- Bosch washing machine device

- Service test

- Why else is there an imbalance?

- Tips

- Electronics problems

- Tips

- Typical malfunctions of Bosch washing machines

- Water does not heat up

- Water is not drawn

- Water does not drain

- Drum not spinning

- Excessive noise and vibration

- Washing machine does not turn on

- Useful repair tips

- Where to begin

- Reload the SMA scheme.

- Check power, signal loops.

- Check power, signal loops

- What did they do before?

Bosch washing machine device

According to a number of sources, in all Bosch washing machines, the body consists of 28 parts. They are always located in the same way, and disassembly can be performed without the use of special tools. The drum pulley is attached to a special bolt. Reinforced protection against leaks is required. And also, of course, there are the following elements:

- anti-shake stabilizers;

- overload protection system;

- accurate pollution sensors.

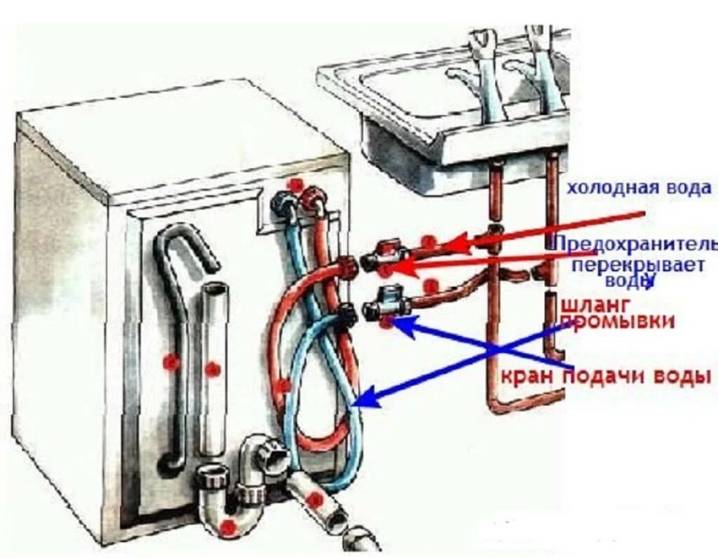

As for the connection, it can be done in various ways. A direct connection method is possible for almost any model produced by a German company. But the problem is that the installation of a hose directly into the water supply is not available everywhere.Often you have to use plumbing "doubles" and even "tees". In systems with old mixers, water is supplied through adapters with a tap installed at the mixer inlet. An extension sleeve is then used to supply hot water. In the second method, the hose is connected through a tee mounted in the shower head line. Sometimes a simple connection to flexible hoses is used.

Old metal pipes allow you to use various methods of self-tie-in. But the polypropylene pipes used after the overhaul do not give such an opportunity. You will have to connect to them using a special soldering iron. And almost all people should call a professional plumber. They are usually connected to cross-linked polyethylene and metal-plastic through special fittings.

Service test

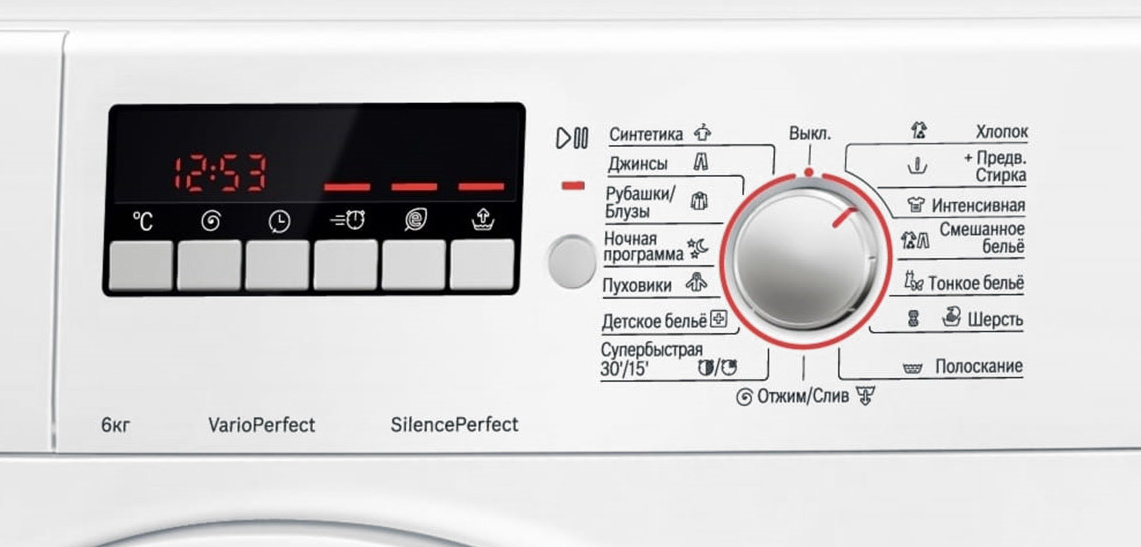

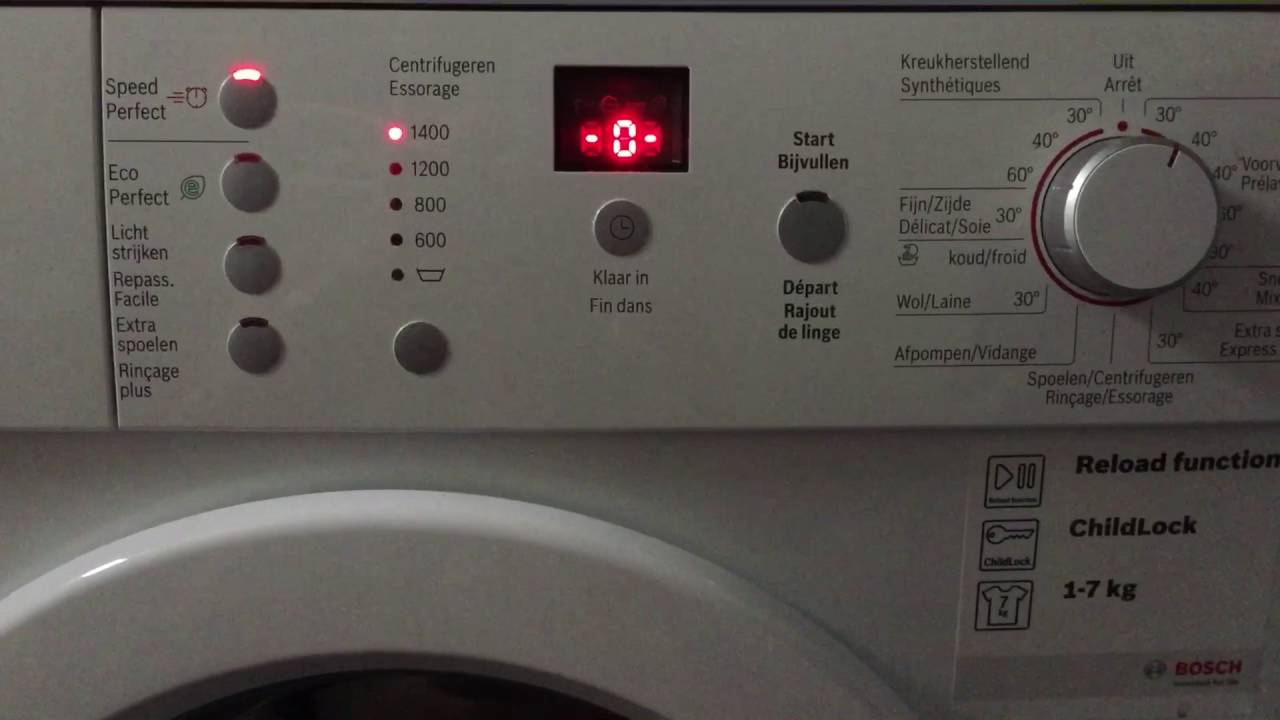

To run the Bosch Maxx 4 self-diagnosis, the machine must be switched off. To do this, simultaneously press the buttons for additional options and turn the options knob 30 degrees cotton. After a successful start, you can choose a test.

Bosch Maxx 4 programs comply with the following tests:

- cotton 60 - check the electric motor;

- cotton 60 economy - drain pump;

- cotton 90 - heater;

- spin - main valve;

- drain - preliminary valve.

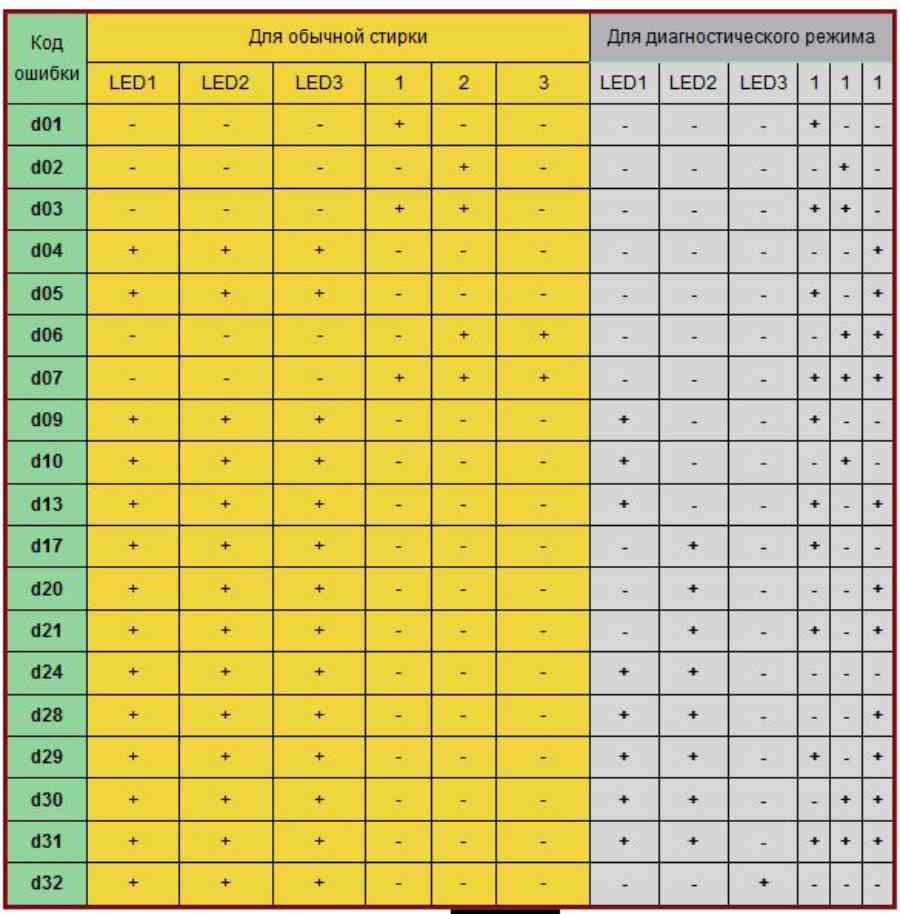

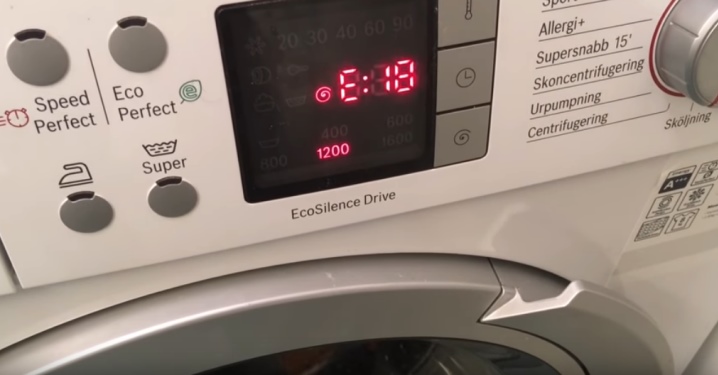

To start the program, you need to click on the start button. Combinations of indicators indicate breakdowns. In new models, all error codes are displayed on the screen.

Why else is there an imbalance?

Most often, an imbalance leads to an overweight or underweight of linen. In the first case, the drum becomes too heavy and goes astray from the intended "orbit", and in the second case, things crumple and upset the balance. Troubleshooting is simple: just open the hatch, pull out excess clothes or report more.

It is more difficult if a malfunction with the E32 is caused by improper installation of the washer or damage to the design of the machine. So, five breakdowns and failures lead to an imbalance at once.

Shipping bolts not removed. Such fasteners are necessary for the safe transportation of the washing machine, as they fix the drum in a fixed position. Before the first wash, all 4 latches must be removed, and plastic plugs are inserted in their place. If you start a tank clamped by screws, the engine will try to spin it, which will lead to shaking, “jumps” and internal mechanical damage. Moreover, such breakdowns are not covered by the free warranty, as this is a serious violation of the Bosch operating rules.

Incorrect installation of the washer. According to the instructions, the machine must be placed on a flat and hard surface - concrete or tile. The more stable the equipment is, the more vibration is suppressed and the less likely to be unbalanced, so wood, linoleum and carpet are considered poor coverage.

It is also important to level the unit at the building level by adjusting the height of the legs. It is recommended to use special anti-vibration nozzles and mats.

Broken bearing assembly. If you do not know what to do with damaged bearings, then it is better to entrust their repair to professionals.

The work is long, difficult and costly.

Damaged damping system. The drum in the washing machine is suspended, and the springs and shock absorbers holding it are designed to smooth out the pressure of centrifugal force and suppress outgoing vibrations. However, when the struts are worn or the fasteners are loose, the dampers do not perform their functions to the full, which leads to an imbalance.It is not difficult to check the integrity and elasticity of the shock absorption: just remove the top cover, put pressure on the tank and evaluate its behavior. If the tank jumped up and fell into place, then everything is in order; if chaotic pitching begins, a replacement is required.

Broken counterweights. Designed to suppress the vibrations of the accelerating drum and counterweights - concrete blocks located on top, bottom and sides of the hull. They add weight to the washing machine, increasing its stability. But if the concrete collapses or deforms, then the balance is disturbed. We remove the cover, check the integrity of the stones and try to fix it: we tighten the bolts and cover the cracks with PVA glue.

If you do not know what to do with damaged bearings, then it is better to entrust their repair to professionals. The work is long, difficult and costly.

Damaged damping system. The drum in the washing machine is suspended, and the springs and shock absorbers holding it are designed to smooth out the pressure of centrifugal force and suppress outgoing vibrations. However, when the struts are worn or the fasteners are loose, the dampers do not perform their functions to the full, which leads to an imbalance. It is not difficult to check the integrity and elasticity of the shock absorption: just remove the top cover, put pressure on the tank and evaluate its behavior. If the tank jumped up and fell into place, then everything is in order; if chaotic pitching begins, a replacement is required.

Broken counterweights. Designed to suppress the vibrations of the accelerating drum and counterweights - concrete blocks located on top, bottom and sides of the hull. They add weight to the washing machine, increasing its stability.But if the concrete collapses or deforms, then the balance is disturbed. We remove the cover, check the integrity of the stones and try to fix it: we tighten the bolts and cover the cracks with PVA glue.

The imbalance protection function is often referred to as the “self-preservation instinct” of the washer. Here, as in nature: the machine feels the approach of danger, anticipates the consequences and leaves the race, reducing the risk of breakdowns. The owner needs to respond to the Bosch signal in a timely manner and restore the balance of the drum.

Tips

In addition to the poor quality of equipment and the technical wear and tear of its elements, as well as violations of the rules for using the unit, objective factors that directly affect the functioning of household appliances can also cause malfunctions - this is the quality of water and electricity supply. These are the ones that most often lead to errors.

Any drops in the network have the most adverse effect on the operation of the washing machine, lead to its rapid failure - which is why the problem must be eliminated. At the same time, you should not completely rely on the built-in voltage surge protection system inside the most modern machine models - the more often it works, the faster it will wear out. It is best to get an external voltage stabilizer - this will allow you to save money on repairing equipment in case of problems in the mains.

This will result in equipment failure.

To prevent the appearance of limescale, you can use chemical compounds. They will not be able to cope with significant "salt deposits" and will not remove old formations. Such compositions contain a weak concentration of acid, so the processing of equipment should be carried out regularly.

Folk remedies act more radically - they clean quickly, reliably and very high quality. Most often, citric acid is used for this, which can be purchased at any grocery store. To do this, take 2-3 packs of 100 g each and pour them into the powder compartment, after which they turn on the machine at idle. When the work is completed, it remains only to remove the pieces of scale that have fallen off.

However, manufacturers of household appliances claim that such measures are fraught with the most dangerous consequences for machines and cause damage to their parts. However, as testified by the reviews of many users who have been using acid for many years, such assurances are nothing more than anti-advertising.

Which tool to use is up to you.

In addition, failure is often the result of a human factor. For example, any forgotten metal thing in your pockets significantly increases the risk of equipment failure.

In order for the Bosch machine to serve faithfully for many years, it needs regular maintenance. It can be current and capital. The current one is made after each wash, the capital one needs to be done every three years.

During the overhaul, the machine is partially disassembled and the degree of wear of its parts is checked. Timely replacement of old elements can save the machine from downtime, breakdowns, and even flooding of the bathroom. These rules apply to all Bosch machines, including the Logixx, Maxx, Classixx series.

How to reset an error on a Bosch washing machine, see below.

Electronics problems

If, after diagnosing the door and UBL, the error code E3 does not disappear, it is recommended to check the wiring for an open. When it is “clean” here, then the problem is in the control board. Most likely, one of three problems has occurred:

- a semiconductor broke on the module, which is “responsible” for the Bosch self-diagnosis system (another option is that the corresponding “track” burned out);

- the element connecting the electronic unit and the blocker has burned out (the “track” is often damaged);

- another important component of the module failed.

It is almost impossible to cope with the diagnostics and repair of the board on your own. It is necessary to carefully “ring out” each element of the module and check the system on special equipment

One careless movement can aggravate the situation up to the "fatal outcome" of the technique.

Dealing with the E3 code at home is possible, but difficult. The main thing is not to rush, follow the instructions, and in case of difficulties, contact the service center for professional help.

Share your opinion - leave a comment

Tips

Some users are interested in information on how to reset the F21 error on their own. However, not every person knows why it is necessary to reset the error at all, because there is an opinion that it will disappear on its own after the cause of the breakdown is eliminated. Such an opinion is erroneous. The code will not disappear on its own even after repair, and a blinking error will not allow the washing machine to start working. Therefore, professional masters recommend using the following recommendations.

- First of all, you need to turn the program switch to the “off” mark.

- Now you should turn the switch selector to the "spin" mode.You will need to wait a bit until the information about the error code appears on the screen again.

- Then you should hold down the key for a few seconds, with which the drum speed is switched.

- Next, the switch selector should be set to the "drain" mode.

- It is worth holding down the button for switching revolutions for a few seconds.

If, after the above steps, all indicators begin to blink, and the machine beeps, then the error reset was successful. Otherwise, you will need to repeat all the manipulations again. You can eliminate the occurrence of such an error by regularly diagnosing the washing machine, installing a voltage stabilizer, as well as checking clothing pockets and a more careful attitude to the contents of the drum.

See the video for the causes of the F21 error and their elimination.

Typical malfunctions of Bosch washing machines

The most common malfunctions are:

- lack of water heating;

- water is not drained;

- the drum does not rotate;

- noise and vibration;

- water is not poured after starting the program;

- the electric motor is not working.

Consider each malfunction with an indication of the possible causes that may lead to them.

Water does not heat up

The most vulnerable part of the equipment is the heating element (heater), it is prone to breakage with intensive use of the device and poor water quality, as a result of which a thick layer of scale from salt deposits forms on it. In most cases, the solution to the problem is the self-cleaning of the heating element from scale or its replacement. When operating a washing machine with hard water, as a rule, replacement is required after 3-5 years of operation.

There may be no water heating also due to the choice of an inappropriate washing program, in this case, re-read the instructions and select the appropriate program and mode.

Water is not drawn

Potential reasons:

- low water pressure in the pipeline or shutdown of water supply;

- filling valve is closed;

- failure of the water level controller or inlet valve.

Water does not drain

If water does not drain through the drain hose, the program selection must be checked. Some models have programs without draining. If necessary, select the mode with water drain.

Clogging of the drain hose, which must be cleaned and rinsed, can prevent water from draining. You also need to check the filter and nozzle for the presence of small objects, hair and thread, wool. Other prerequisites may be pump malfunctions, malfunctions of the electronic board.

Washing machine repairs are best left to the professionals!

We present you our unique catalog of private craftsmen and service centers

—

Select your city and master in the filter: by rating, reviews, price!

Drum not spinning

Most modern models have built-in overload protection, that is, the drum will not rotate and the wash will not start until the excess items are removed from the drum. If after that, twisting your hand, it rotates, you can start washing.

Other causes of failure:

- rupture or displacement of the drive belt;

- the heating element burned out;

- breakdown of the tachogenerator or pump;

- the electric motor is not working.

Excessive noise and vibration

If you notice a lot of noise and vibration during the first wash, turn off the device and check if the shipping bolts are removed, because they can cause the machine to vibrate and hum.

Other causes may be insufficient loading, uneven installation, or small objects.

A common cause is also wear on bearings and seals, blockages in the filter and pipe, and malfunctions of the drain pump. All these malfunctions are solved by self-replacement of failed elements, or by cleaning the filter and pipe.

Washing machine does not turn on

First of all, check if there is electricity in the outlet, if the outlet is working, if there is water in the pipeline. If there is water and electricity, then a breakdown can be caused by a malfunction of the electronic module, this should be indicated by the corresponding error code on the display.

The video describes the diagnosis and step-by-step elimination of the spin error. Such problems are associated with breakdowns of the pressure switch, electric motor or control module.

If it is impossible to identify the malfunction, the error code is not displayed, then it is necessary to contact the wizard for special diagnostics.

Useful repair tips

The most important thing in such a case is to understand how serious the problem is. Most damaged mechanical parts can be repaired or replaced by one's own hands

But in case of failures in electronics, to which there are a number of confirmations above, you almost always have to contact a professional service. Serious vibration rarely requires repairs. You can almost always limit yourself to unloading from excess laundry. But if the knock and vibration are constant, we can assume the following:

- broken suspension springs;

- breakage of shock absorbers;

- the need to tighten the ballast bolts.

If a particular node does not work, it is advisable to check all the wires associated with it with a multimeter before replacing or repairing it. Cracking and rattling noises during the wringing process almost always indicate bearing failures. In this case, you need to change them immediately. By postponing this business, they create the risk of failure of the shaft and other important, expensive parts.

How to change bearings on a Bosch washing machine, see below.

Where to begin

Reload the SMA scheme.

Imported equipment, even of Russian assembly, is sensitive to network parameters. Failures (jumps, phase imbalances, low voltage, interference) are the causes of Bosch errors. If the problem is caused by power instability, the DTC will clear.

Method: unplug the plug - wait up to 15 minutes - restart the washing machine.

Check power, signal loops.

SMA Bosch is operated in damp conditions, vibrates during operation. The causes of washing machine errors are broken connections, moisture in the connectors. Regardless of the symbolism of the malfunction, the condition of the contacts and internal wiring is evaluated. Breaks, short circuits, damage to lines are easy to identify and eliminate without involving a professional.

Check power, signal loops

This is the "brain" of the washing machine, which generates errors. If no other cause is identified, the module should be tested. How to proceed is described at the end of the article.

What did they do before?

You can fix the washing machine that displays F00 with your own hands. To find out the reasons for the appearance of the error code, you need to remember what manipulations have been carried out with the machine in recent days. If you repaired the device literally yesterday or the day before yesterday, and today the designation “slows down” the operation of the equipment, then it will be easier to identify the malfunction.Usually, the F00 code occurs after replacing any part of the washer or temporarily turning off an individual element.

Sometimes an error may appear “from scratch”. If the washing machine was not repaired, there was no electrical overload, it is allowed to make an attempt to “reset” the code. If restarting the equipment helps, then you can continue to operate the machine. But what if the manipulations do not give the desired result? If F00 reappears, you will have to look for the root cause of the malfunction. It is possible that the control module is damaged and the board will need to be flashed.

But you should not immediately assume the worst. In most cases, it turns out to reset the code, and it will not bother you anymore. Let's figure out how to get rid of the F00 error.