- Flame and ignition control (faults 5**)

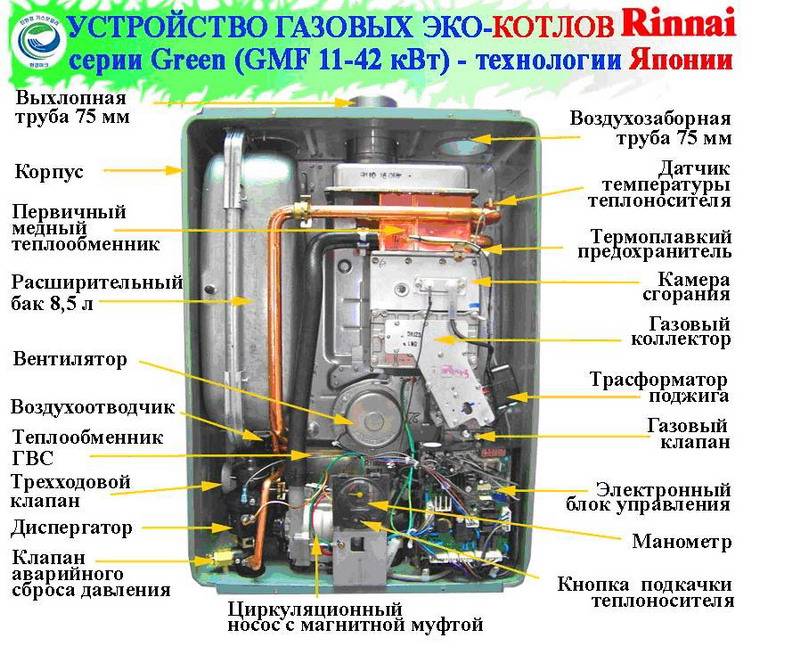

- Product Description

- The main modifications and varieties of boilers "Rinnay"

- RMF

- EMF

- GMF

- SMF

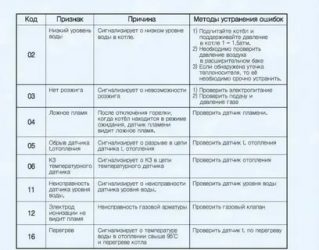

- Elimination of some problems in the operation of the boiler

- Error 01

- Error 02

- Error 10

- Noise and hum without errors on the display

- Error 011

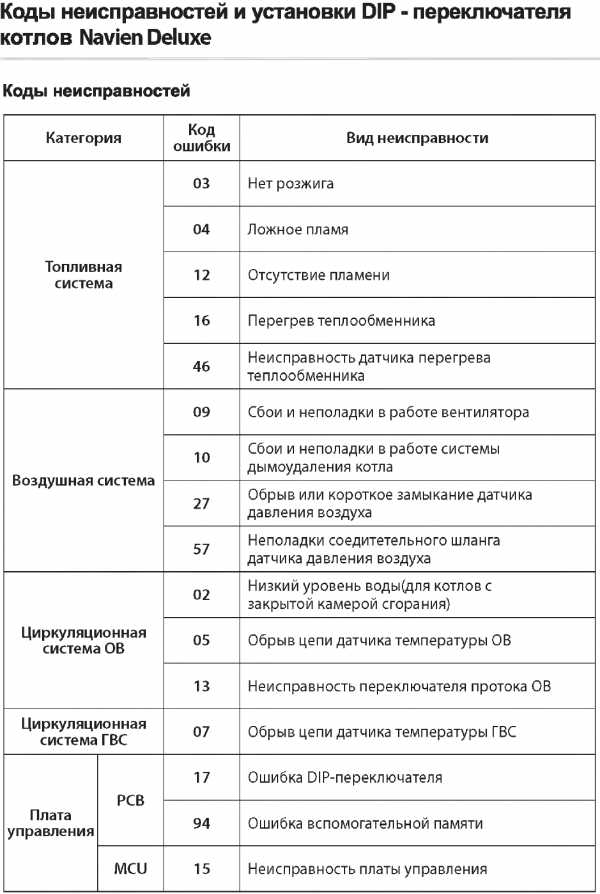

- Innovative solutions in navien products

- The best and most famous models features and prices

- rb 167 rmf

- rb 167 emf

- rb 207 rmf br r24

- br ue30

- rb 277 cmf

- Types of boilers

- Wall equipment made in two variations

- Floor units

- Condensation products

- No flame detected/No ionization current.

- The device and features of the boiler

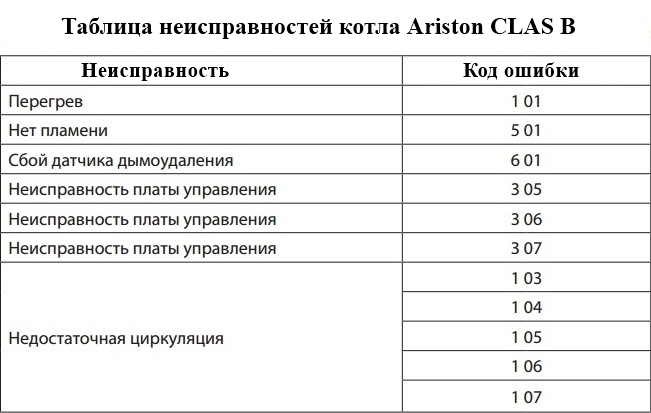

- Less common errors of the Ariston boiler

- 117

- 201

- 307, 308

- 601

- A01

- Sp2

- 1p1, 1p2, ip2

Flame and ignition control (faults 5**)

Problems can arise in both open and closed combustion chambers. Although it must be admitted that there are few types of malfunctions compared to other components of the gas boiler.

Error #501. No flame on ignition.

This situation can happen for many reasons:

- No gas. You need to check the supply valve. It must be open.

- The system will not turn on if the voltage between the neutral and the ground conductor is more than 10 V. It is necessary to eliminate the current leakage.

- The ionization electrode is out of order.Before changing it, you need to check the quality of the connection with the motherboard.

- The power of smooth ignition has gone astray. It is necessary to adjust this parameter according to the instructions for a particular model.

- Malfunction of the main control board.

Error No. 502. Flame registration before gas valve activation. It often occurs in the absence of a ground loop. If it is made according to the standard, then you need to perform the same steps as for error No. 309.

If there was no grounding in the house, then it will have to be done for a gas boiler. And according to all the rules, otherwise the protective mechanisms will block the start of heating

Error No. 504. Flame separation on the burner if it occurs at least 10 times during one cycle. It is necessary to check the gas pressure, the removal of combustion products and the gas valve.

Product Description

According to consumer reviews, the following models are considered the most popular:

Wall-mounted gas boilers are considered the most economical in terms of resource consumption. They can be connected in a chain, providing heat and hot water, both in small apartments and in large houses. The power of Rinnai in space heating mode is 11.6-42 kW at an efficiency of 96%. The area of the serviced space is 30-120 m2, the gas consumption is 0.3-1.15 m3/hour, the hot water supply is 12 l/min. The volume of the expansion tank is 8.5 liters. If you need to work on liquefied fuel, you need to change the nozzles.

The Rinnai design includes a modulating fan-type burner with an automatic function of resource consumption in proportion to pressure. This feature is aimed at saving within 20%, provides a long service life of the heat exchanger and the control system of the gas double-circuit boiler.As a result of complete combustion, there is a low level of toxic waste, which does not allow carbon deposits and soot to settle on the nozzles. The series includes models: RB-107, 167, 207, 257, 307, 367.

An improved version of wall-mounted gas double-circuit boilers from the manufacturer Rinnai. With increased functionality, the equipment makes less noise. The remote control is equipped with a color display, there is a voice control mode, weather-dependent sensors. When heating, you can reduce the power of the device by 20%. An adjustment unit is used to achieve the optimum water temperature. Thanks to periodic heating, an instantaneous supply of hot water is ensured. The Rinnai operates at a minimum head of 2.5 l/min and shuts off at 1.5 l/min pipe pressure. A remote control is included as standard, which, according to user reviews, simplifies the coordination of all systems.

Gas boilers with a closed combustion chamber Rinnai have a capacity of 19-42 kW, heat an area of 190-420 m2. The efficiency is 90%, the volume of the expansion tank is 8 liters. The device is equipped with an ECO program (environmental mode). Has two additional sensors: control of protection against freezing and temperature of the heat carrier. The series includes models: RB-107, 167, 207, 257, 307, 367.

Rinnai gas boilers operate on mains and liquefied fuels, subject to the change of nozzles. The main advantage of this subgroup is absolute environmental friendliness, which is due to the minimum emission of toxic waste into the atmosphere. The automation unit is three-level, the adjustment of the burner flame and heating of the coolant is determined depending on the season and climate. Error diagnostics are displayed on the monitor in text and digital code.Adjustment of the fan operation protects against lack of air for purge.

The power of the wall-mounted gas boiler is 12-42 kW, the heated area is 120-420 m2. The minimum consumption of hot water is 2.7 l / min, a centralized resource - 1.1-4.2, liquefied - 1-3.5 m3 / hour. The volume of the expansion tank is 8.5 l, the maximum temperature of the coolant is 85, DHW is 60 ° C. A coaxial chimney is used to remove combustion products. Series models: RB-166, 206, 256, 306, 366.

Gas boilers manufactured by Rinnai designed to service premises from 100 to 400 m2. Equipped with two heat exchangers, the first is made of copper, the second is fast and produces up to 14 l / min. In the combustion chamber, the fuel-air mixture is smoothly regulated, proportional to the volume of gas. This is achieved by an integrated turbocharged burner. Optimum functionality does not depend on weather conditions. Emission of toxic substances is minimized, which prevents the formation of soot and scale.

The boiler power is 18-42 kW with an efficiency of 90%. The minimum water flow is 2.7 l/min. The temperature range for heating is 40-80 °C, for hot water supply - 35-60 °C. The device has an electronically controlled pump. The microprocessor constantly analyzes the readings of the sensors and sends information to the working nodes. The air intake is forced, from the street. The series includes models: RB-166, 206, 256, 306, 366.

The main modifications and varieties of boilers "Rinnay"

The company has released a number of unique models of four series. Among them are the following:

- RMF,

- emf,

- gmf,

- SMF.

Each development should be operated in certain conditions.With the help of Japanese gas developments of the RMF line, it is possible to heat rooms with an area of 170–390 sq.m. The main advantages of these models should be highlighted:

- the consumer has the opportunity to independently program the heating for several days in advance;

- before the coolant starts to work, it slowly heats up;

- the consumer can work with the boiler using a remote control, which greatly simplifies the process of controlling the device (2 decorative overlays).

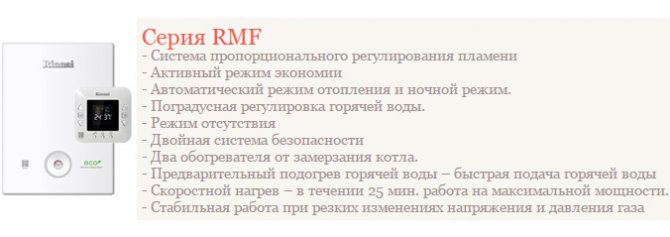

RMF

The line of new products RMF "Rinnay" from 18.6 kW is equipped with two types of consoles. Is it "Standard" or "Deluxe". Models of the Standard class can program the gas boiler 12 hours ahead.

DeLuxe modification offers 5 different modes for 24 hours ahead. You can change the settings if necessary.

EMF

The Rinnai brand is engaged in the production of special units. Among them are wall-mounted double-circuit boilers EMF. Their use is provided for heating with an area of 100-400 square meters. m.

Such developments are used by multi-storey cottages. The unique design of the burner eliminates toxic substances during the gas combustion process.

Important! Thanks to a special system, gas and electricity are automatically turned off

GMF

Models of the GMF series stand out from their competitors with the best performance properties. These products heat the room from 90 to 430 sq. m. This unit is used by the owners of private houses. GMF has many positive qualities:

- 100% frost protection;

- ignition system from an electric spark;

- thanks to self-diagnostics, there is an instant detection of problems in the device;

- many products are optionally equipped with a circulation pump.

SMF

The SMF series also has the best performance.The consumer has the opportunity to switch from natural gas to liquefied gas by replacing the nozzles in the device itself.

Note! Automatic control system ensures 100% operation of the device even at low gas pressure

Elimination of some problems in the operation of the boiler

Of course, when a particular error code appears, you should immediately seek help from specialists who will eliminate it and advise on all issues of operation. But some owners can independently identify this or that malfunction and bring their gas heating boiler into working condition.

Error 01

The most common cause of such a malfunction is a blockage or a decrease in the flow in the heating system, as well as a breakdown of the circulation pump.

To resolve this issue, follow these steps:

- Check the heating system and filter for air and bleed if necessary.

- Check the condition of the pump and the resistance of the coil for a short circuit.

- Check the impeller in the circulation pump for any damage.

Error 02

If a double-circuit boiler gives error 02, warm water flows from a hot tap for several seconds, and then cold water, the water temperature rises sharply on the remote control to a maximum, and then drops sharply. At the same time, everything is fine with heating.

The reasons for this errors in the Navien boiler can be:

- The airiness of the heating system.

- Lack of water.

- The circulation pump is in working condition, but cannot gain rated speed, or the impeller has mechanical damage.

- The flow sensor in the coolant system does not function.

- The heating distribution valve is closed.

How to troubleshoot?

- The system pressure needs to be adjusted.

- Bleed off the air in the system.

- Check the resistance of the pump coil for short circuit, inspect the impeller for damage.

- Check if there is a short circuit resistance of the flow sensor.

- Open the distributing valve of the device.

- Disassemble the sensor housing and clean the flag.

Most likely, the problem arose due to an air lock in the hot water supply system. The water in the circuit heats up as it should, but after air enters the heat exchanger, the temperature rises sharply to a critical one, which results in error 02.

Error 10

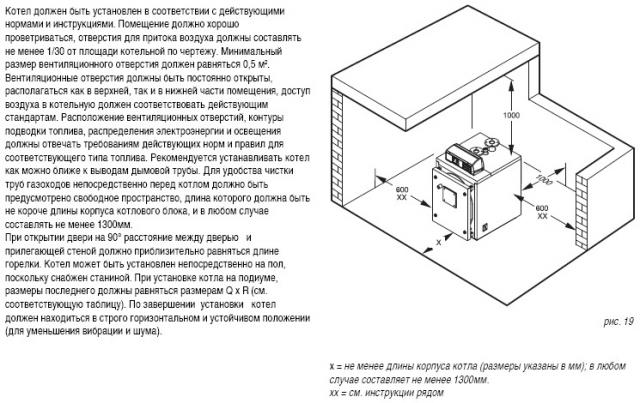

Connecting a gas boiler to the heating system

Error number 10 is usually issued in the following cases:

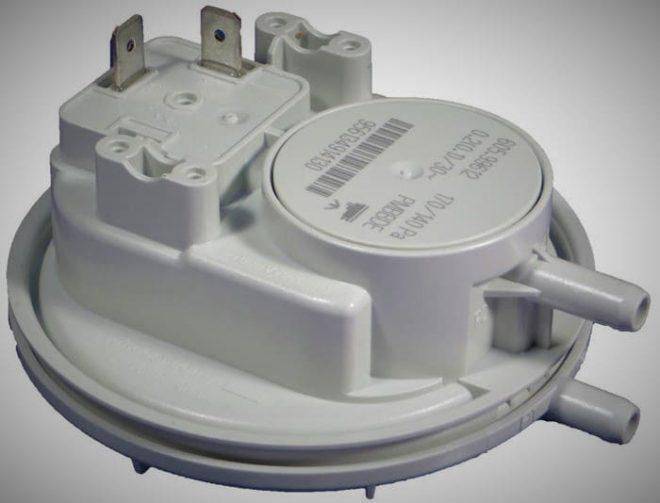

- The operation of the fan is disturbed, a kink has occurred, or the pipes from the air pressure sensor to the fan volute are incorrectly connected.

- Chimney clogged.

- There are strong gusts of wind.

The faults described above are corrected as follows:

- It is necessary to repair or replace the fan of the Navien boiler.

- Check and, if necessary, clean the chimney.

- Check the correct connection of the tubes from the air sensor to the fan coil and the presence of their kink.

Noise and hum without errors on the display

The problem is that the Navien double-circuit boiler, when hot water is turned on, makes noise or buzzing, which is not like the noise from pumps. At the same time, the pressure in the heating circuit is more than 1.5 on the pressure gauge, and the boiler does not give errors on the display.

Elimination - the described situation is quite common in gas boilers. It is associated, as a rule, with clogging of the heat exchanger due to poor-quality coolant. There are two ways out of this situation - dismantling the heat exchanger and cleaning it or replacing the heat exchanger.

Error 011

011 is a coolant filling error. It is not provided for in Navien boilers adapted for the Russian consumer, but is allowed only in those designed for the European market.

Innovative solutions in navien products

The products of the Navien brand implement the most advanced ideas and technologies. The products of this manufacturer are characterized by:

- Reliability - the designs provide for mechanisms that completely exclude emergency situations.

- Convenience - all information about the state of the system is constantly displayed on the LCD, and process management does not require skills.

- Versatility - brand appliances can be used both for heating the house and for hot water supply. And as a fuel, you can use the main and liquefied gas.

- Safety - closed combustion chambers and the installation of a coaxial chimney guarantee the safety of the operation of the devices.

The best and most famous models features and prices

The range of Rinnai wall-mounted gas boilers is quite wide and varied. There are models designed for heating rooms of different sizes. They differ in performance, set of built-in functions and price. Therefore, when choosing a boiler, it is necessary to understand exactly for what purposes it will be used. Below are descriptions of some of the popular models of Rinnai gas equipment.

rb 167 rmf

This model is suitable for use in heating systems for houses up to 180 square meters. m. This boiler is characterized by low noise and stable operation. With not the highest efficiency, the rb 167 rmf model is one of the most economical units in its price category.Additional features include the presence of a remote control and the possibility of synchronizing it with a smartphone via a wireless interface. Which is a rarity for budget models.

rb 167 emf

This boiler is the forerunner of the model described above. It has less functionality, but it is much cheaper. The kit also has a remote control, but there is no way to control the operation of the boiler from a mobile device. There is also no function of long-term programming of the device operation. The main differences of this model are greater efficiency and higher efficiency than the next generation model.

rb 207 rmf br r24

One of the most popular models of gas boilers manufactured by Rinnai. This boiler has more power and is able to effectively heat a room up to 230 square meters. m. Like most models of the brand, the boiler is equipped with a remote control, which greatly simplifies the control of the device. It is possible to program the operating modes of the boiler for several days. The ratio of fuel consumption and performance is considered close to optimal. The design of the boiler provides protection against freezing and overheating.

br ue30

More powerful, efficient, but at the same time an expensive model. The efficiency of the br ue30 boiler exceeds 91%, which is close to the efficiency of boilers from leading European manufacturers. The design of the boiler ensures complete combustion of fuel at any level of installed power. Smooth power adjustment is possible in the range from 25% to 100%. The presence of an additional protective casing ensures almost silent operation of the device. The disadvantages of this model include the lack of an additional circuit for circulating hot water in the water supply system.

rb 277 cmf

One of the most efficient and high-tech boilers on the world market. Rinnai's unique developments allow the device to provide over 104% efficiency. With a maximum power of almost 30 kW, gas consumption is only 1.84 cubic meters. m/hour. The device provides these parameters without failures. In addition, this model meets all modern parameters of environmental friendliness.

Types of boilers

On the market you can find products from Navien in a fairly wide range, where the following models are especially popular:

Wall equipment made in two variations

Devices are normally able to function even with an unstable supply of electricity and gas. The units are equipped with a turbocharger and a frost protection system.

Floor units

Ideal for installation in private homes. They provide the room with hot water and heat. Advantages: compactness, simplicity of design, ease of use. The power indicator can vary from 11 to 34 kW.

Condensation products

With a high power rating and economical energy consumption. In the passport of a boiler of this type, an efficiency level of 108% is indicated. The main advantage: the unit allows you to significantly reduce the cost of heating the room.

No flame detected/No ionization current.

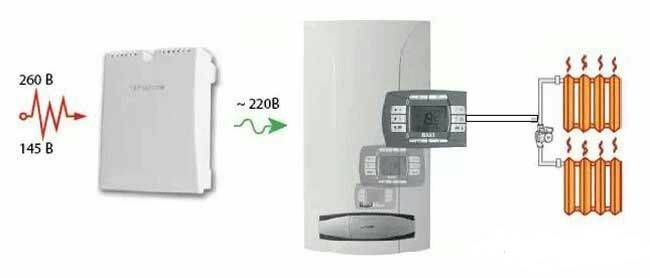

Malfunctions in the electrical network of the boiler: often the cause of many errors.

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

Checking the polarity in the plug-socket connection: turn the plug 90 degrees and insert it back into the socket or stabilizer.

Failures in the gas supply to the house: often the gas supply pressure decreases on the main line and the boiler does not enter the operating mode. The check comes down to igniting all the burners on the stove at maximum mode. Flame tongues with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity, stability - the constancy of pressure and its normal value.

You also need to check:

- The position of the valves controls: perhaps the gas supply valve to the house was accidentally shut off or the shut-off valve worked during a power outage.

- Serviceability, condition of technical devices: meter, reducer (with autonomous gas supply), main filter, tank filling level (gas tank, cylinder group).

Ionization electrode: controls the burner flame, if the electronic board does not receive a signal from the measuring device, the boiler is blocked.

Common causes of electrode failure are:

Damage to the electrical circuit (break, unreliable contact, short circuit to the boiler body).

Defect of the sensor holder: it is located on the same assembly with the ignition electrodes (crack, chipped ceramics).

Wire contamination: dust, soot, oxides accumulate on it, and as a result, the sensor does not detect a flame after ignition. It is solved by cleaning the electrode with a fine-grained sandpaper.

Wire position: during maintenance, the electrode is knocked off by inaccurate actions, it ceases to detect the presence of a burner flame.

Cleaning the burner: flame separation occurs when the nozzles are clogged with dust, there is enough oxygen, but no gas. We clean with a vacuum cleaner and a toothbrush.

Condensation on the electrode: if the boiler is in an unheated room or leaks from the chimney without a reverse slope, dampness can affect all boiler appliances, it is necessary to dry the chamber.

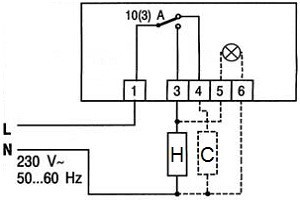

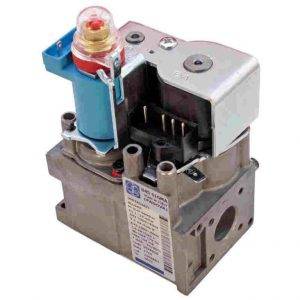

The gas valve of the boiler is faulty: we check the windings of the coils with a multimeter (we measure in kOhm).

Resistance between pins 1 and 3 - 6.5; 1 and 4 - 7.4 (for block SIT SIGMA 845048).

In case of non-compliance, the gas valve is replaced (turn-to-turn short circuit). If R = ∞ is a break, R = 0 is a short circuit.

Check the chimney: blockage that reduces the flue gas duct, icing on the tip. With regard to boilers with an open combustion chamber (air is taken from the room), it is necessary to ensure a good air flow into the room.

We install a temporary jumper (thereby simulating the closure of the contact) and restart the boiler.

Checking the integrity of the manostat and the tubes suitable for it: we blow into the hole of the manostat and fix the switching clicks, if there are no clicks, the manostat needs to be replaced. It will not be superfluous to check the resistance with a multimeter for closing and opening the contact.

Check the operation of the fan: make sure that the fan is working; when turned on, the impeller should spin and pressure should be created in the system. The error also appears when the turbine is running, when the fan does not reach the required speed and the thrust is lower than the calculated one.

- Performance is evaluated in dynamics (~220 per terminal). Remove the casing of the Ariston boiler, fold back the wires, turn on the power from the outlet. If the impeller rotates, there are no complaints about the device.

- The presence of U coming from the ED is checked. With error 607 of the Ariston EGIS PLUS model, the multimeter will show zero - no fan control.

Venturi device: if the boiler model does not provide a condensate trap, the tube cavity is gradually filled with liquid drops: it is easy to remove, blow through and install in place.

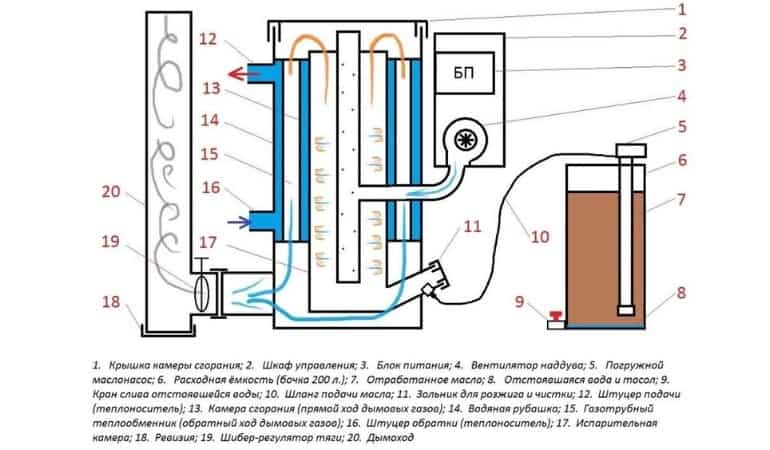

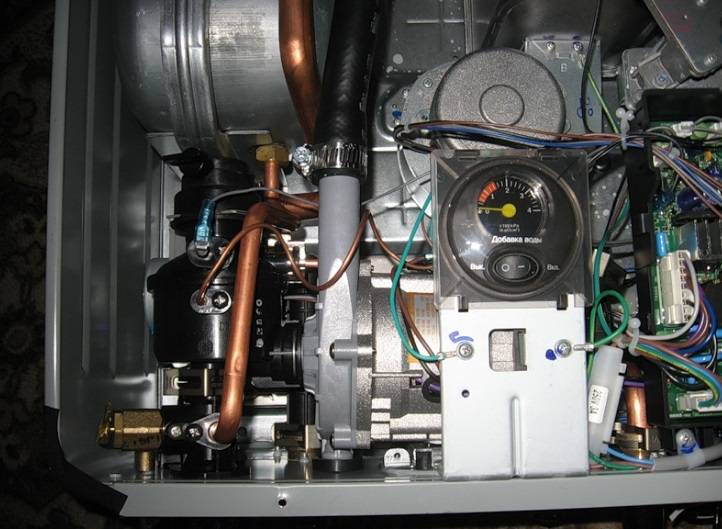

The device and features of the boiler

Japanese-made boilers "Rinnai" are closed-type appliances. These are turbocharged units in which a fan operates to force the removal of combustion products. The coaxial chimney supplies combustion air and removes smoke.

The ignition block is located in the center of the structure. The burner cuts the flame into three parts, so the heat exchanger warms up evenly. At the same time, the flame can be modulated in three modes. For example, in the summer you can turn on only one part, saving on fuel.

The product includes two copper heat exchangers: one for heating, the other for hot water supply (DHW). A three-way valve switches the heating from one system to another. Inside is an expansion tank of 8.5 liters.

Below is a circulation pump. Its rotor is dry, which contributes to the long-term operation of the unit. It ensures the circulation of the coolant through the system. Remote control or keyboard. In the presence of a display that reflects the temperature and other indicators.

Less common errors of the Ariston boiler

Next, we will consider rarely occurring problems of boilers and methods for their elimination.

117

This code is listed Ariston boiler errors BS 24FF. The 117th fault indicates incorrect water circulation. Solution: reboot the unit. Inspection is also needed to check the pump gas boiler Ariston BS 24.

201

The 201st malfunction indicates a breakdown of the touch sensor for heated water or a short circuit. The wiring needs to be replaced.

307, 308

With such designations on the screen, a failure occurs in the electrical module. To throw off the error, you need to hold down the reset button for a short while.

601

When a boiler with an open combustion chamber does not want to start and gives out "601", this indicates that there is no draft. As soon as the cause disappears, after 12 minutes the system will work again.

A01

The boiler does not turn on and shows error A01 when auto ignition fails. This is possible with poor voltage in the mains (a stabilizer will help) or an incorrectly installed outlet (you need to change the phase to "0").

E34 is a breakdown of the pneumatic relay. A part needs to be replaced.

Sp2

The designation Sp2 or 5p2 indicates the 2nd failed attempt to light the wick. This problem is caused by a number of factors:

- decrease in gas pressure;

- breakdown of the ionization sensor;

- lack of air flow;

- non-removal of products of combustion of gas.

It is necessary to check the gas valve, ventilation in the room, the patency of the chimney.

1p1, 1p2, ip2

Designations like 1p1, 1p2 or ip2 appear when there is no water or water circulation is wrong. You need to refer to the paragraph "Error 108, how to fix it."