- How to choose a quality polypropylene pipe

- Effect of errors on welding quality

- What soldering iron to use

- Soldering mode and its influence on the process

- Temperature exposure, its features

- Finally

- We solder polypropylene pipes correctly

- Used equipment

- Basic rules for soldering polypropylene pipes

- The connection point must be dry and free from dirt.

- Do not overheat connections

- The nozzle of the soldering iron must be securely fixed

- After connecting the elements, do not rotate or move them more than 5 degrees

- The movement of the workpiece in the cue ball must be rectilinear

- Neglect of preliminary preparation of the material

- Distribution of polypropylene pipes

- We consider fittings

- Laying methods

- The nuances of soldering

- Common questions and answers for soldering polypropylene

- Errors when soldering polypropylene pipes

- Tips for working with a soldering iron

- Problems that can be encountered during welding work

- General recommendations on how to fix a leak in a polypropylene pipe

- Error related to incorrect positioning

How to choose a quality polypropylene pipe

In order to choose high-quality polypropylene pipes, you should know and consider the following points:

- The dye used in the manufacture of polypropylene pipes also has a fairly high density (1.15 - 2.7). Its content in the pipe is usually from 0.05% to 2%. The content in the fitting is from 0.05 to 3%. Some manufacturers use a very concentrated dye to reduce the percentage in the pipe. The remaining volume is replaced with chalk or talc. As a result of such actions, the quality of polypropylene products decreases. Unfortunately, this is difficult to determine.

- When choosing a polypropylene pipe, you should be guided by GOST 32415-2013. To purchase the highest quality product, it is worth measuring it with a caliper. In the event that the results obtained do not fit into GOST, it is better not to take the product. In addition, do not take oval or sagging pipes.

In addition to the above nuances, there are moments associated with the manufacturer, or with the content of additional substances:

The quality of imported polypropylene products is higher than domestic ones, but at the same time, the price is about 20% higher. Borealis polypropylene pipes are considered the standard of quality.

In the case of choosing pipes up to 60 mm, you should pay attention to Sibur and Lukoil products.

When choosing polypropylene pipes containing glass, you should know that its optimal content in polypropylene is from 17 to 22%. In the event that the limits of this indicator are not met, either a linear expansion of the pipe may occur, or its fragility will increase.

To determine the glass content, it is necessary to multiply its density (2.5 - 2.6) by the volume of the pipe. Then multiply the density of polypropylene (0.9) by the same volume. The difference will show the content of the glass.

When choosing polypropylene pipes with aluminum (foil), it is worth checking the following points. Try to stick a clerical knife between a layer of polypropylene and aluminum. In the event that the knife goes at least 1 mm, you should not take the pipe. A high-quality pipe is made using perforated foil to improve the adhesion of the layers.

In order to choose a quality product without the use of secondary raw materials, it is worth knowing the price of polypropylene on the exchange, adding overheads and profits. As a result, a quality product will cost more than 140 - 160 rubles / kg.

Effect of errors on welding quality

Slow, carefully thought-out actions are a guarantee against mistakes that can nullify all the work. All the details of soldering technology should be taken into account and not deviate from them even a step.

Common mistakes, as a result of which defective nodes of the installed propylene water supply network appear:

- The pipe surface has not been cleaned of grease.

- The cutting angle of the mating parts is different from 90º.

- Loose fit of the end of the pipe inside the fitting.

- Insufficient or excessive heating of the parts to be soldered.

- Incomplete removal of the reinforced layer from the pipe.

- Correction of the position of parts after setting of the polymer.

Sometimes on high quality materials, excessive heating does not give visible external defects. However, internal deformation is noted when the molten polypropylene closes the internal passage of the pipe. In the future, such a node loses its efficiency - it quickly becomes clogged and blocks the flow of water.

An example of a soldering defect resulting from erroneous actions. The master overheated the plastic pipe, which, in turn, was deformed from the inside

If the cut angle of the end parts differs from 90º, at the moment of joining the parts, the ends of the pipes lie in a beveled plane. Misalignment of parts is formed, which becomes noticeable when a line several meters long has already been mounted.

Often, for this reason, you have to redo the entire assembly again. Especially when laying pipes in strobes.

Poor degreasing of the articulating surfaces contributes to the formation of "rejection islands". At such points, polyfusion welding does not occur at all or occurs partially.

For some time, pipes with a similar defect work, but at any moment a rush can form. Also common are errors associated with a loose fit of the pipe inside the fitting.

A common mistake when soldering polypropylene pipes is the loose entry of the end of the pipe into the socket. The pipe must enter to the border of the rim or marking line

A similar result is shown by joints made with incomplete cleaning of the reinforcing layer. As a rule, a pipe with reinforcement is placed on high pressure lines. Residual aluminum foil creates a non-contact zone in the soldering area. This is where leaks often occur.

The grossest mistake is an attempt to correct soldered elements with scrolling around the axis relative to each other. Such actions sharply reduce the effect of polyfusion welding.

However, at some points, a spike is formed, and the so-called "tack" is obtained. With little effort to break the "tack" holds the connection. However, one has only to put the connection under pressure, the soldering will immediately fall apart.

What soldering iron to use

For amateur soldering with your own hands, a simple, inexpensive soldering iron with a power of 800 watts or more will do.But it’s better not to buy the cheapest one, there will most likely be too many shortcomings, and it will probably quickly burn out, fall apart, for example, the handle will break off!

Soldering mode and its influence on the process

The technology of soldering polypropylene pipes consists in heating them, after which the plastic included in their composition softens. When connecting two heated products, diffusion (interpenetration) of polypropylene molecules of one technical product into the molecules of another occurs. As a result, a strong molecular bond is formed, making the resulting material hermetic and durable.

If insufficient mode is observed, then sufficient diffusion will not occur when the two materials are combined. As a result, the joint of the technical product will turn out to be weak, which will lead to a violation of the tightness of the entire material.

The output is a pipeline with a minimum internal hole at the junction, the diameter of which does not meet technological standards.

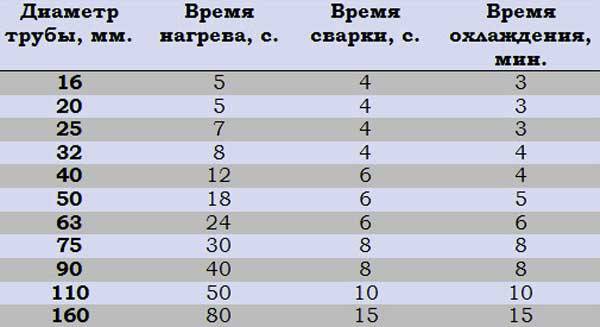

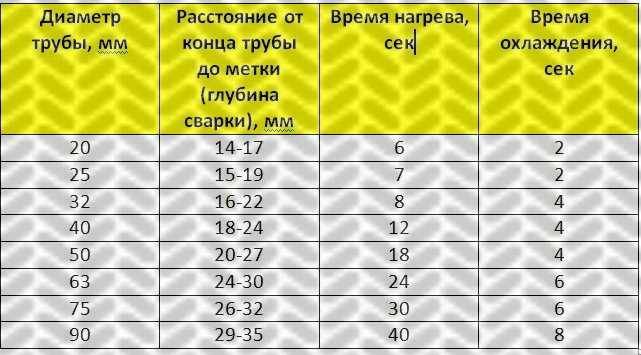

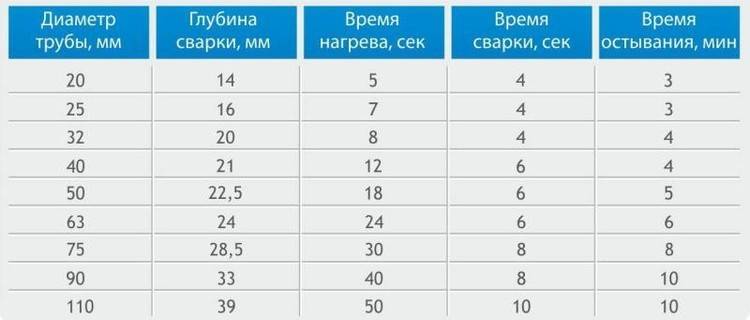

It is necessary to take into account not only the heating temperature when welding polypropylene pipes, but also the time, the temperature regime of the medium and the diameter of technical products. The heating time of pipe materials is directly dependent on their diameter.

The external environment matters. The minimum allowable temperature indicator for welding polypropylene products is -10 C. Its maximum allowable indicator is +90 C. The temperature table for welding polypropylene pipes clearly shows that everything basically depends on time.

The environment has a strong influence on the soldering quality. This is due to the fact that time passes from the moment the materials are removed from the welding apparatus to their direct connection. Such a pause greatly affects the quality of the weld.With a small external temperature regime in the workshop, it is recommended to increase the heating time of the joined products by a few seconds. The external soldering temperature of polypropylene pipes 20 mm must be above 0 C

It is important not to overheat them. There is a risk of polymer flowing into the inner hole of the tubular material and reducing its internal lumen

This will greatly affect the throughput of the future section of the pipeline.

Removing the pipe from the soldering machine

Temperature exposure, its features

Before answering what temperature is needed for welding polypropylene pipes, you need to decide on the welding machine used. A soldering iron is used to solder materials made on the basis of polypropylene. The question arises: what temperature soldering iron for soldering polypropylene pipes should be installed? The optimal value is 260 C. It is permissible to carry out welding work in the range of 255 -280 C. If you overheat the soldering iron over 271 C, reducing the heating time, the upper layer of the products will warm up more than the inner one. The welding film will be excessively thin.

There is a table of soldering temperatures for polypropylene pipes.

| Pipe diameter, mm | Welding time, s | Heating time, s | Cooling time, s | Temperature range, C |

| 20 | 4 | 6 | 120 | 259-280 |

| 25 | 4 | 7 | 180 | 259-280 |

| 32 | 4 | 8 | 240 | 259-280 |

| 40 | 5 | 12 | 240 | 259-280 |

| 50 | 5 | 18 | 300 | 259-280 |

| 63 | 6 | 24 | 360 | from 259 to 280 |

| 75 | 6 | 30 | 390 | from 259 to 280 |

The welding temperature of 20 mm polypropylene pipes ranges from 259 to 280 C, as well as the welding temperature of 25 mm polypropylene pipes.

There are no special requirements for such an indicator as the welding temperature of glass fiber reinforced polypropylene pipes.It is set in the same range as for other technical products made of polypropylene. Before welding, it is necessary to remove the upper reinforced layer from such products with a shaver.

When welding products made of polypropylene, there are features:

- the need to avoid large distances between the soldering iron and the welding site, since there is a loss of heat and a decrease in the welding temperature, leading to poor quality of the seam;

- violation of the procedure for soldering, in which the master does not make the last joint due to the inability to install a soldering iron between two products, which is the result of deformation of the pipeline and the occurrence of static stress in its sections;

- inadmissibility of sequential heating of structural parts.

The fitting and tubing material must be heated at the same time, not sequentially. If the requirement for uniform heating of parts is not observed, the entire technology of the process will be disrupted.

Finally

To achieve the effectiveness of the process, it is necessary that the temperature regime is set in accordance with technological requirements, a high-quality unit is used for welding, the distance between it and the welding site is 1.4 m, and the room is sufficiently heated.

We solder polypropylene pipes correctly

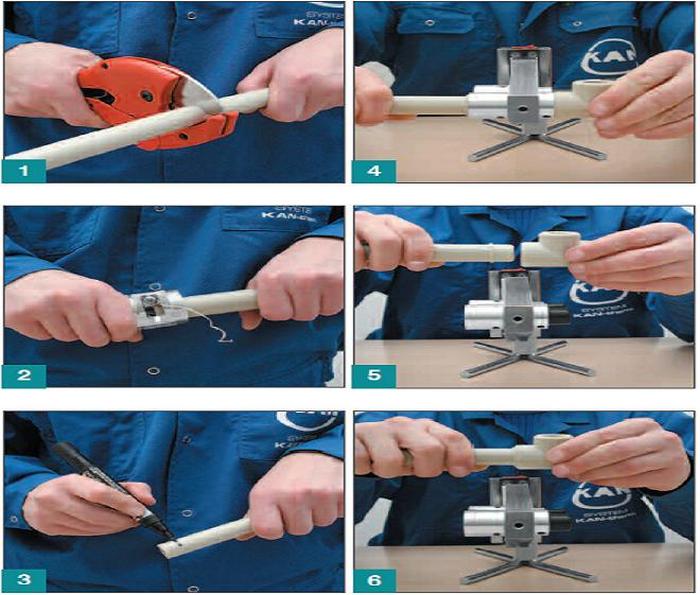

Having dealt with the main mistakes, we will give a small instruction for welding plastic pipes.

Step 1. First, everything that is required for work is prepared:

- the soldering iron itself;

- saw for metal (preferably a pipe cutter, if possible);

- pipes with fittings;

- marker.

Step 2. The soldering iron is assembled, the necessary nozzles are placed on it, then the device is connected to the network and warms up. When it warms up well, it is advisable to turn it off (at least once).A mark is made on the pipe - the depth of its entry into the fitting is indicated. Then you can proceed directly to soldering.

Pipe marking before soldering

Step 3. The pipe is marked out, it is indicated where and how the fitting will be directed (or a tee, a bend, etc.), for which it is better to use a black construction marker. The depth of entry into the fitting is also noted. In the future, this will help to avoid all sorts of errors regarding markup.

Step 4. The pipe is driven on one side of a well-heated soldering iron, and the fitting on the other. The countdown begins (follow the table), after which the joined elements are quickly removed and connected together.

Elements need to be heated for a certain time

Step 5. The fitting is immediately aligned during the connection so that it sits exactly on the pipe. The pipe itself should not be strongly pressed in - it is enough to plant it to the depth noted earlier. If you press too hard, the inner diameter of the pipe may decrease, and this is already a very gross mistake!

In addition, the fitting must not be twisted during connection. In simple terms, you need to: heat, connect, level and hold for about half a minute.

Stages of soldering polypropylene pipes

Used equipment

To connect the elements with a coupling, a special soldering iron is used, which is equipped with a massive metal heater.

On the surface of the plate there is a nest for installing tips corresponding to the diameter of the pipeline sections. For direct or butt welding a device with a mechanism for centering the parts to be connected is required.

Additional equipment and tools used for soldering pipelines:

- special scissors for cutting parts;

- tape measure and tool ruler for marking;

- locksmith square;

- device for stripping reinforced pipes (shaver);

- soft lead pencil or marker for marking;

- knife for cutting chamfers (required for butt welding);

- liquid for degreasing surfaces before soldering.

Basic rules for soldering polypropylene pipes

To obtain quality indicators such as the tightness of the welded joint, the preservation of the inner diameter at the joints of the parts, the aesthetic appearance, etc., the following rules must be taken into account.

The connection point must be dry and free from dirt.

Often, in practice, a situation arises when it is necessary to solder a fitting into an existing plastic wiring. Although the pipeline is equipped with a common valve, due to wear and tear, it cannot fully fulfill its purpose. In such situations, water ingress instead of connection is inevitable. The following steps can be taken to eliminate leakage while soldering the elements:

Step 1. Shut off the common water supply valve, drain the rest of the water into the sewer through the mixer, cut off the pipeline at the junction, taking into account the immersion depth, drain the water, dry the place and weld the nodes. In this case, it is advisable to replace the faulty stop valves.

Step 2. You can temporarily stop the outflow of liquid by displacing or draining the water column from the pipeline, if the water supply stops for some time (30 seconds is enough). If the leak cannot be stopped, then the internal cavity of the water pipe is sealed with bread pulp, and after welding it is removed through the nearest mixer, but before that, the filter is unscrewed from its drain tube.It is not recommended to use toilet paper as a cork, it does not come out of the pipeline well.

Do not overheat connections

Due to excessive overheating, the cross-section of the pipeline decreases, and, accordingly, the intensity of the supply of water or coolant decreases. Overheating can occur as a result of not observing the welding temperature and the holding time of the parts in the nozzle. Table 1 presents data on obtaining a quality weld for some pipe sizes.

The nozzle of the soldering iron must be securely fixed

A wobbling cue ball in the process of working with parts damages the heating surface of the soldering iron and contributes to the formation of misaligned joints.

After connecting the elements, do not rotate or move them more than 5 degrees

To obtain uniform diffusion, it is advisable not to rotate or align the brazed elements after joining during the setting time of the joint.

The movement of the workpiece in the cue ball must be rectilinear

Other movements may reduce the strength of the seam. The junction, of course, will withstand the pressure of water in the central line, which is usually in the range of 2 - 3 bar, but at a nominal pressure (10, 20, 25 bar), it may be possible to pass liquid.

Neglect of preliminary preparation of the material

As a rule, the connection of polypropylene pipes by welding is carried out during repairs, which are invariably accompanied by dust and dirt. Wishing to finish the job faster, workers often neglect the preliminary preparation of the material, in particular, surface cleaning. Pipes, fittings and other components are located on the dusty floor or shelves.If parts are not cleaned at the joints before soldering, leaks are likely to occur in the future, since excess particles will contribute to the formation of gaps and crevices. The problem may not appear immediately, but after several months or even years.

Thorough cleaning of parts before assembly is the key to the durability of the pipeline. All connection areas are required:

- wipe with a damp cloth to eliminate solid dust particles;

- dry dry;

- degrease the surface with an alcohol solution or alcohol-containing wipes.

In order to protect against dust, soldering is best done in a ventilated area. If work is forced to be carried out outdoors, protection from precipitation should be taken care of. During cutting, chips and burrs are unavoidable. Carefully inspect the joints and eliminate all unnecessary.

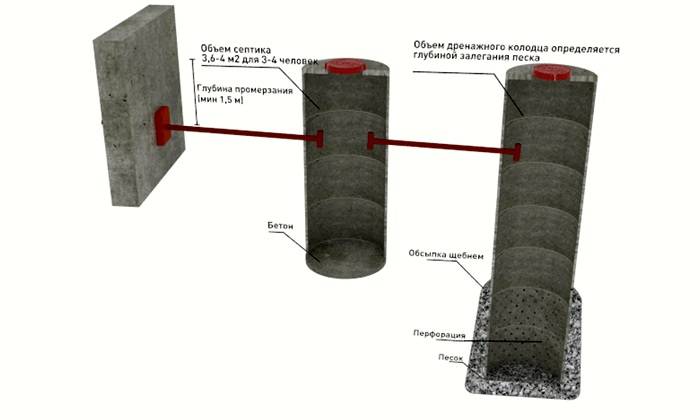

Distribution of polypropylene pipes

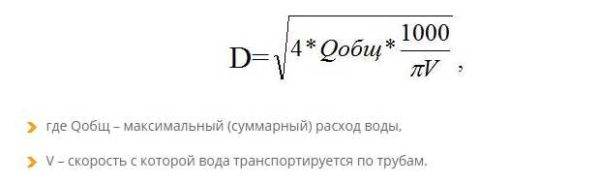

Polypropylene pipes are used for mounting a comb of cold or hot water, heating. The choice of diameter in each case is individual - it depends on the volume of liquid that needs to be pumped per unit of time, the required speed of its movement (the formula in the photo).

Formula calculation of the diameter of polypropylene

Calculation of pipe diameters for heating systems is a separate issue (the diameter must be determined after each branch), for water pipes everything is easier. In apartments and houses, pipes with a diameter of 16 mm to 30 mm are used for these purposes, with the most popular ones being 20 mm and 25 mm.

We consider fittings

After determining the diameter, the total length of the pipeline is considered, depending on its structure, fittings are purchased in addition.With the length of the pipes, everything is relatively simple - measure the length, add about 20% for the error and possible marriages in the work. A piping diagram is required to determine which fittings are needed. Draw it, indicating all the taps and devices to which you want to connect.

Example wiring polypropylene pipes in the bathroom

To connect to many devices, a transition to metal is required. There are also such polypropylene fittings. They have a brass thread on one side, and a regular solder fitting on the other. Immediately you need to look at the diameter of the pipe of the connected device and the type of thread that should be on the fitting (internal or external). In order not to be mistaken, it is better to write everything down on the diagram - above the branch where this fitting will be installed.

Further, according to the scheme, the number of "T" and "G" figurative compounds is considered. For them, tees and corners are bought. There are also crosses, but they are rarely used. Corners, by the way, are not only at 90 °. There are 45°, 120°. Do not forget about couplings - these are fittings for joining two pipe sections. Do not forget that polypropylene pipes are completely inelastic and do not bend, so each turn is done using fittings.

When you purchase materials, agree with the seller on the possibility of replacing or returning part of the fittings. Problems usually do not arise, since even professionals cannot always immediately determine exactly the required assortment. In addition, during the installation process, sometimes it is necessary to change the structure of the pipeline, which means that the set of fittings changes.

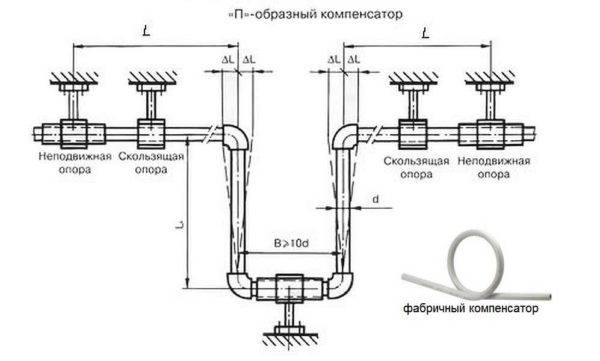

Compensator for hot water supply and heating from polypropylene pipes

Polypropylene has a fairly significant coefficient of thermal expansion.If a polypropylene hot water supply or heating system is being installed, it is required to make a compensator, with which the lengthening or shortening of the pipeline will be leveled. This can be a factory-made compensator loop, or a compensator assembled according to the scheme from finigs and pieces of pipes (pictured above).

Laying methods

There are two ways to install polypropylene pipes - open (along the wall) and closed - in strobes in the wall or in the screed. On the wall or in the strobe, pipes made of polypropylene are mounted on clip holders. They are single - for laying one pipe, there are double - when two branches run in parallel. They are fastened at a distance of 50-70 cm. The pipe is simply inserted into the clip and held due to the force of elasticity.

Fastening polypropylene pipes to walls

When laying in a screed, if it is a warm floor, the pipes are attached to the reinforcing mesh, no other additional fastening is required. If the connection to the radiators is monolithic, the pipes can not be fixed. They are rigid, they do not change their position even when filled with coolant.

Option concealed and outdoor wiring in one pipeline (behind the bathroom, the wiring was made open - less work)

The nuances of soldering

The process of welding polypropylene pipes, as you have seen, does not leave much work, but there are a lot of subtleties. For example, it is not clear how, when joining pipes, to adjust the sections so that the pipes are exactly the length that is required.

Another point of welding polypropylene pipes is soldering in hard-to-reach places. It is not always possible to put a pipe and a fitting on the soldering iron on both sides. For example, soldering in the corner. Soldering iron, you have to put it in a corner, on one side the nozzle rests directly against the wall, you can’t pull the fitting on it.In this case, a second set of nozzles of the same diameter is installed and the fitting is heated on it.

How to solder polypropylene pipes in a hard-to-reach place

How to switch from iron pipe to polypropylene.

Common questions and answers for soldering polypropylene

Is it possible to solder pipes of one manufacturer, and fittings of another? Of course it is possible, but I want to warn you that both couplings and pipes should be of good quality. Not

it is worth using parts from unnamed manufacturers. In non-professional stores, pipes of different companies are often sold, and the fittings are the same, from an unnamed manufacturer. I don't

I recommend using this link. In general, nothing prevents soldering pipes and fittings from different manufacturers, with or without different reinforcement on opposite sides of the coupling.

Can polypropylene pipes be bent? You can not bend them, neither during installation, nor after. If there is a need to bend the pipe during installation, then you should use bypasses or

corner combinations. In fairness, it should be noted that the weak point of the pipeline for bending is the junction of the pipe and fitting. This conjugation point breaks off at some

breaking force. To verify this, it is enough to solder a trial construction from a corner and two pieces of pipe 50 cm each, and try to break this “poker” with your hands.

Sometimes there is a need to solder a knot with a non-standard angle. Let me remind you that only two types of PP corners are printed: 90 and 45 degrees, at least they are different for me

did not meet. But what if you need to turn the pipe of a different degree? There are two methods that I know of:

With the help of two 45 ° corners, you can make any angle by changing the angle of rotation of the corners relative to each other.The disadvantage of this method is that due to non-standard

rotation, the connection will not be in the same plane.

The second way is to misalign the pipe and fitting at multiple connections. Do not forget that the straightness at the junction of the pipe and fitting should not deviate

more than 5°.

How to solder pipes if the crane does not hold? It is strictly forbidden to weld if water is present in the area to be soldered. If, for any reason, it is completely blocked

water fails, you need to stop it for the duration of welding. On the Internet, it is advised to plug the pipe with a bread crumb, but the problem is that the crumb immediately squeezes out the newly created

pressure in the pipe. Therefore, the method will work only when it is possible to open the area to the place of soldering for air to escape. And when the pipes are soldered, the crumb is easy

pops up when pressure is applied.

Tip: if during welding you could hear the hiss of water on the nozzle, it is better to cut the knot and redo it! It is better to spend extra time during installation than to correct and eliminate

flow in the future, with a bunch of crawled out problems!

In this photo, you can see that the plug is unscrewed at the filter and excess water flows down the rag from there. And in the place of soldering, a bread crumb is plugged.

In this photo, you can see that the plug is unscrewed at the filter and excess water flows down the rag from there. And in the place of soldering, a bread crumb is plugged.

Thanks to the open filter, we had a little over a minute to complete the soldering before the water squeezed out the crumb.

Actually on this I propose to end the presentation of information. I plan to expand the list of common questions about soldering polypropylene pipes over time.

Rate this post:

- Currently 3.86

Rating: 3.9 (22 votes)

Errors when soldering polypropylene pipes

It is necessary to follow the recommendations for welding polypropylene pipes and follow all steps of the instructions.

Defective nodes in systems appear due to the following errors:

- Dirt and grease film is not removed from the surface of the parts to be joined.

- Trimming of tubular products is not carried out at a right angle.

- The end of the pipe is loosely inserted into the fitting.

- The time delay is not observed when the elements are heated on the soldering iron.

- The reinforced layer is not completely removed from the products.

- Correction of details is carried out longer than the specified time.

On high-quality materials, an external defect may not be visible when overheated, but deformation still occurs inside. It leads to a reduction in cross section.

Therefore, during the operation of engineering communications, the network bandwidth is reduced. The narrowing of the passage also causes faster clogging. This also blocks the movement of water.

If the cut is not made at a right angle, the tubular products are joined in a beveled plane. As a result, the elements are out of alignment. It becomes especially noticeable when installing long sections.

As a result, it is often necessary to dismantle and carry out the whole process again. With misalignment, the product is difficult to lay in the strobes.

Be sure to degrease the surfaces before soldering. Otherwise, so-called islands of rejection appear. In such areas, polyfusion welding is poorly performed or does not occur at all.

This error will allow you to start operating engineering communications, but after a certain time period a leak will appear. It also often occurs when the temperature of the soldering iron is set incorrectly.

If insufficient removal of the reinforcing layer occurs, the remaining aluminum foil contributes to the formation of unwelded areas. In such areas, leaks most often appear.

A gross mistake is to scroll through the details. Such an action does not allow obtaining a homogeneous structure around the entire circumference of the joint. The connection made will not be complete, because it will collapse when the pressure in the system rises.

Tips for working with a soldering iron

Let's briefly understand what exactly is a soldering iron. It includes a heating indicator, heating sleeves, a thermostat, a flat element (iron) in its composition. Immediately before soldering, you should mount the body of the soldering iron with a stand and heating sleeves.

First you need to arrange a large nozzle closer to the body, and a smaller sleeve should be fixed on the nose of the iron.

Now the soldering iron can be connected to electricity. The optimum operating temperature of this soldering iron is 260 degrees. But before work, he should warm up for half an hour. At the moment of optimal temperature, the light will signal.

Problems that can be encountered during welding work

Even masters cannot avoid problems in the process of welding polypropylene pipes. The first of these is the implementation of non-perpendicular connections. If welding is not performed exactly at an angle of 90 degrees, then this will not affect the reliability of welding in terms of mechanical indicators, but will cause inconvenience, if necessary, to join extended sections of the pipeline. From an aesthetic point of view, pipes welded in this way will look messy.

Without the experience of welding the first time, it is unlikely that it will turn out exactly, so you should think about how to decorate the pipes after all the installation work has been completed.

The second problem may be the appearance at the junction of the pipe with fittings. In these places, rings and other anomalies are formed, which some consider to be an indicator of the reliability of the water supply, while others indicate the unprofessionalism of the master. However, in practice, the formation of such rings does not affect the reliability of the water supply and the pipe itself.

To make the connections look more attractive, you must do the following. Before you heat the pipe, you need to put on it, in addition to the main mark, an additional one. The pipe must be heated to an additional mark, and when the connection is made, the pipe must be inserted to the main mark. This will move the excess plastic to the side of the fitting and create one ring.

When installing polypropylene water pipes, it is impossible to do without special clamps. For this, it is best to use special plastic holders. The pipes in them simply snap into place without any additional effort.

General recommendations on how to fix a leak in a polypropylene pipe

In fact, if a leak has formed in the pipe, the master is not always to blame. Other factors may also play a role here:

-

Wrong temperature selected when soldering polypropylene pipes. Because of this, a gap may form at the junction of the pipe with the fastener. There is only one way to eliminate a leak in a polypropylene pipe - to change the defective structural element to a new one.

-

Loose nut. If the lock nut really just loosened, then tighten it, and thereby eliminate the leakage of the tightening fitting, there will be no problems. If the nut is defective (or the inner gasket has deteriorated), then there is a reason for a more serious repair. Some in such situations cover the leak with sealant. But this is only a temporary solution to fix a leak in a polypropylene pipe. The fitting needs to be changed, and the sooner the better.

-

Poorly prepared pipe. Polypropylene pipes with uneven cuts, when installed using sliding fittings, will leak in any case.

-

Joints of polypropylene pipes connected with gluewill leak if:

-

the wrong type of glue is used;

-

everything is in order with the adhesive, but after installing the polypropylene pipes, water was let in too early; the glue did not have time to "grab" properly, as a result, a leak appears.

-

Options for repairing leaks in a polypropylene pipe can be very different, and they differ, first of all, in their quality. The most reliable way to fix a leak is to replace the damaged pipe section with a new one.

Soldering through fittings using the high-temperature interface method gives excellent results. But sometimes it is not available, and therefore, in certain situations, other methods are used to eliminate the leak.

So, a polypropylene pipe burst in your house. It is quite possible to eliminate the leak on your own. This is not to say that it will be easy, but there is nothing super complicated in such a repair either. The main thing is to have the right tools and supplies at hand.

To eliminate leaks in polypropylene pipes using standard soldering, you will need a special soldering iron (the so-called polyfus).But, unfortunately, it is not always at hand, or even the neighbors have it.

It is not difficult to get out of the situation in this case, there is a method of "handicraft welding". When using this method, breaks in a polypropylene pipe are sealed using the material of which this pipe is made. What do we have to do? Attach some hot metal object to the crack (for example, an ordinary nail or a screwdriver). Polypropylene will begin to melt, which you need to immediately use and cover up the hole. Sometimes the nail does not have to be heated; an ordinary lighter is enough to eliminate the leak.

Sometimes it is not possible to eliminate a leak in a polypropylene pipe with a soldering iron. This usually happens when a crack has formed at the junction of pipes, and it is problematic to get to it with a soldering iron. In such situations, use an alternative method to fix the leak. To do this, you need only two things: firstly, a collar of the right size, which can be bought at any hardware store, and, secondly, a special industrial hair dryer to heat the junction. We heat until the polypropylene softens, then we put a clamp on the pipe and tighten it more tightly. The leak in the polypropylene pipe has been fixed. Of course, not every person keeps an industrial hair dryer at home, but if necessary, it is easy to rent it.

Read related material:

Wholesale of polypropylene pipes at competitive prices

Error related to incorrect positioning

After the two heated parts of the structure have been connected, the master has only a few moments to properly position them relative to each other. The less time spent on this process, the better.If the time limit has been exhausted, the deformation cannot be changed and the strength of the system will be significantly reduced.

Inexperienced editors often try to immediately remove the streaks that appeared during soldering. This cannot be done, because the connection that has not completely cooled down during this period can be easily deformed. It is necessary to remove the splashes only after the connection has completely cooled down. And it's best not to overheat the pipe so that the sagging does not appear.