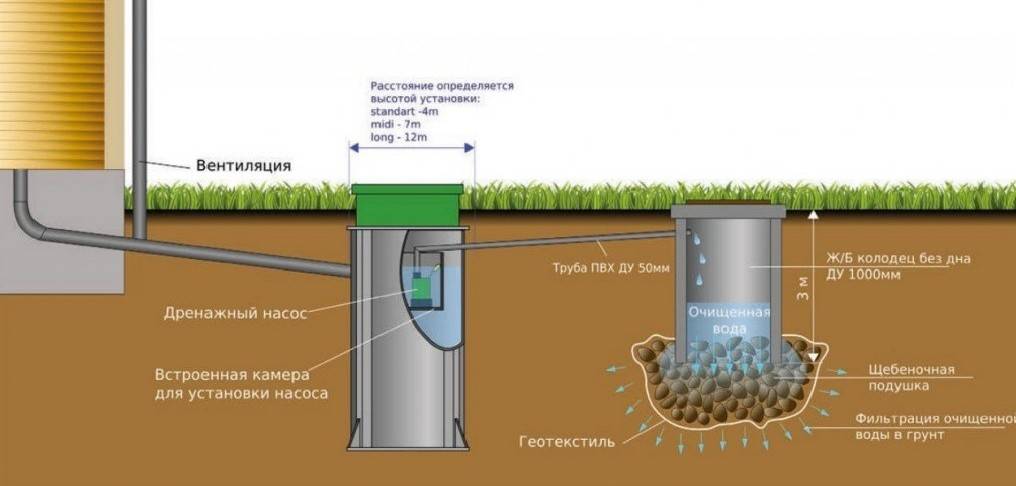

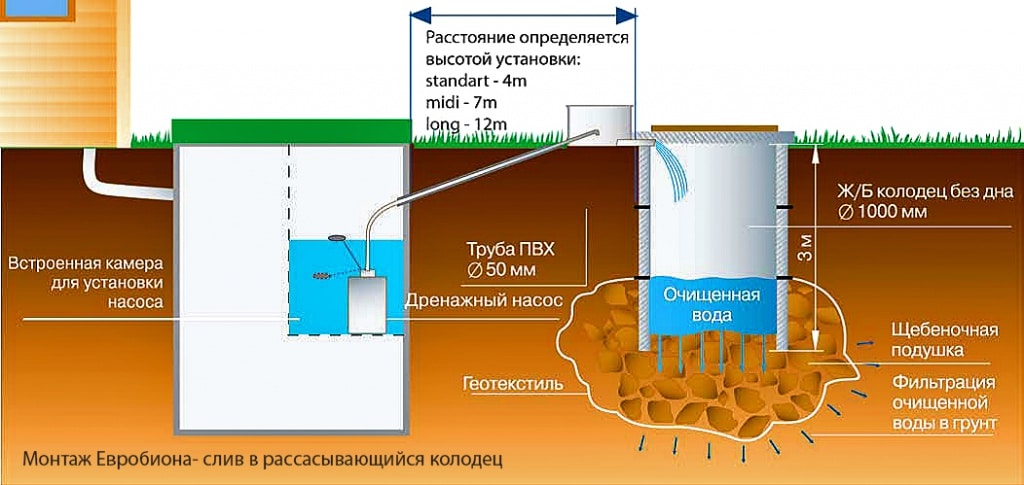

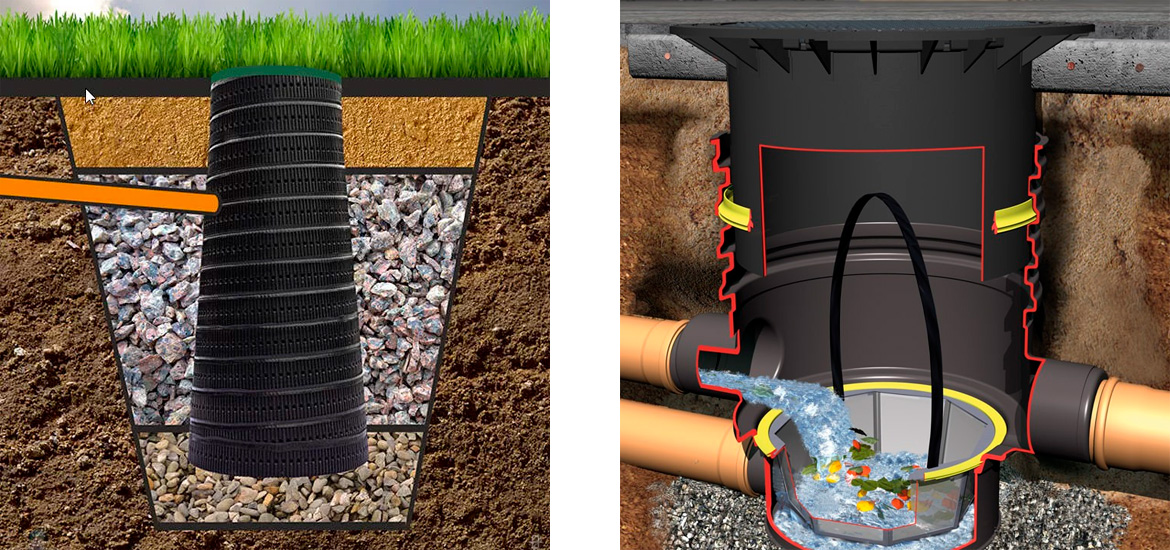

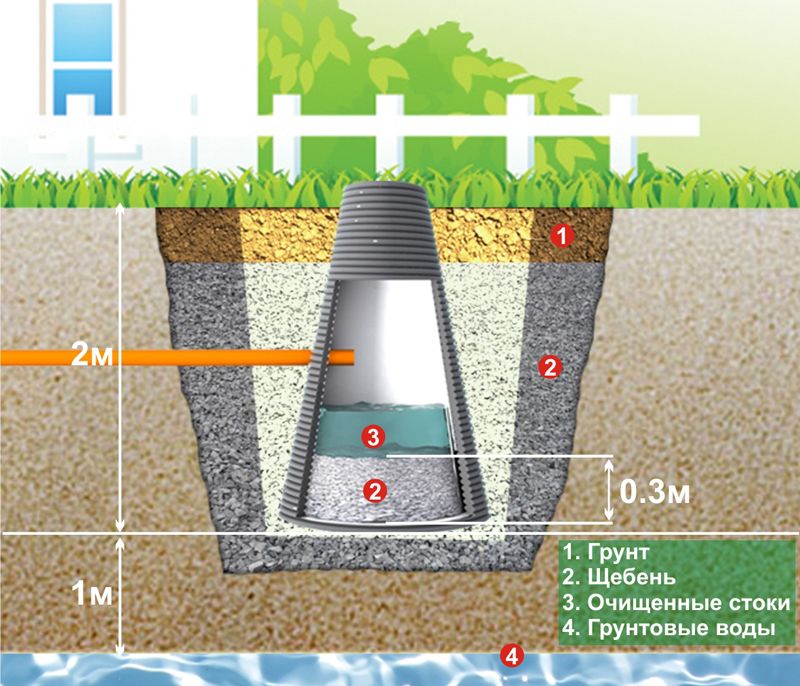

If it is required to install a drainage well of an absorption type, then the type of soil on the site must be taken into account. The water in this device must enter the receiver, be filtered, for which a layer of crushed stone is poured. Then it enters the underlying soil layers through special holes.

The water absorption capacity of the soil must be sufficient to allow the installation to cope with the volume of liquid that enters the well. This type of soil is considered coarse sand. If there is an aquiclude, then the water entering the well will not go into the soil and will overflow the reservoir of the drainage system. The collected water, as it is collected, should be pumped out using a drainage pump, and then discharged into a ditch outside the land or used for watering plants.

A hermetically sealed storage well can be used in places with high GWL, soil that does not have a high water absorption capacity.

Before constructing a drain, a hydrogeological test of the soil should always be carried out to determine its composition and water absorption capacity. Without the data obtained, it is not recommended to start equipping the drainage, since blind installation will not give a positive result.

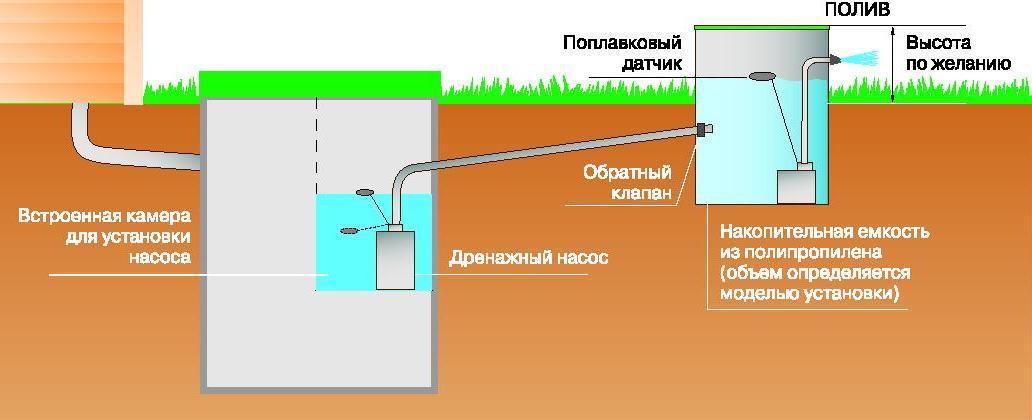

The device of the storage drainage well

Installation of a drainage well from concrete rings is extremely simple. You will need to dig 1-2 rings into the ground, making holes in them, through which pipes usually pass. From above, the structure should close the hatch. However, this type of structure is more difficult to install than others. In the collector tank there is an accumulation of water coming from the drain pipes.

To install a collector well on your land, you must perform the following types of work:

- dig a hole at least 2 m deep;

- lower concrete rings to the bottom of the pit;

- fill the bottom of the well with gravel;

- make holes for pipes.

The diameter of the prepared pit, in which it is planned to install concrete rings, must exceed the diameter of each of them.The first is located at the bottom of the pit, and subsequent rings are installed one on top of the other. Gravel should be poured into the gap behind the walls of the structure. Holes for pipes in concrete are made in top of the structure by diamond drilling. The following types of structures can be used to redirect water from a storage well with pumps:

- sewerage;

- septic tank;

- cesspool.

A drainage well made of concrete rings usually has 2 types of pumps:

- Surface. It is located above the level of the well, which allows only the hose to be lowered into the drainage system.

- Submersible. It is placed in a container, and only the pumping element is lowered into the main body.

Water from a storage drainage system can be put to good use. For example, for watering plantations, a hose or a system of automatic irrigation equipment is connected to the drainage pump.

Materials used to build a well shaft

When designing drainage systems, it is necessary to immediately determine the materials from which the well shaft will be built.

As a rule, in modern practice two options are used:

- Ready reinforced concrete rings;

- Finished plastic containers.

The advantage of the first option is the rather high strength of the structure and its durability. But the disadvantages include the complex installation of sewer wells of this type, since for their device you will have to hire a crane. Therefore, today more and more often choose the second option.

The advantages of this choice are many, these are:

- Light weight. This factor determines the ease of installation, in addition, the need to use special equipment is eliminated;

- Absolute tightness of containers and junctions with pipes;

- Durability.

As a rule, corrugated polymer shafts are used for the construction of wells. Another advantage of this design is the ability to change linear dimensions in height. This quality is very important in winter, since when the soil freezes and thaws, there is no deformation of the containers.

Thus, when designing a drainage system, it is worth giving preference to plastic containers for the construction of wells.

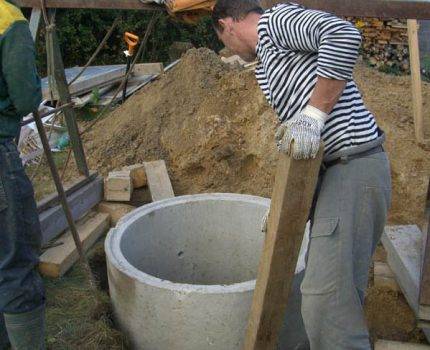

Construction of a well from concrete rings

For the well, it is necessary to purchase reinforced concrete rings, which are made from moisture-resistant concrete. The dimensions and diameter of the rings are selected based on the type and purpose of the well. But it must be borne in mind that the depth of their occurrence should be at least two meters.

Concrete rings are available in various sizes (height from 10 cm to 1 m and diameter from 70 cm to 2 m), so choosing a product is not difficult. For a well, rings are usually chosen with a height of 50-60 and a diameter of 70-150 cm. Their weight, depending on the size, ranges from 230-900 kg.

Concrete rings are lowered one by one into a pre-dug hole and stacked on top of each other.

Of course, such a weight is not impossible to lift alone, so you will have to invite one or two assistants. You can install the structure in two ways. If the diameter of the ring allows a person to fit inside, then you can simply put it on the ground, and then proceed to excavate the soil from the inside.

The ring will press its own weight on the ground and gradually sag as the soil is dug out from under it. Thus, it is possible to install all the rings, laying them on top of each other and fastening them together with metal brackets.

The second option is to first dig a pit, the width of which should be about 40 cm larger than the diameter of the rings. If the soil is soft, the bottom should be covered with gravel with a layer of 15-20 cm, and then the concrete rings should be lowered. With this method, if a revision or storage well is being made, it is advisable to install a lower ring with a blank bottom.

After installation concrete rings for place, it is necessary to carefully seal all the cracks with bitumen. In the ceiling, you can make a viewing window for visual inspection of the well

If there is no bottom, then you will need to make it yourself. To do this, the lower part of the well is poured with concrete mortar with reinforcement. When installing an absorption structure, the bottom of the tank is equipped with a filter system, as described above.

All joints between the rings are smeared with a cement-sand mixture, and then, after drying, sealed with bitumen-polymer waterproofing.

Further from the well, according to the developed scheme, a trench is dug for drainage pipes, but do not rush to lay them, because first you will have to do another rather laborious job - to make holes in the concrete to connect the pipes. This can be done with a puncher and victorious or diamond crowns for concrete. They have different diameters, so choosing the right size is easy, but their cost is quite high.

If there was no concrete crown on the farm, and you don’t want to spend money on buying it, you can resort to another cheaper method. In the place where the outlet is supposed to be made, attach the pipe and draw a circle of the required diameter with a pencil. Drill through holes along the contour of the drawn line.

Holes are drilled with a concrete drill in increments of 1-2 cm from each other, one is made in the center of the circle

Point the crowbar into the central hole and start to break it slowly, as the hole expands, take a large hammer or sledgehammer and bring the process to the end. Now you can bring pipes and putting on them protective rubber seals, insert into the hole made. Also coat the entry points with bitumen. Install the cover.

A concrete well is covered with rubble from all sides, on height about 50 cm, and then clay is poured to the very top and well compacted. Such a clay pad will prevent water seepage and extend the life of the well.

Varieties

The drainage well can be:

1. Rotary. Its feature is that it must be periodically cleaned with water pressure. They are usually mounted in places of convergence or turns of pipes. The dimensions of this design may be different.

2. Inspection. They are designed to inspect the drainage system, as well as to monitor the condition of the drainage system. Such wells are large and allow a person to climb inside.

3. Absorbent. Their feature is that the water is not removed into the reservoir and is not pumped out of the tank. It goes into the lower layers of the soil. That is, such a structure has no bottom.

4. Water inlets.They are installed if there is no reservoir near the site into which excess liquid could be dumped. Wells in this case are closed tanks. Water from them is pumped out from time to time and used for household needs.

As for the materials of manufacture, the drainage well, the price of which ranges from 5,000 rubles and more, can be equipped with reinforced concrete rings, metal, even plastic.

What are drainage wells for and what are they

A private house or cottage is often located in an area prone to waterlogging, their foundations can gradually collapse under the influence of groundwater. Also, the owners are often faced with the fact that there is no sewerage, which means there is nowhere to put the water from the septic tank. There is a likely threat of flooding of residential and non-residential buildings, especially such as a cellar, garage, bathhouse, garden and vegetable garden. In these cases, a drainage well is needed, and possibly an entire drainage system.

To collect excess water in an underground container, by gravity or pumping, with their constant or periodic removal - this is the meaning of a well for drainage. The system is installed once and will work during the entire period of operation of the house. But in the process of use, the drain well requires periodic cleaning. To do this, silt deposits are lifted from the bottom of a clogged well with a stream of water, followed by their pumping or draining.

The drainage well device can be of three types:

Inspection (inspection), drainage well for sewerage, located at the places of rotation and intersection of drainage pipes or every 40-50 meters drains, they are periodically cleaned, and if there is no drain, they are pumped out.To equip such wells, it is enough to use a pipe with a diameter of 34 cm or more.

Manhole at the intersection of drainage pipes

- Collector (water intake) - these are the end points for draining water, most often only surface water (storm, melting, stream), with their pumping into a sewer, a reservoir, or using it for household needs. They are distinguished by a rather large volume, often an impenetrable bottom, they usually have a built-in staircase. The placement of the pump and maintenance procedures impose restrictions on their diameter - at least 70 - 100 cm.

- Grouting (absorption, filtration), they are located in places that want to get rid of puddles, for example, after washing cars. Around them, it is planned to fill a large mass of rock, crushed stone, screenings, both for supplying water to the well, and for draining through its bottom into deep water horizons. In particular, the bottom of the grouting well is covered with a layer of crushed stone 30 cm thick. In this device, partial bacterial and mechanical treatment of wastewater occurs, with periodic washing or mechanical extraction of sediments of silt and sand.

This is how the filtration well scheme looks like

In cases of mixed type wells, their functions are superimposed, and the design of the drainage well is changed. So, a water intake well can discharge water into a grouting well. In this case, it does not need a sealed bottom and can do without a pump, but it does need periodic inspection and cleaning, like an inspection well.