- The device and principle of operation of Bosch boilers

- Failures in electronics (error 3**)

- Rules for safe operation

- Other malfunctions

- Specifications

- Expert advice

- Helpful Hints

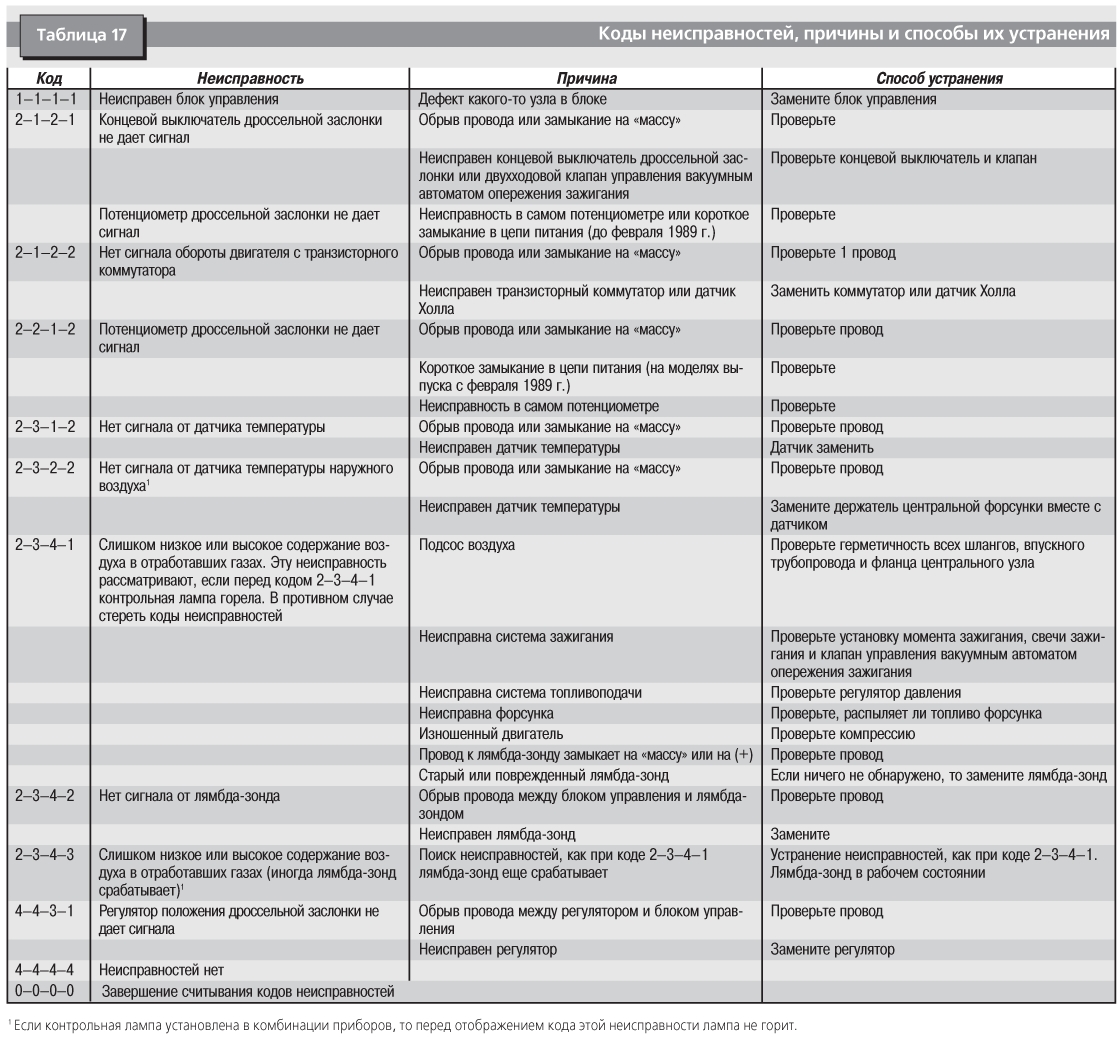

- Error codes archive

- Bosch 6000 boiler errors

- Category A

- Categories C, D, E, P and F

- Variations of breakdowns with code E4

- Malfunctions of ignition of boilers Ariston. Error 501

- How to properly set up the boiler

- Other errors of Bosch gas boilers

- Features of Ariston gas boilers

- Operating principle

- Elimination of defects in work

- Why does the pressure in the boiler drop?

- Conclusions and useful video on the topic

- Conclusion

The device and principle of operation of Bosch boilers

The most popular models among the Bosch boiler line are double-circuit ones. They have two tasks: the first is heating the room to a predetermined temperature, the second is the provision of hot water for domestic needs.

Bosch devices, namely the Bosch Gas 4000 W and Junkers Bosch models, are equipped with two independent heat exchangers, which allows them to perfectly perform two tasks: heating water and providing heat in the room.

In each of the models, it is possible to choose the power of the device that suits you from 12 to 35 kW, when choosing, the area of \u200b\u200bthe room is taken into account.As for heating the liquid for household needs, the performance is about 8-13 liters per minute.

Advantages of a wall-mounted double-circuit boiler:

Flaws:

The first 20-40 seconds after you turn on the hot water faucet, cold water flows.

Let's take a closer look at how the device works, using the example of the Bosch Gas 4000 W ZWA 24 model. When the boiler is operating in heating mode, heat is transferred using a gas burner to the primary heat exchanger, which is a structure of copper tubes and plates.

In order for them not to deteriorate from exposure to high temperatures and water, their surface is covered with a protective layer. Its main task is to transfer the heat generated during the combustion of the flame to the heating system. The movement of water in the system is provided by the pump.

Also, the design provides a three-way valve, its task is to prevent water from entering the secondary heat exchanger. The secondary heat exchanger is necessary for domestic water heating. The heated liquid for the heating circuit leaves the device through the heating supply line, and the cooled liquid enters through the heating return line.

When the boiler is set to heat domestic hot water, the 3-way valve closes the heating circuit. The heated liquid flows from the primary heat exchanger to the secondary one, and then flows out of the device.

Bosch boiler three-way valve

Bosch boiler three-way valve

The advantage when using different heat exchangers is obvious. When heating, plain water is often used, and it usually contains impurities.When it is heated, impurities begin to form deposits that adversely affect the heat exchanger, reduce its throughput, prevent water from heating, and shorten its service life.

And when the liquid that flows through the primary heat exchanger is in a closed circuit, it does not change its chemical properties and minimizes negative consequences.

The fluid that flows through the secondary heat exchanger will form deposits over time, and over time, the heat exchanger will need to be replaced or cleaned. If the fault occurs during the winter period, your boiler will be able to operate uninterruptedly in heating mode using the primary radiator.

Failures in electronics (error 3**)

Such complex modern equipment as gas boilers is equipped with electronics for automatic operation and response to different situations. Control boards can fail as a result of aging, power surges, excessive moisture, or mechanical damage.

Error No. 301. Problems with the EEPROM board (non-volatile memory) of the display. If such a message occurs, you need to check the correct installation of the EEPROM key on the motherboard. This must be done as described in the user manual for the respective model.

If the key is working correctly, then you need to check the contacts of the cable from the motherboard to the display board. There may also be a problem with the LCD screen itself. Then it will have to be replaced.

The display is connected to the board with a cable. If the boiler is working, and the screen is off, then first of all you need to check the quality of the connection. Naturally, when the power is completely off

Error number 302 is a special case of the previous problem.Both boards pass the test, but the connection between them is unstable. Usually the problem is a broken cable that will have to be replaced. If it is in order, then the fault is on one of the boards. They can be removed and taken to a service center.

Error No. 303. Malfunction of the main board. Rebooting usually does not help, but sometimes it is enough to turn off the boiler from the network, wait and turn it on again (this is the first sign of aging capacitors). If such a problem becomes regular, then the board will have to be changed.

Error #304 - More than 5 reboots in the last 15 minutes. Talks about the frequency of problems that arise. You need to turn off the boiler, wait a while and turn it on again. It should be monitored for some time to identify the type of warnings if they reappear.

Error number 305. Crash in the program. It is necessary to let the boiler stand for some time off. If the problem persists, you will have to reflash the board. You need to do this at a service center.

Error No. 306. Problem with the EEPROM key. The boiler needs to be restarted. If the error persists, you will have to change the board.

Error number 307. Problem with the Hall sensor. Either the sensor itself is faulty, or there is a problem on the motherboard.

Error No. 308. The type of combustion chamber is set incorrectly. It is necessary to check the type of combustion chamber installed in the menu. If the problem persists, then the wrong EEPROM key is installed or the motherboard is faulty.

You can try to fix any electronic boards in computer repair shops. Especially if the problem is caused by loss of contact or aging capacitors.

Error No. 309. Flame registration after blocking the gas valve.In addition to a malfunction of the motherboard (it will have to be replaced), there may be a problem in the ignition unit - a loose closing of the gas valve or a malfunction of the ionization electrode. If the problem is in the electrode, then you can try to simply dry it.

Rules for safe operation

Any gas boiler is used for the processing of fuel that is dangerous to the life and health of consumers in the event of its leakage, the release of its utilization products and the leakage of the coolant heated by it.

Boilers of the Japanese manufacturer Rinnai are known for their highest reliability and excellent performance. Basically, factory defects are extremely rare on these devices and technical errors are associated with improper operation and untimely preventive inspections.

Boilers of the Japanese manufacturer Rinnai are known for their highest reliability and excellent performance. Basically, factory defects are extremely rare on these devices and technical errors are associated with improper operation and untimely preventive inspections.

All work on the repair and replacement of gas-using equipment should be carried out by specialists from the service department or GRO. Otherwise, you may be threatened with shutting off the gas supply at best, and at worst - a threat to health and life.

Moreover, the cost of such devices, especially from well-known manufacturers, is not always budgetary, and the warranty is long. An intrusion into the gas boiler system can be regarded as a violation of the warranty immunity and, accordingly, it is not worth waiting for free repair and replacement of individual elements from the service department.

But again, it is quite possible to eliminate some points in boiler malfunctions on your own, or knowing them, you can determine what work to call the master and ask how much the repair will cost.

Other malfunctions

Bosch boilers have problems that are not displayed as an error.

Burner not working

It is necessary to check the status and turn on the emergency and start switches.If one of the circuit breakers is defective, repair it or replace it with a working device.

Also carry out diagnostics of temperature controllers, outlet product relays. Do a preventive cleaning of the furnace, burner, nozzles, outlet pipes.

No spark, no ignition

Look for the problem in:

- Ignition electrode. Strip it, place it closer to the burner.

- burner.

- Ignition transformer.

Noise and hum when the boiler is turned on

Clean the parts, including the heat exchanger, from scale. Salt deposits interfere with heat transfer, so the water boils and hisses. If plaque is not removed, the assembly will overheat and fail.

Hot water does not turn on

If there is no hot water when you open the faucet, inspect the three-way valve. If it breaks, it must be replaced. Also make sure that the mixer is in good condition, clean the pipes and filters from blockages.

Whistle when igniting the burner

The size of the nozzles does not correspond to the pressure in the gas line. Change them.

Black smoke and soot

The ignition unit needs to be cleaned. Parts and holes clogged with dust and dirt.

Claps, noise during ignition

What could have happened:

- Gas supply set incorrectly.

- Wrong nozzle size.

- Chimney clogged.

- Incorrect structure of the chimney shaft.

- Poor ventilation in the room.

We hope that after reading the article, you will determine the cause of the breakdown. You can do the repair yourself if you are tech savvy. However, remember: before starting work, it is necessary to turn off the gas and water supply.

Specifications

Most of the Arderia gas boiler components are imported. Most often these are Japanese, Danish and German spare parts.It is this part that is a kind of disadvantage of this equipment, as it complicates the maintenance of the units.

For a more detailed consideration of Arderia boilers, it is necessary to understand their technical characteristics.

- Heat exchanger. The heating performance of the boilers under consideration increases due to the fact that copper heat exchangers are used in the primary circuit. As for these components of the secondary circuit, they are made of stainless steel.

- Monitoring of the operating voltage in the control circuit. These boilers have a voltage stabilizer. It supports the correct operation of electronics and enables it to work in large ranges: from 150 V to 290 V and even more. This feature allows you to extend the life of boiler automation. It is worth noting that all Arderia gas boilers are equipped with a good security system. Special systems monitor excessive heating, current status, utilization of combustion products, and also control unexpected gas leaks.

- To improve the combustion possibilities and increase the efficiency of the boilers, an additional pressurization is used, which is achieved by using a fan. It runs on electricity. Using a fan helps prolong the life of the machine.

- The use of a Grundfos circulation pump, running on a dry rotor, reduces the susceptibility to current, as well as improves the operating conditions of the pump.

Arderia heating boilers use a three-way valve. It is installed in order to achieve the optimal level of heating, and the pipes are heated evenly. This spare part is most often made of stainless steel or bronze. These materials are durable and have positive reviews among the owners.

Expert advice

- Before proceeding with the repair of the Ariston boiler, you need to press the "RESET" button (translated as reset, playback, reset) and restart the heating installation. Often this helps to restore its performance. As a rule, the appearance of an error is caused by voltage instability - a typical case for the private sector.

- If the Ariston boiler is without a display and its indicator lights are flashing, it is not a fact that a malfunction has occurred. This happens when the "Comfort" mode is on. The heat generator is forced to adapt to the microclimate in the room, hence its periodic switching off / on

Helpful Hints

Checking all electrical circuits

Errors that appear on the Buderus display are generated in the electronic board of the boiler based on the signals coming from the corresponding sensors. First step in solving any problem should be a check of all electrical circuits. Weakened contacts, oxidized lamellas - this is eliminated in a few minutes. Not much more time will be needed to replace the wire in case of insulation melting, breakage.

Instability in the power network often initiates the appearance of Buderus errors. This often manifests itself in objects in areas of intensive development. Periodic switching on of welding machines, powerful heaters lead to power surges, phase imbalance. The conclusion is simple: before looking for the cause of the boiler error, you need to check the parameters of the power supply.

The uninterrupted operation of Buderus is ensured by its connection via a UPS. The stabilizer will not give the desired effect, especially since it is provided in the electronic circuit of the boiler.The power supply provides voltage even in case of problems with power lines due to built-in batteries; depending on their total capacity from 2 to 14 hours. For suburban objects - the solution is more than rational.

Not everyone is carefully acquainted with the obligations of the manufacturer. One of the conditions of the Buderus warranty is professional installation. The absence of a service organization mark in the boiler passport is the reason for refusal in case of user claims. In order not to pay for warranty service, it is better not to engage in Buderus repair of heating equipment from your own pocket, self-installation and piping (in order to save money).

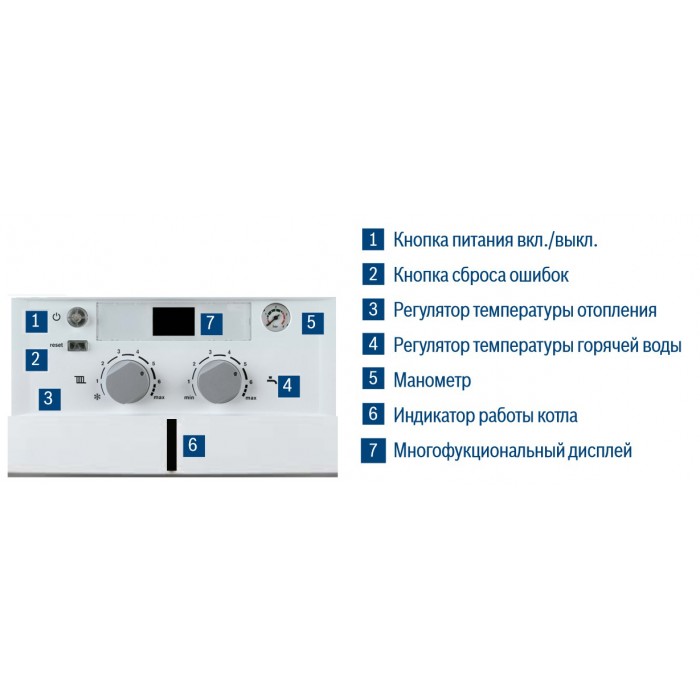

Error codes archive

You can look at the boiler archive of errors and blocking.

Error codes appear on the display of the Baltgaz gas boiler

Pay special attention to the K1 button through which the blocking that occurs after some errors will be reset and to other buttons with the letter “K”, which will not only control hot water and heating, but also navigate through the settings, for example, access to the error archive . Unfortunately, the error archive is not provided for all models of gas boilers.

Unfortunately, the error archive is not provided for all models of gas boilers.

To access the archive, proceed as follows:

- Plug in the gas boiler.

- Press the reset button (K1). Hold it down for 10 seconds to activate some boiler functions.

- Using the buttons K5 and K6 you need to get into the H1 archive.

- When In appears on the display, press K1.

- To select an item in the archive that you need, navigate through the menu using K5.

- After selecting the desired parameter, you must press K3 (or K4).

To exit the archive, you must either press K2 or wait 2 minutes for automatic exit in inactivity.

The archive of errors is needed to diagnose the "disease" of the boiler by the service department specialists or in case you are not at home at the time the code appears, when no one else has recorded it.

Bosch 6000 boiler errors

In total, there are several classifications of boiler errors. from manufacturer Bosch: A, C, D, E and F. Most often, problems are the result of improper installation or configuration of equipment. To eliminate them, it is enough to correctly specify the necessary values \u200b\u200band replace a specific part.

Bosch 6000 boiler errors

Category A

Errors that are classified by the system with the symbol A are usually the most common. They are associated with incorrectly installed equipment or a breakdown in a particular node. Almost always, such problems can be fixed on their own, without resorting to the help of masters. The list below provides a description of each error and how to fix it:

- A2 - indicates the presence of foreign gases, which are most often located on the combustion chamber. Usually the problem disappears after removing the dirt on the heat exchanger.

- A3 - the system did not detect a temperature sensor for exhaust gases. Check that the wires are connected correctly, and also make sure that the meter itself is present. It cannot be ruled out that the temperature sensor was simply forgotten to be connected.

- A6 - notifies about the absence or damage of the temperature sensor, which is intended for the combustion chamber. All you need to do is check the wires for damage and replace them if necessary.

- A7 - indicates a malfunction of the hot water temperature sensor. Most likely, the meter is completely out of order as a result of a short circuit.There is only one way out in this situation - a complete replacement of the sensor and wiring.

- A9 - the hot water temperature sensor is installed incorrectly. Remove it, add thermal paste and reinstall.

- Ad – the system cannot detect the boiler temperature sensor. Check the correct installation of the equipment and, if necessary, consult with the masters.

These errors usually occur as a result of physical impact, so repairing the boiler does not require large financial investments.

Categories C, D, E, P and F

These errors are quite rare on the Bosch 6000 boiler, but they can also be encountered. As in the previous case, read the description of failures below:

- C6 - the pressure switch does not close or is damaged. It is enough to remove the relay and remove the accumulated condensate from the tubes. Best of all, a regular hair dryer copes with the task.

- C7 - check the operation of the fan, and if necessary, replace it.

- CE - indicates too low pressure in the heating system. When the indicator is in the red area, it is enough to add water through the make-up tap. If in green, then here you can’t do without the help of experienced craftsmen.

- D4 - too large temperature difference. Make sure the bypass valve and pump are working properly.

Valve principle

- D7 - notifies of a malfunction of the gas fittings. Most likely, the damaged connecting wire needs to be replaced.

- E0 - problems with the board, so it's better to contact the masters or replace it yourself.

Bosch boiler board

- F0 - internal fault. Check the tightness of the plug contacts and wires on the board.

- P - boiler type not installed.In the case of the Bosch 6000, the value 31 must be entered.

- SE - notifies that the heating system is not sufficiently filled with water. Try adding liquids as this is usually sufficient.

Here were presented the main errors that appear on the Bosch 6000 boiler. If you do not understand the repair of such equipment, then it is better to contact specialists.

Variations of breakdowns with code E4

Not all manufacturers of equipment for heating coolant and water in mixers adhere to the error coding and decoding system developed by Electrolux. For example, the operation of Baxi brand heaters is blocked for a completely different reason.

When error 04 appears on the display, the operation of the boiler is interrupted due to the command given by the flame control electrode. If the sensor responsible for this process detects a flame that is six times smaller than the standard, the fuel supply to the gas burner stops.

Blocking the operation of the Baxi brand gas heater occurs due to the command given by the flame fixation sensor. The device registers a decrease in combustion and a change in color

The reasons for the decrease in the intensity of combustion include:

- Faults in the smoke exhaust system. If flue gases are poorly removed from the combustion chamber, the sensor will detect a change in color or a reduction in the size of the flame tongue.

- Clogged ignition electrode. It must be regularly cleaned of carbon and dust.

- Lack of contact between the sensor and the electronic board that controls its operation.

Of course, in addition to the indicated reasons, the failure of the control board or sensor can cause blocking of the boiler.

In order not to be mistaken in diagnosing malfunctions of the gas boiler, carefully study the device of your model and the technical documentation attached to it. It tells you what happened to the equipment and how to fix it.

The owners of the boilers Gaslux, Neva Lux, the E4 error that appears on the scoreboard will report the overheating of the heat exchanger. This can be caused both by malfunctions in the operation of the temperature sensor, and by a reduction in the flow of water passing through the heat exchanger.

With a decrease in the speed of movement and the volume of water passing through the heat exchanger, it is necessary:

- Clean the heating circuit filter. Clogged with scale and mineral sediment, the device significantly complicates the movement of water through a closed pipeline.

- Check the pressure in the water supply system. It is possible that these are punctures in the work of public utilities.

- Install the filter on the water supply branch that supplies water to the heater.

If the above measures did not help, check the performance of the sensor and the board, and also test the electrical connections.

But the display of error 04 on the display of Navien Ace units is associated with the fixation of a false flame or a short circuit in the electrical connection of the flame sensor with the control board. In 99% of cases, you end up having to change the board.

Malfunctions of ignition of boilers Ariston. Error 501

Fault code 501 means no flame on the burner.

Fault code 502, on the contrary, means the presence of a flame on the burner, but with the gas valve closed.

Also, the control system can issue several alert codes, which respectively indicate unsuccessful ignition attempts in different modes (codes 5P1, 5P2, 5P3).

Attempt 1: ignition is carried out at a power equal to 80% of the nominal (for soft ignition mode), if after 8 seconds of a protective delay the flame is not detected by the sensor, the system issues an alert 5 P1 and the boiler goes to the second attempt;

Attempt 2: 90% of the soft ignition power is set and if after the end of the safety pause 8 s. there is no flame on the burner - 5 P2 is issued, the device makes a last attempt;

Attempt 3 - full power if no flame is detected - the boiler gives the user a 501 error, while the fan continues to run at maximum speed for 40 seconds, and then another 2 minutes at minimum speed.

One example of this malfunction on a condensing boiler is shown in the video:

With error 501 ignition of the gas boiler, it is recommended to perform the following checks:

- condition and position of the ignition electrodes

- the position of the flame control electrode and the reliability of contact with the board

- reliability of contact between the supply wire and the ignition generator

- failure of the control board (diagnostics required)

How to properly set up the boiler

The Immergas boiler is set up in service mode. It is made during the first start-up or after repair work.

All gas boilers undergo bench tests and adjustment at the enterprise, therefore, before starting, they only adjust the main parameters of the unit to obtain maximum efficiency in the existing conditions and reduce fuel consumption.

Usually set up:

- The temperature of the extract air and hot water (upper and lower limits).

- Gas pressure (upper and lower limits corresponding to the supply mode in the line).

- The pressure of the RH and DHW in the respective circuits.

Special boiler power settings are made mechanically on the gas valve.The maximum and minimum levels are set, forming the range of operating parameters of the unit.

On the control panel, only the maximum power of the heating mode is adjusted, for which they enter the service menu and set the required values.

Other errors of Bosch gas boilers

These are not the main codes, and they are not included in the main categories. Occur in all or only specific models.

11 - corresponds to the above error E9. Occurs on the Bosch BWC 42 boiler.

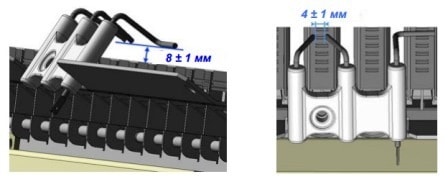

Professional flushing of the heat exchanger: prevention of error E9 includes flushing every 2 years to maintain the efficiency of the boiler, and for this you will need a 20-liter container and flushing solution

50 - no flame. Appears on boilers Bosch Gaz 4000 W ZWA 24-2 A and 24-2 K.

Follow these steps:

- Inspect the protective cable and restore its integrity.

- Open the gas cock to the maximum.

- Determine the gas pressure in the line. If there is a discrepancy with the nominal indicator according to the device passport, call the gas service.

- Check if there is voltage, if it corresponds to the normal value.

- Look into the chimney and clean it if necessary.

- Test throttle adjustment for minimum and maximum levels. Adjust according to the instruction tables.

- Check the gas control relay and replace if necessary.

- Inspect the gas fitting for external damage. Do not check its functionality, repair or replace it. Let the gasman or gas boiler master do it.

- Clean and flush the heat exchanger.

70 - failure of the differential relay at startup. The most common cause of this error can be problems in the relay itself. Inspect its condition, determine the resistance.Change to a new one if the resistance does not match the nominal.

There may also be mechanical damage to the wires and contacts going to the relay. If so, then you need to restore connections. Another reason may be incorrect fan settings or failure. Reconfigure the device. If it doesn't work, fix it or buy a new one.

b1 - Coding plug not found. Insert it correctly. If the error has not disappeared, ring the plug and replace it if it breaks.

P - it is impossible to determine the type of boiler. Set its type.

A coaxial chimney can have a complex pattern due to an electric blower, but according to general requirements for high-quality work, its total length should not exceed 4 meters

se - the heating system is not filled enough. Add water and check the result. The error also appears due to depressurization of heating pipes and leaks. Reduce the heating temperature and find the problem area. Seal joints and seal leaks.

With hot pipes, this will not work - a small amount of water will quickly evaporate. If the heating pipes are in order, remove and wash the heat exchanger.

There is also code 23. This is not an error, but an indicator of the type of gas used.

Features of Ariston gas boilers

The popularity of Hotpoint / Ariston branded equipment is associated not only with the low price of all products. The functionality of this technique is often close in its characteristics to the flagship models of well-known manufacturers.

So, for gas appliances of this developer, the presence of such functions is considered the norm:

- Automatic maintenance of the outlet water temperature regardless of any changes in the environment, as well as fluctuations in the temperature of the water itself and a change in its pressure. The intensity of the flame is adjustable without user intervention;

- Automatic pumping of air from the heating system, which creates safe conditions for the operation of the device;

- In the event of emergency situations, the operation of the circulation pumps is blocked.

Rice. one

All protective systems, as well as the flame maintenance and regulation unit, work through an electronic board. This allows you to organize not only a convenient panel with control buttons, but also an indication of the current mode of operation, and, if necessary, error codes indicating the alleged cause of the problem.

The decoding of these codes is usually presented in the instruction manual. The owner of the equipment can independently understand the situation and, as far as the skills are available, also eliminate the cause. But in most cases, such information is useful only in order to determine whether it will be enough to simply restart the boiler or whether it is time to call the master to the house.

Operating principle

The Arderia gas heating boiler has two varieties: it can have one bithermic heat exchanger or two radiators. The first type is distinguished by the fact that water is simultaneously heated for both water supply and heating.

The second type consists of two nodes. They heat up individually. One radiator is made of copper, the second is made of stainless steel. Water is circulated by a pump. The removal of combustion products is also forced. It happens with the help of a special fan.

All Arderia gas heating boilers have a number of features, which include:

- this equipment is fully suitable for Russian heating systems;

- boilers have a special voltage stabilizer that helps the device work smoothly even with power surges;

- boilers have a gearbox that stabilizes operation when the gas pressure drops;

- Arderia gas heating boilers are practical, stylish and of high quality.

The scheme of the principle of operation of these boilers is as follows:

- the first step is to set the required temperature using the remote control;

- the boiler turns on automatically using a temperature sensor and works until it reaches the set parameters;

- after that, the sensor turns off the boiler;

- as soon as the temperature drops by 15 degrees Celsius, the sensor turns on the boiler again.

Elimination of defects in work

Usually, the appearance of an error does not mean a breakdown of the boiler. It is possible that the sensor may falsely trigger in response to a power surge or for other reasons.

Therefore, the first reaction to the appearance of an error is to reset it and restart the boiler. If the error appears again and again, more effective measures must be taken.

Consider ways to eliminate the most common errors:

- F03. Boiler overheating. The temperature of the OB has risen to the limiting 95°. After the temperature drops, the boiler will start automatically. If the error persists, the thermal fuse must be reset.

- F04. Failure of the DHW sensor. Check the contacts, clean them from oxides. As a last resort, replace the sensor.

- F10-11. The failure of the temperature sensors of the supply or return water causes the boiler to turn off due to the inability to control the degree of heating of the system. Check the condition of the sensors, clean the contacts, if the problem persists, replace the defective element.

- F20.Overheating of the boiler can happen for various reasons. Most often, the fault is poor circulation due to a breakdown of the pump impeller. It is also often difficult to heat water due to deposits on the walls of pipelines. The sensors do not confirm that the set temperature has been reached, and the heat exchanger is already too hot outside. The solution to the problem will be flushing the heat exchanger.

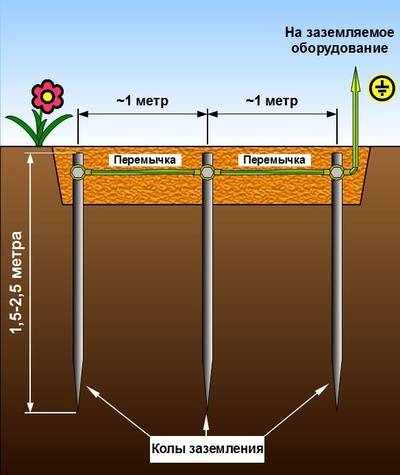

- F28. Check for gas in the line. Clean the ionization electrode with fine sandpaper. Check the condition of the boiler ground loop. If all these measures do not give a positive result, look for the cause in the electronic board of the boiler. Most often you have to change it.

- F62. Gas valve malfunction. Maintenance, cleaning and lubrication of the device is required. There may also be problems with the electronic control board.

- F75. Problems with the pressure sensor. Check the total pressure in the system. Check the condition of the pump. Bleed the air in the radiators using the Mayevsky crane.

It is not advisable to give a complete list of problems and ways to fix them, since the very name of the error most often contains a hint on how to fix it. The predominant type of solution to the problem is the replacement of an unreliable element.

Why does the pressure in the boiler drop?

The main cause of pressure drop is coolant leakage.

Various reasons may be involved here:

- The valve for resetting the boiler or one of the radiators of the system is open. If this happens, the coolant is constantly removed from the system, which causes a pressure drop. The solution to the problem is obvious - close the tap, or repair it.

- There was a leak into which the coolant goes. This case is much more difficult, since it is not possible to detect a leak immediately.Sometimes it is found only by wet spots on the floor or on the ceiling of the neighbors. The detected leak is immediately eliminated by changing the pipeline or the problematic radiator.

- Expansion tank membrane failure. In such a situation, the pressure drop continues only until the moment when the entire volume of the tank is completely filled with liquid. After that, the pressure stabilizes for a short time, and then begins to grow to a critical value. By these signs, the problem is usually determined. The solution is to replace the expansion tank (or repair if possible).

Conclusions and useful video on the topic

Video briefing will help you visually understand the essence of the problem and understand the methods of its elimination:

p> Information about the decoding of a violation in the operation of gas equipment coded by the manufacturer will help to prevent negative consequences in a timely manner. All owners of units that consume gaseous fuel in operation need to know what they mean. It is a pity that almost all boilers do not have the same error values.

However, the causes of violations are almost always identical. The main thing is to understand what is connected with what and choose the appropriate diagnostic path. We have analyzed a significant number of problems in the presented article, you can deal with most of them on your own.

Conclusion

An error can occur on any model (for example: GAZ 4000, GAZ 6000 18 and 24 kW) and any design and form factor (double-circuit and single-circuit, wall-mounted and floor-standing).

The performance of Bosch gas boilers depends on the quality of the supply of resources, power supply and system settings.

All malfunctions that occur during operation must be carefully investigated.

The causes of their occurrence must be precisely determined and completely eliminated so that the probability of a recurrence of a malfunction is zero.

This is the only way to achieve durable and stable operation of the boiler, to get the expected effect from using a Bosch gas unit.