- The most common breakdowns and their causes

- Mitsubishi

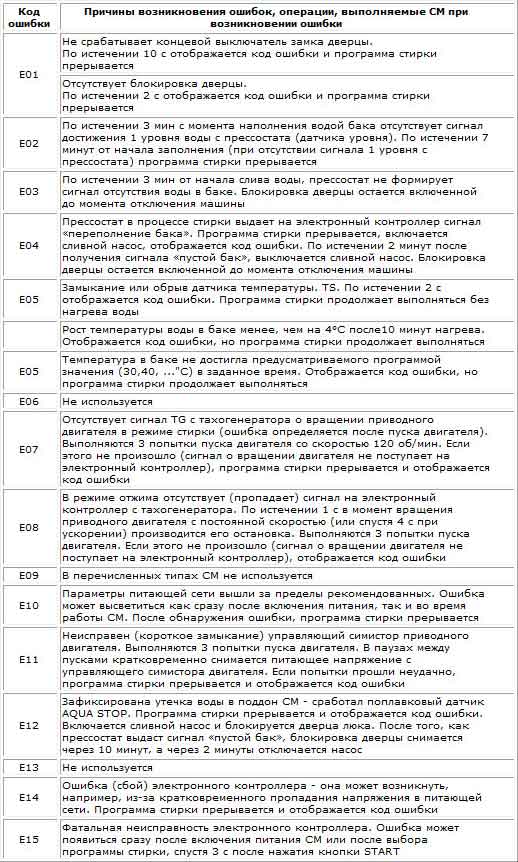

- Codes of the main faults in Zanussi washing machines

- Control panel EWM 1000

- EWM 2000 control panel

- Video

- Changing the blocking device

- Panasonic

- Instructions for the control panel and Vertex air conditioners

- Water heating violation: main failure codes

- Zanussi Fault Codes

- Engine Related Fault Codes

- Fault codes regarding water heating

- Sensor related fault codes

- Other breakdowns

- How to detect a breakdown using indicators?

- Repair of the control module

The most common breakdowns and their causes

Specialists of service centers have been repairing Zanussi washing appliances for many years. During this time, enough information has accumulated to provide statistics on common failures of CMs of this brand and the causes leading to breakdowns:

- Unreliable drive belts that stretch and slip in the pulley over time, causing the drum to spin slowly. It is possible to stop the drum due to a belt that has flown off the pulley.

- Hatch blocking devices (hereinafter also - UBL, lock) are not of high quality. A lot of Zanussi SM repairs are connected with this breakdown.

- Tubular electric heaters (hereinafter also referred to as heating elements) are not designed to work with hard water, therefore they quickly become covered with scale and burn out from overheating.

In addition to the manufacturer's shortcomings, there are problems in operation that are common to SM of all brands, including units with both front and top loading:

- Blockages in the water drain system, as a result of which the machines do not spin the laundry well and do not completely drain the water from the tank.

- Rapid wear of parts due to contact with hard and contaminated water. Dirty and rusty water from the water supply clogs the inlet filters, disrupting the performance of the AFM.

The main causes of breakdowns of Zanussi washing machines are violation of the rules of operation and hard water in the plumbing

The main causes of breakdowns of Zanussi washing machines are violation of the rules of operation and hard water in the plumbing

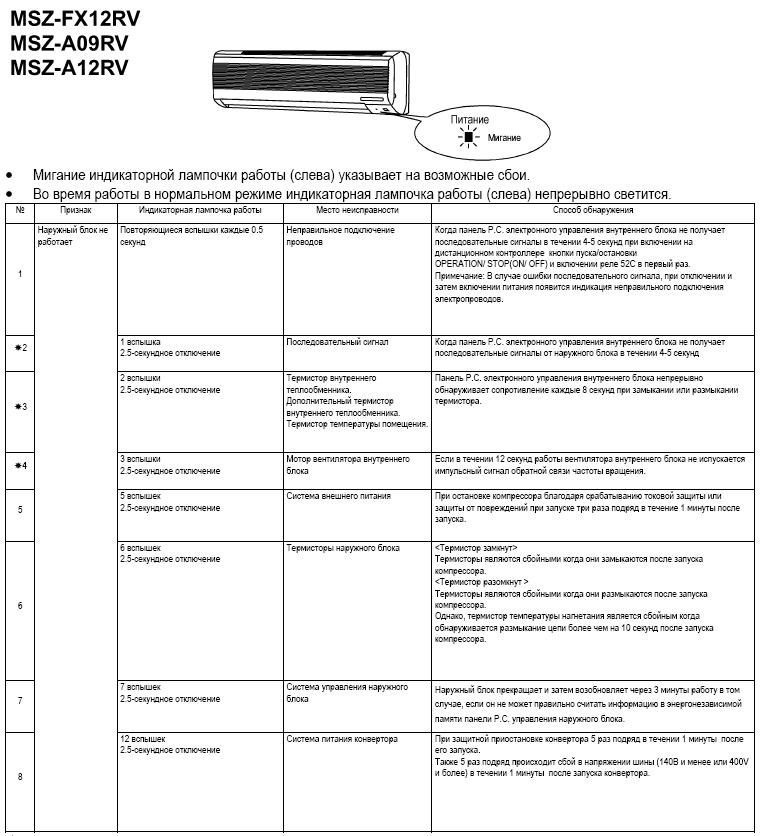

Mitsubishi

What a specific air conditioner error means depends directly on which series the selected equipment belongs to.

At Mitsubishi Electric, the code that appears shows:

- E0, E36 problems with the control panel;

- E1, E2: problems with the control board;

- E9, EE: lost communication between indoor and outdoor air conditioning units;

- Fb: failed board that controls the capacitor;

- P2: failure of the sensor controlling the heat exchanger TH5;

- P5: pump failure drainage;

- P6: overheating or freezing of equipment;

- P9: incorrectness of the sensor controlling the heat exchanger TH2;

- U1, Ud: equipment overheating or pressure increase;

- U2: little refrigerant in the refrigerant circuit;

- U3, U4: problems with the capacitor temperature sensor, short circuit;

- U5: Conder temperature does not match the set parameters;

- U6: problems with the power module, forced blocking of the compressor;

- U7: insufficient refrigerant;

- U8: condenser fan stopped;

- U9, UH: insufficient or excessive voltage in the power supply system, the current sensor is faulty;

- UF: compressor stuck;

- UP: the compressor has stopped.

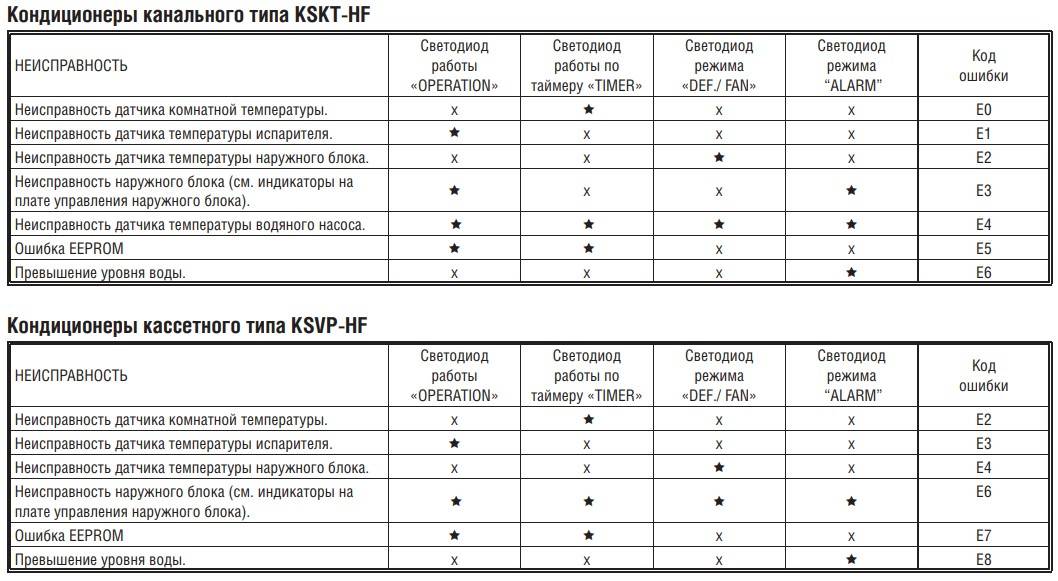

At Mitsubishi Heavy air conditioner errors are somewhat different:

- E1: problems with the control panel, incorrect operation of the evaporator board;

- E32: open connection, incorrect phase connection;

- E35: the temperature of the condenser has increased or the temperature sensor is faulty;

- E36: the air leaving the air conditioner is heated above the value set by the user;

- E37: capacitor temperature sensor is defective;

- E39: problems with the temperature sensor of the discharge pipe;

- E5: capacitor control board is defective;

- E54: low pressure sensor connection required;

- E57: coolant level below the set value;

- E59: it is impossible to start the compressor;

- E6: the evaporator sensor does not work;

- E60: compressor position adjustment required;

- E63: the evaporator has crashed;

- E7: evaporator sensor does not work;

- E8: evaporator overloaded;

- E9: The drain pump does not work.

Codes of the main faults in Zanussi washing machines

Modern SMs have a self-diagnostic system that allows you to quickly localize a breakdown. Error codes for Zanussi washing machines are displayed on the displays as an alphanumeric combination. The first character is the Latin letter "E", followed by a code of two digits or a letter and one digit. The same fault codes are used in ACM brands Electrolux and AEG. The main malfunctions and their corresponding designations are listed below.

| The code | Malfunction |

| E10, E11 | Water does not enter the tank or flows slowly. The cause may be a clogged strainer at the inlet valve inlet, low water pressure in the water supply, or damage to the valve that lets water into the tank. |

| E20, E21 | The liquid does not drain from the tank after washing.Possible causes - breakdown of the drain pump, clogged drain filter, malfunction of the electronic control unit (hereinafter also - ECU) |

| EF1 | blockage drain filter or hose, the liquid drains slowly from the tank |

| EF4 | There is no signal from the sensor that fixes the flow of water when the inlet valve is open. Causes - low water pressure in the water supply, clogging of the inlet strainer |

| EA3 | The processor does not detect the rotation of the motor pulley. One reason could be a broken drive belt. |

| E61 | The heating element does not heat water during the set time. Most often, the malfunction is associated with the formation of a layer of scale on the heater. |

| E69 | The heater is not working. Possible causes - malfunction of the heater, an open in the circuit supplying voltage to the heating element |

| E40 | The hatch is not closed. Possible cause - a malfunction of the hatch door lock |

| E41 | The hatch door is not tightly closed |

| E42 | out of order sunroof locking device |

| E43 | On the ECU board, the triac that controls the operation of the UBL is damaged |

| E44 | Sunroof closing sensor does not work. Perhaps the sensor or the lock blocking the sunroof is faulty |

Under the Zanussi brand, a wide range of models are produced that do not have a display, for example, FL 504 NN, ZWP 581 (CM with top load), ZWS 382, ZWS 3102, FE 802, FA 832, CM series Aquacycle and many others. Error codes in such units are determined by indicators. Deciphering faults is not so easy, because in such CMs there are several types of controllers, and each of them displays codes in its own way.

Control panel EWM 1000

Such control panels have a horizontal or vertical arrangement of buttons.

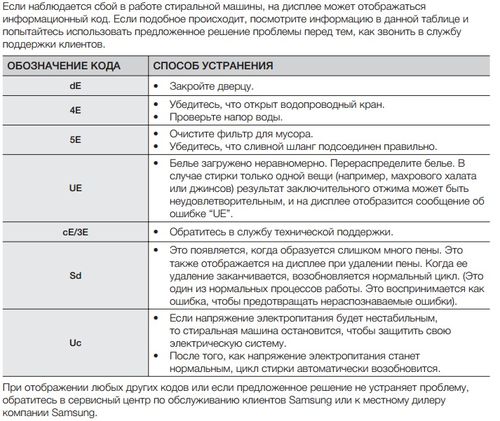

EWM 1000 with horizontal buttons

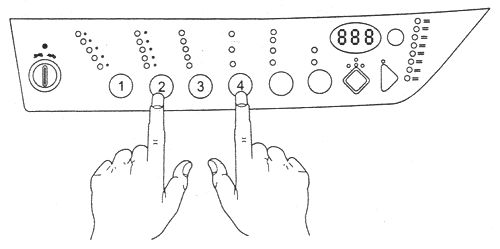

Panel EWM 1000 with vertical buttons

Panel EWM 1000 with vertical buttons

The error code is calculated by the number of flashes of two indicators: "End of program" displays the first digit of the code, and "Start / Pause" - the second digit (according to the table above). The letter "E" is not reflected as it is present in all codes.

Letters A (10 flashes) to F (15 flashes) are displayed according to the hexadecimal code. The pause between flashes is about 0.5 sec. The cycle repeats after 2.5 seconds.

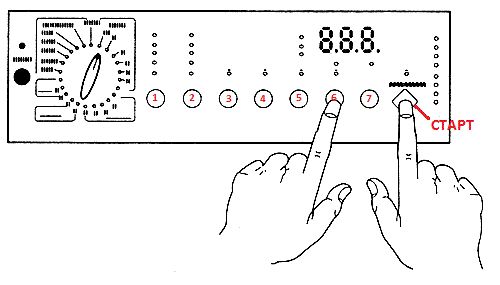

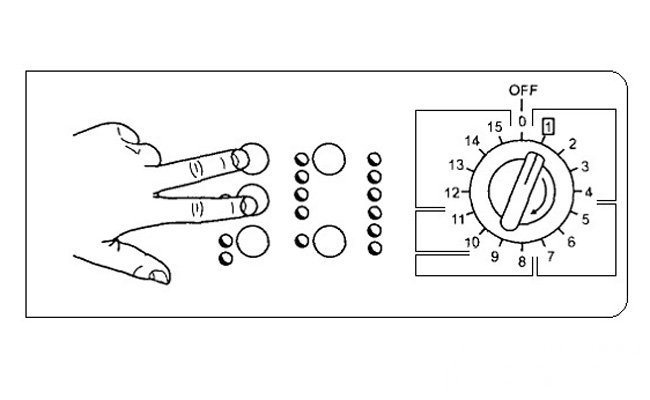

EWM 2000 control panel

Such a controller is installed, for example, in the popular CM Aquacycle 900 model.

Error E41 displayed by the indicators on the EWM 2000 control panel

4 lights at the top display the first digit of the code, 4 at the bottom - the second digit. Each indicator has its own value, increasing from the lower LED to the upper one: 1, 2, 4, 8. When they are added, the final figure is obtained. Values greater than 9 correspond to the letters of the hexadecimal code: for example, the number 15 corresponds to F.

Video

Diagnostics faults and error codes washing machines Zanussi and Electrolux:

The procedure for disassembling the Zanussi washing machine to replace the drum bearings:

About the author:

Found an error? Select the text with the mouse and click:

Do you know that:

The threads of gold and silver, with which clothes were embroidered in the old days, are called gimp. To obtain them, the metal wire was pulled for a long time with tongs to the state of the required fineness. This is where the expression “pull (raise) the gimp” came from - “engage in long monotonous work” or “delay the execution of the case”.

Changing the blocking device

However, an error under the E40 code does not always indicate serious problems with the machine's components. Therefore, do not enter the diagnostic mode immediately after the display shows an error.First, press the hatch door with your knee, gently, but quite strongly. In some cases, after such actions, the machine starts to work normally. However, if this does not help, diagnose the error using the above method, or check the malfunction of the machine parts yourself. It is best to start with UBL.

- Open the door and remove the clamp from the elastic of the hatch - the cuff.

- The lock is attached to the door with special bolts, they are clearly visible from the outside, unscrew them.

- Get the lock.

- Check all pins (pins 3 and 4 are closed and pins 4 and 5 are open).

- Install a new lock, carefully freeing the old one from the wires

- Return the clamp to its original position.

- Turn on the wash mode to check the operation of the machine.

If everything is working properly, then you have completed the task and now you know what to do and how to fix the problem that has arisen. Error E40 can occur at any time, and the fact that you know how to act in this situation will save you a lot of time.

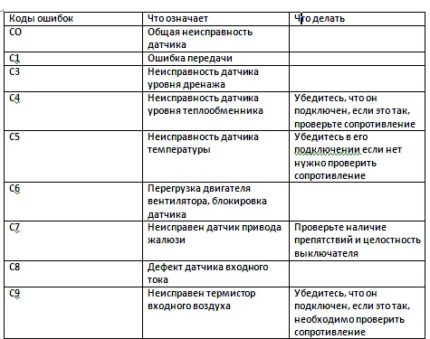

Panasonic

Panasonic air conditioner error codes are labeled differently. The manufacturer purposefully divided them into several groups, which allows you to determine the place where the problem occurs.

In some cases, the symbol "F" is present in the marking of the codes:

- F11: four-way valve signal is incorrect;

- F17: frost on the air conditioner inside;

- F90, F93: damage to the compressor winding;

- F94: Supercharger pressure exceeded.

Also, error codes for Panasonic air conditioners are marked with the symbol "H":

- H00: System OK, no intervention required

- H11: no relationship between blocks;

- H12: the capacities of air conditioner units installed inside and outside have different numerical value;

- H14, H15: problems with air sensors and controlling the degree of heating of the compressor;

- H16: not enough freon in the units placed outside;

- H17: breakage of the temperature sensor on the tube used to evaporate freon or another substance with similar properties;

- H19: board failure;

- H23, H24: breakage of the evaporator temperature sensors;

- H25, H26: malfunction, ionizer failure;

- H27, H28, H30, H32, H34: short circuit of thermal sensors outside, on the condenser, of the module heatsink;

- H33: problems in the joints of the air conditioner units;

- H35: pump failure, drain blockage;

- H36: closed the gas pipe temperature sensor;

- H38: impossibility of joint functioning of modules installed inside and outside;

- H39, H41: wiring incorrectly assembled, solenoid valve defective;

- H51: Nozzle clogged.

Instructions for the control panel and Vertex air conditioners

The simplest, window, air conditioners do not have remote controls and the setting of operating modes is carried out directly on the device unit. More complex models have two control options: a remote control for the air conditioner and a minimum control on the indoor unit. Additionally, some models can be controlled via Wi-Fi.

Control panels for climate control equipment are universalized. Modes not supported by this model will not be available on the remote control. On all types of consoles, an intuitive choice of the main operating modes:

- Cooling (COOL);

- Heating (HEAT);

- Ventilation (FAN);

- Dehumidification (DRY);

- Automatic (AUTO).

In addition to them, in each model, operating modes specific to this equipment can be added. The manual for air conditioners contains a detailed description of all modes of operation and their setting from the remote control. Due to possible significant differences between models, remotes and instructions from different models may not be suitable.The buttons on the indoor units allow you to turn on / off the equipment to the already configured operating modes. They also have an indicator that displays error codes for air conditioners.

Water heating violation: main failure codes

| The code | Explanation | Cause |

| E61 | During the allotted time, the water was not heated to the desired temperature mark. | To remove error E61, eliminate the cause of the breakdown - heater failure. To do this, check the resistance with a tester. A working heating element in the Zanussi washer will show 30 ohms. |

| E62 | Error value E62 - water overheating. In 5 minutes, the water temperature jumps to 90 degrees. | The cause of the breakdown may be a breakdown of the heating element on the body. In this case, when measuring the resistance of the heater, a good element will show from 5.7 to 6.3 ohms. |

| E66, E3A | With codes E66 and E3A, the heater relay may fail. | Damage to the heater, contacts, control board is possible. |

| E68 | The machine shows the code E68 on the display when the ground in the heating element circuit is activated. | |

| E69 | With E69, it is possible to diagnose a complete breakdown of the heating element. |

Zanussi Fault Codes

When the dishwasher is blocking work, or you notice that the machine is malfunctioning, it is difficult to immediately determine what is wrong. You can disassemble the equipment and inspect all the nodes, but this will take a lot of time. Therefore, the PMM electronic module is equipped with a self-diagnosis system.

If the error appeared on the display for the first time, do not rush to call the service. It could just be a system failure after a power outage.

You can eliminate the failure by rebooting the machine. If the code disappears, then there is nothing to worry about, continue to operate as before.But if it appeared again, then look for the decryption and start repairing the PMM.

How to reload:

- Disconnect the machine from the power supply;

- Wait 10-15 minutes;

- Reconnect.

The values for all Zanussi errors are collected in our table. You will also find possible solutions to the problem in it.

| Error code | Number of blinks of the END indicator | What means? | Reasons for the appearance | DIY repair |

| i10 | 1 | No water is taken into the hopper. | During the allotted time, the water level did not reach the norm:

| Check for water in the line. If the pressure is ok:

|

| i20 | 2 | Waste fluid does not leave the tank. |

| How to fix:

|

| i30 | 3 | Overflow in the system. The Aquastop protection worked. |

| Look carefully:

|

| i50 | 5 | Closed the control triac of the engine. | The circulation pump runs at an uncontrolled speed. Short circuit triac. | Electronic board repair. Contact the service center. |

| i60 | 6 | Underheating or overheating of water in the tank. |

| What to do:

|

| i70 | 7 | The temperature sensor circuit has broken or shorted. | This happens during power surges in the network. | Installation of the correct part. |

| i80 | 8 | Lost connection to external EEPROM memory. | Broken wiring, violation of the control board. | Call the master. |

| i90 | 9 | Software problem. | Management problems. | |

| iA0 | 10 | Spray gun does not rotate. | The item is blocked by something. | Check that the dishes do not block the rotation of the rocker. Remove foreign objects. |

| ib0 | 11 | Meaning: The turbidity sensor has failed. | Damage to the sensor, its wiring or control element on the board. | Installation of new elements. |

| iC0 | 12 | There is no contact with the user interface. | Open circuit, violation of control. | Contacting a service center. |

| id0 | 13 | No connection to Hall sensor. | Damaged wiring. The tachogenerator, which controls the engine speed, is broken. | Replacing the tachometer or its wiring. |

| iF0 | 14 | Which means: incorrect water intake time. | Usually, after draining the liquid, the code is reset. What could have happened:

| What to do:

|

Zanussi dishwasher breakdown codes will help you determine the location of the problem. Now you can safely call the master, having understood what exactly needs to be repaired. Some problems are easily fixable with your own hands. To prevent damage, clean the PMM filters at least once a week, use high-quality washing powders.

Badly

1

Interesting

2

Super

Engine Related Fault Codes

E51 - poor contact of the triac of the electric motor.

E52 - information is not received from the motor tachometer to the electronic board. Most often, in such situations, the washer that holds the tachometer flies off.

E53 - on the electronic board, the circuit that controls the triac of the electric motor is interrupted.

E54 - the relay contacts are stuck together, providing the reverse of the electric motor.

E55 - the engine electrical circuit is broken.

E56 - the tachometer signal does not appear for a long time.

E57 - the system current is more than 15A, the cause is a breakdown of the motor or electronic board.

E58 - the phase current of the electric motor is more than 4.5A, the reason is the breakdown of the motor or the electronic board.

E59 - 3 seconds there is no signal from the tachometer, this may indicate a breakdown in the wiring between the motor and the inverter element, a breakdown of the inverter board.

EA3 - DSP system does not fix the motor pulley. Need to check:

- drive belt;

- DSP system;

- electrical wiring;

- fee.

Fault codes regarding water heating

E61 - the machine does not heat water to the selected temperature in the set time. With such an error, the resistance of the heating element is checked, which is 30 ohms.

- E62 - water heats up very quickly and after 5 minutes has a temperature of almost 90C.In this situation, the heating element is checked for breakdown, the resistance of the heating element is measured, which under normal conditions varies from 5.7 to 6.3 ohms.

- E66, E3A - breakdown of the heating element relay.

- E68 - grounding in the heating element circuit has worked.

- E69 - heating element does not work.

Sensor related fault codes

E31 - the water pressure switch has broken. With such an error, change the wiring or the relay itself.

E32 - fluctuations in the frequencies of the sensor responsible for water pressure. This most often occurs due to:

- blocked water supply;

- filling valve malfunctions;

- drain filter clogged with debris;

- broken water level sensor tube;

- faulty pressure switch.

E33 - the sensor that determines the amount of water and the sensor that prevents the heating element from turning on "dry" are not synchronized. Check required:

- operability of sensors;

- serviceability of tubes;

- voltage leakage to earth;

- whether the mains voltage is exceeded.

E34 - this error is displayed for about a minute and notifies of the inconsistent operation of the anti-boiling sensor and the pressure switch.

E35 - too much water is poured into the tank, check the pressure switch.

E36 - ABS heating element protection sensor does not work.

E37 - L1S sensor does not work.

E38 - the tube leading from the tank to the pressure switch is clogged, so there is no fixation of the pressure difference.

E39 - the sensor that protects against water overflow HV1S does not work.

E44 - the hatch door closing sensor does not work.

E71 - the resistance of the temperature sensor does not correspond to the limits of the norm.

E74 - the location of the temperature sensor has gone astray.

EC2 - the sensor that determines the turbidity of the water does not work.

EF4- no signal from flow sensor when the filling valve is on. It is possible that there is no pressure in the water supply.

Other breakdowns

- There are two ways to decrypt this code. First, the door is not closed. The second - the door lock broke.The designation of this error code E40 is now very rare. Usually other codes are used.

- The door does not close tightly enough.

- For some reason, the lock didn't work.

- The Zanussi washing machine is not set correctly. In this case, the correct program will help correct the situation.

- Error in setting wash modes.

- Too much foam has formed in the drum or the drain hose is clogged.

- There is a leak inside the device.

- The spinning process does not start due to a large amount of laundry in the drum.

How to detect a breakdown using indicators?

To do this, you need to find out which module the device is running under:

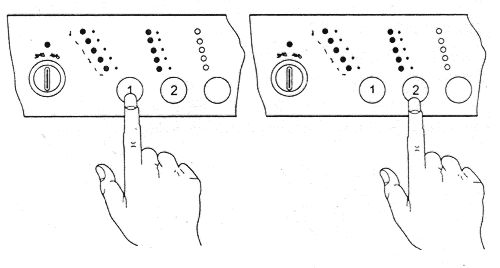

- If it is EWM1000, then the error codes of washing machines without a display are determined by how the start / pause indicator and the end of washing indicator flash. The end indicator shows the first digit of the code, and the start indicator shows the second. For example, the finish indicator blinked 4 times, and the start indicator blinked 3 times. This means that there is a breakdown with the code

- If the device is controlled by the EWM2000 module, such as the Zanussi FE 1024 n washing machine, you need to monitor the eight indicators located on the control panel. The top four are the first digit of the code, and the bottom four are the second. To translate the indicators into understandable notation, you will have to use a special table.

What should I do if the Zanussi washing machine error codes flash? First of all, find out what kind of breakdown occurred. Perhaps the door (E40) simply did not close, or out of order water supply or drain system (E10, E20). All error codes are the same for devices of any modification. The only difference is how they are fed: to the display or to the control panel (indicators), as, for example, in the FE904 or FE 1024n models.

Repair of the control module

Removing the electronic board on Zanussi washing machines is not difficult - you just need to disconnect either the front panel or the top one, depending on the model. Having reached the module, it can be easily removed.

- the board shows signs of burning, scorching or blackout;

- the varnish coating on the damping coils has a damaged appearance (burnout, microcracks, etc.);

- the heads of the capacitors are swollen or torn at the place of the cross notch;

- the legs of the microcircuit are not identical to each other in appearance, color, shape, etc. this indicates the presence of damage;

- the place of installation of the processor darkened.

In these cases, you will have to consult a specialist to fix the problem, unless you are a professional solderer, since it is unlikely that you can do without re-soldering some elements.

If voltage drops in your apartment are not uncommon, there are two ways to minimize damage. The most reliable is to buy and install a voltage stabilizer by connecting the CM and / or other devices to it. The second is to disconnect the machine from the network if possible. If at the moment it does not erase, and the jump occurs, this does not affect the device in any way.