- Samsung washing machine error codes displayed on the display

- Error codes

- OE: water does not drain from the tank

- Solutions to the problem

- PF error in LG washing machine - how to remove

- Reasons for the error

- Solutions to the problem

- Self repair

- AE or AOE

- Now let's figure out what you can do without calling the wizard from the service center.

- Pressure switch

- Number 3. Problems with the water supply system

- PF

- What to do if this problem occurs

- Home repair

- Breakdown of the heating element

- Problems with the control unit

- Thermal sensor (thermistor) malfunction

- Dry sensor problems

- Symptoms

- IE

- E1

- Water leak

- The reasons

- Depressurization of elements of the filling and drain system

- Leak adjustment sensor

Samsung washing machine error codes displayed on the display

| 5e | No water drain from machine tank | Clogged drain hose. |

| 5s | Blockage in the sewer system. | |

| e2 | 1) Clogging of internal hose communications. 2) Clogged filter on the drain pump. 3) Kink in the drain hose (no water flow). 4) Non-working drain pump. 5) Crystallization of water inside the machine (storage at negative temperatures). | |

| n1 n2 not not1 not2 | No water heating | Lack of food. Incorrect connection to the electrical network. |

| ns ns1 ns2 | The heating element does not heat the water for washing. | |

| e5 e6 | Faulty heating element for drying clothes. | |

| 4e 4c e1 | No water supply to the machine | 1) Shut-off valve is closed. 2) Lack of water in the water supply system. 3) Bent hose for filling water. 4) Clogged hose or mesh filter. 5) Aqua stop protection has been activated. |

| 4c2 | Water supply with temperature above 50°С | The supply hose is connected to the hot water system. |

| sud sd (5d) | Abundant foaming | 1) The volume of powder is over the norm. 2) Washing powder is not for automatic washing machine. 3) Counterfeit washing powder. |

| ue ub e4 | Drum rotation imbalance | 1) Twisting of laundry or the formation of a coma from it. 2) Not enough laundry. 3) Too much laundry. |

| le lc e9 | Spontaneous draining of water | 1) Drain line too low. 2) Incorrect connection to the sewer system. 3) Violation of the sealing of the tank. |

| 3e 3e1 3e2 3e3 3e4 | Drive motor failure | 1) Exceeding the load (overloading with linen). 2) Blocking by a third-party object. 3) Lack of power. 4) Breakdown of the drive motor. |

| 3s 3s1 3s2 3s3 3s4 | ||

| ea | ||

| uc 9c | Floating voltage in the power supply network | Permissible voltage parameters go beyond the parameters: 200 V and 250 V for more than 0.5 minutes. |

| de de1 de2 | No signal that the loading door is closed | 1) Loose closure. 2) The mechanism for fixing the door in a non-working state. |

| dc dc1 dc2 | ||

| ed | ||

| dc3 | No signal to close the Add Door | 1) Not closed before the start of the wash cycle. 2) Closing mechanism in non-working condition. |

| ddc | Incorrect opening | The door was opened without pressing the pause button. |

| le1 lc1 | Water at the bottom of the car | 1) Leak from drain filter. 2) Powder loading block leak. 3) Leakage from internal connections. 4) Leak from under the door. |

| te te1 te2 te3 | The temperature control sensor does not send a signal | 1) The sensor is out of order. 2) Absence contact in the mounting block. |

| tc tc1 tc2 tc3 tc4 | ||

| ec | ||

| 0e 0f 0c e3 | Water collected above the norm | 1) The water supply valve does not close. 2) Water does not drain. |

| 1e 1c e7 | There is no signal from the water level sensor | 1) The sensor is out of order. 2) Lack of contact in the mounting block. |

| ve ve1 ve2 ve3 sun2 ev | No signal from the buttons on the panel | Sticky or jammed buttons. |

| ae ac ac6 | No connection | No feedback between control boards. |

| ce ac ac6 | Drain water temperature 55°C or higher | The supply hose is connected to the hot water system. |

| 8e 8e1 8c 8c1 | No signal from vibration sensor | 1) The sensor is out of order. 2) Lack of contact in the mounting block. |

| her | No signal from dry sensor | 1) The sensor is out of order. 2) Lack of contact in the mounting block. |

| fe fc | Drying fan does not turn on | 1) The fan is out of order. 2) Lack of contact in the mounting block. |

| sdc | Automatic dispenser broken | Breaking |

| 6s | Broken automatic dispenser drive | Breaking |

| hot | The temperature exceeds the threshold of 70°C | Disable the "start" button without disconnecting from the network |

| pof | Lack of power during washing | |

| sun | Short circuit (short circuit) in the control circuit | 1) The triac is out of order, which is responsible for: turning on and off the electric motor; regulation of its speed. 2) Contact closure on the connector due to water ingress. |

The names of the faults are identical to the machines equipped with displays, except that some functions are missing in budget machines. The first two vertical rows indicate the presence of a malfunction, and the combination of the lights of the third row forms an error code.

| Combination of signaling devices | |||

| Error codes | 1 vertical row | 2 vertical row | 3 vertical row |

| 4e 4c e1 | ¤ | ¤ | 1 2 3 4 – ¤ |

| 5e 5c e2 | ¤ | ¤ | 1 – ¤ 2 – ¤ 3 4 – ¤ |

| 0e 0 f oc e3 | ¤ | ¤ | 1 – ¤ 2 – ¤ 3 4 |

| ue ub e 4 | ¤ | ¤ | 1 – ¤ 2 3 – ¤ 4 – ¤ |

| not ns e5 e6 | ¤ | ¤ | 1 – ¤ 2 3 4 – ¤ |

| de dc ed | ¤ | ¤ | 1 2 3 4 |

| 1e 1c e7 | ¤ | ¤ | 1 – ¤ 2 3 4 |

| 4c2 | ¤ | ¤ | 1 2 – ¤ 3 – ¤ 4 – ¤ |

| le lc e 9 | ¤ | ¤ | 1 2 – ¤ 3 – ¤ 4 |

| ve | ¤ | ¤ | 1 2 – ¤ 3 4 |

| te tc ec | ¤ | ¤ | 1 2 3 – ¤ 4 – ¤ |

Conventions

¤ - lights up.

Error codes

Most modern models of automatic washing machines are equipped with a self-diagnosis system. This means that the user does not have to independently identify the problem, the device can easily determine at what stage of operation a failure occurred, and provide the information received in the form of a combination of a letter and a number on the display.

If the booklet for the washing machine is lost, you can use the tables below with data on the most popular appliances.

Error codes for washing machines Indesit, Ariston:

| The code | Decryption |

| F01 | A short circuit has occurred in the control system, as a result of which the motor will not start. |

| F02 | A failure occurred in one of the sections of the electrical circuit of the control system. |

| F03 | The start signal is not sent to the heating element. |

| F04 | Error in the operation of the water level sensor. |

| F05 | Damage to the drain pump. |

| F06 | The signal from the control panel buttons does not pass. |

| F07 | Breakage of the heating element (heater). |

| F08 | An error in the operation of the heating element caused by a breakdown in the water level switch. |

| F09 | Malfunction of the central control system. |

| F10 | The water level sensor does not send a signal to the control system. |

| F11 | The drain pump does not receive a signal to start work. |

| F12 | Error on the interaction circuit of the central control system and the selector. |

| F13 | Dryer control system malfunction. |

| F14 | No signal to start drying operation. |

| F15 | No signal to end drying operation. |

| F17 | The door does not lock. |

| F18 | CPU failure. |

Bosch washing machine error codes:

| The code | Decryption |

| F01 | The door does not lock. |

| F02 | The drum does not fill with water. |

| F03 | Drain fault. |

| F04 | Leak in the tank. |

| F16 | The door is good, but not closed properly. |

| F17 | Water enters the drum too slowly. |

| F18 | The drain pump runs slowly. |

| F19 | The water is not heated, but the wash will continue. |

| F20 | Uncontrolled activation of the heating element. |

| F21 | An error in the operation of the electric motor. |

| F22 | The heating sensor is defective. |

| F23 | Leak recovery mode enabled. |

| F25 | Water hardness is not determined. |

| F26 | Pressure sensor error, washing is not possible. |

| F27 | The settings of the pressure sensor have gone astray, the operation occurs according to random parameters. |

| F28 | The pressure sensor does not respond to the control system. |

| F29 | Stream error. |

| F31 | The volume of water entered the tank exceeds the nominal one. |

| F34 | Door lock defective. |

| F36 | An error in the operation of the blocker at the level of the control system. |

| F37 F38 | Heat sensor failure. |

| F40 | Control system settings have been changed. |

| F42 | The engine is working hard. |

| F43 | Drum does not rotate. |

| F44 | The motor does not rotate in one direction. |

| F59 | There is a problem with the 3D sensor. |

| F60 | The water supply pressure is too high. |

| F61 | The door does not respond when polled by the control system. |

| F63 | Malfunctions in the protection system. |

| F67 | Invalid card code. |

| E02 | Engine breakdown. |

| E67 | Failure of the main module. |

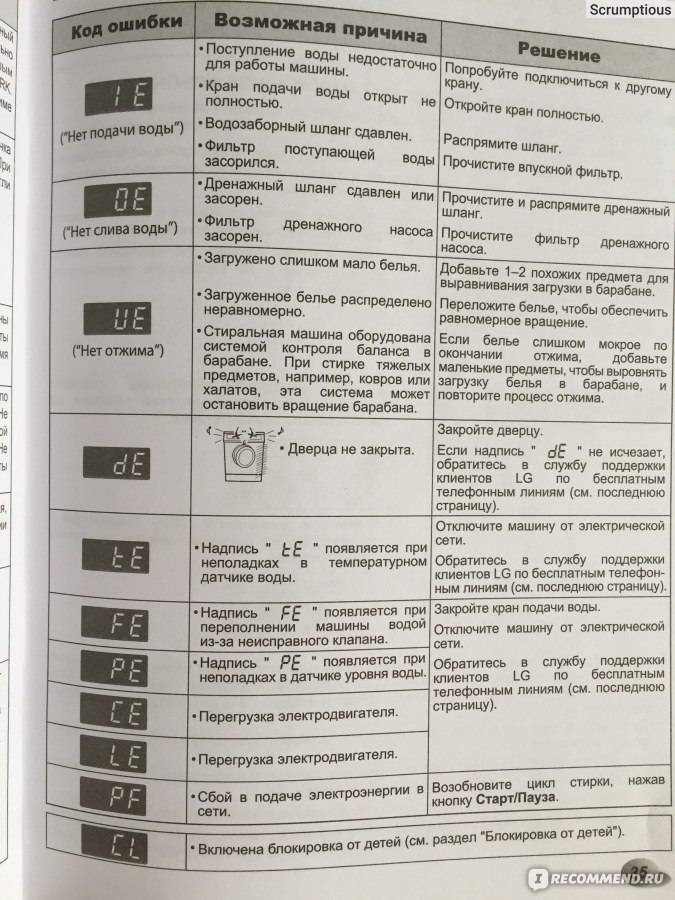

LG washing machine error codes:

| The code | Decryption |

| PE | Error in determining the water level. |

| F.E. | The volume of water entered the tank is higher than normal. |

| dE | The door is not closed. |

| IE | Water collection does not occur. |

| OE | Drainage system failure. |

| UE | Drum failure. |

| tE | Temperature violation. |

| LE | Blocker problem. |

| CE | Motor overloaded. |

| E3 | Load detection error. |

| AE | Faulty auto power off. |

| E1 | Tank leak. |

| HE | Heating element failure. |

| SE | Drive motor switching error. |

Samsung washing machine error codes:

| The code | Decryption |

| E1 | Error in the water supply system. |

| E2 | Error in the drain system. |

| E3 | Loaded volume of water exceeding the nominal. |

| DE | Broken door lock. |

| E4 | The allowable amount of laundry has been exceeded. |

| E5 E6 | Problems in the process of heating water. |

| E7 | Water level detection problems. |

| E8 | Water temperature mismatch with the selected washing mode. |

| E9 | Tank leak. |

If the washing machine gives an error, you do not need to immediately panic and choose a new appliance, many problems can be fixed on your own, for example, a door malfunction or a drain problem caused by a clogged filter. If everything is done correctly, the error code will disappear from the display and the machine will work as usual.

OE: water does not drain from the tank

The machine gives an error if the water does not drain from the tank 5 minutes after the wash is completed.

Experts point out the reasons:

- drain pump filter clogged with debris;

- the hose is kinked or burst;

- defective pressure sensor in the hose;

- the air chamber is out of order;

- failure of the water level sensor.

Examine the drain pump. Check the condition of the water drain hose connection.

Elimination:

- To get rid of debris in the filter, remove the accumulated debris from it.

- Check the hose. If it is bent over, straighten it and the water will begin to drain. If a tube is leaking, patch it with a patch or replace the hose.

- If a sensor malfunction is found, replace it yourself or with the help of a wizard.

Solutions to the problem

Before disassembling the LG washer, try simpler methods for resetting the PF error. What does it mean:

- When there is a temporary power outage, you only need to press the On/Off button. This is enough to run the program.

- Check the power cord and CM LG plug. Perhaps the insulation was broken, the wire was damaged. Then you can either localize the damaged area, or change the cord and plug.

- If the washer is connected through an adapter, this can also cause the code to appear. Remember, the LG washing machine (Lji) should only be connected to a separate power line with a machine.

- Check mains voltage. Maybe it's not enough to power the machine. Then you should call an electrician.

- Possibly broken wiring between noise filter and electronic controller. Inspect this area, replace damaged wires.

Please note that a short circuit can render the equipment unusable, moreover, it can cause a fire. Therefore, do not let things go by themselves.

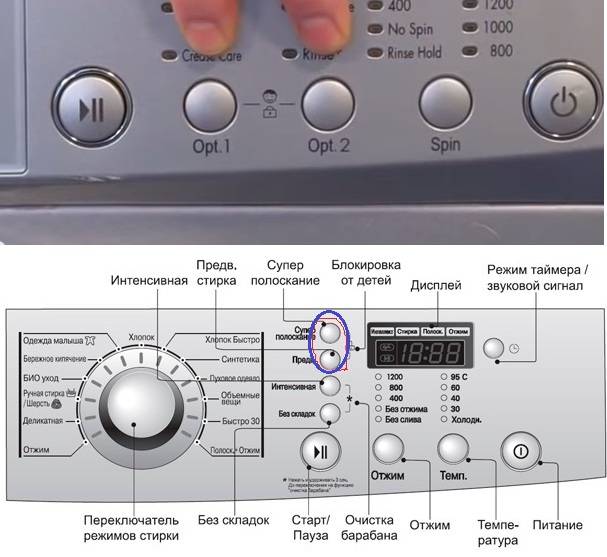

PF error in LG washing machine - how to remove

The self-diagnosis system of the washing machine is able to detect a malfunction and display its code on the scoreboard. If your LG washing machine stops while washing, and then the display shows the error code PF, this is a signal of unstable mains voltage.

Moreover, an error can appear in any washing mode. What the user should do in these cases, read below.

Reasons for the error

To figure out how to fix the problem, you need to find out the causes of the fault code.

- A one-time power outage can cause a PF error.

- Sudden voltage drops when it drops by 10% and rises by 5%.

- Turning on a powerful device (tool, device) that causes a power surge on the line.

Let's figure out how you can fix the problem yourself.

Solutions to the problem

Before disassembling the LG washer, try simpler methods for resetting the PF error. What does it mean:

- When there is a temporary power outage, you only need to press the On/Off button. This is enough to run the program.

- Check the power cord and CM LG plug. Perhaps the insulation was broken, the wire was damaged. Then you can either localize the damaged area, or change the cord and plug.

- If the washer is connected through an adapter, this can also cause the code to appear. Remember, the LG washing machine (Lji) should only be connected to a separate power line with a machine.

- Check mains voltage. Maybe it's not enough to power the machine. Then you should call an electrician.

- Possibly broken wiring between noise filter and electronic controller. Inspect this area, replace damaged wires.

Please note that a short circuit can render the equipment unusable, moreover, it can cause a fire. Therefore, do not let things go by themselves.

Self repair

Another, more serious reason for the appearance of the PF code is the breakdown of parts inside the LG machine. Since this damage is not easy to fix, you need to be careful.

Failure of the control unit is characterized by stopping the program in the "Washing", "Rinse", "Spin" modes and issuing a PF error.You can install a new module yourself, but not everyone can solder the contacts and clean the elements. It might be better to call a specialist.

If you yourself want to solve the problem of replacing the module with LG SM, then:

- After disconnecting from the mains, unscrew the bolts of the top panel at the back.

- Remove the panel, release the water supply hoses from the clamps.

- Unscrew the partition and remove it along with the hoses.

- Remove the pressure switch along with the hose.

- Remove the clips securing the control box.

- Remove the screws and take out the module.

- Release the clips and lift the cover.

- You can take a picture of the position of the connectors so that you can connect them correctly later.

- Swap the connectors to the new block.

- Fasten the cover and install in reverse order.

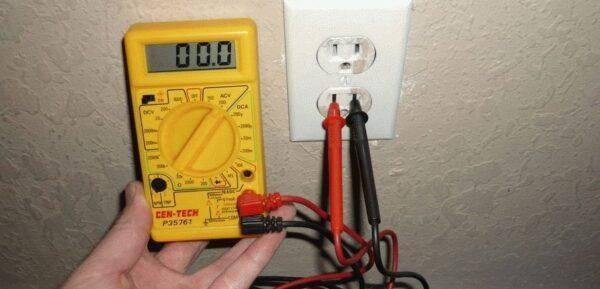

As already mentioned above, the breakdown may lie in the wiring between the FPS (noise filter) and the module. In this case, the CMA LG freezes, and the PF error burns on any program. Let's tell you more about how to check it:

- Be sure to de-energize the washer by pulling the plug out of the socket.

- Unscrew the bolts of the CM LG top panel, put it aside.

- The filter is located at the end of the power cord under the rear wall, as shown in the photo:

- Check all connections.

- Wiring performance can be checked with a multimeter.

The last thing to check is the heating element (electric heater). What may indicate problems with the heating element:

- Knocks out automatic transmission.

- Fault code PF is on.

This means a malfunction of the heating element. As a result of the short circuit of the heating element on the body of the washer, the switch in the switchboard is knocked out.

- Remove the rear panel of the CMA.

- The heating element is located below on the left side, as in the photo:

- Disconnect heater and temperature sensor connections.

- Loosen the nut on the central screw and disconnect the ground terminal.

- By pressing, push the bolt inward and pull out the heating element.

- Install the new part in reverse order.

We hope the recommendations helped you remove the error and return the machine to working capacity. Additionally, we recommend watching a video on repairing the control module:

Did the article help you?

Not really

AE or AOE

Auto shutdown error.

The reasons for such an error may be a violation of the tightness of the chamber and the ingress of water into the case. In vending machines equipped with the Aquastop system, the special tray must be checked. Due to the accumulation of water, a float sensor could work and signal a leak.

To eliminate the cause of the leak, you need to inspect and fix all the clamps and connections that may have appeared when the machine was displaced or rearranged.

In the event of a power failure, first try disconnecting the machine from the power supply, wait 15-20 minutes and start it again. During this time, the operation of the machine can be restored to normal.

If the problem persists, we advise you to call the wizard, you need to check the entire electronic system.

Now let's figure out what you can do without calling the wizard from the service center.

- In case the problem is in the pressure of the water from the water supply, you can try to open the inlet tap more or less, thereby adjusting the pressure.

- If the program fails, unplug the washing machine immediately from the socket, wait 10 - 15 minutes and plug it back into the mains.

- The pressure switch may not work due to a simple blockage in the tube. In this case, it will be enough for you to blow it.

- You can correct the connections of the wire loops connecting the water level sensor.If suddenly you see that the wires are broken for some reason, you can connect them with a twist.

ATTENTION! The washing machine must be disconnected from the mains! Do not forget to isolate the connection with heat shrink!

And, of course, you should check the correct installation of the washing machine, or rather, the location of the drain.

In case of any difficulties in fixing the PE error yourself, you can always contact the wizard.

Thus, we systematize the signs and causes occurrence and ways to eliminate PE errors in the table.

| Signs of error | Possible reason | Solutions | Price (work and start) |

| LG washing machine gives a PE error. Washing does not start. | Insufficient or excessive water pressure. | Adjust the water pressure in the plumbing. | from 1800 to 3800 rubles. |

| Program crash. | Turn off the power for 10 - 15 minutes. | ||

| Pressostat malfunction. | Blow out the pressure switch tube or replace the pressure switch. | ||

| Incorrect drain setting. | Install drain according to instructions to the washing machine. | ||

| The PE error appears immediately after starting or during the execution of the program. | Faulty control module, or microcircuit (failure, reflow) | Repair of elements in the control module. Replacing the control unit chip. | Repair: from 2900 to 3900 rubles. Replacement: |

| PE error appears and disappears | Damaged wiring inside the washing machine | Twisting wires. Replacing loops. | from 1400 to 3000 rubles. |

If it is impossible to fix the PE error on your own and you need professional repair, just call the master

Specialists will definitely contact you to save your “assistant” LG: they will arrive at the appointed time, find out the cause of the malfunction and, if necessary, offer and provide repair services.

Repair of washing machines is open daily from 8:00 to 24:00.

TOP stores of washing machines and household appliances:

- /- household appliances store, a large catalog of washing machines

- — profitable modern online store of home appliances

- — a modern online store of home appliances and electronics, cheaper than offline stores!

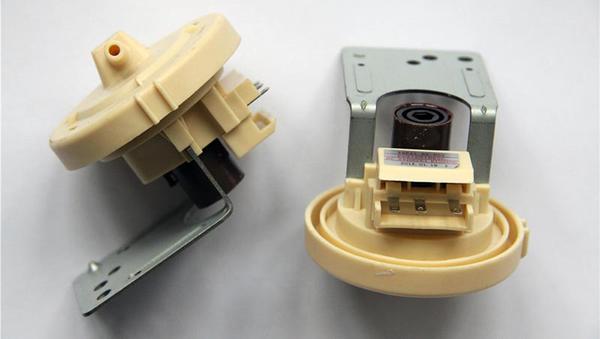

Pressure switch

What to do if the measures taken earlier did not help? Probably the water level sensor is not working properly. To make sure that the pressure switch relay is working, it is necessary to disconnect the water intake hose. You can access the sensor as follows:

What to do if the measures taken earlier did not help? Probably the water level sensor is not working properly. To make sure that the pressure switch relay is working, it is necessary to disconnect the water intake hose. You can access the sensor as follows:

- unplug the washing machine;

- remove the top cover of the unit housing (to do this, unscrew the two bolts holding it).

The pressure switch on LG models is located on one of the walls of the washer, very close to the top. Having found the water level sensor, disconnect the inlet hose from it, which is fixed with a clamp. Connect a special tube of suitable diameter to the vacated place, which should be prepared in advance. Lightly blow into it. If the contacts of the pressure switch are working, you will hear a clear click. The number of clicks directly depends on the model of the machine, how many levels of water intake are provided in the system to perform various modes.

It is also necessary to examine all hoses and tubes for integrity. If defects are found, the pipes will have to be replaced. It is good to inspect the contacts of the pressure switch relay, if they are dirty, be sure to clean the connectors. If the contacts stick, you will have to completely replace the pressure switch.

At the end of the work, connect the inlet hose in place, fix it with a clamp. Then replace the housing cover and check the machine. After all the measures taken, it will definitely be possible to fix the OE error. To prevent such a problem, it is necessary to periodically clean the garbage filter, inspect the clothes well before loading them into the drum for foreign objects in the pockets.

Share your opinion - leave a comment

Number 3. Problems with the water supply system

How to decipher errors 4E, 4C or E1? If during washing or rinsing the machine stops running the program, and the indicated flashing combinations appear on the display, this is a message that water has stopped flowing into the laundry drum. On models without a screen, in this case, the indicator lights for washing modes and minimum temperature light up.

There can be several reasons for the error:

- The inlet hose, through which water enters the machine, is blocked by something.

- The filter located at the outlet of the same hose has become clogged.

- The user simply forgot to open the tap valve that supplies water.

- The pressure is too low.

- There is no cold water in the system.

To accurately determine the cause, you should restart the program and listen for the sound of pouring water.

The filter through which water passes prevents organic and mineral contaminants from entering the tank of the machine. Even small particles lingering on its mesh can prevent the washer from functioning normally. Further actions completely depend on the presence or absence of sound:

- If it is heard, but the machine stops and continues to indicate an error, the drum may be overloaded or things are being washed that absorb almost all the water from the tank.

- When you can clearly hear that water is coming in, the weight of the laundry complies with the norms specified in the instructions and the fabric does not absorb water much, but the flashing display still indicates an error, you need to check the water pressure. He is most likely weak.

If there is no sound of pouring water with the supply tap open and normal pressure in the system, do the following: clean the filter, restart the control unit by turning it off from the outlet for 15 minutes, then plug the machine into the outlet and restart the same washing mode.

The filter of the water intake system in the machine needs to be cleaned periodically. An unscheduled check and cleaning is carried out in the absence of water in the tank when the work is activated, the tap is open and the pressure in the water supply is normal.

PF

The error indicates a power problem. When the main module does not have enough power, or, conversely, there is too much of it, then PF lights up on the panel. Most often, power surges or a banal lack of light are to blame. In such cases, restarting the equipment helps.

The main board of the washing machine is a rather finicky device, so if there are frequent power outages, it makes sense to install a voltage stabilizer. Otherwise, there is a risk of burning the electronics of the equipment, the repair of which will result in serious financial expenses.

When the problem occurs intermittently despite a stable power supply, the entire circuit must be checked.

Particular attention should be focused on the plug with a socket. It's possible that the wires are shorted.

As a rule, such a process is accompanied by a barely perceptible smell of burning.

We de-energize the house / apartment and call the outlet. If necessary, replace damaged wires with new ones. We also check the plug together with the contact group with a multimeter.The cable of washing machines is thick, so it is quite difficult to detect a broken wire by touch.

It is also necessary to check the contact group of the plug, which is located inside the washing machine: ring, correct or replace the terminals.

What to do if this problem occurs

Errors that are fixed by the washing machine can be divided into three main types:

- In rare cases, it may happen that the error simply stops appearing over time. In this case, it turns out that she passed by herself.

- In this situation, the user makes certain efforts, after which the machine becomes operational.

- This category belongs to the most difficult cases. We have to invite a specialist. He will decide how to fix the breakdown, make repairs and fix the car, but the cost of repairs will be quite high.

Therefore, a reasonable course of action would be such that first the user will do everything he can, and if it does not work, he will turn to the wizard.

If the display shows DE, it is necessary to check the possible presence of small objects preventing the closing. It can be detached parts of clothing or buttons. It is also possible that small items, such as coins, were left in the pockets of clothes intended for washing.

With almost any error codes, there is a small chance that we are talking about a system failure.

To check this version, when it issues DE, you need to disconnect the washing machine from the mains and wait a while. Before turning off, close the hatch tightly. Usually the wait is 10 to 20 minutes.

After that, the machine is turned on again. The hatch must be tightly closed.

If the failure diagnostic message no longer appears, it can be assumed that this was an accidental failure.

It is advisable to repeat this procedure several times with a break of 10-15 minutes.

If the attempt fails, it is necessary to perform the diagnostic procedure for the situation when an error code DE is issued, developed by LG specialists:

- You need to see how much the parts have worn out. To do this, you need to examine both the hatch closing mechanism and the hinges to which it is attached.

- In some cases, the wear of the hinges leads to the skew of the hatch. To correct the situation, it will be enough to tighten them.

- One of the common causes of an error when DE is on is a broken handle that closes the hatch.

- The test begins with an inspection of the hatch cover and determining the health of the locking hook. In order to make sure that it works, you need to move your finger a lot. The hook is usually made of plastic or an alloy called silumin. If it is broken, it cannot be repaired. To replace it, you will have to buy a complete locking mechanism.

- If no fault is found, check the counterpart of the locking mechanism. It needs to be disconnected from the car. In order to do this, you need to unscrew the two screws that hold this part.

- Now we pull out the blocking device, while making sure that the sensor is still connected to the control controller. Now turn on the washing machine. On the narrow part of this device, you can easily see the contact. It needs to be closed.

- See if the diagnostic system gives this error. If this is not the case, we check whether it is possible in this situation to set the washing mode.If possible, it should be concluded that the sunroof blocking device is faulty and needs to be repaired or replaced.

If this procedure has shown that the lock is working properly, you need to continue the diagnostic procedure. This suggests that the cause of the failure is in faulty electronics. To check this, we do the following:

- First you need to remove the plastic cover. To do this, pry off the plastic clips that hold it with a screwdriver.

- Now you need to disconnect the electronic unit. To do this, unscrew the screws that hold it.

- The block consists of two parts. One of them, which is larger, includes an information display. The other, smaller one, controls the start and shutdown of the machine. We need a second board.

- We simply disconnect the large board and put it aside.

- Now we have to carefully examine the remaining board. In this case, you need to look for possible mechanical or other damage on it.

- If the board looks serviceable and there are no damages, then now it remains to contact the specialists.

One of the characteristic signs of damage to the control board is the smell of burning.

It is also possible to damage the wires connecting the sensor to the control board.

Home repair

Solving the problem yourself is not always possible, but worth a try.

Breakdown of the heating element

What are the symptoms that indicate a heater problem?

- The machine washes in cold water, stops in the middle of the program.

- The display shows the code tE.

In this case, 80% of breakdowns fall on the tubular electric heater (TEN), it is he who is responsible for heating the water. Only the installation of a new, serviceable element will help.

Problems with the control unit

The washing machine worked as usual, but after the start of work it stopped and gave an error tE. Since the module is responsible for all processes in the SMA, if it breaks down, the parts do not receive a signal to act and work. Therefore, you need to get the control unit, inspect the board for damage.

If you are sure that you can repair the board, proceed. If the module is defective, the element must be replaced.

Thermal sensor (thermistor) malfunction

The temperature sensor is responsible for measuring the water temperature. Therefore, if it malfunctions, the water in the LG machine does not heat up, the system slows down washing and gives an error tE.

How to make a replacement:

- Disconnect the SM from the network.

- Remove the back panel of the machine.

- Loosen the screws and remove the bracket.

- The temperature sensor is located inside the heating element heater.

- Disconnect all connectors, then, pressing the latch, pull out the temperature sensor connector.

- Loosen the central nut in the heater and pull out the thermistor.

- Installation of a new element is carried out in the reverse order.

Dry sensor problems

The dryer sensor monitors the temperature while the clothes are drying. Therefore, an error code can be displayed both at the washing stage and during drying (if this program is provided in the washing machine). In this case, the work of the SM is interrupted.

What can be done:

- Disconnect the LG washer, remove the top cover and the bracket under it.

- Disconnect the door cuff and connectors on the heating chamber.

- After unscrewing the bolts, open the heating chamber.

- You will immediately see the sensor. Remove it and install a new part.

Watching the video will help in replacing:

Symptoms

Check the serviceability of your equipment, turn on the test mode. If the ue sign does not appear, then the machine is in good condition.

- every time the spin is started, the error ue.The programmer (control module) may have failed;

- the error code appears already at the stage of washing, rinsing and spinning. If the machine is direct drive, then the drum starts to twitch. Most likely, the malfunction touched the sensor that regulates the speed of rotation of the drum. It will have to be replaced;

- rotation when the spin mode is on does not pick up speed, and then stops altogether, an error sign appears on the display. An imbalance can be caused by a stretched or delaminated drive belt. In this case, professional intervention will also be required;

- washing appliances with a long period of use often show a spin error and rumble at the same time. There are black oil blots under the car. Most likely the bearing has worn out.

The latest lg machines of the latest generation are equipped with a direct drive, eliminating the belt drive. This allows you to differentiate the rotation speed in six or more modes. The algorithm of work directly depends on the characteristics of the fabric, the size of the processed clothes and linen. This new model is unlikely to confuse the consumer with sudden failure rates when spinning, operating in the "blanket", "mixed fabrics" and so on.

IE

If the washing machine stops working and the IE code appears on the display, this indicates that there is no water supply. There may be several reasons:

- Small water pressure.

- Fill valve not working.

- The sensor that determines the amount of water in the tank is out of order.

Inspect the inlet hose, it must not be kinked or compressed. The valve that shuts off the water must be fully open, and the filter at the inlet must be clean, if necessary, it must be cleaned and rinsed.

Switch off for 20 minutes and start the machine again.If you cannot fix the damage yourself, call a specialist.

E1

Failure E1 appears in the event of a malfunction in the fluid filling system. The presence of a malfunction does not allow washing.

Water leak

The average duration of a set of water in the tank is 4-5 minutes. If during this period the water does not reach the required level, there is a high probability of leakage.

The reasons

The causes of failure often lie in the breakdown of internal mechanisms. Basically, the error is related to the drain system and the leak sensor.

Depressurization of elements of the filling and drain system

Depressurization occurs due to damage to the elements. In this case, it is necessary to replace or restore integrity.

Leak adjustment sensor

Lack of control over leakage leads to disruption of the operation of the drain and water inlet. A broken sensor must be repaired or replaced.