- Webasto Thermo Top Evo Start malfunctions that you can fix yourself

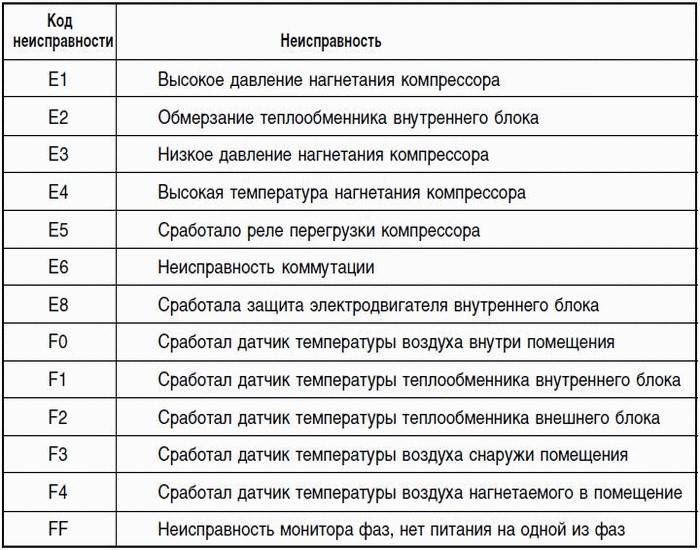

- Error codes for Vertex air conditioners

- Self-diagnosis system of modern air conditioners

- Water heating problems

- Failure of the heating element or pressure switch and codes F04, F07

- Malfunctions in the heating circuit and symbol F08

- Refrigerators

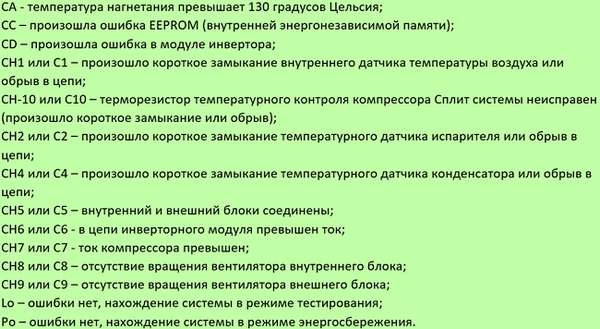

- AUX Split System Error Codes

- Problems in the operation of Kiturami boilers

- Instructions for the control panel and Artel air conditioners

- Webasto Thermo 50/90S/90ST/230/300/350

- FLAGMAN and CYBORG series error codes

- Common failures FLAGMAN 07-18, CYBORG

- Intrinsic flaws FLAGMAN 24-28

- Common breakdowns of FLAGMAN 30-36

- Conclusions and useful video on the topic

Webasto Thermo Top Evo Start malfunctions that you can fix yourself

If a fault occurs, check the condition of the fuses and plug connections, as well as their correct installation and connection. In the event of a fault, the heater enters a lockout state that is not displayed on the controls.

Before contacting a Webasto service center, try to remove the malfunction lock yourself.

You can troubleshoot the following problems yourself.

| Description of the fault | Possible reasons | Corrective action |

|---|---|---|

| The heater switches off automatically (emergency shutdown). | There is no combustion after starting and its repetition, the flame goes out during operation. | Turn off and turn on the heater (no more than two times). |

| The heater does not turn on. | There is no power supply to the heater. | Check the power supply of the heater, as well as its connection to ground. |

| The heater is switched off in heating mode (emergency stop). | The heater has overheated due to lack of coolant. | Add coolant according to manufacturer's recommendations. |

Error codes for Vertex air conditioners

This option is available only for models with self-diagnosis. An exact description of the faults is given in the manual for the corresponding model. The codes can be reflected on the indicator built into the indoor unit and on the display of the remote control.

Fault indication looks like a flashing of certain symbols. For example:

- E1 blinks once - damage to the room temperature measurement sensor;

- E2 flashes twice - damage to the sensor for measuring the temperature of the pipe in the room;

- E6 flashes six times - damage to the indoor unit fan motor.

It is not at all necessary that the error code that appears means a serious repair of the air conditioner. There may have been some kind of glitch. You can try to turn off the device first (it is better to turn off the power completely by pulling it out of the socket or turning off the machine, depending on the specific scheme for implementing the power supply). Wait a couple of minutes and turn it on again. During this time, there will be a discharge of containers, a reset of electrostatics, and zeroing of random errors in the control system. If after this the error continues to flash, it is better to call a service specialist.

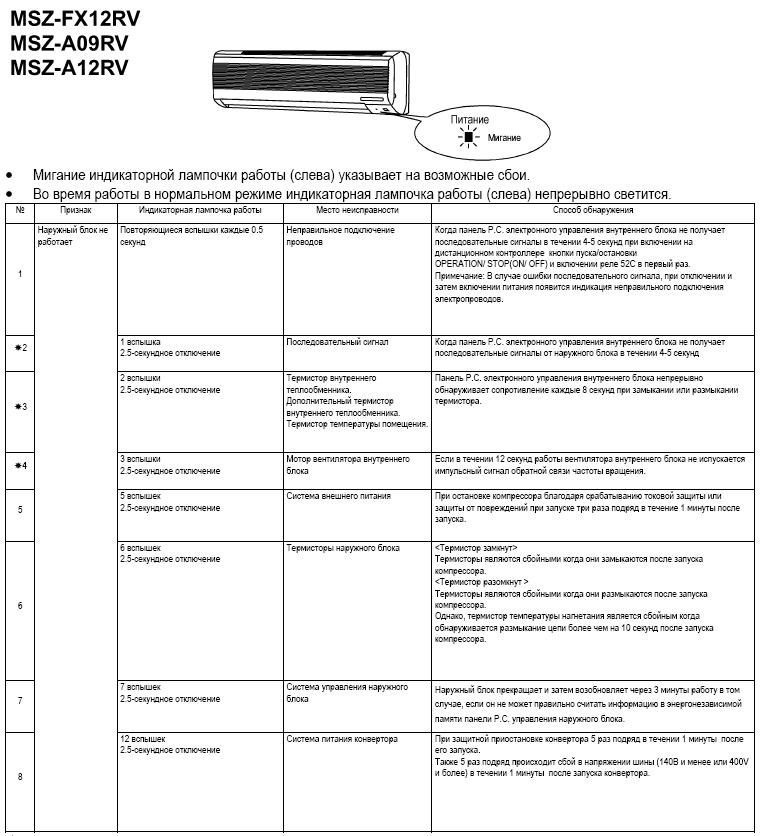

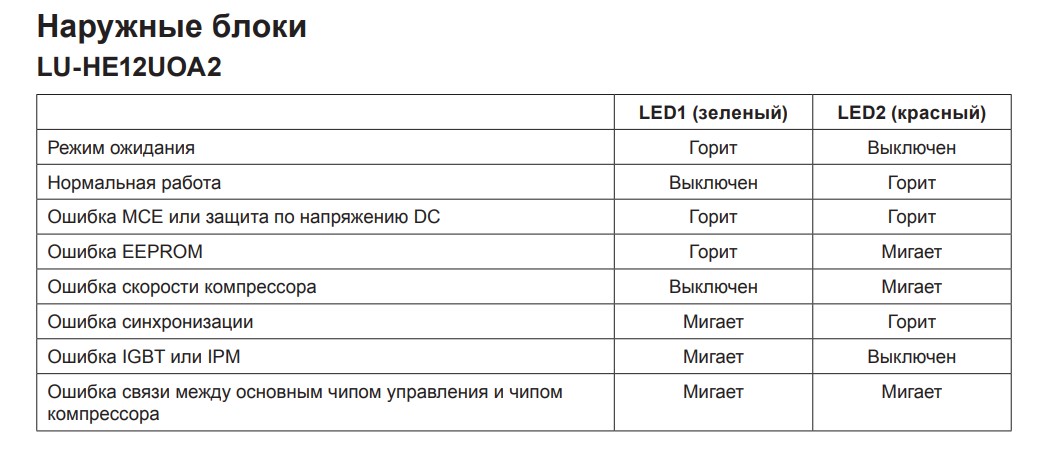

Self-diagnosis system of modern air conditioners

New generation household appliances are usually equipped with a self-diagnostic system designed to detect malfunctions and errors in operation at their first occurrence. The self-diagnosis system is a single network of sensors that monitor the state of one or another working unit of the unit.

When the air conditioner is turned on, the sensors automatically start working and continue to perform their functions in continuous mode until the device is disconnected from the power supply. Sometimes, to eliminate failures and errors, it is enough for the owner of the air conditioner to perform simple actions with his own hands, sometimes you have to invite masters from the authorized General Climate service.

Consider possible errors and their codes in various models of GC air conditioners and split systems, their causes and ways to eliminate them. We will try to figure out in which cases hand-made actions are appropriate, and in which cases an experienced master should be invited.

GC air conditioners are equipped with a modern self-diagnosis system that sends signals in case of failures and errors in operation to the control module

GC air conditioners are equipped with a modern self-diagnosis system that sends signals in case of failures and errors in operation to the control module

When the operating parameters of the node on which the sensor is installed are changed, an error signal is immediately sent to the control module, which is displayed on the device display. If necessary, the control module also blocks the equipment in order to avoid incorrect operation of the air conditioner and its final breakdown.

Fault codes for different models of General Climate air conditioners may differ from each other. We will try to consider in detail the codes of each model.

Water heating problems

If during the washing mode the washing machine freezes for a long time, stops, does not heat up or constantly drains water, the causes of the breakdown should be sought in the heating circuit.The device will signal these problems with codes F04, F07 or F08.

Failure of the heating element or pressure switch and codes F04, F07

In washing modes that require heating, the error may appear immediately after start-up, or after water is drawn, but rinsing or washing in cold water will work normally. In this case, there are several options for solving the problem (in addition to the standard turn on / off the machine to restart the controller).

If the code appeared on the display at the washing stage or at startup (the machine does not even want to draw water), most likely the reason lies in the heating element itself. It can "punch" on the case when the contacts are separated or simply burn out.

To fix the problem, you need to get to the heating element, check all its connections, change the resistance with a multimeter (at a power of 1800 W it should give out about 25 ohms).

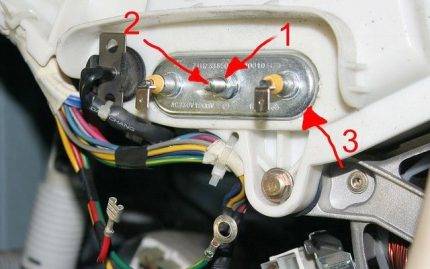

To replace a faulty heating element, disconnect the cable with wires, unscrew the fixing nut (1), press on the pin (2) and pry off the sealing rubber (3), after which install a new part and assemble in reverse order

If the device collects and then immediately drains water, the cause may be a breakdown of the pressure switch - the water level sensor. In the event of a malfunction, this element can provide the controller with information that the heater was not immersed in water, so the machine does not start heating.

In this case, it is necessary to check the tube of the water pressure sensor with the pressure switch (the hose may become clogged, bent, frayed or come off). At the same time, inspect the contacts of the sensor itself - it may be necessary to clean them. But more precisely, code F04 “says” about the breakdown of the pressure switch - most likely, the part will require replacement.

To check the operation of the pressure switch, you need to put on its inlet fitting a small piece of hose with a diameter identical to the removed tube and blow - characteristic clicks will be heard from a serviceable part

In some cases, the problem may be in the board itself, faulty wiring or contact groups in the area from the board to the heater or water level sensor. Therefore, you should ring all the elements of the control unit associated with the operation of the heating circuit, if necessary, replace burnt tracks or the controller itself.

Malfunctions in the heating circuit and symbol F08

If the water heating does not work correctly (or the machine “seems” that it starts when the tank is empty), error code F08 will appear on the display. The most common cause is a malfunction in the pressure switch circuit.

Such a problem may occur due to high humidity in the room, which adversely affects the controller. To make sure that the board is in order, inspect it, wipe it dry or blow it with a hair dryer.

Another simple solution to the problem can be the disconnected contacts of the heating element and the pressure switch, especially if the device was first started after transportation. In other cases, a more professional inspection with possible replacement of parts will be required.

First, make sure that there really is no water in the tank, then remove the back panel of the machine and check the heating element with a tester

First, make sure that there really is no water in the tank, then remove the back panel of the machine and check the heating element with a tester

Possible malfunctions of Ariston machines, indicated by code F8:

- If the washing mode is interrupted immediately after starting or during the washing phase and the appliance does not heat the water, it is likely that the heating element will need to be replaced.

- If the machine stops after starting, when switching to the rinse mode or does not wring out, it is possible that the contact group of the heating element relay has “sticked” on the controller in the on state.In this case, you can replace the failed elements of the microcircuit and, if necessary, reflash the board.

- If the device “freezes” in various modes (and this can be either washing or rinsing or spinning), the wiring or contacts in the heater circuit may be damaged, or the pressure switch may break, which considers that the machine does not receive enough water.

But if, when checking all the connections of the circuit and separately the pressure switch, the heating element relay and the heating element itself, no damage is detected, the controller will have to be changed.

Refrigerators

| Error code | Description | Remedy |

| E2 | The control panel does not receive a signal from the temperature sensor of the freezer | Checking the sensor, wiring integrity, replacing the sensor |

| E4 | The control panel does not receive a signal from the temperature sensor of the refrigerating chamber | |

| E6 | No signal from temperature sensors (for models with one sensor for refrigerators and freezers) | |

| Flashing indicators | ||

| 3 (continuous burning) | Indicates the stable operation of the refrigeration compartment | |

| 3 (blink) | The NTC temperature sensor does not work in the refrigerator compartment | Replacing the sensor, checking contacts, ringing the circuit with replacing damaged areas |

| 4 (continuous burning) | Indicates the stable operation of the freezer compartment | |

| 4 (flicker at 0.5 Hz) | NTC temperature sensor not working in freezer | Replacing the sensor, checking contacts, ringing the circuit with replacing damaged areas |

| 4 (flickering at 2 Hz) | No signal from memory controller | Professional diagnostics and repair |

| 4 (flickering at 5 Hz) | Freezer Temperature Sensor Error or Controller Memory Error | Replacing the sensor, restoring the integrity of the circuit, checking the contacts |

| 6 (continuous burning) | Fast freeze mode is working | |

| 6 (blink) | Exceeding the critical temperature in the freezer | Checking the tightness of the door, replacing the sensor, control board |

AUX Split System Error Codes

All Aux brand air conditioners have a self-diagnostic system, which, when problems are detected, displays equipment error codes on the display. This is a hint where to look for the cause of the malfunction. The failure coding consists of numbers and Latin letters. Error indications on different models of climate control equipment may vary slightly.

Unified commands include:

- Type of failure Display of digital pipe (no alphanumeric designation) - malfunction of the display of the indoor unit.

- E1 - malfunction of the temperature sensor (thermistor) of the indoor unit. In parallel with this indicator, the yellow timer LED on the indoor unit flashes (every 8 seconds). The system at this moment is completely stopped and does not respond to external commands.

- E2 and E3 - evaporator sensor errors.

- E4 - malfunctions of the fan motor (PG feedback motor).

- E5 - errors of the outdoor unit of air conditioning equipment (Outdoor protection function).

- E6 - errors in the fan motor of the indoor unit of the split system.

In this case, the exact nature of the error depends on at what point in the operation of the air conditioner this or that indicator on the device was lit.

Error E3 most often appears after 5-10 minutes of operation of the split system. This may be due to:

- problems with power contacts;

- severe contamination of the filter or evaporator (because of this, the fan accelerates extremely quickly without load;

- malfunctions of the PRM sensor speed sensor, etc.

When error E4 occurs, the air conditioner, as a rule, does not work in ventilation and cooling modes. But when you turn on the device in heating mode, it immediately gives an error. The problem indicates a malfunction of the fan of the indoor unit of the Aux brand air conditioner.

The fan of the indoor unit is an important part of the air conditioner, which provides forced air circulation through the heat exchanger due to the fact that it blows the cold formed on the radiator into the room

When diagnosing an air conditioner, you need to take into account the time at which the error is generated. If the code is displayed with the device turned off, this may indicate problems with the controller, and not with the part itself.

Those. the controller just hangs and periodically issues an error code. If, after checking all the elements of the split system, it is clear that they are in good condition, you need to check the control board and, if it is faulty, replace it.

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

The "Network" indicator is not lit - check the power in the socket and the fuse on the ignition transformer. If there is no voltage in the mains, call an electrician, if there is, call the service department.

The low water indicator on the control unit is on - there is no water in the device or the level is too low. Damage to the black wire of the boiler and the red cable of the sensor also lead to a malfunction.

The room temperature sensor works fine, but the radiators are cold - the circulation pump does not accelerate the coolant through the pipes or does it too weakly. Inspect the locking parts on the heating pipes.Check the pump itself.

The “Overheating” light came on - the heating system is not working properly. Check her out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The mesh filter may need to be cleaned. Examine it.

- Check circulation pump, repair or replace if necessary.

The "Safety" diode is lit - gas enters the boiler burner in small quantities or does not enter at all. Inspect the valves and open them if necessary. The problem remains - call the gasmen.

Schematic representation of a room remote thermostat: 5 main modes are laid in it, including presence, absence, shower, sleep, water heating control

The pump is running too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air pockets in it. Release the air.

The boiler began to heat up longer - look for a problem with gas pressure and the condition of the filters.

The burner vibrates when turned on - the size of the chimney is not enough for the normal removal of gases.

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system enters the boiler. The chemical treatment of the circuits and the heat exchanger will help.

Instructions for the control panel and Artel air conditioners

To remotely change operating modes and control the temperature, a remote control for the air conditioner is included in the kit. It has a standard design, the buttons are located conveniently for the user. The advantage of the design is a large and informative liquid crystal display.

The remote control is designed to perform the following actions:

- turning on/off the equipment;

- change in the degree of heating or cooling of the air;

- control of the position of the shutters of the indoor module;

- activation and deactivation of night mode, Turbo, timer programming;

- displays information about the results of self-diagnosis.

The remote device has a built-in backlight, but no temperature sensor. Mode icons are intuitive and easy to read.

The instructions for air conditioners contain information about the installation rules: the maximum allowable length of pipelines, height difference are indicated. This document contains a service manual.

Webasto Thermo 50/90S/90ST/230/300/350

When a malfunction occurs, an electronic lock is activated and the heater issues a malfunction code. Check the fuses and connectors for correct operation and tightness.

The blockage can be removed by restarting the heater or removing the blue 15 A fuse on the heater cable harness for a short while while the PJ is on.

After setting the fuse, the heater is switched on. If the lock has not been removed, you need to determine the cause of the malfunction.

Webasto timer 1531

If the heater is equipped with a 1531 timer (with alarm clock), the following error codes are displayed on the timer display after the emergency lockout.

| The code | Malfunction |

|---|---|

| F01 | There is no start. |

| F02 | Flame failure (repeated more than 5 times). |

| F03 | Voltage drop below the allowable or increase above the allowable. |

| F04 | Premature flame detection. |

| F05 | Open circuit or short circuit of the flame sensor. |

| F06 | Open circuit or short circuit of the temperature sensor. |

| F07 | Open circuit or short circuit in the metering pump. |

| F08 | Open circuit, short circuit or incorrect speed of the blower motor. |

| F09 | Open circuit or short circuit of the glow plug. |

| F10 | Heater overheating. |

| F11 | Open circuit or short circuit of the circulation pump. |

| F12* | Emergency blocking due to repeated malfunctions or flame failure: this blocking is released by switching the heater back on and disconnecting it from the vehicle battery during the start process. |

* — only for preheaters Webasto Thermo 230/300/350

If the heater is equipped with a switch or timer 1529 (without an alarm clock) as a control element, then error codes are transmitted in the form of light signals (flashing). Turn off the heater, after 5 short flashes, long pulses are emitted.

The number of pulses corresponds to the number after the letter F given in the table above.

Webasto HL32 Heater Room Thermostat

FLAGMAN and CYBORG series error codes

In the split systems GC FLAGMAN and CYBORG, in addition to the indicator lights, errors in operation are reported by alphanumeric characters on the display.

In some models of air conditioners and GC split systems, alphanumeric error codes are displayed on the display of the system control panel

When deciphering the error code of these General Climate models, you should not forget to pay attention to the remote control display

Common failures FLAGMAN 07-18, CYBORG

E1, Operation blinks 1 time, Timer off - EEPROM error.

E2, Operation blinks 2 times, Timer is off - there is a problem with the electronic board of the indoor unit.

EC, Operation blinks 2 times, Timer is on - freon leak, while the pipe sensor does not show any changes.

E3, Operation blinks 3 times, Timer is off - the fan motor in the indoor unit does not start for more than 1 minute.

E5, Operation blinks 5 times, Timer is off - problems with the air temperature sensor of the indoor unit.

E6, Operation blinks 6 times, Timer is off - problems with the pipe sensor of the indoor unit.

Intrinsic flaws FLAGMAN 24-28

Error codes for GC FLAGMAN 24-28 air conditioners are similar to FLAGMAN 07-18 codes, but one more position has been added to them.

E9, Operation blinks 9 times, Timer is off - communication failure between the outdoor and indoor units.

Common breakdowns of FLAGMAN 30-36

For models of split systems GC FLAGMAN 30-36, 2 more positions have been added to the errors listed above.

E7, Operation blinks 7 times, Timer is off - problems with the pipe sensor of the outdoor unit

E8, Operation blinks 8 times, Timer is off - phase problems (skew, absence, incorrect alternation).

Conclusions and useful video on the topic

AT help for home craftsmen we have collected several videos about various malfunctions Ariston washing machines, options for decoding code information and practical tips for identifying the culprit of the breakdown.

Error code F08, inspection and repair of the machine:

How to repair the electronic controller:

How to fix errors drain code F05:

As you can see, even the tips of smart technology do not always clearly indicate the cause of the breakdown, because malfunctions of various parts can be hidden under the same code.

Of course, with the proper skills in working with electronics, it is quite possible to eliminate most of them without the help of professionals.But if there is no such experience, you should not rush to extremes and change one part after another - perhaps in the workshop you will be offered a simpler solution to the problem.

Do you want to ask a question about the topic of the article? Please write it in the comments section, and our specialists will answer you as soon as possible. Here you also have the opportunity to provide interesting information on the topic or share your own troubleshooting experience in the Ariston washing machine.