- Installation Features

- Problems in the operation of Kiturami boilers

- Starting the Kiturami boiler

- Price range

- Operation features

- Boiler overheating.

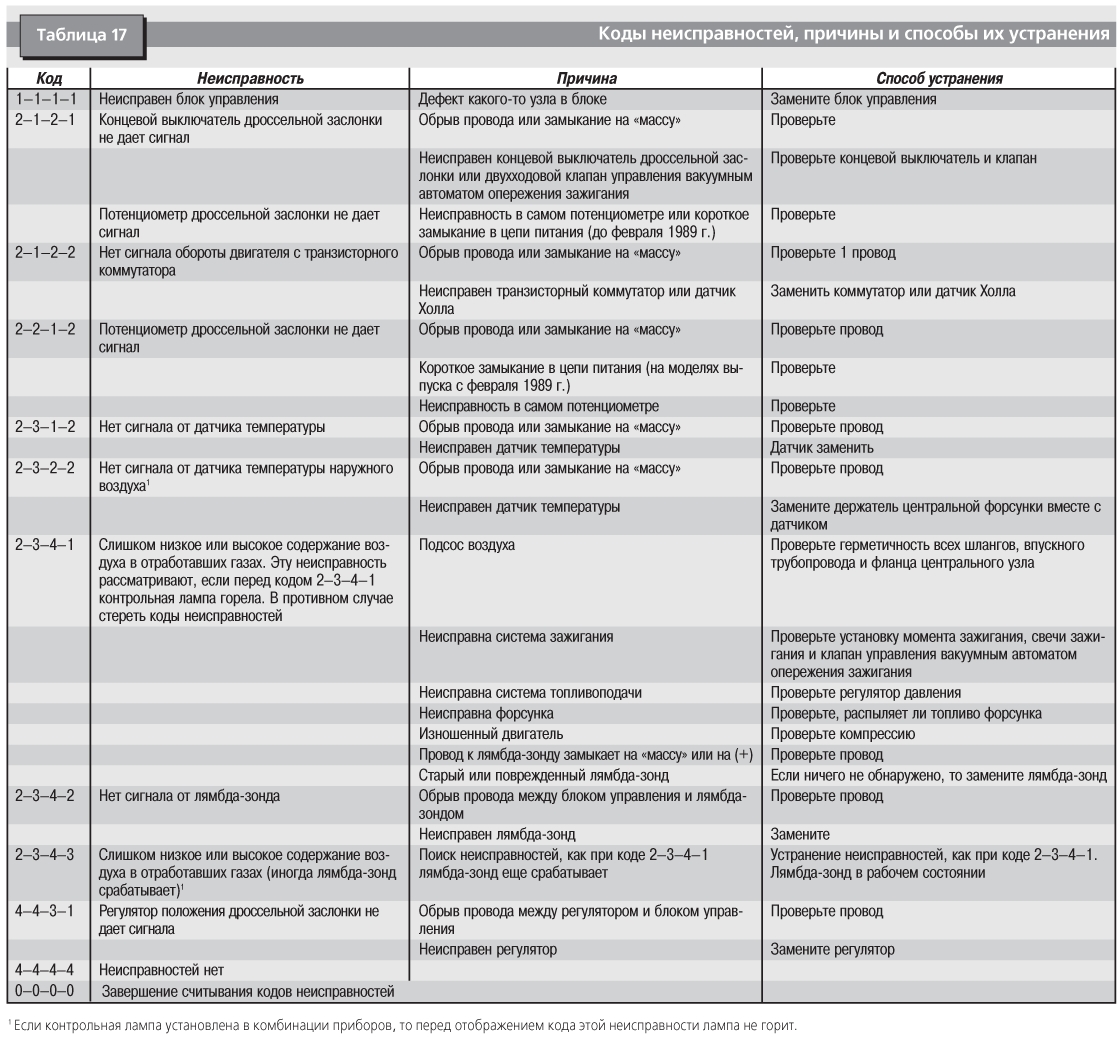

- Main malfunctions

- The main malfunctions of Immergas gas boilers

- Gas boilers from Kiturami

- Features and arrangement of boilers

- Mounted

- floor standing

- Why error 104 may occur - Insufficient circulation. Troubleshooting

Installation Features

When installing a heating boiler, the manufacturer recommends considering the following factors:

- the weight of the wall model is 30 - 45 kg, so it is not recommended to place it on light partitions; a load-bearing wall can be considered the best option for installation;

- it is recommended to use a rubber gasket to reduce noise from possible vibration;

- it is desirable that the installation site is not waterlogged.

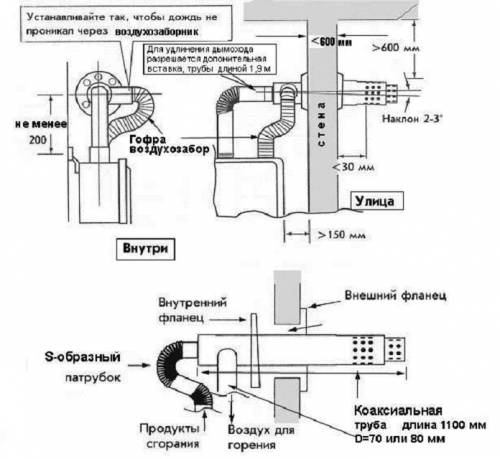

Particular attention should be paid to the installation of the chimney; a coaxial chimney is used to remove combustion products. To facilitate the work, the use of telescopic chimneys is allowed.

Everything you need to install a chimney

The installation instructions for the pipe look like this:

- when connecting individual elements, a sealing tape is necessarily used, and the tightness of the joint is achieved by tightening the connecting bolts;

- in the case of a pipe outlet outside the wall, the manufacturer recommends limiting the maximum length to 2.5 m;

- as for the installation of a pipe through the roof, it is necessary that a free descent to the pipe be provided throughout the length of the pipe;

- the horizontal section of the pipe in the section from the outlet of the boiler to the vertical section should not exceed 90 cm, otherwise the draft may deteriorate.

The diagram shows a chimney through the wall

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

The "Network" indicator is not lit - check the power in the socket and the fuse on the ignition transformer. If there is no voltage in the mains, call an electrician, if there is, call the service department.

The low water indicator on the control unit is on - there is no water in the device or the level is too low. Damage to the black wire of the boiler and the red cable of the sensor also lead to a malfunction.

The room temperature sensor works fine, but the radiators are cold - the circulation pump does not accelerate the coolant through the pipes or does it too weakly. Inspect the locking parts on the heating pipes. Check the pump itself.

The “Overheating” light came on - the heating system is not working properly. Check her out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The mesh filter may need to be cleaned. Examine it.

- Check circulation pump, repair or replace if necessary.

The "Safety" diode is lit - gas enters the boiler burner in small quantities or does not enter at all. Inspect the valves and open them if necessary. The problem remains - call the gasmen.

Schematic representation of a room remote thermostat: 5 main modes are laid in it, including presence, absence, shower, sleep, water heating control

The pump is running too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air pockets in it. Release the air.

The boiler began to heat up longer - look for a problem with gas pressure and the condition of the filters.

The burner vibrates when turned on - the size of the chimney is not enough for the normal removal of gases.

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system enters the boiler. The chemical treatment of the circuits and the heat exchanger will help.

Starting the Kiturami boiler

Everything is very simple: set the temperature threshold on the thermostat higher than the temperature in the house - the boiler turned on. The auger began to rotate and pellets fell into the closed burner. Just a few seconds and there was a pleasant smell of smoldering wood, like during a labor lesson, when we burned congratulations to mothers on March 8 on plywood.

Barely visible smoke appeared above the pipe and immediately disappeared. In the peephole of the combustion chamber, you can see how the flame is raging inside. The temperature of the coolant in the boiler reached the preset 60 degrees and the small circuit pump turned on, supplying the heated coolant to the hydraulic gun.

From the hydraulic arrow, part of the heated coolant mixed with cold returns to the boiler, and part goes to consumers. The controller turns on the radiator loading pump, and if the water temperature in the boiler is 2 degrees colder than the coolant temperature, then the other controller turns on the boiler loading pump. That's all.

It remains only once every few days to look into the boiler room and add pellets to the boiler bunker.

In case you forgot to look and the pellets ran out at night - the electric boiler turns on by timer every night and if it sees that the temperature of the coolant is below the set value (60 degrees) - it turns on its heating elements. Naturally at the night rate.

Price range

The range of Kiturami gas boilers is very wide. The cost of household models (for a private house) is in the range of 30-60 thousand rubles, but there are also more powerful models that will cost 100-800 thousand rubles.

Such a difference in prices is due to the degree of power and capabilities of the boiler, its purpose and design features.

As a rule, users choose units of lower power and, accordingly, cost.

Before buying, you should clarify the terms of delivery. Boilers in the basic configuration do not have a chimney, so you need to immediately decide which type is needed and order it. You should also immediately acquire filters and a voltage stabilizer.

Operation features

The design of the boiler may differ depending on the series. So, the Habitat double-circuit device (Habitat 2) can heat an area of up to 280 m², while it has compact dimensions.

Ignition occurs automatically, the boiler is equipped with sensors to protect against draft disturbance, overheating, flame extinction. The equipment reacts to voltage drops: at the same time, the automation is activated and the fuel stops flowing into the burner.

The Micra series (Micra 2) also belongs to the dual-circuit types. The secondary heat exchanger allows you to heat water for hot water supply (DHW). Adjustment of settings is mechanical, the body has a wall-mounted arrangement. There is a flame control, ignition.

From the new line, the Herman Thesi 23 E models are presented. The power of the equipment is 30 kW, and the throughput is 17 liters per minute. These models of boilers have an automatic make-up function, which turns on at reduced pressure.

Boiler overheating.

A common cause of such a malfunction is a violation of the circulation of the coolant due to a breakdown of the pump, contamination of the filters of the heating system, the formation of boiler stone in the boiler heat exchanger and increased hydraulic resistance of the heating system. First, check the condition of the temperature sensor and its connection to the electronic board, as well as the serviceability of the circulation pump. After resetting the error, turn on the boiler to minimum power and check the temperature difference between the direct and return pipelines. In case of a significant difference in temperature, it is necessary to check the condition of the heating system (pressure, air pockets, shut-off valves, sumps, etc.). The contamination of the heat exchanger is determined by the characteristic noises during heating of the boiler, as well as a significant pressure drop in the return pipeline.

Main malfunctions

Kiturami boilers are renowned for their reliability and durability of parts. However, the possibility of individual malfunctions cannot be ruled out.

Most often, the nodes under maximum load fail - the heat exchanger and the gas burner.

A layer of lime deposits develops in the heat exchanger, which reduces the efficiency of heat transfer.

It is necessary to increase the combustion temperature, as a result of which the outer part of the assembly receives too much heat and fails.

The gas burner is prone to clogged nozzles and other problems that lead to the extinction of the flame and difficulties in igniting the boiler.

Often there are malfunctions of the sensors of the self-diagnosis system themselves - poor contact, open circuit, short circuit.

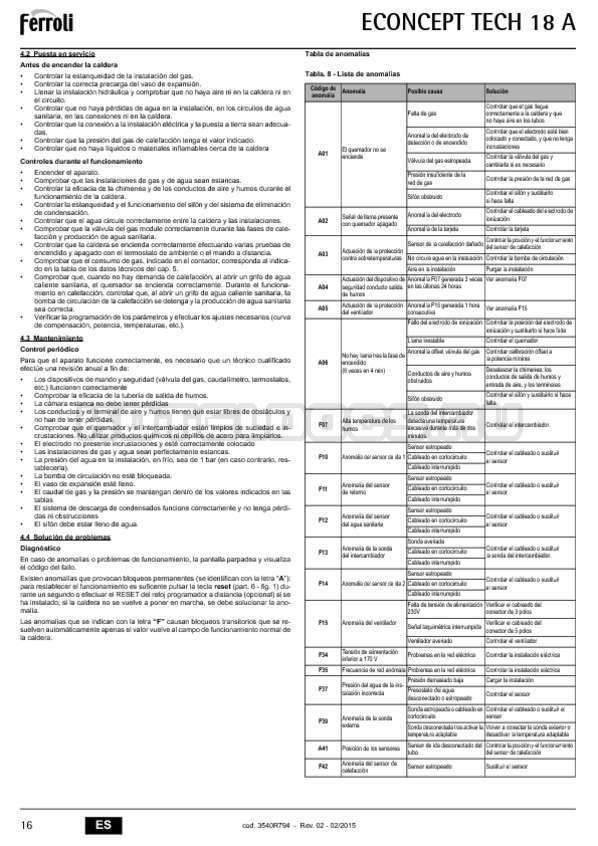

The main malfunctions of Immergas gas boilers

The most common problem is with the ignition of the burner.

It is indicated by the code 01 and can have several reasons:

- Gas supply problems. There may be a lack of pressure in the gas pipeline, a closed gas valve, a gas valve failure, and other problems.

- Poor condition of the burner nozzles. They can be clogged with soot, soot.

- Incorrect power connection. All European boilers are phase-dependent, they need a certain connection of all electrodes and the obligatory presence of grounding. If the connection is not made correctly, the boiler is immediately blocked at startup and cannot start working.

NOTE!

Sometimes the boiler suddenly stops starting for unknown reasons. You should check the connection of the electrodes on the common shield, they may have been accidentally mixed up during the repair. The second common problem is overheating of the boiler

The second common problem is overheating of the boiler.

It can also be caused by several reasons:

- The fluid circulation rate has dropped due to problems with the pump.

- Too hard water has caused the formation of a scale layer inside the heat exchanger, which is a natural heat insulator and reduces the heating efficiency. This caused an increase in the combustion regime. A situation has arisen when, in order to obtain the desired temperature, it is necessary to heat the heat exchanger more strongly, which causes an excessive load on the metal, increases gas consumption, and prematurely disables all boiler components.

Another error that often appears on the display is the presence of a parasitic flame (error 20). The system sees a flame on the burner that is currently off.

The reasons for this condition may be:

- Presence of condensation drops on the control board.

- Due to poor grounding, a static charge appears, which is perceived by the system as a signal from a burning flame.

In addition to these errors, there may be other, less frequent and not determined by electronics errors:

- Smell of gas, indicating a leak.

- Failure of the pressure switch at start-up, requiring cleaning the chimney.

- Weak, orange flame showing soot or soot clogging in the nozzle passages.

Most errors that occur for the first time are immediately reset. This is done because the boiler electronics are highly sensitive and often take electrical pickups as sensor signals.

However, if the error occurs again and again, you should immediately contact the service department.

Gas boilers from Kiturami

The South Korean company Kiturami was founded in 1962 as a small metalworking workshop.

During its existence, a small company has managed to develop into a solid and powerful corporation that produces a wide range of heating equipment for various purposes. Scientific and technical research is being carried out, new components and parts are being tested.

Kiturami gas boilers are built with the most efficient and advanced technology, but without being over-loaded with unused features that only add to the cost.

The result of this approach is a range of economical and durable units capable of performing tasks of any complexity and volume, with high reliability, resistance to external loads and durability.

Features and arrangement of boilers

Czech-made Thermona heating equipment comes with one and two circuits. More powerful floor standing units require a separate installation room as well as a solid foundation. Wall-mounted appliances are popular in apartments, their compact body fits perfectly into small kitchens.

The design is no different from other boilers. Includes an expansion tank to collect excess fluid when heated. Electronic control, easy adjustment thanks to the automatic system.

Mounted

These are devices with power from 14 to 90 kW. Water heating is carried out both in a flowing way and with the help of an additionally connected boiler. The device effectively works on the main and liquefied fuel. The combustion chamber is open and closed. Depend on your chimney type.

The burner with flame modulation allows you to adjust the heating power, save fuel. Ignition is carried out automatically. Provided protection system:

- Sensor of overheating, ionization, removal of combustion products.

- Bypass.

- Antifreeze mode.

Among the model range you will find convection (standard) units and condensing units. The latter additionally use the energy of condensate, which increases their efficiency up to 107%.

floor standing

There are non-volatile models that do not require connection to electricity. Cast iron heat exchangers with a long service life increase the efficiency of the gas boiler. Power is controlled by a reduction gear. Such devices are not equipped with a pump, so the liquid circulates naturally. Electronic ignition.

Why error 104 may occur - Insufficient circulation. Troubleshooting

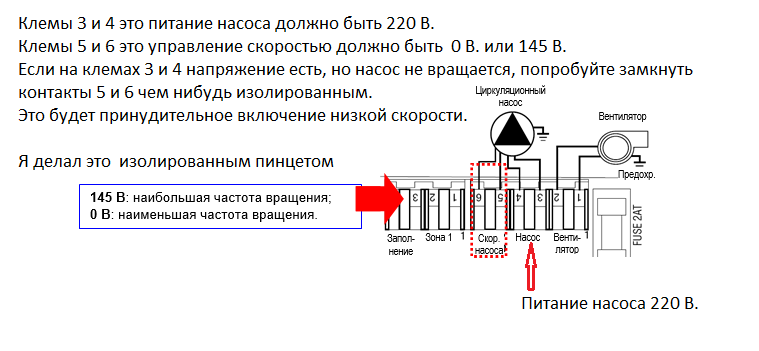

The circulation pump of the boiler has two speeds of rotation in the manual, they are designated as V2 (55 W) and V3 (80 W). The ECU naturally controls the speed of the pump.

In domestic hot water (DHW) mode The pump runs at speed V3 for better heat transfer.

In central heating (CH) mode, the control unit switches the pump speed depending on the temperature difference at the inlet and outlet of the heating system.

Therefore, the pump is controlled by not one, but two relays. One supplies 220V power and the other controls the speed.

To check these power circuits of the pump, it will have to be turned on. But for this you don’t need to light the cauldron, we don’t want to rape him! There is a simple and quick way to turn on the pump without lighting the burner.

It is necessary to transfer the boiler to the “Purge” mode. To do this, press the ESC button on the boiler panel and hold it pressed for more than 5 seconds. Purge mode is activated - During this mode, the circulation pump starts and runs in cycles of 60 seconds. incl. 30 sec off and so on for 6 minutes. and at the same time without ignition of the burner. And we need it!

This mode is designed to remove air from the heat exchanger and circuit, but we use it to control the operation of the pump. It turns on for 6 minutes, or you can turn it off forcibly by pressing ESC again.

So, we start the "Purge" mode and measure the alternating voltage at the terminals. Let's look at the drawing.

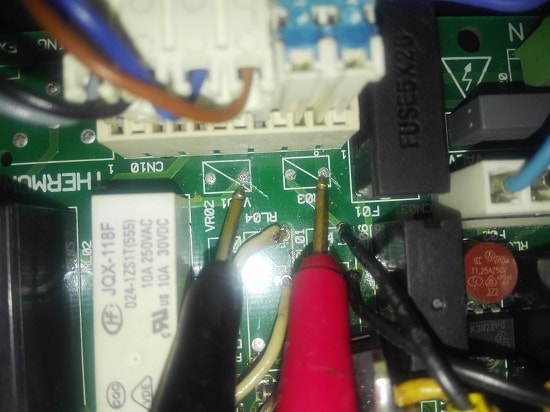

Addition: The voltage is 220 volts, with the relay RL 04 (the relay supplying power to the pump) it is possible and easier to measure at the control points on the board, see the photo below, (there are no two relays on the board, they are on the wires to the side) and the points where the probes indicate and there are needed. If they receive 220 volts, relay 04 is working.

Contacts on the board for voltage measurement with relay RL04

In my case, this was the case, 220 V was supplied to contacts 3 and 4 from the RL 04 relay. but the pump did not turn.

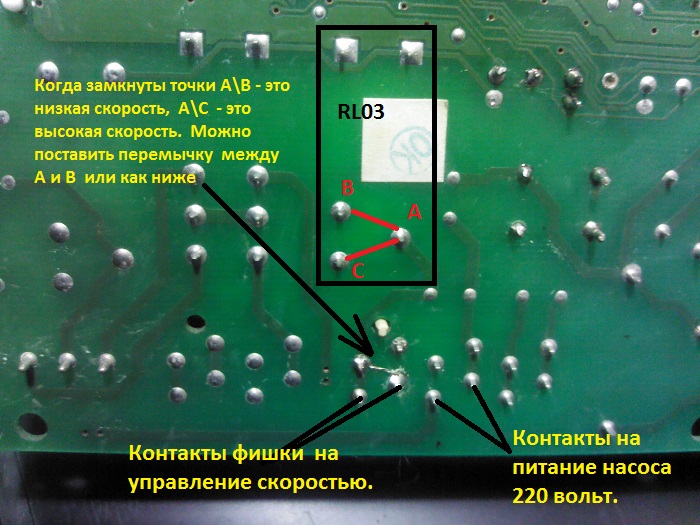

Relay contacts RL03 (pump speed control relay type JQX 118F) when the boiler was turned off, the multimeter rang shortly, which is the norm for a lower rotation speed, but under load the relay behaved incomprehensibly as the pump motor did not spin at all. As soon as pins 5 and 6 were closed with tweezers, the pump started to work. The output of the relay controlling the speed of the pump is faulty.

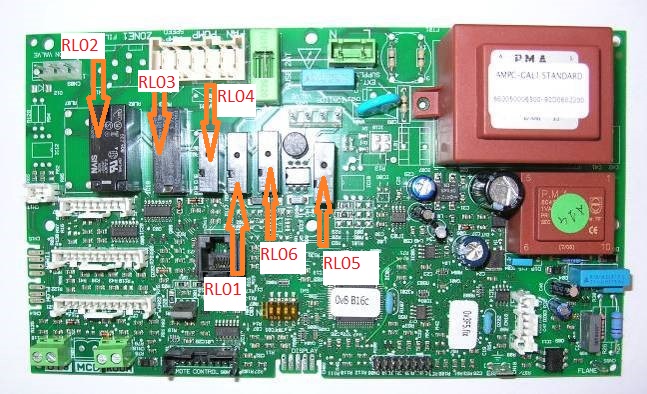

Therefore, until the time I pick up a relay for replacement, I just soldered the jumper, i.e. jumped from the installation side 5 and 6 conclusions. In fact, a working relay does almost the same job, closes this circuit or switches it to another contact, this is how the pump speed switches. Below are photos that will help you not to make a mistake.

Scheme and numbering of the location of the relay on the board

Photo of the board with explanations for installing a jumper on the RL03 relay - pump speed control.

So, these closed contacts, directly on the relay (Points A and B) or on the chip below, which are essentially the same, forcibly turn on the low speed of the pump.

But still, finally I found a great option to replace this relay, and now, in February 2018. my boiler has found its usefulness.