- Other malfunctions

- Low coolant pressure

- Why does pressure drop

- Elimination of some problems in the operation of the boiler

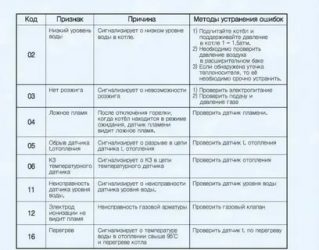

- Error 01e

- 02e

- 03e

- 05e

- 10th

- 11th

- Noise and hum

- No hot water

- Problems with multi-zone control (errors 7**)

- Connecting a room thermostat

- Air supply and flue gas removal (errors 6**)

- No flame sensor signal.

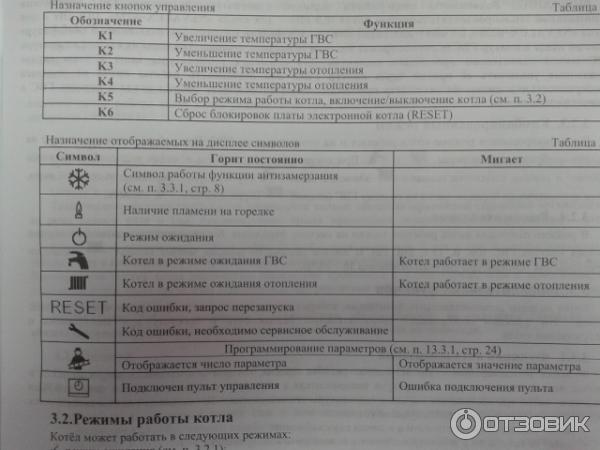

- Error codes displayed

- Conclusions and useful video on the topic

Other malfunctions

There are breakdowns that are not indicated by errors on the display. You can identify them by signs.

The boiler does not turn on:

- The device is not connected to the network. Plug in the socket.

- Board fuse defective. Install a new item.

- The board has been exposed to moisture. Disassemble the device, dry the board.

Pops on ignition:

- Large accumulation of air in the gas, incorrect pressure adjustment. Carry out the adjustment in accordance with the recommendations in the instructions.

- The burner is clogged with dust. Clean its nozzles of dirt.

Weak pressure in the tap:

- The line is under pressure. Wait a while. Install the pump for a steady flow.

- The water filter is clogged with debris. Cleaning required.

- The secondary radiator is clogged. Remove cover and remove debris.

These are typical malfunctions of Master Gas boilers.Are you familiar with one of the problems? Then use our recommendations to solve it.

Low coolant pressure

On the front panel of each boiler there is a manometer indicating the pressure in the heating system. It has red zones for too low and too high readings. A pressure of 1.5 bar is considered normal for a cold boiler: at 1 bar the arrow is already in the red zone, and at 0.5 bar the boiler will turn off by error CE or CF until the pressure is restored.

If the boiler was installed recently - a few weeks ago, this situation is common, you just need to add clean water through a special tap. But do not rush to add water to a system that has been in operation for more than a year.

When heated, the water expands and the pressure rises - this is the norm. However, if it immediately jumps to 0.7 - 1.5 bar, this indicates a lack of air in the expansion tank.

If in such a situation, add water, heating up, it will increase the pressure too much and the safety valve will work, dumping excess coolant.

The built-in expansion tank differs from the external one: it is flat and located at the back of the boiler. Inlet connection - top, with threaded cap

In order to pump up the tank, you first need to relieve the pressure on the switched off boiler by draining some water. Then connect a pump or compressor to the fitting in the upper rear part of the tank and pump it up to 1.3 - 1.4 bar. After turning off the pump, add water, bringing the pressure in the cold system to 1.5 - 1.6.

If even when the boiler is heated, low pressure in the heating circuit persists, then it is really necessary to add water.Where to find the tube intended for this is indicated in the instructions for the device model, but we will only remind you of the need to fill this tube with water before opening the tap so that air does not enter the pump and batteries.

Be sure to check all taps, connections and radiators, as well as the inside of the boiler for leaks - the water that circulated in the system has gone somewhere.

Why does pressure drop

The pressure drop in the gas boiler indicates the occurrence of coolant leaks, which can be located both in the external circuit and in the boiler itself.

If the lack of pressure occurs constantly, after each replenishment of the coolant volume, the boiler itself and the entire external part of the circuit should be carefully examined. Perhaps the drain valve is open or out of order, the expansion tank is damaged.

If the condition of the units of the unit is normal, it is necessary to check the radiators and pipelines of the external part of the circuit.

In private homes, leaks are possible in places that are invisible to the eye, which must be found and repaired. If, after taking measures, the pressure has ceased to fall, then the cause has been detected and eliminated.

Elimination of some problems in the operation of the boiler

Like any, even the most reliable technique, some problems may occur in Navien boilers, some of which the owner of the device can fix on their own.

First of all, it is important to recognize the cause of the breakdown. So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code

So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code.

Here are the Navien boiler trouble codes:

- 01e - the equipment has overheated.

- 02e - there is little water in the heating / the circuit of the flow sensor has broken.

- 03e - there is no signal about the flame: it may not really exist, or there may be problems with the corresponding sensor.

- 04e - false data about the presence of a flame / short circuit in the flame sensor.

- 05e - problems with the heating water t sensor.

- 06e - short circuit in the heating water sensor t.

- 07e - problems with the hot water supply t sensor.

- 08e - short circuit in the hot water supply t sensor.

- 09e - a problem with the fan.

- 10e - problem with smoke removal.

- 12th - the flame went out during work.

- 13e - short circuit in the heating flow sensor.

- 14e - no gas supply.

- 15e - a problem with the control board.

- 16th - the boiler is overheated.

- 17e - error with the DIP switch.

- 18e - the smoke removal sensor is overheated.

- 27e - a problem with the air pressure sensor (open or short circuit).

Error 01e

Overheating of the equipment can happen due to the fact that the ducts have narrowed as a result of blockage, or the circulation pump has broken.

What you can do yourself:

- Examine the impeller of the circulation pump for damage to the impeller.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Check the heating system for air. If there is, it needs to be bled.

02e

An error that there is little coolant can be generated by the boiler if there is air in the system, little water, the impeller of the circulation pump is damaged, the distribution valve is closed, or the flow sensor is broken.

What can be done:

- Bleed the air.

- Adjust pressure.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Open distribution valve.

- Check the flow sensor - is there a short circuit in it, is there resistance.

- Open the sensor housing, clean the flag (moving mechanism with a magnet).

Most often, the problem is the presence of air in the hot water system.

03e

No flame signal. The reasons for this may be:

- Damage to the ionization sensor.

- No gas.

- No ignition.

- The faucet is closed.

- Faulty boiler grounding.

The blockage on the flame sensor must be cleaned. The gray coating on the electrode is cleaned off with fine sandpaper.

05e

What can be done:

- Check the resistance on the entire circuit from the controller to the sensor. Having found a malfunction, replace the sensor.

- Disconnect the controller and sensor connectors and reconnect.

10th

Smoke removal problems can occur due to fan failure, kinking, or improperly connecting sensor tubes to the fan. In addition, the chimney may be clogged, or there was simply a sharp and strong gust of wind.

What can be done:

- Repair the fan or replace it.

- Check the correct connection of the sensor tubes.

- Clean the chimney from blockages.

11th

A problem with the water filling sensor - this error is provided only for European-made boilers equipped with the appropriate sensors.

Noise and hum

It may happen that the error does not appear on the display, but an unnatural buzz or noise appears in the device. This happens when water hardly passes through the pipes due to scale, overheats and boils. The reason may be a bad coolant.

Coolant Navien

Troubleshooting procedure:

- You can fix the problem by disassembling the unit and cleaning the heat exchanger. If this fails, the part must be replaced.

- In addition, you need to check the taps - whether they are open to the maximum.

- Turn the water temperature down. It is possible that the boiler capacity is excessive for the pipeline to which it is connected.

No hot water

It happens that the heating boiler heats up as it should, but the water for hot water supply has stopped heating. This is a problem with the three way valve. Cleaning and repairs will not save - you need to change the part! The problem is not rare, the valves work normally for about 4 years.

So. Navien boilers are reliable and economical equipment. With proper operation and a competent approach to the difficulties that have arisen, problems can be eliminated even without the involvement of specialists from the service.

Problems with multi-zone control (errors 7**)

Ariston brand boilers allow you to divide the house into zones, each of which will have its own heating mode. If a problem occurs with one of the sections, the system accurately determines the malfunction, so the repair of a particular circuit can be carried out without interfering with the rest of the normally operating fragments of the heating network.

Error #70X. There is a problem with the flow temperature sensor in zone X. Check the sensor contacts or replace this part.

Mistake #71X. The same thing, only with the sensor on the return line.

Error #72X. Overheating has been detected in zone X. First of all, you need to check the operation of the thermostat responsible for this area. It may simply be a loose contact or a broken node. If it works correctly, then you need to change the settings.

Error No. 750. Hydraulic circuit error. The correct type of connected hydraulic module must be set (menu parameter 720). If there is no error here, then the problem is in the settings of the circuit itself.

Connecting a room thermostat

The room thermostat allows you to more accurately adjust the microclimate in the room. Its sensor checks the air temperature, which gives more accurate results than the RH temperature check, which is produced by the boiler electronics.

Using a room thermostat allows you to turn off the boiler when the set values \u200b\u200bare reached, when the device’s own sensors are not yet ready to give a command to stop heating.

The thermostat is included in a special break in the control board, the contacts of which are closed by a jumper by default.

To connect, the boiler is turned off, the lid is opened and the jumper is removed. Then, in the required order, the room thermostat is connected and a test switch is made.

If the device is working properly, close the lid and proceed to further operation of the boiler with an additional device. If problems are found, they are fixed immediately.

IMPORTANT!

Detailed instructions for connecting a room thermostat are available both on the device itself and in the user manual for the boiler. Under no circumstances should you act randomly.

Air supply and flue gas removal (errors 6**)

The system for supplying air and removing flue gases generated during the operation of a gas boiler can be natural and forced. Therefore, for different devices, some errors may not occur. But we will consider them all.

Error No. 601. The operation of the draft thermostat occurs when the contact is broken or the internal breakdown of the smoke exhaust thermostat. It is also possible that the air intake system is clogged.

Error No. 602. The same, only for VMC type combustion chambers.

Error No. 604. Faulty Hall sensor (it needs to be replaced) or low speed of the fan blades (it needs to be cleaned or also replaced).

Error #607.The contacts of the controlling pneumatic relay turned out to be closed before the fan was turned on. This detail confirms the sufficient amount of draft before ignition. To eliminate an early short circuit, you need to carefully remove the pneumatic relay and blow through its tubes, removing dirt or condensate. If this does not help, then the part will have to be replaced.

The pneumatic relay is connected to the exhaust chamber with a silicone tube. Sometimes there is a condensate collector. If the problem is with the pressure switch, then first you need to check the integrity of the tube

Error No. 610. The thermal fuse contacts are open. This part needs to be replaced.

Error No. 612. The same as error No. 604, but on early Ariston models.

No flame sensor signal.

The malfunction indicates the absence of a flame or a signal from the ionization sensor (photocell) after the burner ignition command. If the flame appears and the boiler goes into error after 2-3 seconds, it is necessary to check the circuit of the flame control sensor (ionization electrode) and the electronic board. The error can also appear due to incorrect phasing or lack of grounding. If there is no flame, check the gas valve (multiblock) and the ignition system of the boiler. The periodic appearance of such an error may indicate a low value of the ionization current (less than 2-7 μA.) or a malfunction of the electronic board (combustion machine).

Error codes displayed

The following error codes are displayed:

Error 01. This error indicates an unsuccessful ignition. The boiler does not turn on:

Error 02. Overheating of the coolant. The boiler does not work:

Error 03. No traction:

Error 04. Low water pressure in the circuit:

Error 05. Failure of the temperature sensor of the heating system:

Error 06.Failure of the DHW temperature sensor:

- sensor malfunction;

- open or short in the electrical circuit between the sensor and the electronic board.

If the electronic board was accidentally flooded with water. It is necessary to turn off the boiler from the network and dry the board with warm air from a hair dryer. Sometimes there may be a malfunction in the electronics. To reset to the original position, press the RESET button. If it does not help, then disconnect the boiler from the network for a few minutes and turn it on again.

If you smell gas, find and repair the leak immediately.

If you cannot fix the leak yourself, it is recommended to call the gas service on the emergency number 104.

In chapter Service, care and repair to the question Boiler Neva Lux 8224. Constant error 03. Condensate accumulates in the tubes of the pressure switch. How to fix this problem. given by the author Vladimir the best answer is Need more detailed information about where it is located, external temperature, fuel (gas or diesel), winter or summer, etc. And condensate from what (water, gas)? What can be done to prevent condensation from collecting in the Pitot tubes? The Neva Lux 8224 boiler turns off every year in January, showing error 03. Of course, I eliminate the condensate and start the boiler until the next accumulation of condensate, but this problem is pretty annoying. Help!

Answer from Yotas Shabanov1. Check whether the make-up tap is completely closed.2. If the make-up tap is closed all the way, it is possible that the make-up tap is not hermetic. Replace the make-up tap.3. Check if the secondary heat exchanger is leaking.4. Also check if the pressure sensor and the connectors of its contacts are working. Another option: slightly opening the plug on the right side at the top so that warm air enters the combustion chamber and condensate does not form in the pressure switch tubes.

In the section on the question Boiler Neva Lux 8224. Constant error 03. Condensation accumulates in the tubes of the pressure switch. How to fix this problem. given by the author Vladimir the best answer is Need more detailed information about where it is located, external temperature, fuel (gas or diesel), winter or summer, etc. And condensate from what (water, gas)? What can be done to prevent condensation from collecting in the Pitot tubes? The Neva Lux 8224 boiler turns off every year in January, showing error 03. Of course, I eliminate the condensate and start the boiler until the next accumulation of condensate, but this problem is pretty annoying. Help!

Answer from Yotas Shabanov1. Check whether the make-up tap is completely closed.2. If the make-up tap is closed all the way, it is possible that the make-up tap is not hermetic. Replace the make-up tap.3. Check if the secondary heat exchanger is leaking.4. Also check if the pressure sensor and the connectors of its contacts are working. Another option: slightly opening the plug on the right side at the top so that warm air enters the combustion chamber and condensate does not form in the pressure switch tubes.

The Neva Lux geyser from a domestic manufacturer is a technically complex product. The entire cycle of operation from turning on the column to heating the water is controlled by automation, which eventually fails. To better understand the malfunction, the company's engineers placed an indicator window on the front panel, in which one or another error code is displayed during an emergency stop. Let's consider them in more detail.

ATTENTION!

Maintenance operations for the repair of geysers, associated with the dismantling of its gas or water communications, must be carried out by qualified craftsmen.Self-repair can have the opposite effect, in the raft before buying a new device

Conclusions and useful video on the topic

The following video clip will acquaint you with the rules for servicing South Korean boilers of the Master Gas Seoul brand:

The rules and specifics of decoding errors are extremely useful information that allows you to quickly respond to all possible violations in the operation of the boiler. Nevertheless, the owner will have to face all kinds of failures first. Him and decide on further actions.

Do you want to share your own experience in deciphering Master Gas boiler errors and promptly fixing the problem? Do you have useful information not listed in the article? Please leave comments in the block form below, ask questions and post thematic photos.