- Hayer washing machine: error codes

- Air filter cleaning rules

- Classification of fault codes

- Causes of breakdowns of Haier air conditioners

- Reasons for the appearance

- Features of the self-diagnosis

- Universal repair recommendations

- General principles of diagnosis

- Decoding error codes

- Deciphering the codes responsible for the malfunction of the sensor system

- Malfunctions and their decoding

- DIY troubleshooting

- Split system stopped working

- Insufficient cooling or heating

- Disruptions in work for various reasons

- AUX Split System Error Codes

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Hayer washing machine: error codes

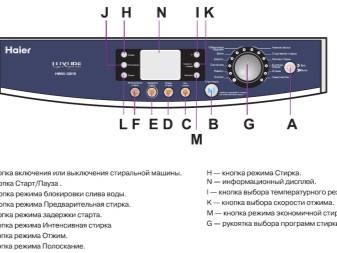

CMA does not always give an error immediately after a breakdown. Sometimes the user himself understands that there are problems with the operation of the machine. But how to understand what's the matter? In this case, a test mode is provided. It starts like this:

- Hold down the Start Delay and No Drain keys.

- Make sure the hatch door is closed.

- After 10 seconds, the sunroof lock will turn on.

- Testing will begin.

Depending on the numbers on the display, the knot check will change. So:

- Screen 77:77 shows solenoid valve diagnostics.

- 66:66 - engine.

- 55:55 - pressure switch.

- 44:44 - motor during washing.

- 33:33 - TENA.

- 22:22 - drain pump.

- END - end of the test.

If the code lights up on the display on its own, try resetting the error. You can only do this once. If the error is displayed repeatedly, it cannot be ignored.

- Disconnect the SM from the network.

- Wait 10-15 minutes.

- Restart.

What does the code mean and how to fix it, see below.

| Fault codes | What does it mean? | Solution |

| ERR1 (ERR1) | SMA program does not start | Press the hatch door tighter until you hear a click. The lock should work. View:

Defective parts must be replaced |

| ERR2 flashed (EPR2) | Water takes a long time to leave the tank | How to fix the situation:

Install correct items |

| ERR3 (ERR3) | No heating | Checking the thermistor, its wiring. Installing a new sensor |

| ERR4 (ERR4) | Water heating problems | Carry out diagnostics of the heating element. Examine the connecting chain. Damaged parts require replacement |

| ERR5 (ERR5) | Water does not enter the tank | Check for water in the line. Open the supply valve more. Disconnect the intake hose, clean it from blockage, rinse with warm water. Take out the mesh filter. Clean with a solution of citric acid or rinse under the tap. Diagnose the solenoid valve coils. If broken, install a new element |

| ERR6 (EPR6) on the display is on | Problems in the connecting circuit of the main unit | Inspection and replacement of damaged areas |

| ERR7 (ERP7) | Electronic board is defective | The board needs to be replaced. Contact the service center |

| ERR8 (ERR8) | Water overflow | Checking the pressure sensor, cleaning its hoses from debris. Diagnostics of the pressure switch control triac on the board.Repair and replacement of broken parts |

| ERR9 (ERR9) | Lots of liquid in the tank | Intake valve problems. If its membrane does not close, a new valve is mounted |

| ERR10 (ERR10) | Problems with water intake | Check the operation of the pressure switch, its wiring. Clean up contacts. Failure of the pressure switch leads to a complete reinstallation of the part |

| UNB | Imbalance | Things got off to one side, so the washer stopped working. How to remove the error:

|

| EUAR (EUAR) | Malfunctions in the control electronics | call the wizard |

| NO SALT (no salt) | Detergent not suitable for washing machine | Make sure you don't forget to pour the powder into the laundry compartment. You may need to increase the dose or change the powder. Take out the dispenser, rinse it from sticking detergents |

Prevention is always better than repair. In time, clean the filler and drain path from blockages. Do not overload the drum with laundry and pour in a high-quality detergent.

Badly

23

Interesting

20

Super

18

Air filter cleaning rules

The manufacturer recommends that the air filter be cleaned after 100 hours of equipment operation.

The algorithm of the procedure is simple:

- We turn off the device. Open the front panel.

- Gently pull the filter lever towards you. Retrieve the element.

- Wash the filter in warm water with detergent solution.

- We dry the part in the shade, set it in place, close the device.

If the front panel is also dirty, fix it in the upper position, pull it towards you, remove it, and wash it.

Do not use gasoline, solvents, abrasive cleaners for cleaning.

Do not allow water to enter the indoor unit of the machine.There is a risk of electric shock. Therefore, parts must be removed and washed separately from the unit itself.

If the air conditioner is operating in a very dirty room, you need to wash the filter every two weeks.

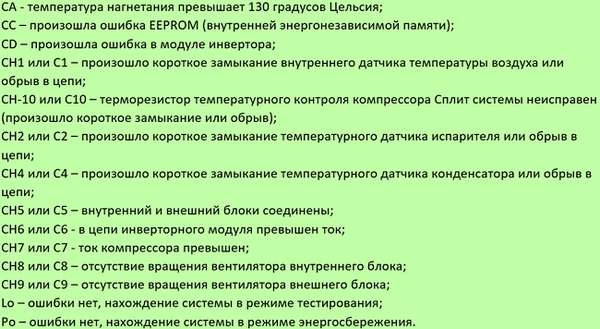

Classification of fault codes

There is a generally accepted system for combining symbols when denoting certain errors. So, the sequence can consist of two, three or more characters:

- numbers only (sometimes groups are separated by a hyphen);

- a letter of the Latin alphabet and one or two digits (for example, E6, P6) or the designations "Er / Err" (short for the English word "error" - "error");

- two letters (for example, "EC").

By the letter at the beginning of the cipher, you can understand exactly where the failure occurred:

- "A" or "B" - breakdown of the indoor unit;

- "E" - malfunction of the power unit (often due to unstable current);

- "F" - problems with temperature sensors (no signal, damaged as a result of a short circuit);

- "H" - power outages;

- "L" - malfunctions of the external unit;

- "P" - blocking of fan motors, breakdown of pumps for drainage or electronic board of the indoor unit;

- "U" and "M" are system errors.

Many manufacturers code errors in a similar way, but due to different components, technologies, functions and other technical features, the codes differ both for different brands and for individual lines. Therefore, in the event of a similar situation, it is necessary to refer to the instructions, which describe the code values \u200b\u200bof faults and options for their elimination. It will also be useful to find out which breakdowns of air conditioners are the most common.

Causes of breakdowns of Haier air conditioners

Hyer air conditioners are not afraid of intensive operational loads and operate around the clock without failures.Efficiently cool/heat residential, work and office premises.

About 92% of problems occur as a result of improper operation of devices and voltage drops in the network. By the way, so that not only the air conditioner, but also other equipment does not suffer due to voltage drops, you can install a stabilizer.

Identified damage must be repaired as soon as possible. Operating a faulty appliance exacerbates the problem and often results in damage to dependent or adjacent parts, and then the cost of repairs increases significantly.

Some private craftsmen rely on the incompetence of the client, try to impose unnecessary services, repair working elements, etc. A person who understands error codes will immediately notice this and stop attempts to deceive

To avoid most breakdowns, it is necessary to properly connect the unit and operate it in strict accordance with the manufacturer's recommendations. Then Haier will last a long time and will not cause any problems.

Reasons for the appearance

Errors in the operation of any washing machine cannot occur just like that. Most often they are the result of:

- power surges;

- too hard water level;

- improper operation of the device itself;

- lack of preventive inspection and timely minor repairs;

- non-compliance with safety regulations.

But preventing the occurrence of such situations is much easier than solving the problem itself later. Therefore, when purchasing a Haier machine, you must:

- install it correctly - for this it is best to use the building level;

- use only detergents recommended by the manufacturer for washing and cleaning or protecting the appliance from scale;

- timely preventive inspection of the device and minor repairs;

- use only original spare parts if necessary.

But if, despite all the precautions, the error code is still displayed on the display of the machine, and it does not work as it should, the problem must be solved immediately.

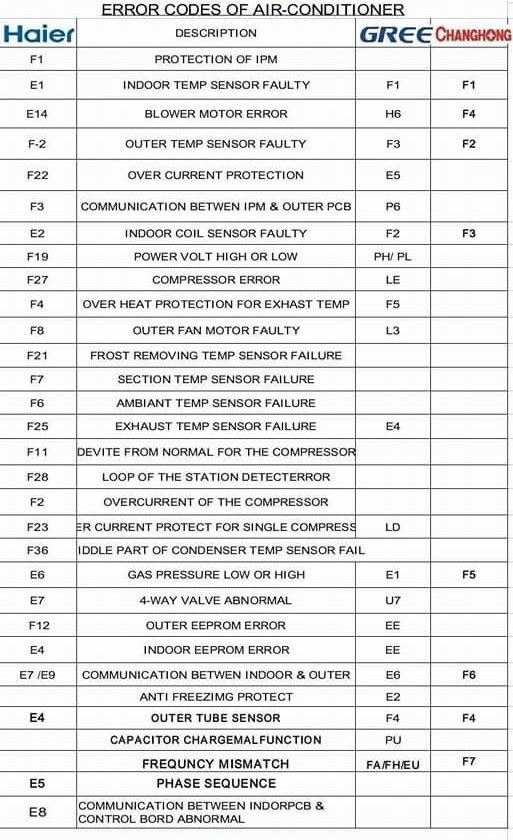

Features of the self-diagnosis

If a breakdown, failure in the electronics is detected, the Lessar climate unit diagnostic system issues an error code on the front of the indoor unit panel or on the control panel. The fault code is a letter on the screen and a combination of LEDs that flash in a certain order.

The error indication and the alphanumeric code are displayed until the malfunction of the system is completely eliminated.

All models of Lessar equipment are subject to some breakdowns in cases of improper installation and operation. To do this, each model of the air conditioner is equipped with an auto-detection of errors for the subsequent elimination of identified malfunctions.

If the split system is not functioning properly, you need to pay attention to the display. There is a device error displayed.

Thanks to their presence, the user will be able to independently identify the cause of the malfunction and, if possible, eliminate it. In the event of a complex violation, you will need to contact the service center for help.

For independent troubleshooting, it is necessary to understand in more detail the design features of climatic equipment.

Household (wall-mounted, multi-split systems) and semi-industrial (cassette, floor-ceiling, channel, column type) systems consist of two parts, which are interconnected by a freon route - an indoor and outdoor compressor and condenser unit.

The air conditioning line connects the blocks to each other and consists of a signal and connecting power cable, copper tubes for the passage of freon and a drainage tube for draining liquid from the room. To protect against environmental factors, the track is placed in a durable PVC tube

The design of the indoor evaporative unit consists of a network cable, a front panel, filter elements, shutters, an evaporator, a fan, a drip tray for accumulated condensate, and a control board.

The components of the external unit of the split system are: compressor, 4-way valve, condenser temperature sensor, capillary tube, filter, control board, fan. More powerful air conditioners - 36-60 thousand BTU - are additionally equipped with a high and low pressure switch, a silencer, various filters, an accumulator, an air temperature sensor.

After getting acquainted with the scheme of the air conditioning system, the user will be able to identify a breakdown, change and even repair a part or mechanism that has failed.

Universal repair recommendations

Before starting work, disconnect the air conditioner from the mains.

Carefully read the instructions that came with the device. This will save time searching for unscrewing fasteners and plastic latches that hold the external elements of the climate control housing.

When repairing the air conditioner at home, use a tool with electrical insulation.Be careful and careful, do not touch rotating and live parts

Film the sequence of parsing the inside of the block on a smartphone. This will help to properly assemble the unit and ensure that all parts are in place. Do not make any changes to the operation of the instrument. For replacement, use only original parts or equivalents approved by the manufacturer.

Don't rush repairs. Allocate at least 1-2 free hours to this activity. Check if the necessary tools are available.

You will definitely need:

- slotted (flat) and Phillips screwdrivers of small and medium sizes;

- wire cutters;

- pliers;

- multimeter;

- jumper wire.

Depending on the model, spanners and hex keys may be required. If most of the tools are not available, think carefully about whether it is worth starting a repair.

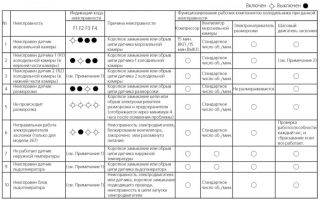

General principles of diagnosis

The indicators of the sensors of the outdoor unit are displayed on the control panel and the indoor unit. Errors are displayed on the remote control, which are duplicated by flashing indicator lights. Their location and purpose is easy to remember, there are only three of them.

Or you don’t have to remember, on a number of models they are signed and their names are definitely in the instructions:

- The indicator of work (Running), its blinking is responsible for errors with the letters E and H6.

- Heat indicator (Heating mode), it “winks” if Griya’s air conditioner generated errors with the letters H0-H9, FA, FH.

- Cold indicator (Cooling mode), errors F0-F9, FF.

The lights flash in a certain sequence, thereby “giving out” one or another error. Also, errors are duplicated on the block itself and on the remote control. So counting the number of winks that repeat every 3 seconds is optional. Moreover, there may be 9 or 11 of them.

A number of Gree air conditioner models have an uninformative display or none at all. Therefore, it is easiest to use the remote control for diagnostics, on which everything you need to know to determine the malfunction is written. Diagnostics is based on the data of numerous sensors of the air conditioner.

Decoding error codes

Cooling air is a key function of an air conditioner, so the related systems and parts are under constant stress and tightly controlled. Both passive sensors, relays, and a system of periodic checks are used, the interval of which is controlled by an internal timer. The following are some error codes that describe malfunctions in the air conditioning system.

H11 - the indoor and outdoor units cannot establish communication or the control does not work due to a malfunction in the electronic boards.

H12 - the outdoor unit does not have the appropriate power to work with the indoor unit.

H15 - malfunctions of the compressor temperature control sensor.

H16 - malfunctions in the freon exchange system, manifested in the fact that the external unit consumes low current. Another reason is an open circuit of the transformer or a malfunction of the IPM power module, disassembly is necessary. This check is controlled by a timer and is repeated continuously.

Deciphering the codes responsible for the malfunction of the sensor system

Below are some codes that show a break or failure of control devices, relays, sensors, which makes it impossible to control the air conditioner. A clear sign that replacement parts are needed.

H14 - air sensor.

H21 - float sensor.

H51 - the relay of the AC Robot system, which is responsible for controlling nozzle clogging, has tripped.

H52 - malfunction of the limiter relay.

H98 - the temperature relay has tripped, which controls the operation mode of the indoor unit when the air is heated, the signal indicates insufficient heat extraction.

Error codes for panasonic air conditioners

By correctly identifying problems, you can clearly understand what spare parts are needed, what repairs are to be done, whether the electronic control system needs intervention, or signal markings indicate minor problems. In general, advice can be given - if the timer light is on or flashing, you should call a qualified craftsman.

Malfunctions and their decoding

Modern automatic washing machines are equipped with a special self-diagnosis function. This means that in the event of any malfunction, a digital error code appears on the display. Having learned its meaning, you can try to solve the problem yourself.

If the device does not work, and the code does not appear on the display, the following steps must be taken:

- simultaneously press two buttons - "Delayed start" and "Without draining";

- now close the door and wait for it to automatically lock;

- after no more than 15 seconds, automatic diagnostics will begin.

At the end of it, the machine will either work properly, or a digital code will appear on its display. First of all, you need to try to reset it. For this:

- disconnect the fully automatic washing machine from the mains;

- wait at least 10 minutes;

- turn it on again and activate the washing mode.

If these actions did not help and the code is also displayed on the scoreboard, then you need to find out its meaning:

- ERR1 (E1) - the selected mode of operation of the device is not activated;

- ERR2 (E2) - the tank is too slowly freed from water;

- ERR3 (E3) and ERR4 (E4) - problems with water heating: it either does not heat up at all, or does not reach the minimum required temperature for proper operation;

- ERR5 (E5) - water does not enter the tank of the washing machine at all;

- ERR6 (E6) - the connecting circuit of the main unit has completely or partially become unusable;

- ERR7 (E7) - the electronic board of the washing machine is faulty;

- ERR8 (E8), ERR9 (E9) and ERR10 (E10) - problems with water: this is either an overflow of water, or too much of it in the tank and in the machine as a whole;

- UNB (UNB) - this error indicates an imbalance, this may be due to an unevenly installed device or because inside the drum all things have huddled together;

- EUAR (EYAR) - the electronics of the control system is out of order;

- NO SALT (no salt) - the detergent used is not suitable for the washing machine / forgot to pour it / poured too much detergent.

DIY troubleshooting

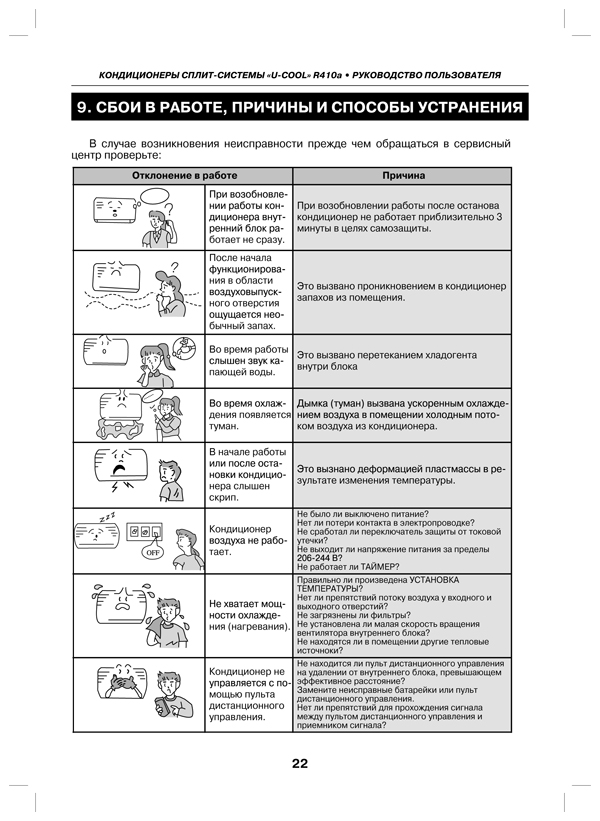

And now we will consider what troubles the owner of a conventional split system may encounter, and find out how they can be eliminated by “legal” methods.

The manufacturer divides all the "oddities" of the operation or stop of the device into 2 categories:

- malfunctions;

- phenomena that resemble malfunctions, but are not them.

First, let's look at cases from the first category, when the air conditioner really does not work or does not work correctly. They can be divided into 3 groups.

Split system stopped working

The unit can stop due to a breakdown of any important unit, but more often it does not turn on for banal reasons.First, check the power supply to the device: is the “On” button pressed, is the power cable plug in the socket and is the machine cut out due to overvoltage

Perhaps these are general power outages - try turning on the lights. If the lights do not light up, just wait for the power supply to resume or call the Energy Supervision operator

To begin with, check the power supply to the device: is the “On” button pressed, is the power cable plug in the socket and is the machine cut out due to overvoltage. Perhaps these are general power outages - try turning on the lights. If the lights do not light up, just wait for the power supply to resume or call the Energy Supervision operator.

If you are using a remote control or wall panel, the signal may not come out due to a bad battery. Just replace the batteries with new ones, after checking the expiration date

Owners of units with a timer should never forget about the settings. If you want to turn on the split system before the specified time, it will not work, of course. Be sure to check the preset settings and adjust them or just reset them.

If no action helps, and the air conditioner does not react in any way to attempts to turn it on, you will have to call the technical service.

Insufficient cooling or heating

If the equipment is operating normally, but the temperature in the room does not change, first check that the windows and doors are closed.

The next step is to adjust the settings. The heating or cooling settings may have been set too low, causing the unit to only maintain normal room temperature.

Do not forget about such a feature of the split system as a possible 3-minute turn-on delay.Just wait until the unit starts working.

While waiting, you can look outside and make sure that the outdoor unit is free and that nothing has accidentally fallen on it from the balcony or upper floors. Air access to the grate must always be open

A common cause of any malfunction is filter contamination. Clean quickly with a vacuum cleaner or more thoroughly with soap and water.

Filter cleaning instructions:

- Raise the front panel until it clicks, so that it stays open.

- Carefully take the filter frame by the fasteners, lift it up and remove it.

- For dry cleaning, use a vacuum cleaner, for wet cleaning, use a cloth soaked in water.

- If, in addition to coarse filters, bactericidal and carbon filters are installed, remove them and vacuum them, and replace them after six months of use.

Do not use aggressive or abrasive agents. If you clean the filters every 2 weeks, the operation of the split system will stabilize, and problems will occur much less frequently.

Disruptions in work for various reasons

Much less often, Kentatsu air conditioners have malfunctions that require the immediate intervention of technical support workers.

On the territory of Russia there are more than 80 authorized service centers, mainly in large cities.

If you live outside the city, you can call the master at home or consult by phone. Often a few professional tips will help you troubleshoot problems.

Reasons for qualified intervention:

- frequent or random flashing of indicators that does not stop after several attempts to turn on / off;

- permanent shutdown of the machine on the electrical panel;

- ingress of foreign objects or water into the body;

- Interruptions in the operation of the remote control or the power button.

Do not forget that the incorrect installation of one of the units may cause poor performance. That is why the manufacturer recommends contacting professional installers, and not connecting the split system yourself.

AUX Split System Error Codes

All Aux brand air conditioners have a self-diagnostic system, which, when problems are detected, displays equipment error codes on the display. This is a hint where to look for the cause of the malfunction. The failure coding consists of numbers and Latin letters. Error indications on different models of climate control equipment may vary slightly.

Unified commands include:

- Type of failure Display of digital pipe (no alphanumeric designation) - malfunction of the display of the indoor unit.

- E1 - malfunction of the temperature sensor (thermistor) of the indoor unit. In parallel with this indicator, the yellow timer LED on the indoor unit flashes (every 8 seconds). The system at this moment is completely stopped and does not respond to external commands.

- E2 and E3 - evaporator sensor errors.

- E4 - malfunctions of the fan motor (PG feedback motor).

- E5 - errors of the outdoor unit of air conditioning equipment (Outdoor protection function).

- E6 - errors in the fan motor of the indoor unit of the split system.

In this case, the exact nature of the error depends on at what point in the operation of the air conditioner this or that indicator on the device was lit.

Error E3 most often appears after 5-10 minutes of operation of the split system. This may be due to:

- problems with power contacts;

- severe contamination of the filter or evaporator (because of this, the fan accelerates extremely quickly without load;

- malfunctions of the PRM sensor speed sensor, etc.

When error E4 occurs, the air conditioner, as a rule, does not work in ventilation and cooling modes. But when you turn on the device in heating mode, it immediately gives an error. The problem indicates a malfunction of the fan of the indoor unit of the Aux brand air conditioner.

The fan of the indoor unit is an important part of the air conditioner, which provides forced air circulation through the heat exchanger due to the fact that it blows the cold formed on the radiator into the room

When diagnosing an air conditioner, you need to take into account the time at which the error is generated. If the code is displayed with the device turned off, this may indicate problems with the controller, and not with the part itself.

Those. the controller just hangs and periodically issues an error code. If, after checking all the elements of the split system, it is clear that they are in good condition, you need to check the control board and, if it is faulty, replace it.

Conclusions and useful video on the topic

You can see how the Panasonic air conditioner is cleaned in this video:

How to check the internal module for errors, the following video will clearly demonstrate:

Panasonic intelligent air conditioner systems are able to timely notify the owner of the climate control device about a malfunction that has occurred in the bowels of the unit. Information on decoding can be found in the passport or video review.

Having found out the error code, a person can decide whether to correct the situation on his own (for example, clean the drainage) or call the master for a more complex repair.

Tell us about how you determined a violation in the operation of the Panasonic brand climate system by code. Share the nuances of diagnosing and troubleshooting that you know. Please leave comments in the block below, post photos and ask questions on controversial and interesting points.

Conclusions and useful video on the topic

Timely disassembly and cleaning of the air conditioner will help to avoid errors in operation:

An example of the signal of the air conditioner indicator lights when an error occurs:

This video clearly shows how to disassemble the General Climate air conditioner fan motor with your own hands:

When there are signals of mistakes the owner of the air conditioner General Climate should not delay eliminating them. Self-repair of household appliances requires certain skills and the availability of specific tools. If the owner of the unit has both, he may well try to fix the breakdown on his own.

Otherwise, intervention in the complex mechanism of an air conditioner or split system is fraught with more serious problems. An inexperienced owner of the equipment is advised to invite an air conditioner repairman from an authorized service, without trying to fix the device with his own hands.

Want to talk about how you independently determined the cause of the failure of the air conditioner? Or do you want to share your own experience in performing simple repairs? Write comments, please, in the block form below, publish photos on the topic of the article, ask questions.