- Care requirements

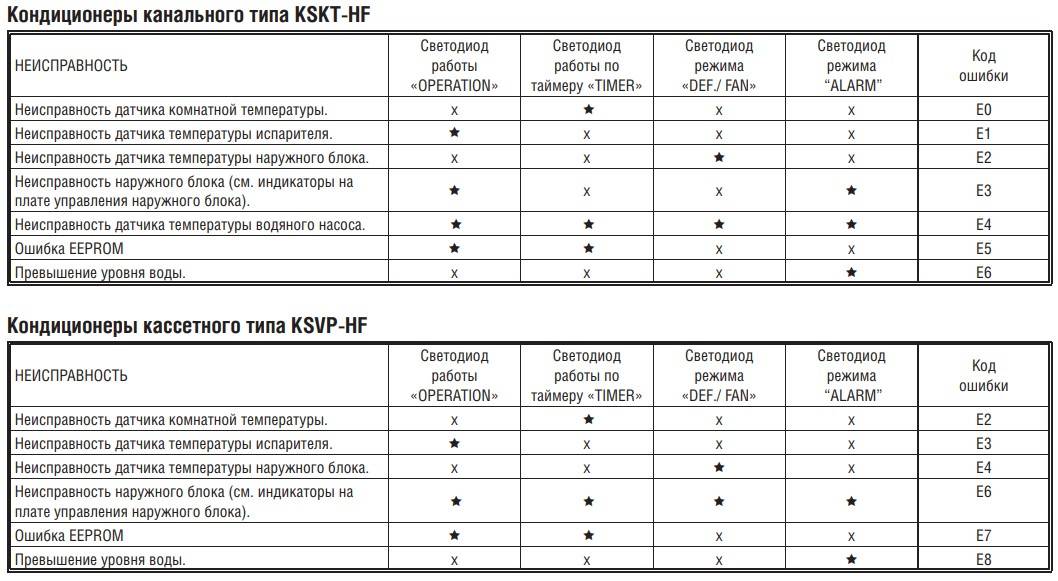

- How do malfunctions of Panasonic climate systems differ?

- How to determine what happened and what malfunctions require attention

- Microwave, error 5E or SE. Who had?

- Error codes for climate technology

- Errors on the indicator of the air conditioner (E)

- How to troubleshoot on your own?

- Deciphering breakdowns for Samsung washing machines without a display

- Water does not fill (4E, 4C, E1)

- Does not drain (5E, 5C, E2)

- Too much water (0E, OF, OC, E3)

- Imbalance (UE, UB, E4)

- Does not heat up (HE, HC, E5, E6)

- Sunroof lock not working (DE, DC, ED)

- Level sensor does not perform a function (1E, 1C, E7)

- Temperature above required (4C2)

- Water at the bottom of the unit (LE, LC, E9)

- Panel buttons do not respond (BE)

- No signal from temperature sensor (TE, TC, EC)

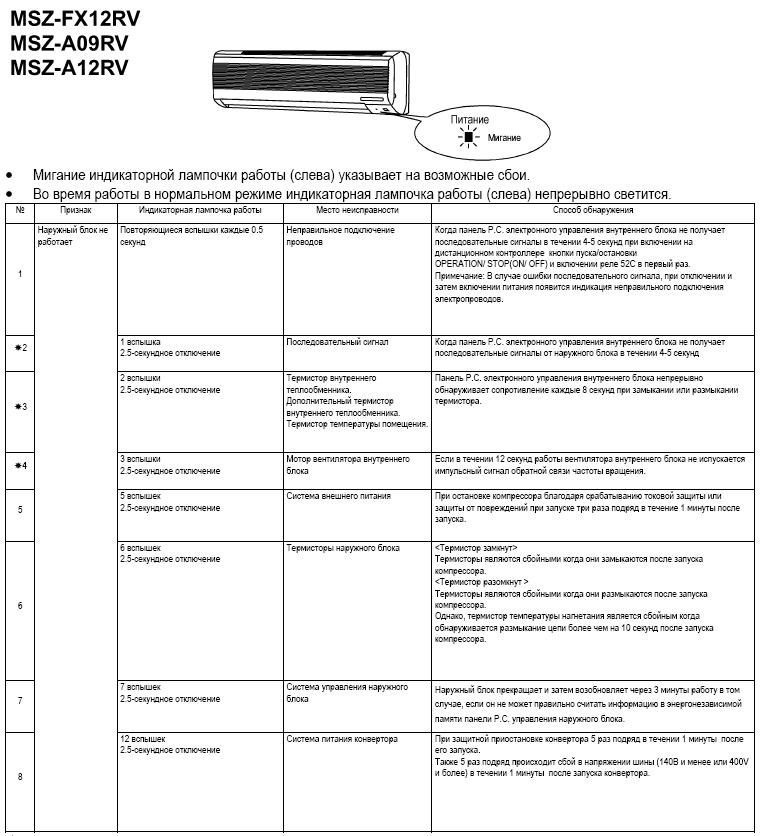

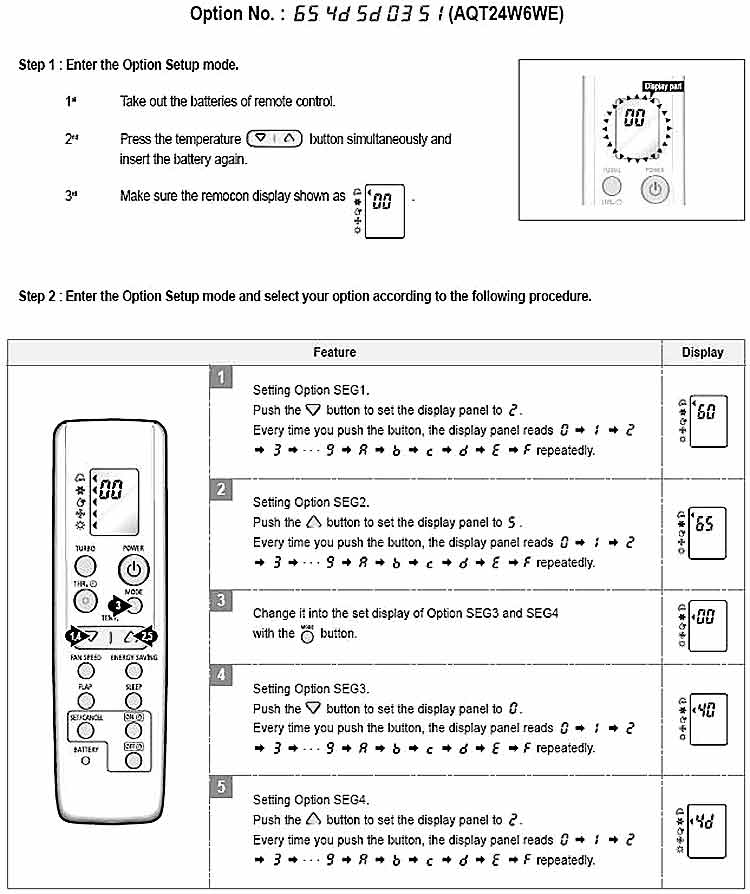

- Technical problems with the air conditioner

- About major faults

- In case of poor cooling in the room

- Short cycle unit

- Condensate leakage from the indoor unit

- DIY troubleshooting

- Split system stopped working

- Insufficient cooling or heating

- Disruptions in work for various reasons

- Decoding error codes

- Deciphering the codes responsible for the malfunction of the sensor system

- How to disassemble the microwave magnetron and replace it yourself

- Cap replacement

- Capacitor replacement

- How to replace the magnetron in the microwave yourself

- Water leak occurs (E9, LC, LE1 and LE)

- Self Service Safety Precautions

- Error codes and solutions

- Conclusions and useful video on the topic

Care requirements

Air Purifying Bacteria and Virus Killing System

The instruction manual for the air conditioner describes the periodic maintenance procedures for the Panasonic product. This is a critical piece of documentation that needs to be studied just as carefully as operating mode management.

Repairs and spare parts to restore functionality and troubleshooting can be very expensive. Therefore, maintenance in compliance with all manufacturer's requirements is critical for Panasonic equipment.

Some maintenance procedures do not take much time, while others require partial disassembly indoor or outdoor unitfor which it is better to use the help of a qualified specialist.

How do malfunctions of Panasonic climate systems differ?

Problems and malfunctions of climate technology, which are signaled by a timer and a flashing light, can be divided into large groups. A short list looks like this:

- malfunctions in the air conditioning system;

- the device does not turn on, because a signal is received from control sensors that record the parameters going out of safe limits;

- the blocking of work is caused by the indoor or outdoor unit;

- there are malfunctions in the electronic control system.

How to determine what happened and what malfunctions require attention

If the air conditioner does not turn on and the signal light flashes, it is necessary to determine the nature of the malfunction.This requires reading and deciphering the corresponding code returned by the device's control system. Panasonic air conditioner error codes can be determined in the following ways, depending on the model marking and its design features:

- a device equipped with a screen displays the fault code on its own. At the same time, the internal timer periodically triggers a re-diagnosis;

- model without digital indicator and test button on the remote control requires pressing the UP button on the timer setting panel, then on the remote control on the indicator it is easy to parse the error code. You just need to scroll through the list, if the block error matches the code on the remote control, the device will emit a beep;

- in the case when the control panel has a test button (it looks like a hole), it must be pressed and held. When the first error code appears on the screen, you need to scroll through the list. When the displayed error, the code of which is easy to understand, matches the contents of the unit's memory, the air conditioner will emit a long beep or a series of short ones.

The location of the check button in the recess on the remote management

It is extremely rare, but there are problems when the control relay of the warning system fails and it is not possible to determine the error code of the unit and the spare parts to be replaced. In this case, you should immediately seek qualified help.

It should be remembered that the control and monitoring system is present in two parts of the air conditioner. Therefore, if there is a problem, you should “interrogate” both the indoor and outdoor units and determine the corresponding error code and the required repair.

Microwave, error 5E or SE. Who had?

A microwave is as common a household appliance as a refrigerator or stove.

If you're thinking about buying one, look no further than the Samsung Microwave Oven, which combines innovation, proven technology and a well-known brand reputation. And in case of a breakdown, the masters of Rembytservis will help you with ease! You can contact us for help by calling 8 We have 3 permanent reception points: st.

South 8, st. Severnaya Pravda 41a, st. Pushkin

When connected to the network and choosing to work in microwave mode, it gives an error 5E, the fuses are intact, the blocking circuits rang.

Error codes for climate technology

The usual error codes on the TCL split system have a standard form. At the beginning of the code is the letter E, followed by a number or a Latin letter.

These combinations mean:

- E0 - code indicating the lack of communication between the indoor and outdoor units (to correct the problem, check the interconnection, as well as the boards of the outdoor and indoor units);

- E2 - indication of a malfunction of the evaporator temperature sensor;

- E3 - condenser temperature sensor error code;

- E4 - general indicator of system failure;

- E5 - the indicator indicates a type mismatch;

- E6 - error code of the air conditioning indoor unit;

- E7 - a combination indicating problems with the temperature sensor of the outdoor unit;

- E8 - error code of the compressor discharge temperature sensor;

- E9 - inverter board failure indicator;

- EF - indication indicating problems with the indoor unit fan motor;

- EA - an indicator of problems with the current sensor;

- EE - firmware fault code;

- EP - indication of problems with the compressor shutdown thermostat;

- EU - a combination of voltage sensor faults;

- EH is the error code for the temperature indicator of the suction pipe.

Emergency stop error codes have other designations. At the beginning of the code is the Latin letter P, followed by a number.

These indicators include:

- P1 - indicator of low or high voltage;

- P2 - code indicating problems with overcurrent protection;

- P4 - indication of errors in protection against exhaust overheating;

- P5 - an indicator of problems with hypothermia protection in cooling mode;

- P6 - code of problems of protection against overheating in cooling mode;

- P7 - indication of errors of protection against overheating in heating mode;

- P8 - indicator of open overheating or overcooling protection;

- P9 - code indicating a problem in the protection of the drive (within the framework of program control);

- P0 – module protection error indicator (hardware control).

The error code is a hint. It indicates the direction of the search for the problem. If you know what exactly this or that combination means, you can determine in advance whether you should contact the service center or there is no need for this.

Errors on the indicator of the air conditioner (E)

Error E0 air conditioner Gree means insufficiently high starting voltage. That is, most likely, “in the socket” there is simply insufficient voltage. For an air conditioner, this is potentially dangerous, since prolonged exposure to inrush currents on its electrical network can cause overheating, which will “burn” the wiring insulation, and then the electrical appliance itself.

If the matter is “in the socket”, then the problem is solved by purchasing a voltage stabilizer, which will bring the voltage to the required 220V.

But it is possible that the matter is in the wiring of the air conditioner itself. Therefore, if the mains voltage is 220V, but the air conditioner still gives an E0 error, then you need to check it.

Connecting both units of the split system to the power line is not so simple. Incorrect connection will almost certainly cause errors and malfunctions.

Error E1 is a shutdown to protect the compressor from too high pressure. Error E3 means that too low pressure is applied to the compressor.

Sometimes, to eliminate E1, it is enough to wash the air conditioner air condenser well. If it is not blown enough, then this leads to an increase in freon pressure. If the air conditioner has a water condenser, the water supply must be checked. Another possible reason is an excess of freon itself or an unadjusted thermostatic valve.

Just in case, you should immediately check the valve. It should at least be open. If visually everything is normal, then you will have to call the master to adjust the contour. On your own, besides, without skills and a pressure gauge, it is unlikely that you can adjust the valve (you may also have to adjust the discharge valve) and refill freon according to the scales.

Most errors on the indicator of work are associated with the protection of the compressor - one of the most important components of the air conditioner

Too low pressure in the circuit can occur if the evaporator, fan or filter is dirty. That is, the algorithm of actions is exactly the same. First, dirt is removed, and then the contour is adjusted. It is also necessary to check the tightness of the rolling joints. If traces of oil are visible on them, then the mixture is leaking.

Error E2 means that the indoor unit of the air conditioner may start to freeze or is already frosting over.

Using this error as an example, we can explain the general principle of diagnosing problems associated with the compressor (E1-E5):

- Some kind of sensor is triggered, warning of a problem.

- We remove contaminants that can cause temperature extremes. Check the fan impeller. Is the console still giving an error?

- Most likely, the problem is in the level of freon, loosely rolled copper pipes are leaking, the thermostatic valve or pressure valve is incorrectly adjusted.

If so, then most likely you will have to call the wizard. Since we are talking about either an initially incorrect installation of the air conditioner (you will have to turn the pipes and refill the air conditioner with freon), or more serious problems that require replacement of components.

The same principle solves problems E5 (activation of the compressor overload protection sensor) and E4 (activation of the compressor discharge tube protection sensor from overheating).

Error E6 indicates that there is no phase, that is, it is necessary to reconnect the switching. It is also necessary to check the commutations with an error H6. By acting consistently and slowly, you can find a problem in the electrical circuit.

Error E7 - a contradiction in the specified modes, typical for multi-split systems. One block of the multi-split system is set to a mode that contradicts another block of the same system. The air conditioner, to put it simply, is confused.

Error E8 means that the indoor unit motor sensor indicates evaporator overheating. Again, it is necessary to check the thermostatic valve and the pressure valve. If they are in order, then it is possible that the freon simply ends in the evaporator. Or maybe the evaporator tubes are clogged.

Adjusting the circuit with a thermostatic expansion valve and a pressure valve is a delicate job that requires care and accuracy. Read the pressure gauge carefully.

E8 error shutdown protects against too cold air in heating mode. Cold air can cause liquid to build up which, if it enters the compressor, will almost certainly damage it.

And finally, the F0 error means that the pressure sensor is broken. Most likely, they are.

How to troubleshoot on your own?

Seeing the H1 error on the display, you do not need to immediately call the master. You can try to deal with the problem on your own.

However, you should not rely too much on success, since this code most often indicates a breakdown that requires the help of a professional.

You can try to fix the problem in the following ways:

- Check the reliability of the connection of the unit to the network. You need to make sure that the cord and plug are not damaged. If the machine is connected through an extension cord or adapter, it is necessary to evaluate their performance.

- If the code is displayed for the first time, you need to disconnect the device from the power source. After 10 minutes, it is connected and the result is evaluated. This measure helps in the event that a failure has occurred in the control module.

- Check if the wires from the heating element to the control module are securely connected. This is especially true in the case when the device was previously disassembled in order to repair other parts. It is possible that the contacts were hurt and they just need to be corrected.

A step-by-step algorithm for gaining access to the heating element and performing self-diagnostics of its performance:

- Disconnect the device from the mains.

- Remove the front cover and remove the protective cover from the heating element.

- Inspect the heating element for damage. Sometimes oxidized contacts are visible, their unreliable fastening.

- If the house has a multimeter, it is used for self-diagnosis.

- After disconnecting the wires, you need to measure the resistance. When the number 1 appears on the multimeter screen, we can assume that the problem has been found (the heating element has burned out). If the indicators remain at the level of 28-30 ohms, then the part is in working order.

- In a similar way, measure the resistance level on the wires.

- Once the problem is found, simple repairs can be made. They buy a serviceable part in the store, unscrew the broken heater, clean its seat and contacts, and then install a new heating element. It remains to tighten the nuts, connect the wires and continue to use the washing machine.

If the above actions did not help to cope with the problem, then you need to contact a specialist.

Deciphering breakdowns for Samsung washing machines without a display

washing machine without display cannot give an alphanumeric signal to the owner, this function is performed by lit LEDs.

To recognize what prevents the unit from working in the usual mode, the table for various Samsung models will help, in which the burning indicators are marked with *:

| S821XX / S621XX | The code | Problem | R1031GWS/YLR, R831GWS/YLR | ||||||

| Bio 60℃ | 60℃ | 40℃ | Cold | 95℃ | 60℃ | 40℃ | 30℃ | ||

| * | 4E 4C E1 | Water is not collected | * | ||||||

| * | 5E 5C E2 | Doesn't drain | * | ||||||

| * | * | HE HC E5 E6 | Does not heat up | * | * | ||||

| * | * | * | * | ||||||

| * | 4C2CE | Hot (above 50℃) | * | ||||||

| * | * | LE LC E9 | Leaking | * | * | ||||

| * | * | OE OF OC E3 | In excess | * | * | ||||

| * | UE UB E4 | Imbalance | * | ||||||

| * | * | * | * | DE DC ED | Hatch lock | * | * | * | * |

| * | * | * | 1E 1C E7 | Pressure switch malfunction | * | * | * | ||

| * | * | — | Tachogenerator | * | * | ||||

| * | * | TE TC EC | temperature sensor | * | * | ||||

| * | * | * | BE | Panel buttons | * | * | * |

Instructions for a specific model will help you fix problems on your own Samsung washing machine.

Not all problems can be fixed with your own hands, so it is important to contact the repair shop in a timely manner.

Water does not fill (4E, 4C, E1)

The error is accompanied by a stop of the washing machine during washing or rinsing. Possible reasons:

- There is no cold water in the system.

- Weak pressure.

- The water supply valve to the unit is closed.

- Hose deformed.

- Exhaust filter clogged.

It is recommended to check all parts that are responsible for the flow of water and fix the problem. If the reason is in the filter, it must be cleared and the program restarted.

Does not drain (5E, 5C, E2)

Reasons for clogging:

- drain hose;

- filter;

- siphon leading to the sewer.

Components must be checked and cleaned, and then continue washing.

Too much water (0E, OF, OC, E3)

The problem occurs due to problems with:

- water level sensor;

- his hose;

- valve membrane.

It is necessary to call the master for diagnostics and repair.

Imbalance (UE, UB, E4)

The weight, amount of laundry loaded does not correspond to the manufacturer's recommendations or it is unevenly distributed over the drum. It is necessary to stop the program, eliminate the cause and continue the cycle.

If the code does not disappear, the problem is in the unbalance of the unit and a specialist call is necessary.

Does not heat up (HE, HC, E5, E6)

An error occurs if:

- The water level in the tank is insufficient.

- The temperature sensor signal is incorrect.

- TEN burnt out.

Professional diagnosis and repair required.

Sunroof lock not working (DE, DC, ED)

The signal appears if the washing machine door is not closed until it clicks.To fix the problem, just close it again. If the cause is deformation, displacement or failure of the hatch, you must contact the master.

Level sensor does not perform a function (1E, 1C, E7)

The code appears after starting the wash mode.

The reasons:

- the pressure switch is faulty;

- the tube departing from it is clogged;

- burned out contacts.

Inspection, repair of the sensor and wiring are necessary. It is better to contact the repair shop.

Temperature above required (4C2)

The most common reason is connecting the unit to hot water. If an error was made during the installation, you must contact the wizard who carried it out.

Water at the bottom of the unit (LE, LC, E9)

To fix the problem, you need to inspect all parts of the washing machine from which water can flow:

- hoses;

- door and its components;

- tank;

- dispenser;

- nozzles;

- drain pump.

If damage is found, replacement is required. For this, it is better to call the master.

Panel buttons do not respond (BE)

The problem occurs due to deformation of the plastic parts of the control panel or a short circuit in the relay. If restarting the washing machine does not work, consult a specialist.

No signal from temperature sensor (TE, TC, EC)

Possible causes of a malfunction in a malfunction:

- wiring;

- resistance;

- the sensor itself.

You need to call the wizard.

Technical problems with the air conditioner

There are more serious reasons why the technique does not work. The self-diagnosis system of modern Samsung and lg air conditioners is designed in such a way that if any problems are detected, the operation of the entire unit completely stops.A malfunction is indicated by flashing LEDs on the panel of the indoor (sometimes outdoor) unit. The lights start to burn or flash in a certain sequence, which indicates a specific error. You can find out the reason why the Samsung aq09 air conditioner and similar ones turn off if you start the test mode. It is activated simply: just press the on / off button and hold for 5 seconds.

There are several reasons why the outdoor or outdoor unit does not start. The most common are the following:

- indoor unit temperature sensor error;

- indoor fan motor speed error (less than 450 rpm);

- indoor unit heat exchanger temperature sensor error;

- option data error.

About major faults

It is not recommended to repair the damage that has occurred on your own. If repairs are made by oneself, and then problems arise, the manufacturer is likely to refuse warranty obligations.

In case of poor cooling in the room

This is usually due to the following reasons:

- Weak power.

- The appearance of internal breakdowns.

Sometimes it happens that the power of the air conditioner is not enough to maintain the temperature in a particular room. An example is due to a sudden change in the climate in which the operation is carried out. The average temperature range is from -7 to +40 degrees. These are the main indicators that apply to all devices.

In other situations, the problem is related to internal breakdowns of the device. It is recommended to immediately contact for technical service, it is also difficult to solve something here on your own.

Short cycle unit

First, the device is turned on, but it stops working literally after 15-20 minutes.

This problem is due to several reasons:

- Dirty radiator.

- Broken thermostat.

- Broken control board.

- Settings failure.

External radiators are exposed to various mechanical damages and loads, especially in the summer. When foreign objects get inside, overheating of the entire system begins. Because of this, all work stops. The problem is eliminated by flushing the radiator, with water and strong pressure. This will help eliminate other breakdowns of air conditioners.

Refrigerant imbalance may occur after charging. It is enough to measure the working pressure of the compressor to understand how severe the problem has become. If there is an overload, excess fluid is simply disposed of.

Condensate leakage from the indoor unit

This is also one of the signals of faulty equipment. This can happen due to a clogged condenser tube.

The fix involves a few simple steps:

- Turning off the air conditioner. You have to wait 10 minutes.

- Disconnecting the plastic drain tube.

- Cleaning and drying.

- Returning the structure to its original position. This often helps if the air conditioner is broken.

DIY troubleshooting

And now we will consider what troubles the owner of a conventional split system may encounter, and find out how they can be eliminated by “legal” methods.

The manufacturer divides all the "oddities" of the operation or stop of the device into 2 categories:

- malfunctions;

- phenomena that resemble malfunctions, but are not them.

First, let's look at cases from the first category, when the air conditioner really does not work or does not work correctly. They can be divided into 3 groups.

Split system stopped working

The unit can stop due to a breakdown of any important unit, but more often it does not turn on for banal reasons. First, check the power supply to the device: is the “On” button pressed, is the power cable plug in the socket and is the machine cut out due to overvoltage

Perhaps these are general power outages - try turning on the lights. If the lights do not light up, just wait for the power supply to resume or call the Energy Supervision operator

To begin with, check the power supply to the device: is the “On” button pressed, is the power cable plug in the socket and is the machine cut out due to overvoltage. Perhaps these are general power outages - try turning on the lights. If the lights do not light up, just wait for the power supply to resume or call the Energy Supervision operator.

If you are using a remote control or wall panel, the signal may not come out due to a bad battery. Just replace the batteries with new ones, after checking the expiration date

Owners of units with a timer should never forget about the settings. If you want to turn on the split system before the specified time, it will not work, of course. Be sure to check the preset settings and adjust them or just reset them.

If no action helps, and the air conditioner does not react in any way to attempts to turn it on, you will have to call the technical service.

Insufficient cooling or heating

If the equipment is operating normally, but the temperature in the room does not change, first check that the windows and doors are closed.

The next step is to adjust the settings.The heating or cooling settings may have been set too low, causing the unit to only maintain normal room temperature.

Do not forget about such a feature of the split system as a possible 3-minute turn-on delay. Just wait until the unit starts working.

While waiting, you can look outside and make sure that the outdoor unit is free and that nothing has accidentally fallen on it from the balcony or upper floors. Air access to the grate must always be open

A common cause of any malfunction is filter contamination. Clean quickly with a vacuum cleaner or more thoroughly with soap and water.

Cleaning instructions filters:

- Raise the front panel until it clicks, so that it stays open.

- Carefully take the filter frame by the fasteners, lift it up and remove it.

- For dry cleaning, use a vacuum cleaner, for wet cleaning, use a cloth soaked in water.

- If, in addition to coarse filters, bactericidal and carbon filters are installed, remove them and vacuum them, and replace them after six months of use.

Do not use aggressive or abrasive agents. If you clean the filters every 2 weeks, the operation of the split system will stabilize, and problems will occur much less frequently.

Disruptions in work for various reasons

Much less often, Kentatsu air conditioners have malfunctions that require the immediate intervention of technical support workers.

On the territory of Russia there are more than 80 authorized service centers, mainly in large cities.

If you live outside the city, you can call the master at home or consult by phone. Often a few professional tips will help you troubleshoot problems.

Reasons for qualified intervention:

- frequent or random flashing of indicators that does not stop after several attempts to turn on / off;

- permanent shutdown of the machine on the electrical panel;

- ingress of foreign objects or water into the body;

- Interruptions in the operation of the remote control or the power button.

Do not forget that the incorrect installation of one of the units may cause poor performance. That is why the manufacturer recommends contacting professional installers, and not connecting the split system yourself.

Decoding error codes

Cooling air is a key function of an air conditioner, so the related systems and parts are under constant stress and tightly controlled. Both passive sensors, relays, and a system of periodic checks are used, the interval of which is controlled by an internal timer. The following are some error codes that describe malfunctions in the air conditioning system.

H11 - the indoor and outdoor units cannot establish communication or the control does not work due to a malfunction in the electronic boards.

H12 - the outdoor unit does not have the appropriate power to work with the indoor unit.

H15 - malfunctions of the compressor temperature control sensor.

H16 - malfunctions in the freon exchange system, manifested in the fact that the external unit consumes low current. Another reason - open transformer circuit or IPM power module failure, disassembly required. This check is controlled by a timer and is repeated continuously.

Deciphering the codes responsible for the malfunction of the sensor system

Below are some codes showing the breakage or failure of control devices, relays, sensors, what does air conditioning control do impossible. A clear sign that replacement parts are needed.

H14 - air sensor.

H21 - float sensor.

H51 - the relay of the AC Robot system, which is responsible for controlling nozzle clogging, has tripped.

H52 - malfunction of the limiter relay.

H98 - the temperature relay has tripped, which controls the operation mode of the indoor unit when the air is heated, the signal indicates insufficient heat extraction.

Error codes for panasonic air conditioners

By correctly identifying problems, you can clearly understand what spare parts are needed, what repairs are to be done, whether the electronic control system needs intervention, or signal markings indicate minor problems. In general, advice can be given - if the timer light is on or flashing, you should call a qualified craftsman.

How to disassemble the microwave magnetron and replace it yourself

Most often, the microwave oven magnetron cannot be repaired. If the part is worn out, it has been depressurized or the filament has broken, it is replaced with a new one. When the cap on the antenna or the feed-through capacitor fails, they are changed if tools are available.

Before proceeding with the disassembly and repair, the system is checked for operability.

First, pay attention to the power source. Weak voltage causes malfunctions of the device

If it corresponds to the norm, the microwave is dismantled:

- They inspect whether the antenna cap has burnt out, whether there are any deformations, holes and traces of burning on the housing and filter.

- If no external signs of damage are found, the magnetron is called with a multimeter.

- Disconnect wire terminals.

- The tester is turned on and the mode is set to 200 ohms.

- The probes are connected to the leads. If the winding is intact, the multimeter will show low resistance (about 0.5 ohms), and a squeak or ring will be heard.When the tester shows infinity, it means that the filament has broken.

- To ring the pass capacitor, the device is set to the largest measurement mode.

- One probe is connected to any of the contacts, the other to the body.

If everything is in order, the device will show infinity. When the capacitance of the capacitor is damaged, the charge breaks through the case.

If the antenna cap or feed-through capacitor in the magnetron is faulty, the part can be disassembled and repaired.

Cap replacement

The oven is disconnected from the mains, the casing is removed and the power plug is carefully dismantled. Disconnect the fasteners and remove the magnetron. Check the cap. If soot has formed on it, it is cleaned off with fine-grained sandpaper.

If the cap is pierced by current, burned out, it must be replaced. It is removed from the antenna, integrity is checked. If the anode is in order, install a new part. Then the magnetron is returned to its place.

Capacitor replacement

First remove the filter cover. Nippers bite off the contacts of the chokes. Using a drill with a diameter of 3 mm, holes are made around the capacitor. Take it out of the filter housing. To increase the length of the contact, unwind one turn at each inductor.

Contacts are cleaned with fine-grained sandpaper. Then a new capacitor is inserted in place of the old one and bolted. In this case, the contacts are connected so that they do not touch the walls of the box. Close the lid.

How to replace the magnetron in the microwave yourself

If the magnetron is beyond repair, it will have to be replaced. Before buying a new part, study the technical characteristics of the old one. On its outer side there is a sticker indicating the model, power, frequency and location of the power terminals.To get full compatibility, it is recommended to choose a model that matches the microwave oven.

After parsing the equipment, the defective part is disconnected from the wires and removed. A new one is installed in its place, securely screwed with fixing bolts. Then the wires are connected and the furnace casing is installed.

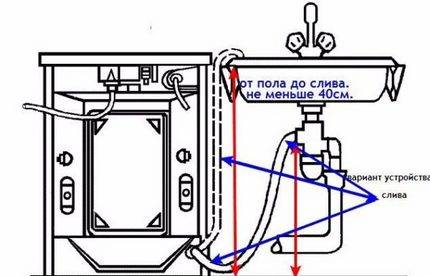

Water leak occurs (E9, LC, LE1 and LE)

Code errors E9, LC, LE1 and LE appear on the display if water spontaneously flows out of the machine.

The reason for the spontaneous draining of water in the washing machine may be the wrong location of the drain hose and its incorrect connection to the sewer

The reason for the spontaneous draining of water in the washing machine may be the wrong location of the drain hose and its incorrect connection to the sewer

This situation can happen due to a number of reasons:

- drain hose position too low;

- the drain hose is not properly connected to the sewer;

- the seal, drain hose or tank itself is leaking;

- the fastening of the heating element has weakened;

- too much foam appeared during the washing process due to excess detergent or the use of a detergent with a high level of foaming;

- the pump cover is installed in violation of the rules;

- defective leak sensor

Disconnect the machine from the power supply, change the position of the drain hose, check the condition of the seals, tank and hose. If the cause of the malfunction is not identified at this stage, and the error code still appears, it is time to show the washing unit to the master.

You can see one of the successful drain device options in this diagram. To avoid unnecessary stressful situations, follow our tips

You can see one of the successful drain device options in this diagram. To avoid unnecessary stressful situations, follow our tips

Self Service Safety Precautions

The air conditioner is a technically complex household appliance, the warranty for which only applies if installed and serviced by organizations specializing in the repair of household appliances.It is better to entrust the work to them.

In addition, the installation of an outdoor unit is often associated with increased hazards when working at height and often requires the use of safety equipment for high-altitude repairs or equipment with a moving platform.

If you live in a multi-storey building, and malfunctions have occurred in the outdoor unit of the air conditioner, it is better to contact the masters from the repair company who have the appropriate equipment for repairs

If you decide to do the work yourself, then follow the necessary safety measures:

- Read the instructions in detail;

- For the period of maintenance and repair of the air conditioner, disconnect it from the mains;

- If repairs require measurements on a device connected to the network, then use a serviceable tool with protective electrical insulation, do not touch current-carrying and rotating parts;

- Do not make changes to the device operation scheme, do not replace protective sensors with “plugs”;

- Observe safety precautions when working at height.

In domestic conditions, it is not always possible to identify all malfunctions and even more so to eliminate them.

Nevertheless, if you have certain skills, it is quite possible to check the correct connection and the integrity of the wires. You can test the presence of contact in the connectors and clamps, the health of the temperature sensors, perform cleaning and other work.

Cleaning the indoor unit from dust and dirt will not only help to avoid the reproduction of harmful microorganisms, but also prevent the fan from jamming and causing an error.

To perform such simple operations, you should have at least Phillips and slotted (flat) screwdrivers of medium and small sizes, pliers, wire cutters, a multimeter, wire for jumpering on the farm.Depending on the model, appropriate wrenches and hex keys may be needed.

Error codes and solutions

Each of the listed system problems has its own code, which is displayed on the display. If more than one error is detected, the fault with the highest priority will be displayed first.

Error code 21 indicates a malfunction of the room temperature sensor. In order to fix the problem in the unit, it is necessary to disconnect the corresponding sensor (indicated as CN43 in the diagram) and measure the resistance. At an air temperature of 25 degrees, it should be no more than 10 kOhm (an error of 3% is allowed). If the difference is significant, the sensor needs to be replaced.

In the air conditioner, the fan of the indoor unit may also be faulty. In this case, error 54 will be displayed on the samsung display. The problem is solved in a few steps. Unplug the power cord from the outlet and replace it after 5 seconds. If power is supplied to the A/C unit and the Operation lamp flashes, check the status of the solid state relay (labeled SS71). If there is no voltage and the relay does not start, then the cause of the non-working air conditioner is a processor malfunction, which entails changing the board.

The appearance of an error like "not programmed board" requires its reprogramming. To do this, you must have a remote control and a code table at hand. It is advisable to carry out these works in an authorized service center.

Conclusions and useful video on the topic

You can see how the Panasonic air conditioner is cleaned in this video:

How to check the internal module for errors, the following video will clearly demonstrate:

Panasonic intelligent air conditioner systems are able to timely notify the owner of the climate control device about a malfunction that has occurred in the bowels of the unit. Information on decoding can be found in the passport or video review.

Having found out the error code, a person can decide whether to correct the situation on his own (for example, clean the drainage) or call the master for a more complex repair.

Tell us about how you determined a violation in the operation of the Panasonic brand climate system by code. Share the nuances of diagnosing and troubleshooting that you know. Please leave comments in the block below, post photos and ask questions on controversial and interesting points.