- Air filter cleaning rules

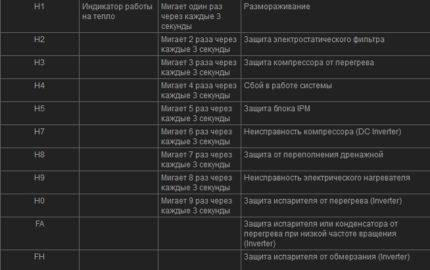

- Errors on the air conditioner cold indicator (F)

- Preventing the recurrence of the problem

- How to respond to error codes

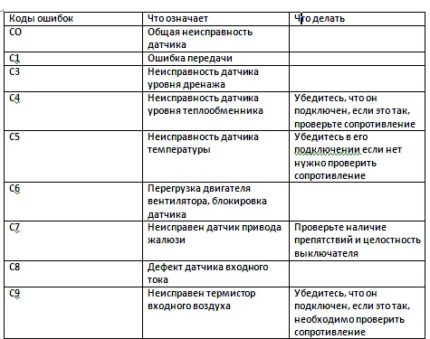

- Error codes for BEKO air conditioners

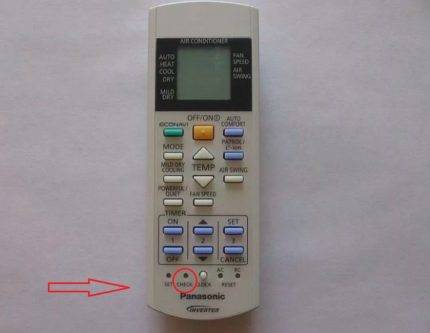

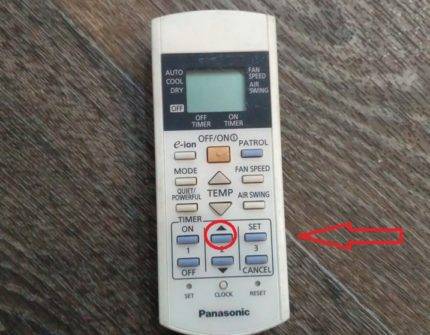

- Errors on the remote control of the air conditioner

- There is a "check" button on the remote control.

- There is no "check" button on the remote

- On display panel

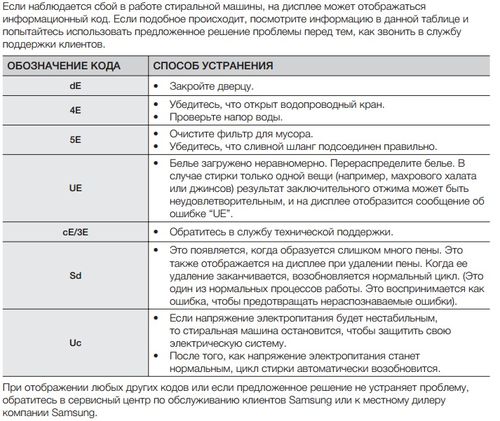

- Troubleshooting for Samsung APH450PG air

- Air Conditioner Diagnosis Sequence

- Atypical values on the display

- Decoding errors on the Samsung AC030JXADCH model

- List of provocative factors depending on the dishwasher model

Air filter cleaning rules

The manufacturer recommends that the air filter be cleaned after 100 hours of equipment operation.

The algorithm of the procedure is simple:

- We turn off the device. Open the front panel.

- Gently pull the filter lever towards you. Retrieve the element.

- Wash the filter in warm water with detergent solution.

- We dry the part in the shade, set it in place, close the device.

If the front panel is also dirty, fix it in the upper position, pull it towards you, remove it, and wash it.

Do not use gasoline, solvents, abrasive cleaners for cleaning.

Do not allow water to enter the indoor unit of the machine. There is a risk of electric shock. Therefore, parts must be removed and washed separately from the unit itself.

Do not allow water to enter the indoor unit of the machine. There is a risk of electric shock. Therefore, parts must be removed and washed separately from the unit itself.

If the air conditioner is operating in a very dirty room, you need to wash the filter every two weeks.

Errors on the air conditioner cold indicator (F)

Errors on the cold indicator indicate a malfunction of the sensors. But how is it? After all, it was written above that almost all errors in the operation indicator can be associated with the fact that the sensor is not working correctly.

This is where the priority rule for potentially more dangerous faults comes into play. The compressor put out of action as a result of an overheat or an overload means final breakage of the conditioner. A disabled sensor is only a potential failure.

In addition, sensors on Gree air conditioners cost a lot. Here are just a few of them:

- on the evaporator (error F1)

- on the capacitor (error F2)

- there is a sensor on the outdoor unit that measures the indicators on the street (error F3)

- discharge temperature sensor (error F4)

- compressor discharge tube sensor (error F5), the same tube that can overheat and give error E4.

If a sensors are not working as it should, then they must be changed, there is no other way out. You can determine whether the temperature sensor is working or not using an ohmmeter or multimeter. They measure the resistance of the sensor. You will also need a thermometer. It measures the air temperature at the time of measurement.

Errors in the cold indicator often indicate a malfunction of the indicator sensors. You can check their serviceability using an ohmmeter, a thermometer and a table.

Errors in the cold indicator often indicate a malfunction of the indicator sensors. You can check their serviceability using an ohmmeter, a thermometer and a table.

The nominal resistance at a specific temperature of the Gree thermistors can be found in the detailed description of the model. In order to measure the resistance of the sensor, it is necessary to remove it from the circuit, so it is better to adequately assess your knowledge of electrical engineering.If they have doubts, it is better to call the master. He also has a multimeter calibrated.

Error F6 means that the capacitor is overheating and the fan is running at low speed. At the same time, the F6 error does not always mean that the fan is working poorly. Maybe it's a freon leak.

Error F7 protects the air conditioner from oil leakage, triggering when it is carried away from the system. Errors F7 and F6 often occur almost simultaneously for the same reason - leakage of the working fluid on the roller copper pipe connections.

It is necessary to carefully examine the connections, if there are traces of oil on them, you can begin to prepare at least for the transfer of all connections - the air conditioner was installed incorrectly.

Codes F8 and F9 indicate a threat to the compressor at low speed. F8 - the compressor is overloaded at low speed, F9 - at high discharge temperature and low speed. The reasons for overloading the compressor in this case can be anything at all. From commonplace dirt to a burnt control board. Therefore, it is better to immediately contact the service.

Error FF indicates a lack of power in one of the phases, it is necessary to check the switching.

Preventing the recurrence of the problem

To do this, follow the following simple rules:

- monitor the hoses, avoid kinks, pinching;

- monitor the filter - carry out preventive cleaning once a month;

- if power surges are observed, install a stabilizer;

- if there is a frequent drop in pressure in the pipeline - install a hydroelectric station;

- use only special means for washing dishes;

- if the water is hard, carry out preventive cleaning once a month to remove scale, or constantly use anti-scaling products;

- take care of the door, carefully closing it, preventing foreign objects from entering.

Everything you need to know about dishwasher water can be found in this section.

How to respond to error codes

Theoretically, codes can be displayed on any models that have a digital display. But in practice, not all models have this functionality. For example, for ordinary Kentatsu air conditioners, the digital display located on the indoor unit serves only to show the air temperature inside the room or the selected operating mode.

But for columnar models, in addition to the general rules of action in case of detection of malfunctions, a small table with codes is usually placed in the instructions.

E01 - temperature sensors have ceased to function correctly or are out of order.

E03 - the compressor cannot work due to low current.

E04 - blocking of the outdoor module is turned on

P02 - compressor overloaded

If you see one of these codes on the display - according to the manufacturer's recommendations, you need to contact the service center. Without fixing the breakdown, the equipment most likely will not return to operating mode.

Many try to solve the problem on their own. This is possible if the unit is already out of warranty and if you have sufficient knowledge and skills

Many try to solve the problem on their own. This is possible if the unit is already out of warranty and if you have sufficient knowledge and skills

E02 - a power overload of the compressor has occurred. It is recommended to turn off the split system for a while, and then press the “On” key again. If the device does not start working or behaves unusually - it makes uncharacteristic sounds, smokes - you need to call a technician.

P03 - when the indoor module is operating in cooling mode, the evaporator temperature has dropped below normal.

P04 - when the indoor module is operating in heating mode, the evaporator temperature has risen above normal.

P05 - the indoor module supplies superheated air to the room.

Most often, these 3 problems arise for a banal reason: due to a clogged air filter. You need to lift the front panel, remove visible dirt and vacuum the filter.

If heavily soiled, remove it, rinse, dry and reinsert. Most often, the operation of the air conditioner is getting better, and if not, the help of a master certified by the manufacturer is required.

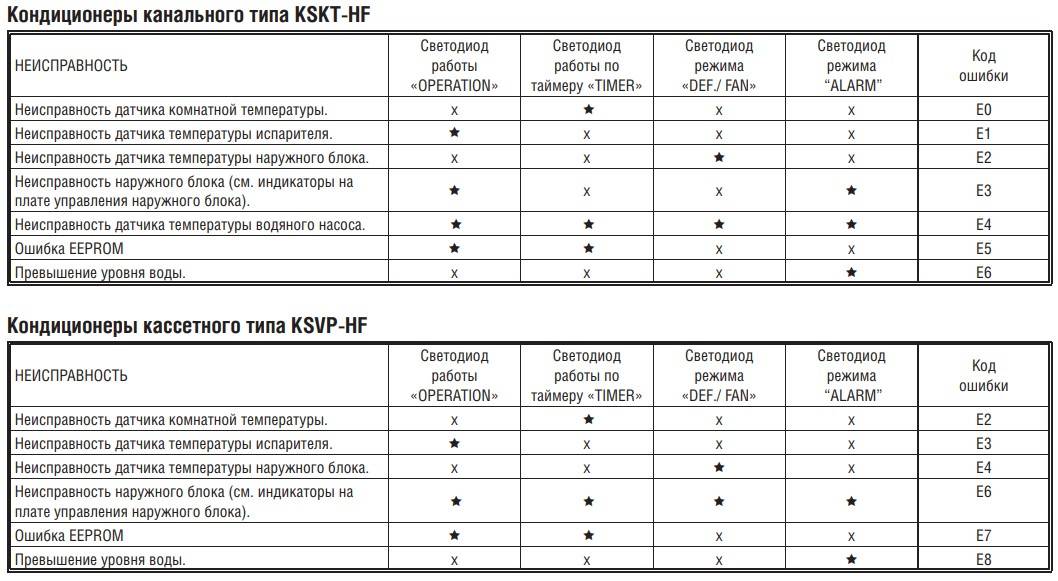

For Kentatsu duct and cassette air conditioners, error codes can be displayed in two ways:

- alphanumeric characters on the electronic display of the control panel;

- indication - a combination of flashing LEDs.

A table with detailed explanations is given in the instructions:

The LED signals in the table are indicated by two types of symbols: a “cross” (x) indicates that the LED is off, and an “asterisk” indicates that it flashes at a frequency of 5 Hz

The manufacturer prohibits cardinally intervening in the operation of the air conditioner, removing or reinstalling important components on its own. But before calling the technical service, he recommends re-checking the power supply and the correctness of the selected mode.

Often, the operation of climate technology stops due to a sharp change in external conditions - for example, due to overheating. It is possible if an additional heat source appears in the room.

Often, the operation of climate technology stops due to a sharp change in external conditions - for example, due to overheating. It is possible if an additional heat source appears in the room.

You also need to monitor the sealing of the room: with open doors or windows, the split system will run idle.

Error codes for BEKO air conditioners

All modern BEKO models are equipped with an innovative self-diagnosis system, which, in the event of any malfunction or incorrect operation of the main operating units, turns on the blocking of the entire device and simultaneously reports the cause of the malfunction by highlighting certain error codes for BEKO air conditioners on the display. When a malfunction is detected in the operation of the device, the display LEDs either start to burn continuously or flash in a certain sequence, which corresponds to the detected error.

If the system detected several errors in the operation of the air conditioner, then first the error code of the malfunction that has the highest priority is displayed, and then the codes of all other errors.

Errors on the remote control of the air conditioner

In different models of air conditioners, different methods can be implemented to read the error codes generated by the system. However, the timer indicator on the indoor unit will always flash. Let's look at how to determine the error code.

There is a "check" button on the remote control.

If there is a “check” button on the control panel, to read the errors, press and hold it for about 5 seconds. After that, the display on the screen will change from temperature values to existing error codes.

To read the error, find the “check” button on the remote control. In order to activate it, you need to press and hold for a few seconds.

To read the error, find the “check” button on the remote control. In order to activate it, you need to press and hold for a few seconds.

We direct the remote control to the internal module of the air conditioner and use the “up” and “down” buttons to scroll through the error log. At that moment, when the desired error is displayed on the display, the air conditioner module will emit a sound. It is necessary to leaf through the magazine completely from the first code to the last.

There is no "check" button on the remote

If there is no “check” button on the remote control, it is necessary to press and hold the “up” timer setting key for 5 seconds. After that, the remote control enters the error code mode.

Next, briefly press the same button and scroll through the errors. At the time of indication, the indoor unit will also emit a sound. It is necessary to scroll through the entire error log, as there may be several.

If there is no “check” button on the remote control, press the timer key up and wait for the error code programmed by the manufacturer to appear on the display

If there is no “check” button on the remote control, press the timer key up and wait for the error code programmed by the manufacturer to appear on the display

In both cases, after a minute, the remote control will return to the normal temperature display mode.

On display panel

This is a standard way to find errors on new models of air conditioners. There is an indicator panel on the indoor unit, on which the error code is displayed. The owner of the air conditioner is only required to look at this code and find out what it means. In multi-split systems, it is necessary to check for errors on all indoor units.

Troubleshooting for Samsung APH450PG air

An approximate action plan for solving errors that have arisen on Samsung APH450PG air conditioners is floor models. The system of these devices uses Refrigerant R-22. Includes remote control, timer and air filter. It is possible to regulate the air flow. The design is a classic white case with colored frames.

<p; three mistakes:

- The code "E1" appeared on the display. The reason is a failure of the internal or external temperature sensor. Check if this position is closed or open. May need replacement.

- Under the code "E5" is a malfunction of the internal or external heat exchange sensor. Check for correctness. If performance is not restored, then replace.

- The code "E7" indicates a malfunction of the sensor responsible for heating. You should check the wiring to the "heat generator". Especially the location of the sensor.

The simplest malfunction that can be solved by the user without calling the air conditioner software recovery wizard. You will need a remote control and a code. Samsung does not provide such information. The twelve-digit model code is entered manually. Upon successful flashing, a melodic signal will sound.

Remote control from which the code is changed

Air Conditioner Diagnosis Sequence

Air conditioner error codes are a universal mechanism, thanks to which the cooling device literally “speaks” about the problems that have arisen. Devices of the old generation after breakdowns stayed in the repair shop for weeks, or even months. A modern, innovative approach to repairing air conditioners of any capacity allows for repair work at the installation site of the unit, without its long-term removal. Stationary activities do not take more than a day, which greatly simplifies the dismantling and reinstallation of the cooling mechanism.

During the initial diagnosis, an experienced craftsman or a smart owner should take consistent, simple steps:

- The device, disconnected from the power supply, is inspected for external damage. The cable connecting the air conditioner to the network is checked. The hydraulic components of the device are examined.

- The fasteners responsible for the correct position of the air conditioning device are checked. Indoor units are amenable to closer inspection.

- Detailed study lends itself to parts that filter the air entering the device.

- The air conditioner is connected to the network, and then smoothly tested in the "cold" and "heat" modes.For such purposes, use the control panel (supplied with the unit).

- Switches are checked that allow you to use all modes of air conditioners without a hitch.

- Blinds are inspected, if necessary, parts are cleaned of dust and accumulated dirt.

- The work of the evaporation system is viewed.

- Finally, you should check the connection of all blocks.

- Drainage inspection is the last step in diagnosing a faulty device.

Self-regulating systems, modern air conditioners with sensors that allow you to see the error code during the initial testing of a faulty device, are also amenable to external inspection. The definition of a problem that has arisen inside or outside of a complex structure is not always clear if one proceeds only from electronic codes. Several problems hidden among themselves can be detected only with an integrated approach to determining the breakdown.

Testing the air conditioner is carried out in the "cold" and "heat" modes

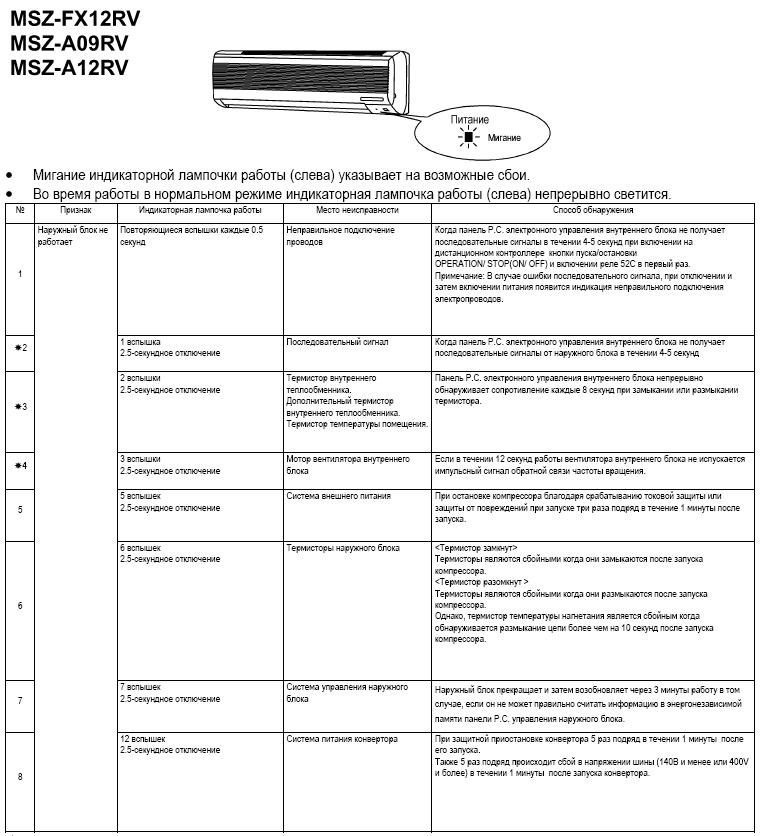

Atypical values on the display

If, when the “Heating” mode is turned on, the device starts to work, but after a while it stops blowing air, the indicator sun blinks and the inscription H1 lights up, this means that the device has switched to the defrost mode.

It is necessary to turn off the device from the remote control, hold down X-FAN and MODE at the same time. After half an hour, the air conditioner should work in a normal rhythm.

Sometimes an incomprehensible code may appear on the display, the decoding of which is not in the instructions and on the manufacturer's website. For example, a flashing sun and the value of H7

Sometimes an incomprehensible code may appear on the display, the decoding of which is not in the instructions and on the manufacturer's website. For example, a flashing sun and the value of H7

In case of error H7, diagnostics of the control and indication module of the device are needed. It can only be performed by a specialist.

The value of H6 stands for the operation of the compressor blocking sensor.This happens in two cases: when the sensor itself is broken and needs to be replaced, or when there is insufficient freon charging.

Also, with such an error, a variant with incorrect power connection of the impeller of the indoor unit is possible, which was not taken into account during assembly. Here you need to disassemble the board to clarify the cause and eliminate it.

Decoding errors on the Samsung AC030JXADCH model

Air conditioners of this series belong to the classic models of air conditioning equipment. They use R-410A refrigerant. This equipment consists of two blocks. An air duct is not provided for this series.

Possible mistakes:

- E508 - there were problems with the installation of "Smart";

- E202 - communication failure between units when the signal from the indoor unit disappears;

- E201 - no connection between blocks during tracking;

- E203 - temporary problem in processing data from the compressor to the indoor unit;

- E221 - malfunction of the outdoor temperature sensor;

- E108 - repeated communication address;

- E251 - there is an error in the data from the temperature sensor that the compressor pumps, check the starting capacitor;

temperature sensor

- E231 - the floor sensor COND is not working;

- E320 - OLP sensor problems;

- E404 - system overload protection has tripped;

- E590 - EEPROM checksum is incorrect;

- E464 - system stop due to DC peak;

- E473 - blocking Comp;

- E465 - compressor overload possible;

- E468 - malfunction of the current sensor;

- E461 - failure of the inverter compressor;

- E469 - DC-link voltage sensor is not working properly;

- E475 - inverter fan 2 needs to be replaced;

- E660 - Failed to load the inverter code;

- E500 - receiving incorrect thermal data from the first inverter;

- E484 - overload PF C;

- E403 - transition of the lower compressor to the frost protection mode, check for presence;

- E440 - the floor temperature has exceeded the default threshold and has reached the TheatJiigh parameter;

- E441 - the floor temperature limit has reached the Tcooljow parameter;

- E556 - inconsistencies in the capacity of the indoor and outdoor units;

- E557 - adjustment of the DPM remote controller option is required;

- E198 - thermal breaker does not work properly;

- E121 - incorrect room temperature indicator data;

- E122 - EVA indoor unit sensor is defective;

- E123 - EVA output sensor of the indoor unit gives an error;

- E154 - incorrect operation of room ventilation;

- El53 - re-detection of a float switch fault.

List of provocative factors depending on the dishwasher model

All dishwashers work on the same principle. But everyone has different spare parts, different software, different “weak” points:

- Indesit - The most common problem with water collection is related to the filling system, it needs to be cleaned more often.

- For Zanussi, the weak point is the filling valve.

- At Beko (Veko) the water level sensor flies more often than in other models. This leads to overflow of water or even to its absence.

- In the second generation of Bosch dishwashers, the lack of water supply is due to an electronic control failure. Cars are very sensitive to low water pressure.

- The third generation of the Bosch range has increased overpressure sensitivity. With it, the “electronic sensor” does not have time to “track” the filling of water and stops the program.