- Decryption

- Restart boiler

- Check grounding

- Inspect the inside of the boiler

- Perform cleaning

- What to check

- Traction control system

- Fan

- Chimney

- Electronic board

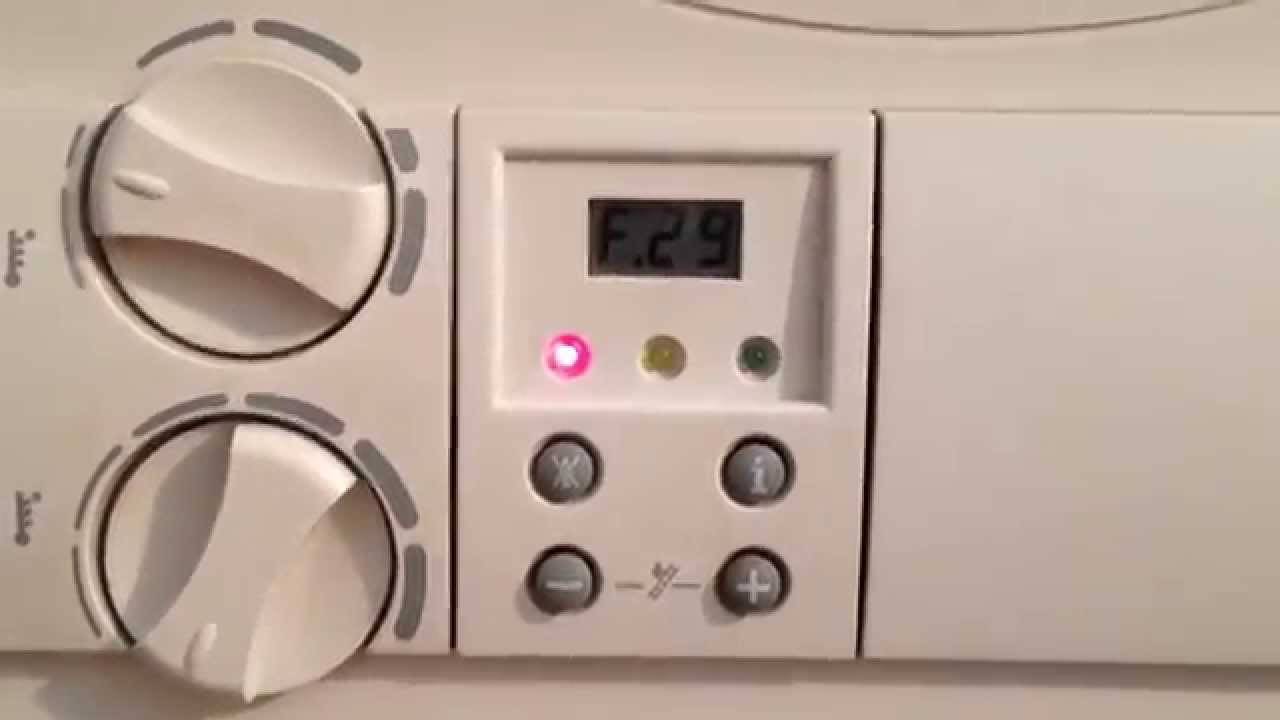

- Reasons for the error

- Repeated breakdown

- Why does pressure drop

- Doesn't restart

- Vaillant boiler error F28: how to fix

- Repair of various models

- Decryption

- Where to begin

- Advice

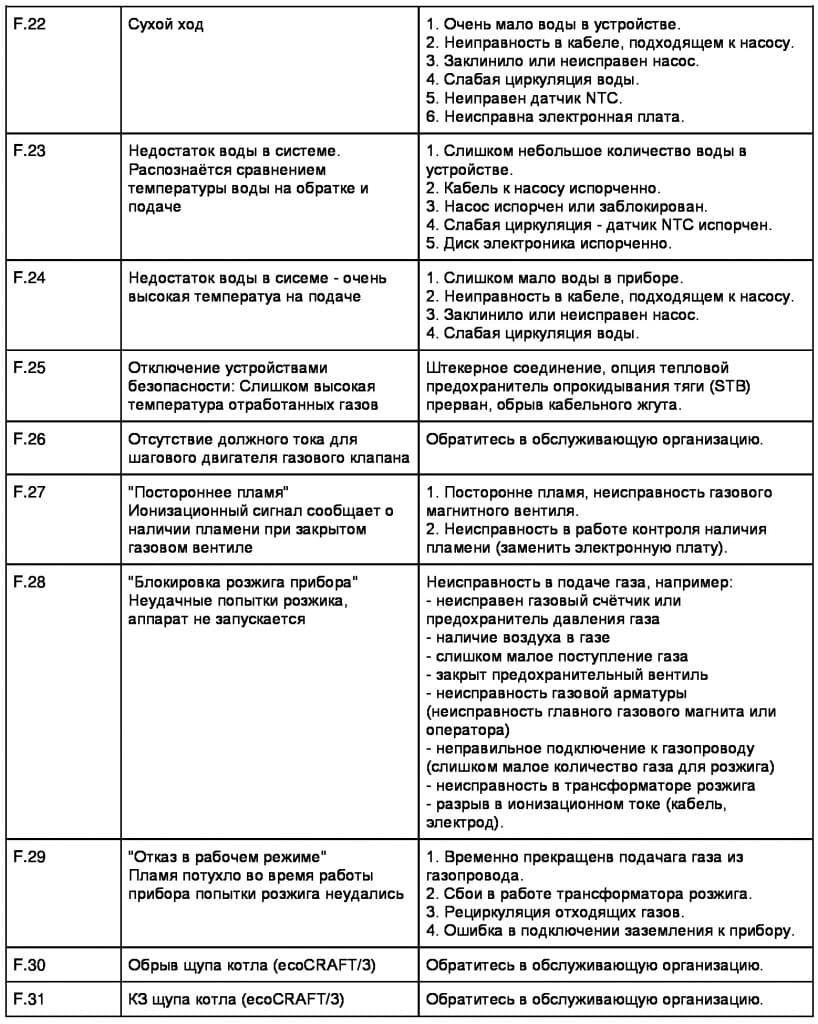

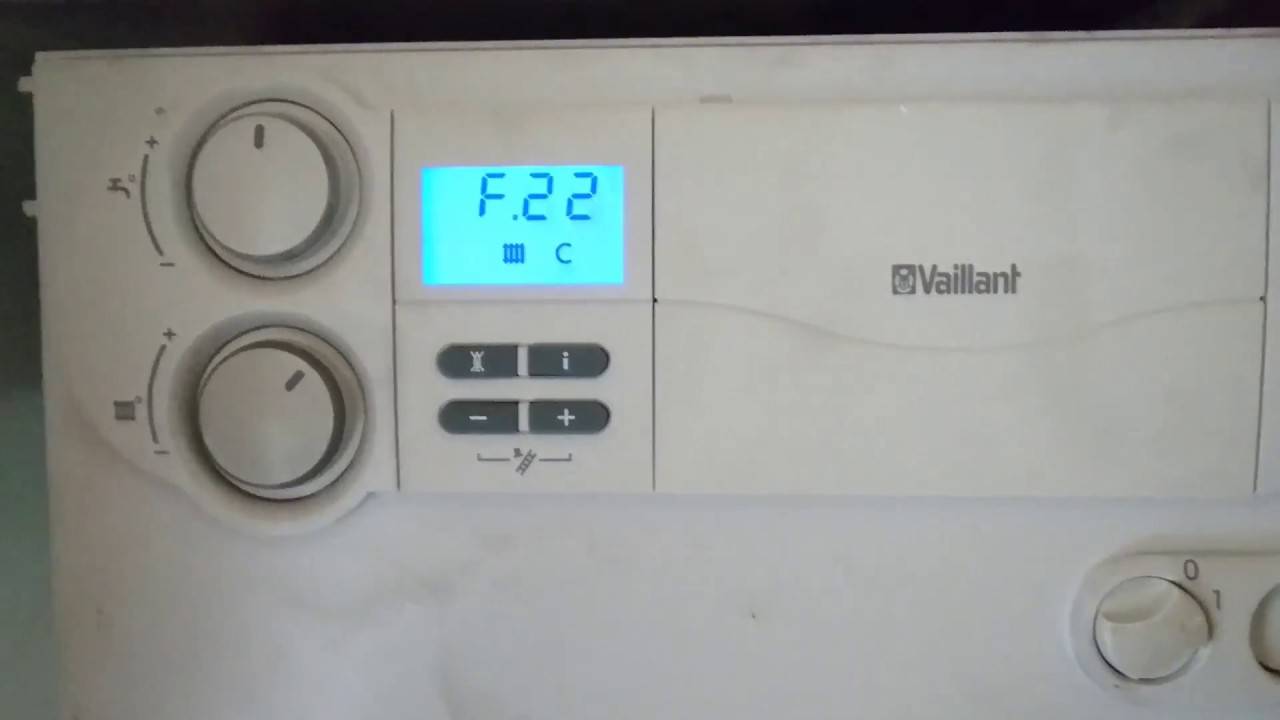

- The most common malfunctions and their causes

- Commissioning sequence for Vaillant boilers

- Error F.75

- VALIANT (Vailant) - Error F.75: after start-up, the boiler does not reach the operating pressure in the system (by 50 bar.), A faulty pressure sensor or circulation pump.

- List of first level problems

- Main error codes (f28, f75) and their brief explanation

- What causes an emergency stop

- Chimney

- Tips

- Violation of recommendations for installation of the unit

- The reasons

- Heat exchanger fouling

- Sensor problem

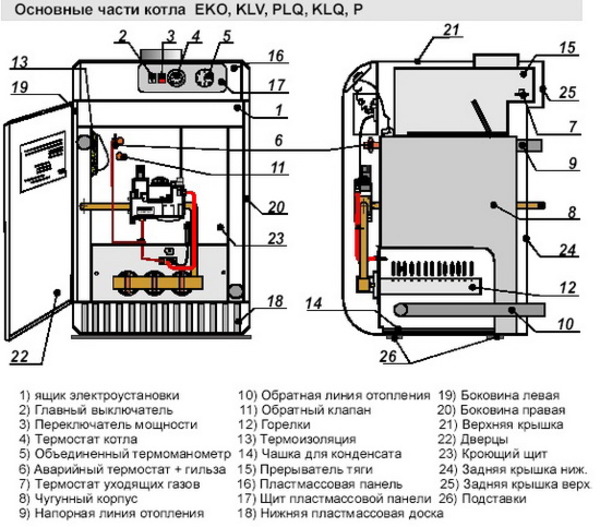

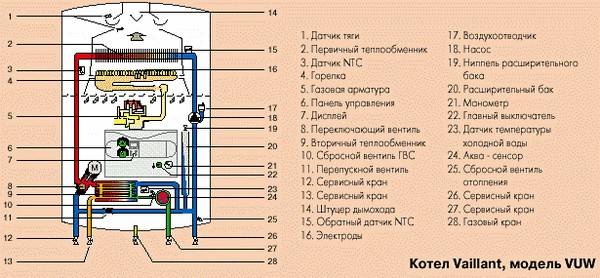

- Types of manufactured boilers

- single circuit

- wall

- floor standing

- How to run self-diagnosis

Decryption

Error f26 informs about a violation in the functioning of the gas fittings of the Vaillant boiler. The control valve, which doses the supply of "blue fuel" to the burner, changes position under the influence of the stepper motor drive.The control signal to the stepper motor is supplied from the electronic board in the form of a "series" of pulses: the number is determined by the set Vaillant operating mode.

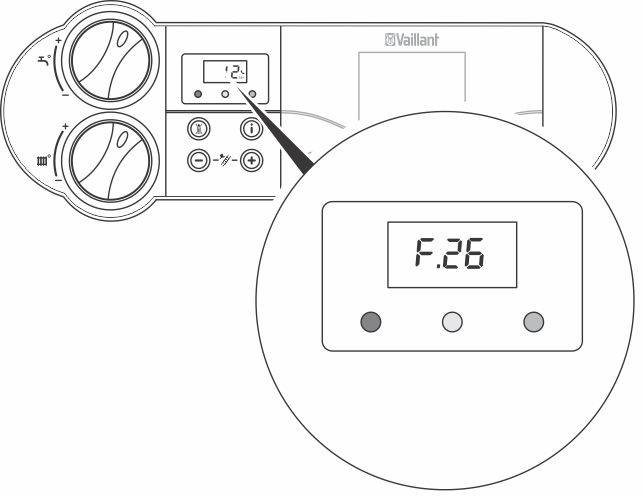

Error F26 is displayed on the control panel of the Vaillant boiler

EPU, by adjusting the number of steps, determines the degree of opening of the gas channel and the amount of fuel passed. The movement of the spindle depends on the interaction of the magnetic fields of the coils. Therefore, the cause of the error f26 of the Vaillant boiler must be sought in the gas valve unit and the EPU.

There is no unequivocal recommendation for eliminating the code, therefore the manufacturer's instructions advise contacting a service organization in case of such a malfunction. The article is written on the basis of the author's personal experience and analysis of the exchange of opinions of masters, users on solving the problem with the f26 error, found on thematic forums.

Electronics presents the most unexpected surprises: different codes are caused by similar problems. When looking for the cause of the 26th error before calling a service representative, it is worth trying to fix the defect yourself.

Restart boiler

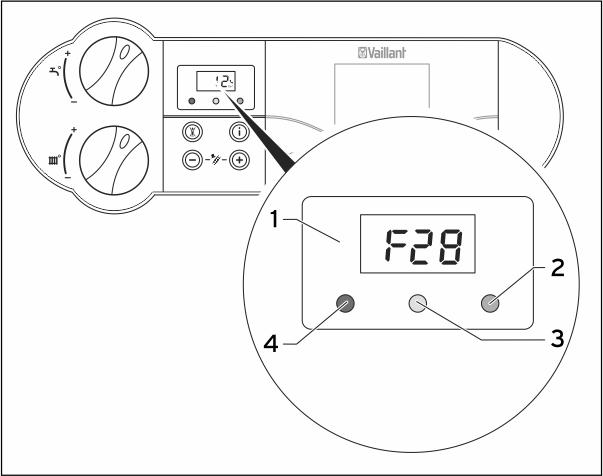

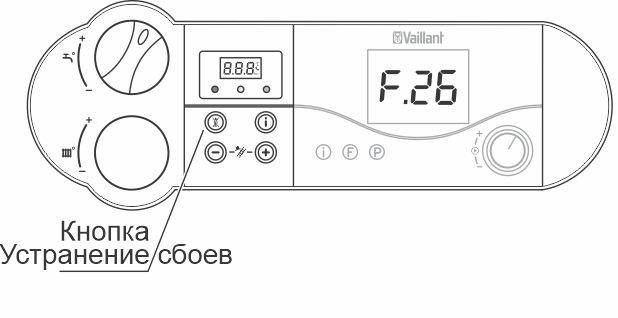

Depending on the type of Vaillant, press the RESET, "NETWORK" or "ON" button. If the error f26 is false, which appeared after the power surge, will disappear.

F26 error reset button for atmoTEC pro, turboTEC pro boilers

Check grounding

The potential on the Vailant boiler body is a common cause of errors. It is revealed by touching the metal part of the unit with an indicator screwdriver. Pickups (stray currents) lead to malfunctions of the electronic board, false fault codes.

The problem is solved by installing a dielectric coupling on the gas pipe, in front of the boiler.

dielectric clutch

It is not in vain that users note that the f26 Vaillant error is displayed after a strong thunderstorm.Violations in the functioning of the heating unit are typical for self-arrangement of grounding without taking into account the requirements of the PUE and the manufacturer's recommendations.

Inspect the inside of the boiler

The condition of the electric circuits between the gas valve unit and the electronic board, the reliability of the connections are assessed. Fused insulation, condensate initiate short circuits, “set” the signal, the command to control the Vaillant boiler valve is lost, error f26 is displayed. Found defects are easy to fix.

Checking the signal lines in the Vaillant boiler

Damage to the EPU is also visually determined. This is indicated by swollen cases of electrolytic capacitors, microcircuits, cracks, chips, burnt tracks.

Vaillant boiler control board

Perform cleaning

Dust is the likely cause of error f26. Accumulating on the details of the fittings, the control board of the boiler Vaillant, gradually absorbs moisture, turning into a conductive layer. Dirt is removed carefully, with a cotton swab, without the use of alcohol-containing and other aggressive liquids. It is recommended to practice regularly, especially for atmospheric-type Vaillant boilers. This minimizes the risk of errors appearing on the display of the unit.

It is not possible to remove the f26 code - contact an authorized service. Independently "picking" the board on the advice from the Internet, various kinds of "experts" is inappropriate for a number of reasons.

-

EPU is expensive, from 7800 to 14300 rubles. You will have to pay no more than 1000 for diagnostics in the workshop at the stand, restoring the operation of the unit.

-

Replacing the processor may not give a result - depending on the type of Vaillant, the year of release, the “firmware” is different.

-

The tight arrangement of parts implies spot soldering. It is carried out on the machine, with temperature control.Otherwise, overheating, damage to the housings of the elements is inevitable.

-

The lack of circuit diagrams forces the user to act "blindly". As a result, the boiler is idle for a long time.

-

Sometimes the cause of error f26 is a malfunction in the display board (display panel). Not repairable - changing.

When placing an application, indicate the date of issue and the type of Vaillant. The master will replace the EPU in a matter of minutes, the problem with error f26 will be solved quickly.

What to check

Traction control system

In Vailant boilers of the Turbo series, the volumetric air flow (after ignition - exhaust gases) is determined using several devices that are structurally connected.

Broke a pitot pipe in a Vaillant boiler

Complete Manostat set with Vaillant boiler tubes

Manostat - Vaillant boiler pressure switch

Connect the multimeter probes to the terminals to measure the resistance. In the initial position, the microswitch contacts are open, therefore, R = ∞. Pinch the inlet port of the manostat with your lips, take a few breaths / exhalations. When the MV is triggered, characteristic clicks are heard, and the multimeter shows 0. If there are no complaints about the sensor, check the reliability of connecting electrical circuits.

Fan

In practice, error f37 indicates a reduced speed. The shaft rotation speed drops for a number of reasons, and you need to start troubleshooting with an external inspection of the turbine. The code is called:

Boiler fan vaillant

-

impeller contamination. Weight increases, which affects the number of revolutions. Cleaning removes error f37;

-

bearing failure;

-

interturn circuit of the winding.

If error f37 of the Vaillant boiler does not disappear after removing dirt from the fan, the turbine is being changed. It is not advisable to carry out its testing, disassembly, repair at home.

Chimney

Another error informs about a malfunction in the smoke exhaust duct. But if the thrust is reduced, the appearance of the 37th is also possible. The instructions say that the pressure sensor operates in the range of 68–80 Pa. Inspect the pipe outlet, remove icicles, ice crust, clean the filter from dirt - a service master is not needed for this.

Clogged chimney

Electronic board

The “brain” of the Vailant boiler receives signals from sensors, generating the corresponding errors. Fault codes are caused by malfunctions of its operation. Testing without a simulator cannot be carried out, but visual diagnostics often help to fix the problem.

Vaillant boiler control board

Reasons for the error

-

board deformation.

-

Dark spots are the result of thermal exposure.

-

Unreliable contacts.

-

Breaks, delamination of tracks.

-

Damaged body parts.

-

Condensate.

-

Dust. Gradually gathering on the surface of the boiler board, Vailant, absorbing moisture, turns into a conductive layer. Careful cleaning of the EPU eliminates error f37.

Repeated breakdown

Not for long the music played, my favorite Vaillant gas boiler failed again. At first I got error f33 and again f28, which means a problem with the gas burner. Since the Vaillant display was naughty, naturally, he sinned on the control board. However, one should not rush to conclusions. Like last time, we act according to a clear plan:

- Shutdown equipment.

- Removing the gas boiler

- Carrying out diagnostics.

- Structural analysis.

- Checking elements.

Since I had previously inspected the unit, I decided to check all the main components. Interested in the state of the crane, sensors, pump. There was no desire to often disassemble the unit, so I thought about how to fix all the malfunctions at once.In the Vaillant gas boiler, some elements are hidden, so it is problematic to get to them without damaging another element.

It's all about the control board. It is located at the bottom of the structure, and to get there, you have to tinker with the bolts, in my case everything looks flimsy. Finally, the Valiant boiler is open and you can look around. The control board is a normal element, the same as in a computer. When disassembling a gas boiler, it is recommended that you do not once again touch the contacts and connecting elements with your fingers, since greasy spots remain on them. All this can affect the operation of automation.

Troubleshooting begins with stripping contacts. As you know, there are tracks on the control board, and they are perfectly cleaned with ordinary clerical grout. As for the sensors, I just removed the dust from them. Upon inspection, I noticed that the three-way valve dangled and, possibly, could fail in the near future. This element is located at the top of the structure, it is responsible for shutting off the gas.

I picked up a similar three-way product in the store, the most interesting thing was with the control board. It is problematic to find a similar variation, fortunately, it contains the exact product code, so I managed to order it via the Internet.

Error F28 may also appear due to a gearbox malfunction. The element is responsible for the gas pressure and is connected to the meter. When I had suspicions about the gearbox, I initially made diagnostics, it is necessary to check the settings. The first step is to turn off the gas valve.

Pay attention to the display. If the error code disappears, then the element must be replaced.It happens that everything is in order with the magnet, the ignition transformer suffers

Soot often accumulates on it and the gas boiler refuses to work. Checking the pressure is not so easy, because you need to remove the casing. Having reached the junction box, the shut-off valve is closed. Inside there are several sealing screws that are fixed on the gas fittings. It is only necessary to loosen them a little, the design is not as strong as it might seem at first glance

It happens that everything is in order with the magnet, the ignition transformer suffers. Soot often accumulates on it and the gas boiler refuses to work. Checking the pressure is not so easy, because you need to remove the casing. Having reached the junction box, the shut-off valve is closed. Inside there are several sealing screws that are fixed on the gas fittings. It is only necessary to loosen them a little, the design is not as strong as it might seem at first glance.

A digital tonometer is used to check the pressure. In the instructions you will find the exact indicators of normal pressure, depending on the modification.

Why does pressure drop

The pressure drop in the boiler has the only reason - the leakage of the coolant. If, after several attempts to increase the pressure using the supply valve, no positive results appear, you should look for a leak in the boiler itself or in the heating circuit.

Difficulty may arise if the boiler is condensing and connected to a floor heating system.

Finding leaks in such conditions is extremely difficult. It may turn out that the malfunction is hidden in the relief valve connected to the sewer system.

The best way to search for causes is to consistently exclude possible causes of leaks so that in the end there is only one, correct one.

NOTE!

Certain information can be obtained if you try to determine the intensity of the leak and analyze the throughput of the boiler elements involved.

Doesn't restart

There are a lot of reasons for refusal to restart the boiler. It is almost impossible to name them all, since most problems in one way or another lead to blocking the installation, and restarting becomes impossible until the cause is eliminated. However, some possible reasons can be named immediately.

For example, the power plug in the outlet may be upside down. Vaillant gas boilers are phase-dependent, i.e. cannot work when the contacts are reversed. If a reconnection occurs during repair work, the unit will no longer be able to start.

In addition, it is possible that the nozzles become clogged with soot, which stop passing gas in the right amount, as a result of which blocking immediately follows at startup.

Vaillant boiler error F28: how to fix

If there is no desire to understand the reasons and finances allow, of course, you can take the equipment to a service center. However, do-it-yourselfers recommend not to give up, try to carry out repairs at home.

I draw your attention to the fact that we are talking about gas equipment, so safety precautions must be observed. The unit must be turned off to be completely safe.

My actions during the breakdown:

My actions during the breakdown:

- There is a reset button.

- Dismantling of equipment.

- Carrying out diagnostics.

- Boiler disassembly.

I am familiar with the design of gas equipment and the first thing I check the electrodes. My first thought was the wiring was damaged.If bare contacts are observed, this problem is easiest to fix. A blowtorch is taken, everything falls into place. However, during the first inspection, I did not find any problems with the wires, the electrodes are all in place (in theory, the electronic board should receive a signal).

The second point is grounding. It is checked with a tester. The most difficult thing is the valve, according to the instructions, it must withstand a certain pressure. In my case, he was clearly junk and did not even know what to do. I decided to just replace the element, the error f 28 disappeared by itself.

Repair of various models

According to the manufacturer's instructions, the Vaillant TurboTEC Pro 28 kW gas boiler must not be repaired in such a way that changes occur in the boiler itself, on the mains supplying water or gas, in the electrical network or in the chimneys. Tighten and loosen the threads of all connections only with open wrenches. It is impossible to use pipe tongs, extension cords and similar equipment for this purpose.

The pressure test is carried out as follows:

- the shell is removed;

- the distribution box leans forward;

- the gas valve is closed;

- the screw in is loosened;

- a manometer is connected;

- the shut-off gas valve opens;

- the device is started at full load;

- the pressure is measured when connected.

If you cannot resolve the problem on your own, you should perform the following steps:

- the boiler needs to be stopped;

- remove the manometer;

- check the tightness of the screw fastening;

- fold down the distribution box;

- return the trim to its place;

- wait for the representatives of the gas service.

Both single-circuit and double-circuit boilers, which consume a lot of gas and give an extremely hot smoke stream, do not need to be repaired.It is necessary to clean and wash the upper heat exchanger. With low hydraulic resistance, the company advises to press the supply valve. In the event of a complete absence of a spark, do not waste time cleaning the gas valve. The problem with a probability of almost 100% is related to the system electronic board. If the AtmoTEC Plus boiler changes pressure rapidly when the temperature changes, it is necessary to pump up the expansion tank.

Decryption

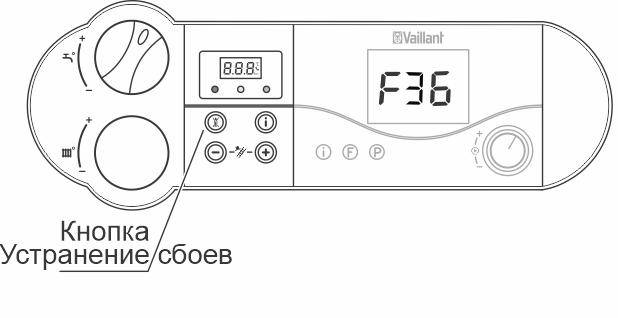

Error f36 should be interpreted as follows: traction violation: falls or the channel is completely blocked. The temperature of the exhaust gases rises sharply, which is recorded by a sensor that controls the chimney. An appropriate signal is sent to the electronic board, code 36 is generated, the heating unit stops.

Error F36 is displayed on the Vaillant boiler

situations in which atmospheric Vaillant boiler shows an error f36, different: initial start, when the weather changes, only in the evening. The article discusses all the likely causes of the problem - the user will definitely find a solution to the problem.

Where to begin

Imported boiler equipment reacts to the instability of the supply voltage. Jumps, phase imbalances, an increased (lower) value of Uc lead to failures in the electronic circuit, false errors appear. Before starting to search for the cause of the fault code, you need to restart the Vailant boiler. Depending on the modification, by pressing the Reset, "Network", "On / Off" buttons. If the appearance of the f36 character is associated with problems in en / supply, the error will be removed.

Reset error F36 on the Vaillant boiler control panel

Advice

The UPS helps to eliminate the possibility of displaying false codes.The inclusion of the Vailant boiler in the home network through the unit guarantees the stable operation of the unit even in the event of a malfunction on the power line, a backup power source. Autonomy is ensured by batteries (built-in or external attached).

Scheme for connecting backup power to the Vailant boiler

The most common malfunctions and their causes

Despite the true German quality, like any other equipment, Vaillant boilers are subject to all sorts of failures. If, nevertheless, this or that problem has arisen, then the device informs the owner about this by displaying an alphanumeric code on the LCD display, including a red light, as mentioned above. Each error has its own code.

If you study thematic forums where boiler owners discuss their malfunctions, then the most popular queries are:

- error code F22, indicating the lack of water in the device or its shortage. It is worth checking if the pump is jammed, whether the pump cables are securely connected to the water pressure sensor, look at the sensor itself or at the pump power. Possibly still weak circulation of water;

- error with code F28, in which the unit does not start at all. The reasons may be different: zero and phase are incorrectly connected, gas oversaturation with air, too low gas pressure, the control board is broken, the boiler is incorrectly grounded, a cable break or a connection error to the gas pipeline. Some problems can be solved by yourself by looking at the instruction manual. For example, check if the gas valve is open or change the gas pressure in the boiler settings by 5 mbar;

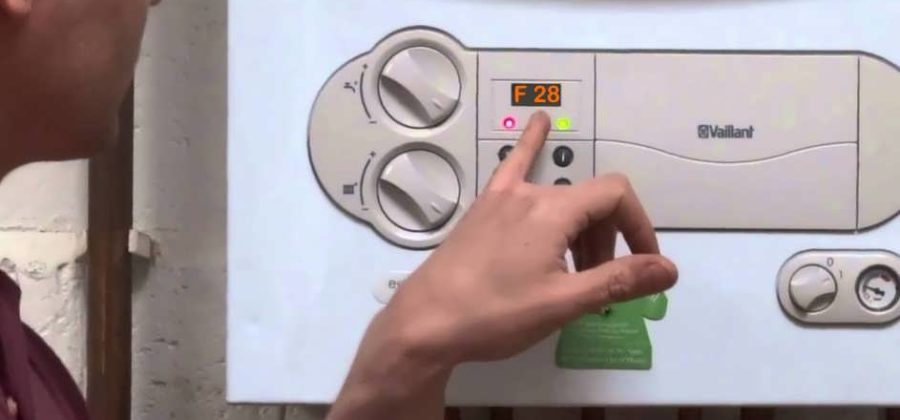

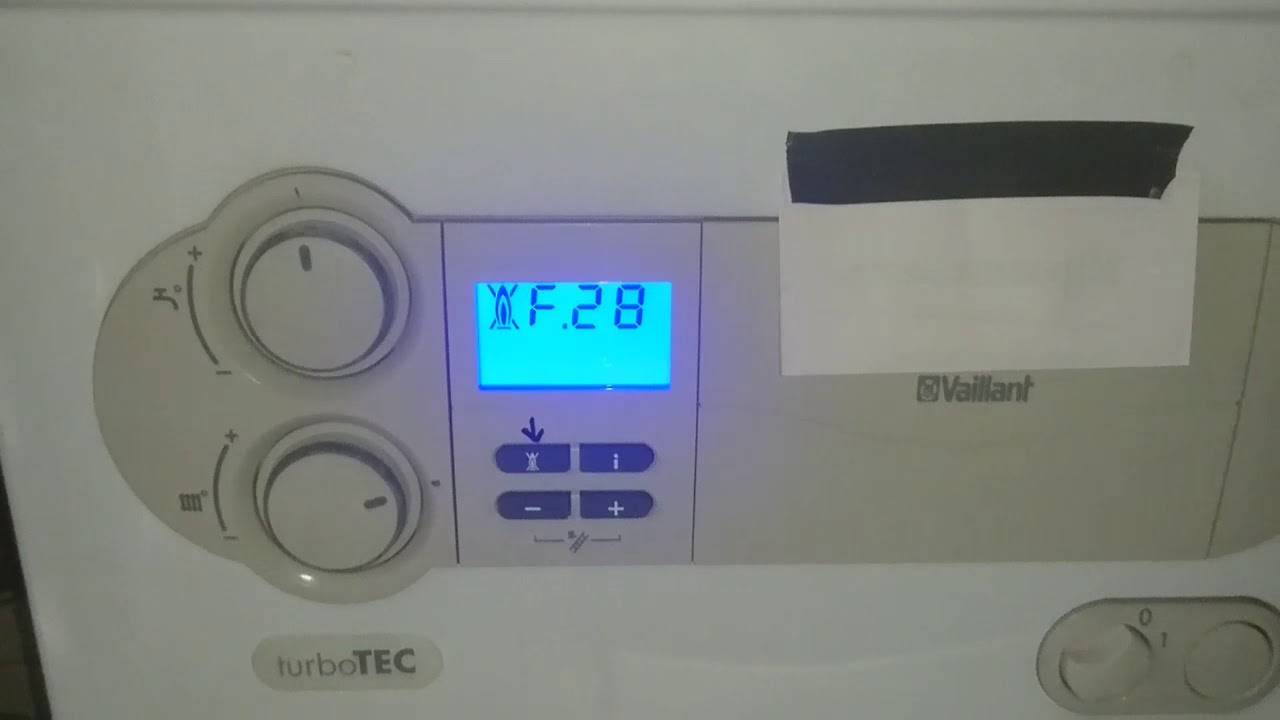

Error F28 on the boiler display

- error with code F29, in which the burner flame constantly goes out, and new ignition attempts are unsuccessful. The reasons may be as follows: the gas boiler is incorrectly grounded, failures in the gas supply in the gas system itself, problems with the ignition transformer or with the gas valve. To fix this problem, it is worth checking the gas pressure, it may drop too low or see if there is enough air for normal fuel combustion;

- error with code F36 (Wailant Atmo), in which combustion products come out. Such a problem may occur due to poor ventilation in the room or poor draft in the chimney, or the temperature in the room is too high. You should also check whether there is sufficient space between the boiler and the wall;

- error with code F75, in which the boiler pump works, but the pressure does not rise. There can also be several reasons: a breakdown of the pump or water pressure sensor, air entering the heating system, improper connection of the expansion tank, or insufficient water pressure. To fix the problem, you can try to clean the water pressure sensor, or you will have to purchase more powerful components.

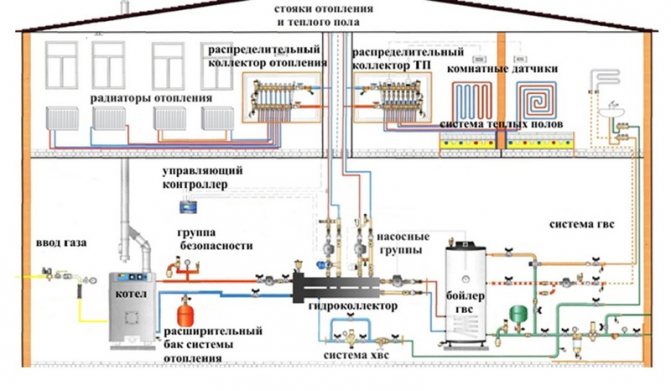

Commissioning sequence for Vaillant boilers

-

before filling it is necessary to thoroughly flush the heating system (large particles remaining after installation work can damage the actuators)

-

check the condition of the automatic air vent on the circulation pump, if it is closed, unscrew it by 1-2 turns

-

shut-off valves on radiators or thermostatic heads must be fully open

-

fill the heating system to a pressure of at least 1 bar (usually 1.3 - 1.5 bar)

-

turn on the boiler and check the pressure, if necessary, feed the system

-

be sure to check the gas deflector for leaks

-

Vaillant requires that the system be filled with prepared water with a hardness of no more than 20 German units and prohibits the addition of antifreeze or corrosion inhibitors to the system.

After the system is filled, it is necessary to carry out the P0 venting program, in which only the pump will operate in a specially designed mode, and excess air will be removed from the heating and DHW circuit

Error F.75

Error f75 of the Vailant boiler means that after starting the pump five times, the pressure does not rise, but remains at a level below 50 mbar. How to fix F75 Vaillant error? What to do:

Check water pressure sensor and pump. It is possible that air has entered the heating system.

Check water pressure and expansion tank.

If your Vaillant boiler gives an error, please contact Sunway. We will make an accurate diagnosis and. All work is guaranteed!

Error F22 on the display indicates that the water does not heat up to the temperature indicated in the program. It can occur in the process, and the washing will continue, although you cannot call it of high quality. Most often, the problem with heating is critical, so the machine will stop completely.

If your model does not have a display, pay attention to the RPM lights. In the described case, three will light up at once: 1000, 800 and 600 (or 800, 600 and 400), that is, all but one:. If there is no error, other signs may indicate problems with the temperature regime.

So, the laundry after the end of the program is still dirty or smells unpleasant. It is worth noting that sometimes this case is misdiagnosed, believing that the cold laundry that you take out of the drum after washing is already a problem.But since rinsing always takes place in cold water, there is no reason to panic in this case.

If there is no error, other signs may indicate problems with the temperature regime. So, the laundry after the end of the program is still dirty or smells unpleasant. It is worth noting that sometimes this case is misdiagnosed, believing that the cold laundry that you take out of the drum after washing is already a problem. But since rinsing always takes place in cold water, there is no reason to panic in this case.

VALIANT (Vailant) - Error F.75: after start-up, the boiler does not reach the operating pressure in the system (by 50 bar.), A faulty pressure sensor or circulation pump.

Solution options:

- Restarting the boiler: Reset / Reset is done with a button on the Vaillant boiler panel or by turning off / on the power.

- We feed the system to the required pressure: when the pressure in the system is below the critical value (0.6 bar), the boiler goes into an accident, because. the pump cannot reach a value of 50 bar, we feed it to a minimum value of 1.2 bar (we move the arrow to the green zone).

Fill the circuit by turning the valve counterclockwise on the cold water line, do not forget to return the faucet to its original position (tighten it clockwise), otherwise the relief valve will start to work.

Accumulation of air in the system: during operation of the boiler, gas formation in the circuit is continuous. If the pump or battery air vent is functioning normally, then the gases are discharged in the normal mode, if not, an error appears.

Dirty valve on bypass: The valve has a spring and in case of pollution it does not completely close the channel (half-open position). When the pump starts, the relay does not respond to the surge of pressure, which leads to an error.

Breakdown of the expansion tank: if the tank is not periodically serviced, the pressure in the air chamber is below normal, it becomes one of the reasons for the appearance of such a fault code. gradually loses elasticity, deposits deposited from the system accumulate in the container body. Also, some of this dirt gets into the pump.

Clogged strainer: it is installed in front of the pressure sensor - in order to protect its cavity from sediment.

Malfunctions in the pressure sensor: xot the whole sensor cannot be repaired, it needs to be replaced.

Pump malfunctions:

Presence of voltage at the terminals. If it is not there, you need to assess the condition of the lamellas, wires: breaks, oxidation, short circuits.

Under the cover is a capacitor of 2 or 2.6 microfarads (specify the rating from the inscription on the case). It provides starting current. “Breakdown” or loss of capacity is one of the causes of the f75 Vaillant error (the boiler pump will not start). A characteristic hum will be heard (when voltage is applied to the motor), but the shaft will remain in a static position.

Winding problem. To determine the integrity, you need to measure its resistance: the norm is 275 ohms. The symbol ∞ on the display of the multimeter indicates an open, if it deviates from the nominal value to a smaller side (R<275) - an interturn short circuit, with R=0 - to the case.

Mechanical problems:

- Impeller deformation.

- Layering on it of soft fractions that slow down the rotation.

- shaft oxidation.

Salt deposits are removed by cleaning and washing. The damaged impeller is replaced. In service workshops, the Vaillant boiler pump can be restored to working capacity: they always have second-hand products, and it is not difficult to find a replacement for any part. But it is better to buy a new pump: it is inexpensive.

List of first level problems

To begin with, let's consider what the owner will be able to “fight” on his own, without fear of getting a complete unsuitability of the product and depriving the guarantee.

There are two options in the list of situations available for correction:

- The boiler does not work at all. Those. the device does not heat the coolant if it is a single-circuit model; it does not heat either the coolant or sanitary water if it is a double-circuit model.

- The boiler heats sanitary water, but does not heat the coolant. This problem is peculiar only to two-circuit units.

Both of these positions have a number of completely removable reasons and several solutions that a zealous owner should familiarize himself with. However, before a detailed study of the situation, you should check whether the boiler is connected to the network at all and whether one of the functions is disabled: heating or hot water.

Now let's look at the typical causes and methods for their elimination in case the boiler does not heat up at all:

- The gas valve is closed. Both locking devices installed by the gas workers on the inlet gas pipe must be opened.

- Shut off cold water supply. Solved by opening the shut-off valve on the water pipe.

- Power failures. The heating unit will stop working if there is no power supply. If the electricity supply is restored, the boiler will start itself.

- Temperature set too low. The owner of the boiler corrects the mistake made when making the settings by simply transferring the unit to the required temperature regime.

- Water pressure drop (F22). The coding will report the lack of pressure in the system for the normal operation of the boiler. Its appearance means that it is necessary to bleed the air from the batteries and open the make-up valve located at the bottom of the device.

- Refusal to ignite (F28).If the third attempt to ignite the gas heating equipment did not lead to the desired result, you need to find the failure reset button on the control panel, press it and hold the position for at least a second. Fail again? Call the gasmen.

- Chimney malfunction (F48). This is a signal of an increase in the temperature of the exhaust gases. They could stagnate and overheat due to a clogged external chimney that needs to be cleaned.

Note that the pressure drop is also signaled by display S76. This code is from the boiler status monitoring group. However, to restore work, the same steps will be required as when fixing error F22.

For the sake of his own safety, the health and safety of his household, the owner of the boiler is obliged to monitor the smoke exhaust system. A full-fledged removal of gases is necessary, since the products of blue fuel processing are extremely toxic

For the sake of his own safety, the health and safety of his household, the owner of the boiler is obliged to monitor the smoke exhaust system. A full-fledged removal of gases is necessary, since the products of blue fuel processing are extremely toxic

The second type of violations, determined by the operation of only DHW without heating the coolant, is most often associated with wizard errors made during the settings. You can change the temperature yourself. The manual attached to the boiler describes in detail how to perform this operation.

Main error codes (f28, f75) and their brief explanation

There are a lot of codes for various errors or malfunctions.

Consider the most common of them:

| The code | Decryption |

| F00 | Feed thermistor open circuit |

| F01 | Open circuit of the return line thermistor |

| F02-03 | Opening of the temperature thermistor or drive sensor |

| F04 | Return thermistor open |

| F10 | Supply thermistor short circuit (exceeding 130°) |

| F11, F14 | Return thermistor short circuit (exceeding 130°) |

| F22 | Dry running (pump failure) |

| F23 | Lack of water. Determined by the temperature difference between the direct and return lines |

| F27 | parasitic flame |

| F28 | Ignition lock |

| F29 | Failure in the operating mode (occurs when the flame is attenuated and an unsuccessful attempt to ignite) |

| F35 | Error in the gas outlet |

| F37 | Unstable or abnormal fan speed |

| F72 | Error in the readings of the sensors of the forward and / or return line |

| F75 | The pump is unable to pressurize |

| F76 | Overheating of the primary heat exchanger |

IMPORTANT!

In addition to error codes marked with the letter F, there are status codes marked with the letter S. They inform about the ongoing process and are not errors.

What causes an emergency stop

Chimney

-

Clogging of the channel, blockage - the error f36 of the Vaillant boiler is often associated with this. Ice on the inner walls and head, a layer of dust, debris, cobwebs on the filter grate - the draft is reduced, the heating unit is blocked by an emergency signal.

-

Illiterate project, violation of installation rules. The manufacturer gives comprehensive recommendations on the arrangement of the chimney for the Vailant boiler: pipe section, length of the route and vertical section, elevation above the roof, slope and a number of others. Mismatch of one of the parameters negatively affects traction, initiates blocking of the unit with error f36. During operation, miscalculations appear when the direction of the wind changes, strong gusts (overturning thrust - the boiler “blows out”), precipitation (liquid overflows from the drainage system into the chimney pipe).

-

There is no condensate trap installed in the channel or the location for the storage tank is incorrectly selected.

-

The hood is calculated based on the characteristics of the heating unit, power.Owners who, in order to save money, connect Vailant to a chimney previously installed for another boiler often encounter error f36. The manufacturer also warns about possible malfunctions - only the Vaillant air line / gas outlet (instruction, section 5.5).

Ventilation air supply to the vaillant boiler through the outer wall

-

Violation of tightness. Unreliable knee joints, air leaks impair traction.

-

Damage (lack) of thermal insulation. A drop in temperature reduces the flow rate of volatile combustion products through the channel - the cause of error f36. Removed by chimney insulation.

Tips

-

There are many recommendations on the Internet for solving the problem with code 36 of the Vaillant boiler. Some are helpful and some are downright harmful. Some of the "experts" suggest how to remove the f36 error: replace the temperature sensor with a response limit of t = 65 With a similar device rated at 95 (temperature values \u200b\u200bare indicated on the case). Unprofessional intervention in the design of the Vaillant boiler is prohibited! We are talking about the removal of carbon monoxide from the room. What causes its accumulation in the room due to the delay in the operation of the thermostat, there is no need to explain.

-

The reduction in draft of an atmospheric boiler is caused by an exhaust device operating near it. Technical means of this category must not be used near Atmo series units.

Violation of recommendations for installation of the unit

The instructions set out the requirements for the room and fastening Vaillant. Unprofessional installation of the boiler causes error f36.

The reasons

-

Vaillant power room size mismatch.

-

Increased room temperature.

-

Insufficient natural ventilation. It is easy to make sure by opening the window and door sashes. Additional air flow will remove error f36.

-

Wrong choice of location. A small interval between the Vaillant boiler and surfaces (walls, floors, ceilings), household appliances that emit thermal energy (gas stove) leads to overheating of structural elements. The minimum distances are indicated in the manual. If not sustained, conditions are created for the operation of the temperature sensor, error f36 is displayed.

Heat exchanger fouling

A layer of dust on the body of the device, in the intercostal space, prevents air from entering the Vailant boiler from the room. Traction drops, emergency stop with error f36. It is removed by cleaning the combustion chamber and the surface of the heat exchanger.

Reduced circulation rate

Sensor problem

Other errors inform about a malfunction of the device (AtmoGuard), but the “behavior” of the electronics is unpredictable: anything can happen. Code 36 is caused by a breakdown or incorrect operation of the thrust sensor. In Vailant boilers, the chimney control system is arranged "cunningly". The difference from heating installations of other manufacturers is that 2 sensors monitor the removal of volatile combustion products. Their precise location in the channel guarantees a quick response to the slightest change in flow.

Boiler draft sensor Vaillant

One part of the sensor (sensor) controls the gases leaving the chimney, the other (external) - their penetration into the room. If this is observed, the electronics turns off the supply of "blue fuel" to the burner after two minutes. After 15–20 minutes (when the sensor cools down), the Vaillant boiler automatically starts working. The blocking of the heating unit with the issuance of error f36 occurs on the condition that this situation is repeated 2 more times.

The instructions do not recommend "deep" testing of the sensor. Only the method of checking for operation is described: block the chimney, start the Vaillant boiler.Next, observe the actions of the electronics: emergency shutdown (2 min), re-ignition (15–20).

Types of manufactured boilers

Vailant produces gas and electrical equipment. Electric boilers are limited to one EloBLOCK model in several power options.

Gas appliances are represented by a more diverse assortment.

Among them:

- traditional (throw away part of the useful heat along with smoke);

- condensing (use additional energy of exhaust gases);

- single circuit VU;

- double-circuit VUW;

- atmospheric Atmo (uses air from the room for combustion, standard chimney for exhaust);

- turbocharged Turbo (allows you to arrange an underwater and outlet path through the wall);

- hinged;

- floor.

single circuit

Boilers with one circuit are designed to heat only the heat carrier of the heating system. For water treatment, you can connect an external boiler.

In double-circuit models, water is prepared separately for heating and for household needs.

wall

Mounted boilers are mounted with fasteners on the wall. Save space due to small dimensions. In the wall-mounted design, domestic installations of low and medium power are manufactured.

floor standing

Powerful domestic and industrial boilers are permanently installed on the floor. They have significant weight and dimensions. In some cases, they require a separate room - a boiler room.

How to run self-diagnosis

The self-diagnosis system is a complex of sensors, consisting of NTC elements (thermistors) or software products.

All of them work continuously, monitoring the status of the connected elements from the moment the boiler is turned on.

Therefore, the self-diagnostic system does not need to be launched - it is always on and operates in a constant mode, controlling the operation mode of components and parts, immediately signaling a malfunction.

In the event of an emergency, a special code will appear on the display, indicating the problematic structural element. The user is only required to respond appropriately to the occurrence of an error.