Inefficient work

This is one of the most common malfunctions, especially noticeable in the hot season. The air conditioner consumes electricity, but does not provide the required temperature. Possible reasons for low efficiency:

Clogged air filters. They look like a small flat or drum-type mesh under the front panel of the unit, and it is through it that air enters the air conditioner. Filters collect all the dust in the house and protect the radiator of the indoor unit from it. Cleaning them is quite simple - remove and rinse under running water, then dry and put back. The procedure is done every two to three weeks, and if there is a lot of dust and soot, then even more often. Otherwise, the radiator airflow rate will decrease, and it will no longer provide the desired temperature. Violation of the mode of operation of the cooling system, in turn, will lead to freezing of copper pipelines. After turning off the frozen ice will melt and water will drip from the air conditioner.In case of severe clogging of the filters, dirt will also penetrate into the drainage system, and water will flow almost in streams. And it will be possible to clean up all this disgrace only with the use of potent chemistry.

Important! The maximum number of filter washes is 6–8 times! Then he loses his performance.

Dust on the impeller of the indoor unit. To fix the problem, you need to remove the panel and remove dust from the impeller.

Clogged outdoor unit heat exchanger. If dirt, dust, fluff or wool from the street gets into the outdoor unit, then the load on the compressor increases, it starts to overheat and may soon fail completely.

Freon leak. You need to know that this happens even in the case of the most professional installation, due to the flaring of the connection between the blocks. And this leak must be regularly (once every two years) compensated by refueling with refrigerant.

If this is not done, the level will drop to the minimum value and the compressor may seize due to overheating. Since the price of a new one is half the cost of the air conditioner itself, this cannot be allowed. To determine whether the volume of freon has decreased, it is enough to take a closer look at the fitting connections of the external unit - if there is ice or frost there. Another indicator would be poor air conditioning. In addition, even a slight crack after flaring the wire can cause freon leakage. Oil leaks under the taps, darkening of the thermal insulation will serve as evidence. When such warning signs appear, the best way out is to turn off the unit and carry out troubleshooting work.

Air conditioner not adapted for winter.Many models, especially from Asian suppliers, where the temperature does not fall below +8 in winter, are not adapted to work in severe frosts. And if you use the winter heating function using a non-adapted model, this will significantly reduce the life of the compressor. As a result, a cold plug occurs, which, when switching from heating to cooling mode, prevents the condensate from draining. The problem is solved by installing a winter kit for heating and heating the drainage system.

Icing on the outdoor unit. It happens if the split is turned on for heating at high humidity and sub-zero air temperature. If it is not equipped with an auto-defrost system, then it must be turned on for a short time in cooling mode. Then defrosting will provide warm air moving outside. In general, it is not recommended to turn on the unit at temperatures below 10 C, as the oil inside the compressor thickens, which increases its wear.

The power of the air conditioner is incorrectly selected, so it cannot cope with the area of \u200b\u200bthe room. In this case, only replacing the equipment with a more powerful one will help.

What does 1E mean?

On a Samsung washing machine, this code can be displayed at any time. Very often it appears on the screen not only during water intake, but also at the beginning of the washing process, in the middle of the program or at its end. It's connected with not quite correct work pressure switch - water level sensor (DU).

The main feature of units with intelligent filling is as follows. Before this error appears on the display screen, the pump of the drain unit very often turns on and the water is pumped out. This happens for the following reason.

The processor monitors the frequency that the remote control gives out (15-30 MHz). Even if it is violated for a few seconds, the control module instructs the drain device to remove liquid from the insides of the washing unit. After three minutes of operation of this unit, the code 1E appears on the display.

It indicates damage to the water level sensor (ODV), pipes attached to it, loss of contact or failure in the electronic “brains” of the machine. The easiest thing is to verify that the control board is working by rebooting the unit.

To do this, the machine must be turned off, be sure to remove the plug from the outlet. A quarter of an hour later it is connected. If the "brains" are working, then the car will flash with lights. Otherwise, it must be disassembled to determine the cause of the breakdown.

How to find and repair damage?

To establish the reasons, you need to get to the pressure switch by disassembling the device. This is pretty easy to do:

- disconnect the power plug;

- close the valve and disconnect the water supply and drain hoses;

- remove the drawer of the receiver of detergents and rinse, set it aside;

- pull out the unit and go from behind, unscrew the two screws that are at the top of the rear wall (they secure the cover);

- move the top plane and remove it.

Near the rear plane at the top of the car is a pressure switch, you can’t confuse it with anything. Having found it, you can immediately check the tube - if it is clogged and if there are holes in it. If nothing is found, they begin checking the sensor itself and its electrical connections.

Pressure switch and its location in a Samsung car

This is very easy to do:

- It is enough to put a piece of hose 30-40 cm on the sensor tube and put it to your ear and blow into it. If nothing happens, you need to change the DUV. The working mechanism of the sensor should make 1-3 clicks.

- If everything is in order, check the electrical part of the DUV. Connect a multimeter to its contacts ("Resistance" mode) and blow again. If the values \u200b\u200bchange from the pressure force, the pressure switch is working.

- After that, all its connections are checked for the possibility of oxidation of the contacts, “ringing” all the wires one by one. If this does not lead to a result, the control board is to blame.

Its repair is difficult. It is better to take this module to the service, where it is examined at a specialized stand.

Technical problems with the air conditioner

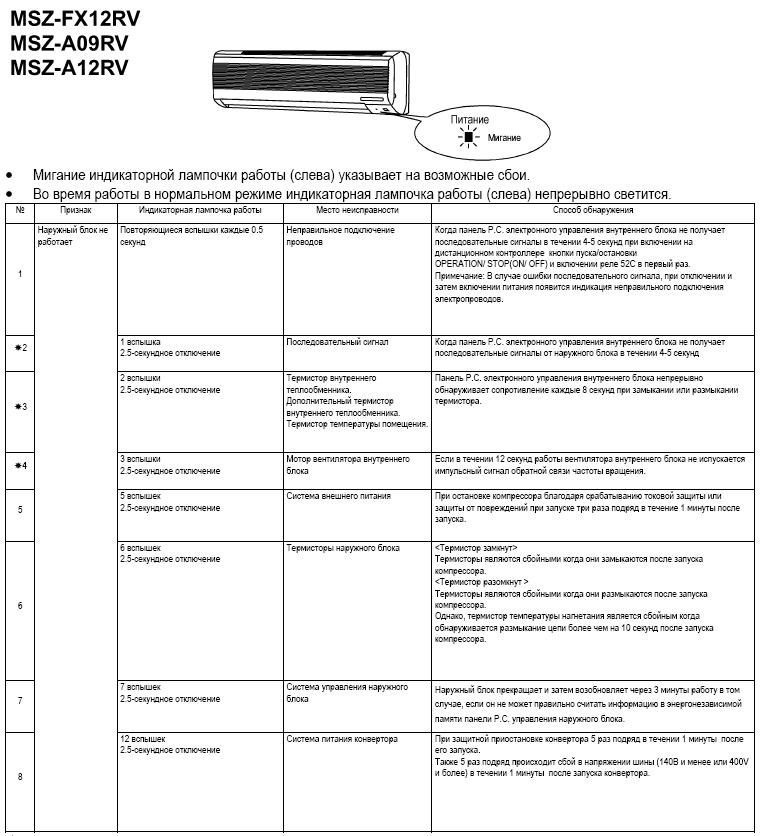

There are more serious reasons why the technique does not work. The self-diagnosis system of modern Samsung and lg air conditioners is designed in such a way that if any problems are detected, the operation of the entire unit completely stops. A malfunction is indicated by flashing LEDs on the panel of the indoor (sometimes outdoor) unit. The lights start to burn or flash in a certain sequence, which indicates a specific error. You can find out the reason why the Samsung aq09 air conditioner and similar ones turn off if you start the test mode. It is activated simply: just press the on / off button and hold for 5 seconds.

There are several reasons why the outdoor or outdoor unit does not start. The most common are the following:

- indoor unit temperature sensor error;

- indoor fan motor speed error (less than 450 rpm);

- indoor unit heat exchanger temperature sensor error;

- option data error.

Error 6E

These signs indicate a malfunction of the electronic part of the machine. On older types, codes bE or Eb occur. On washing units with a three-digit display, the inscriptions bE1, bE2, bE3, 6E1, 6E2, 6E3 appear.

Many mistakenly take the error Eb for E6 and try to find a breakdown in the nodes of the heating element, in fact, the reason is in the electronics.

Program crash

It can occur when a sensor fails or malfunctions. Sometimes it lasts half a second, but the processor reacts to this change and issues an error.

To eliminate the failure, stop the machine and remove the plug from the socket, wait 5 minutes and turn on the unit. If this is the reason, then after restarting the device will immediately work.

Buttons stuck or damaged

If nothing happens when they are pressed, contact is lost. If the process continues continuously, then this indicates sticking of the buttons. The easiest way to determine the malfunction on machines with a three-digit display:

- code bE1 means sticking or loss of power switch contact;

- the appearance of bE2 signals the same problems in other buttons.

Sometimes you can get rid of this if you turn on / off the faulty button several times or loosen the control panel screws a little.

Damage to the socket

The washing unit often refuses to work if there is poor contact (sparking) or an overload in the outlet. When installing the machine, it is desirable to install a separate new electrical outlet for its connection to the network. When sparking in the socket, impulses are transmitted through wires inside the machine. They can damage electronic components.

Malfunctions of this kind and other breakdowns are described in the following table:

| What happens before the appearance of the code 6E, bE or Eb | Cause of error | Troubleshooting |

| After turning on, the drum first gains high speed, as in the spin mode, and then stops abruptly.At the end of the wash, the machine freezes and the code lights up | Due to a short circuit, the triac of the engine (TRIAC) burned out. Its breakdown causes confusion in the signals from other nodes, and the processor sends the wrong code. The reason for the breakdown of the triac may be a sparking socket, because this component does not tolerate current surges | The motor triac needs to be replaced. If the machine does not work, you need to remember that sometimes several parts that switch the motor circuits burn out at once. If you cannot find the cause, you need to call the wizard |

| In the wash or rinse mode, the drum spins normally. After that, the program is interrupted and an error appears | Damaged Hall sensor - tachogenerator. It sends the wrong signal to the triac, which incorrectly interprets this pulse and passes it on to the control module. | If the contacts are connected normally, then the sensor itself is to blame. It needs to be changed |

| The machine does not respond to pressing some buttons. Two-element displays show 6E/bE and three-element displays bE1, bE2, 6E1 or 6E2 | Button contacts are made of springy material. They may stick or break off. When working, dust with microparticles of detergents settles on them. With a sufficient amount of sticky particles fasten the contact, and the button is in the pressed state (sticky). Very often, the contacts are pinched or broken off when pressed hard. control panels to the bodye.g. tightened screws | Damaged buttons need to be replaced. It is not always possible to fix them. If the cause is an incorrect clamp, loosen the screws |

| Buttons do not work properly, including modes that are unusual for them. The motor spins up to maximum speed, and then the signs bE or Eb are displayed on the screen. | Damage to the control module, burning of elements or tracks, broken wires or poor contact at the terminals. Processor failure | It is necessary to replace damaged elements and tracks, check the terminals and wires. If all parts are in order, then this indicates a processor burnout, the need to replace the entire module |

| The machine does not turn on, after 1-2 minutes it gives an error 6E or bE. Units with 3-element monitor show 6E3, bE3. | The motor relay is damaged, its contacts are bent or oxidized. It is located on the control board and its failure will cause an erroneous signal. | Clean contacts or replace relay |

| After turning on or on any program, the machine stops with the code displayed | Open or poor contact in the motor control circuit. Very often the wiring is bitten by rodents | "Ring out" all circuits with a tester or multimeter |

Self Service Safety Precautions

The air conditioner is a technically complex household appliance, the warranty for which only applies if installed and serviced by organizations specializing in the repair of household appliances. It is better to entrust the work to them.

In addition, the installation of an outdoor unit is often associated with increased hazards when working at height and often requires the use of safety equipment for high-altitude repairs or equipment with a moving platform.

If you live in a multi-storey building, and malfunctions have occurred in the outdoor unit of the air conditioner, it is better to contact the masters from the repair company who have the appropriate equipment for repairs

If you live in a multi-storey building, and malfunctions have occurred in the outdoor unit of the air conditioner, it is better to contact the masters from the repair company who have the appropriate equipment for repairs

If you decide to do the work yourself, then follow the necessary safety measures:

- Read the instructions in detail;

- For the period of maintenance and repair of the air conditioner, disconnect it from the mains;

- If repairs require measurements on a device connected to the network, then use a serviceable tool with protective electrical insulation, do not touch current-carrying and rotating parts;

- Do not make changes to the device operation scheme, do not replace protective sensors with “plugs”;

- Observe safety precautions when working at height.

In domestic conditions, it is not always possible to identify all malfunctions and even more so to eliminate them.

Nevertheless, if you have certain skills, it is quite possible to check the correct connection and the integrity of the wires. You can test the presence of contact in the connectors and clamps, the health of the temperature sensors, perform cleaning and other work.

Cleaning the indoor unit from dust and dirt will not only help to avoid the reproduction of harmful microorganisms, but also prevent the fan from jamming and causing an error.

Cleaning the indoor unit from dust and dirt will not only help to avoid the reproduction of harmful microorganisms, but also prevent the fan from jamming and causing an error.

To perform such simple operations, you should have at least Phillips and slotted (flat) screwdrivers of medium and small sizes, pliers, wire cutters, a multimeter, wire for jumpering on the farm. Depending on the model, appropriate wrenches and hex keys may be needed.

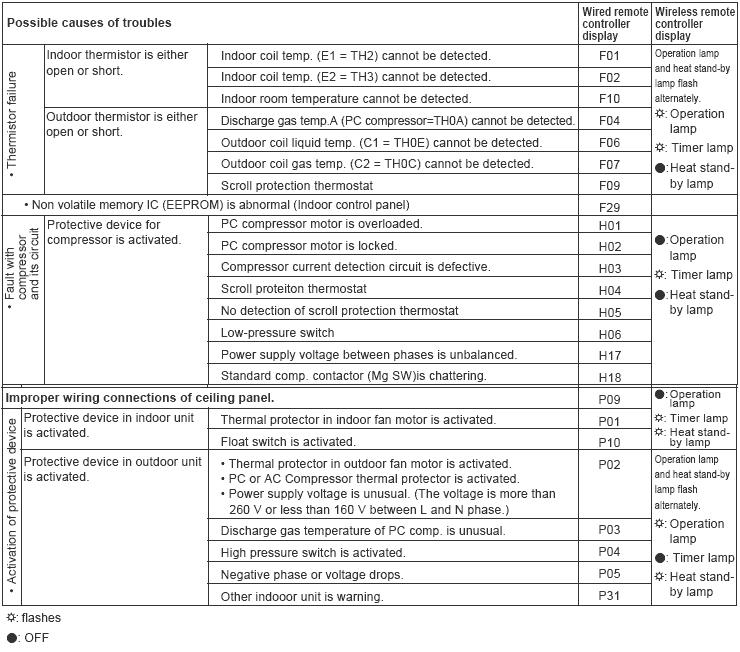

Classification of fault codes

There is a generally accepted system for combining symbols when denoting certain errors. So, the sequence can consist of two, three or more characters:

- numbers only (sometimes groups are separated by a hyphen);

- a letter of the Latin alphabet and one or two digits (for example, E6, P6) or the designations "Er / Err" (short for the English word "error" - "error");

- two letters (for example, "EC").

By the letter at the beginning of the cipher, you can understand exactly where the failure occurred:

- "A" or "B" - breakdown of the indoor unit;

- "E" - malfunction of the power unit (often due to unstable current);

- "F" - problems with temperature sensors (no signal, damaged as a result of a short circuit);

- "H" - power outages;

- "L" - malfunctions of the external unit;

- "P" - blocking of fan motors, breakdown of pumps for drainage or electronic board of the indoor unit;

- "U" and "M" are system errors.

Many manufacturers code errors in a similar way, but due to different components, technologies, functions and other technical features, the codes differ both for different brands and for individual lines. Therefore, in the event of a similar situation, it is necessary to refer to the instructions, which describe the code values \u200b\u200bof faults and options for their elimination. It will also be useful to find out which breakdowns of air conditioners are the most common.