- Error codes and how to fix them

- Error 10

- Code decryption

- Step 1

- Equipment Features

- Turbocharged boilers Navien Deluxe Coaxial

- Design features

- Setting up a gas boiler Navien

- Heating setting

- Heating with air temperature control

- Hot water temperature setting

- Away Mode

- Setting the Timer Mode

- Malfunctions of the gas boiler Navien

- The Navien boiler does not reach the set temperature

- The Navien boiler quickly gains temperature and cools down quickly

- How to fix error 03 in Navien boilers

- Decryption

- Procedure

- Navien boiler error 10

Error codes and how to fix them

Consider the most common mistakes in the video. Many thanks to the Repair-31 channel for this.

Error 10

Automated self-diagnostic complexes, in combination with boiler protection systems, prevent the most serious breakdowns almost at the initial stage. Revealing this or that malfunction, the program turns off the boiler and displays the code on the LCD display.

The most common failures of Navien boilers:

E01 indicates overheating of the coolant in the boiler. For atmospheric ATMO models, the electric pump does not function, since in these modifications there is no heating medium flow sensor, so the pump will need to be replaced.First you need to check the operation of the heating system for airiness and the presence of contamination in the filter installed in front of the boiler.

E02 indicates an error in the circulation of network water. Error 02 on the Navien boiler is eliminated by checking the circuit for leakage. The pressure in the network is set from 1 to 2 bar, if necessary, the network must be recharged. Check work stop valves and three-way valvemaybe they are covered. Check the operation of the flow sensor. If the problem persists after these procedures, the board needs to be replaced.

E03 indicates the absence of an electrical signal due to the presence of a flame in the furnace or a break in the line of the primary sensor. In the Navien boiler, error 03 is checked in the viewing window for the actual presence of a torch. If it is not there, check the electrical resistance of the coils on the gas line cut-off. The presence of a spark on the electronic ignition system and the gas pressure in front of the boiler are controlled. Torch separation is possible due to the large volume of air supplied by the fan.

E04, false alarm on the flame in the burner. Error 04 on the Navien boiler is possible due to a leaky gas shut-off valve or a spark from the ignition system enters the flame sensor. The electrode block will need to be replaced. If the problem persists after this, the board will need to be replaced. First you need to check the grounding in the boiler with a resistance limit of at least 4 ohms.

E05, error 05 - an open in the line of the return temperature sensor or its temperature is less than 14 C. Before carrying out repairs, check the humidity at the sensor connection.

E06, error 06 - short circuit in the return temperature sensor line or its temperature is above 120 C.Check the electrical resistance of the sensor: 20 C - 10.0 kOhm, and 50 C - 3.6 kOhm. If the value is not correct, the sensor will need to be replaced.

E07, violation in the DHW sensor line. A similar sensor test as above is needed.

E08, short circuit in the DHW sensor line. A similar sensor test as above is needed.

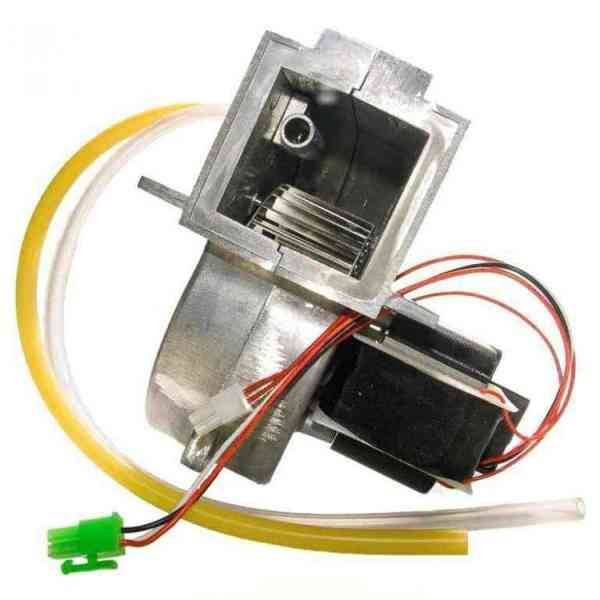

E09, error 09 - fan failure. It will be necessary to control the incoming voltage on the board in the zones where the black and red conductors are turned on. If the voltage parameters are normal, but the rotation speed is low less than 420 rpm, it is necessary to replace the electric fan, since ignition will not be performed. If the fan speed is 2100 rpm. and the failure is not eliminated, most likely, there is a short circuit in the triac line, it is necessary to replace the electronic board.

E010, error 10 confirms a failure in the chimney circuit due to clogging of the chimney channels

Inspection and cleaning of the chimney is required, and pay attention to the air intake grate, whether it is clogged with foreign matter.

Code decryption

The boiler manual says briefly: fan failure. An unambiguous interpretation - failure - is incorrect. Error 09 is not necessarily caused by a breakdown of the device: its incorrect operation is also the cause of Navien's emergency blocking.

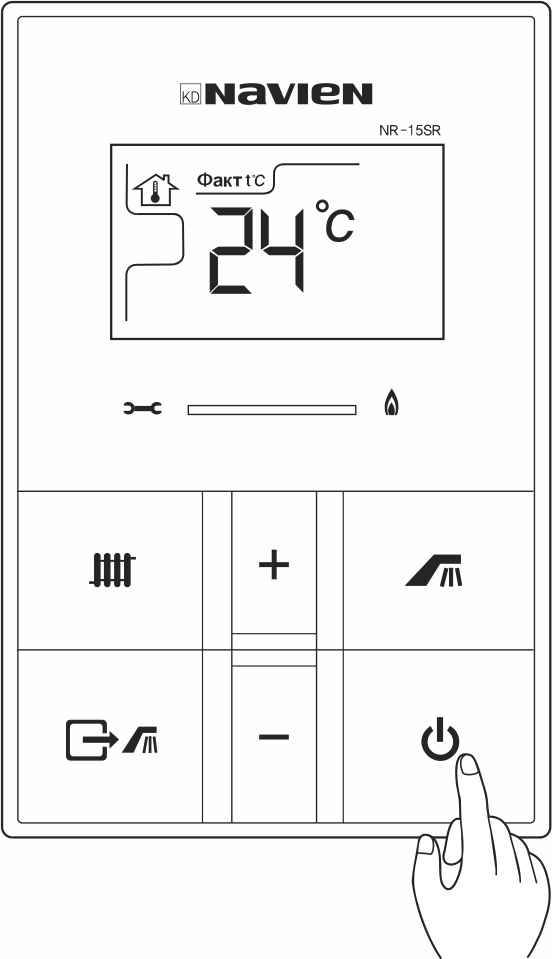

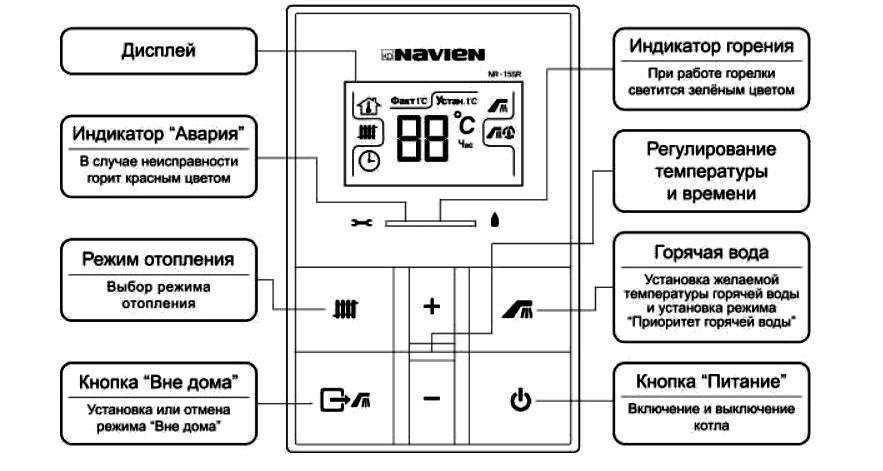

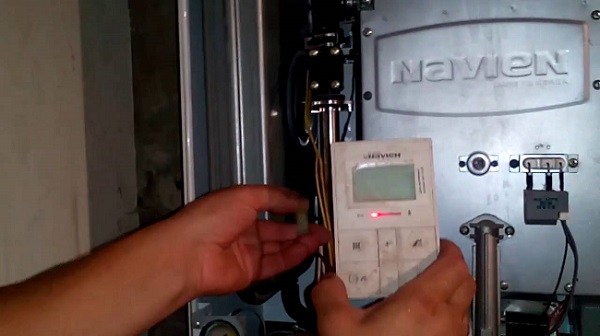

The control panel is not built into Korean boilers. Testing the unit, setting the parameters is done from the remote control. Errors are also displayed on its display. Knowing what the buttons are for, it is easy to perform further actions.

Step 1

Restart Navien. Imported equipment, unlike domestic boilers, responds to power supply problems. And we have enough of them, from phase imbalances to undervoltage.The electronic circuit fixes this as a malfunction and blocks the operation of the heating unit. If error 09 is caused by this cause, it will disappear after reset.

Remote control panel for the Navien boiler with a built-in room temperature sensor. Click on the "Power" button

Step 2

Check connections. Two wires fit the Navien boiler fan. Open, short, unreliable contact - and error 09 is guaranteed.

Check wire pins on Navien fan

Step 3

Measure voltage. The norm for the Navien boiler is 230 / 1f, the maximum deviation is 10%.

Step 4

Check fan. When turned on, its blades must rotate at a speed of at least 400 rpm. Otherwise, even before ignition, the automation will react and block the Navien boiler with error 09. Testing is carried out by lightly touching the impeller. Normal rotation indicates the health of the mechanical part of the fan.

Dust clogged Navien fan

Likely Causes

- Insufficient revolutions due to interturn short circuit or problems with kinematics. If the matter is in the winding, the fan changes, and after maintenance, error 09 disappears. Incorrect operation of the device is caused by a number of factors.

- Blades dirty. It is necessary to dismantle the fan unit and clean it.

- Bearing destruction. Changes independently, shaft centering is not required.

No rotation. If voltage is supplied to the fan of the Navien boiler, there are no complaints about the mechanics, but the impeller is motionless, the point is in the winding. Its resistance is in the range of 23-25 ohms. At R = 0 - short circuit, = ∞ - break: the fan unit changes.

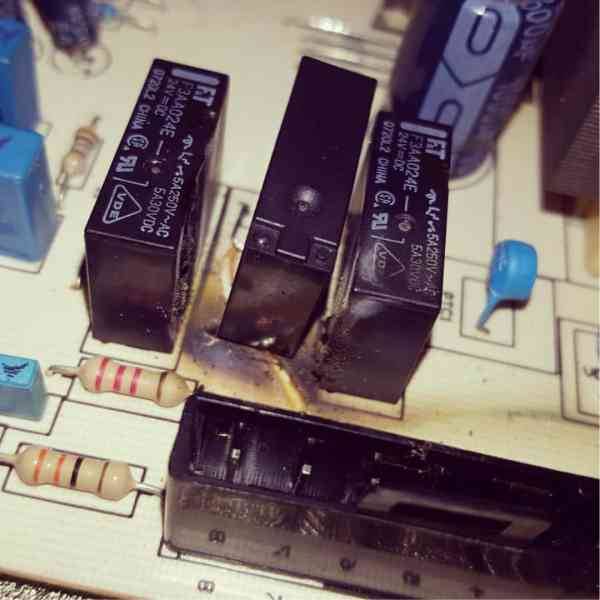

Step 5

Replace the Navien boiler board. If the previous actions did not work, then it is the cause of error 09.It generates fault codes based on the signals coming from the sensors.

Navien boiler board burned out

Helpful Hints

The appearance of false boiler errors caused by the supply voltage can be eliminated by connecting Navien to the network via a UPS. Not everyone understands the difference between this unit and the stabilizer. For the Korean unit, the latter is not needed - the heating installation has its own built-in and efficient circuit. In addition, in case of breaks in the line, problems with the gas generator, this device will not help - the Navien boiler will stop. But the UPS (stabilizer + charger + batteries) will provide long-term offline operation until problems with industrial / voltage are eliminated.

When calling a service representative, you should make sure that the organization is a regional division of Navien or certified by the manufacturer. If this is just a workshop for repairing heating equipment, there may be problems: lack of diagrams, guidelines for eliminating errors, spare parts, trained specialists. As a result - a delay in time, a service of inadequate quality.

Equipment Features

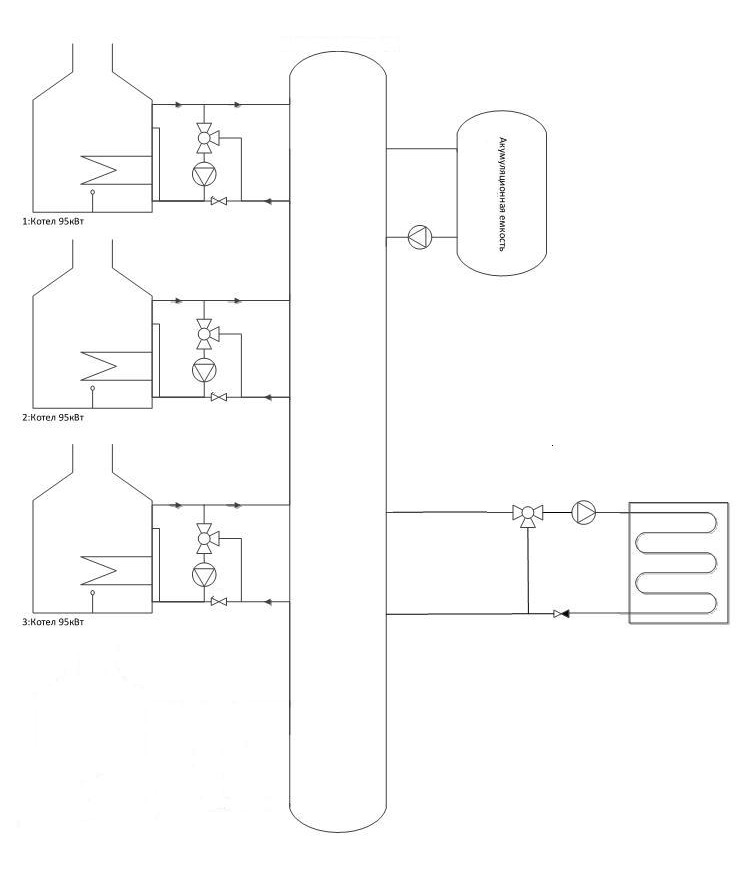

Equipment is wall and floor type. The most popular models are Navien Ice, Navien NCN SteelGA/GST, Navien AceTurbo and Ace Atmo, Navien LST. Among all the variety, you will find boilers with atmospheric and turbocharged combustion chambers. There are also condensing units with a built-in heat exchanger to collect condensate. Read more in the article "What is a gas condensing boiler".

According to the type of operation, the units are divided into double-circuit and single-circuit. Double-circuit are equipped with two heat exchangers for heating water and space heating.All models have a Russified remote control, as well as sensors for monitoring systems.

The control circuit is equipped with a microchip, so the equipment is not afraid of power surges in the network. The design ensures stable operation when the pressure drops to 0.1 bar.

The built-in circulation pump will not allow the coolant to freeze even if the gas is turned off.

The boiler self-diagnosis system allows you to detect a breakdown at an early stage, as well as understand why a problem has occurred, how to fix it. Before proceeding with DIY repairs, make sure that the warranty period has expired. If you open the device, it will become invalid.

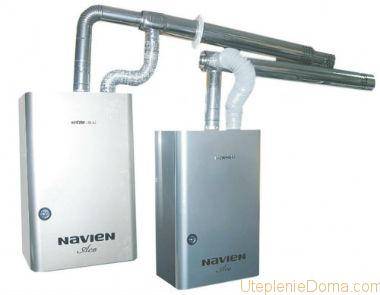

Turbocharged boilers Navien Deluxe Coaxial

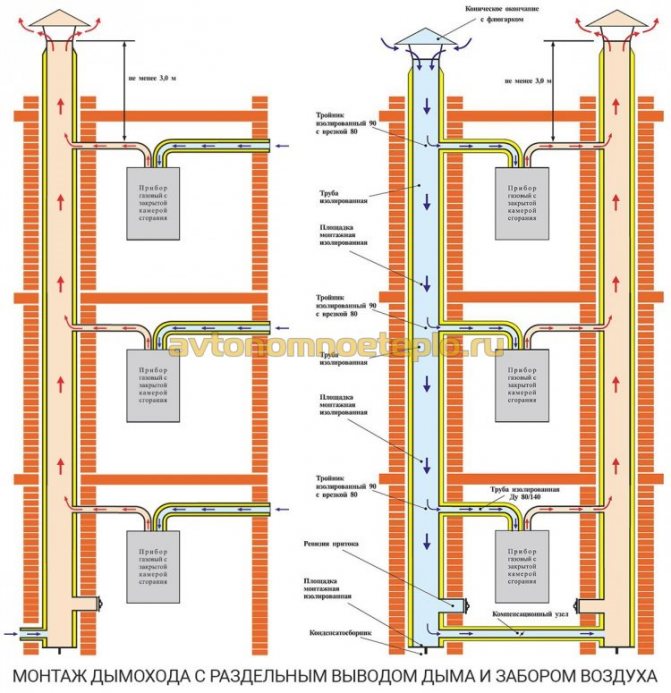

Deluxe and turbo models differ in the method of connecting the chimney.

The Navien deluxe gas boiler must be hung on the wall, it is double-circuit, the combustion chamber is sealed. This means that it can heat water in two directions at once: heating and hot water. The air for the fire is not supplied from the premises, but from the street through a coaxial chimney. A turbine is installed above the burner to take in air and exhaust gases. It is powered by the mains and without it the functioning of the boiler is impossible.

This heater is designed in such a way that it can work in our conditions. This applies to gas pressure, the quality of the coolant, and the harsh Russian winters. This unit has a useful feature that prevents the system from defrosting. This option in Navien gas boilers, according to reviews, saved more than one circuit. When the coolant temperature drops to 10 degrees, the circulation pump automatically turns on. It drives the liquid along the circuit so that it does not freeze.If the temperature continues to fall and reaches 6 degrees, then the boiler turns on and heats the liquid to 21 degrees.

The burner is made of stainless steel. It can be set to turn on and off according to the desired room temperature. The heater easily tolerates:

- water pressure drop to 0.1 bar;

- gas pressure drop to 4 atmospheres;

- malfunctions of the Navien boiler associated with power surges are excluded.

The heaters of this line are produced with a capacity of 10, 13, 16, 20, 24, 30 kW. The power can be adjusted. The boiler heats water for heating in the range of 40-80 degrees, and for hot water 30-60 degrees. To remove the products of gas combustion, a 75/70, 60/100 or 80x80 chimney can be connected to the heater.

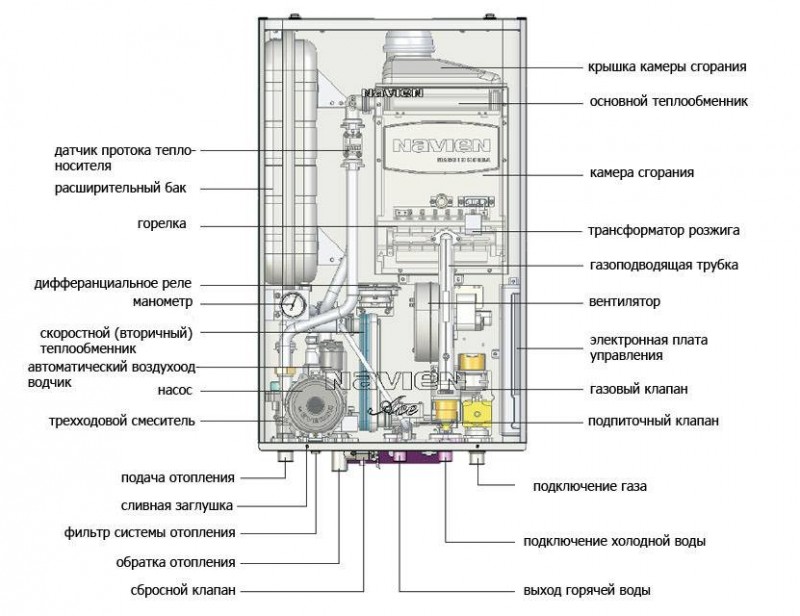

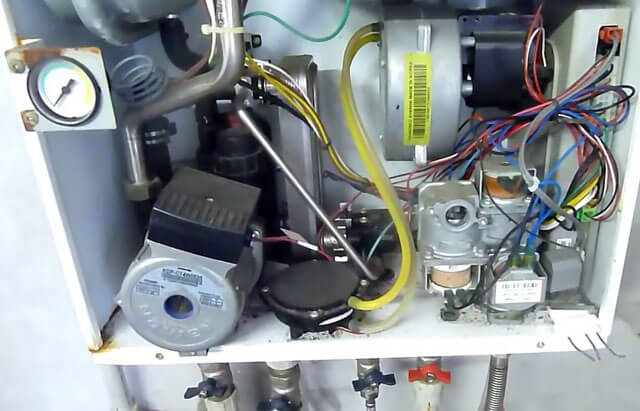

Design features

Boiler device

To attract the attention of buyers, the Korean manufacturer has developed a perfect design of the gas unit, minimized the number of breakdowns and released its product at a relatively low price. One of the advantages of a gas unit is a clear and detailed instruction, which greatly simplifies the setting of the selected mode. The company adheres to the same principles in the installation of the electronic control system, in the regulation of other parameters

The company adheres to the same principles in the installation of the electronic control system, in the regulation of other parameters.

The versatility of a gas boiler can be judged by its working abilities:

- The control circuit with a microprocessor chip allows both protection and smoothing of voltage surges in the power supply network.In case of changes in the operating parameters, the electronic system is able to maintain the mode for the full functioning of all components of the unit, which has a positive effect on the operational life of the device. And also the adjustment scheme allows you to avoid possible malfunctions in case of false switching on of the sensors. This feature of the electronic system is of particular importance for the operation of the equipment, given the instability of the voltage in the power grid and its deviations in a wide range.

- The design of the gas boiler is designed to take into account the possible drop in water pressure to 0.1 bar. This minimizes blocking actions and device breakdowns, which is ideal for installation on the upper floors of a building.

- The Navien boiler is able to neutralize possible malfunctions caused by a decrease in supply pressure to 4 mbar, which is critical for the normal functioning of many modern electronically controlled systems.

- Due to the design features of the Navien gas appliance, the heating system will not freeze even during a gas supply cut. In order to prevent the activation of the emergency mode when the temperature of the coolant drops below 5 degrees, as well as the inability to ignite the burner, a built-in pump was provided for forced and continuous circulation of water.

- There is a double heat exchanger for separate heating of hot water and coolant, which is very convenient (you can optionally set up pre-heating of water). Easy-to-use electronics allow you to accurately set the appropriate mode.

Setting up a gas boiler Navien

Next, we will consider how to set up the Navien Deluxe gas boiler with your own hands.Manipulations are performed using a remote control with a built-in room temperature sensor.

Heating setting

To set the heating mode and set the temperature of the coolant, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture flashes, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Wall-mounted gas boilers Navien - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the "+" and "-" buttons with the "radiator" icon flashing. The possible range is between 40ºC and 80ºC. After setting the temperature, it will be automatically saved. The “radiator” icon will flash for a few seconds, after which the actual coolant temperature will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, hold down the “radiator” button until the “house with a thermometer” image appears on the screen. It stands for "Heating with room temperature control".

When the “house with thermometer” symbol flashes, the desired room temperature is displayed on the screen. When the icon is fixed, the display shows the actual room temperature.

When the icon flashes, the desired level of heating in the room is set using the "+" and "-" buttons, adjustable in the range of 10-40ºC. After that, the temperature is automatically saved and the icon stops flashing.

Hot water temperature setting

To set the hot water temperature, hold down the “faucet with water” button until a similar flashing symbol appears in the right corner. The desired hot water temperature can then be set between 30ºC and 60ºC. The settings will be automatically saved and the water faucet symbol will stop flashing.

Note! In Hot Water Priority mode, the hot water temperature is controlled differently. Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen

Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol.

The "Hot water priority" mode means the preparation of a supply of water at a given temperature even if it is not used. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The "Away from home" mode implies the operation of a gas boiler for the preparation of hot water only.To transfer the unit to this mode, you need to press the button, which shows an arrow and a tap with water. If the water faucet symbol appears on the screen, it means that the Away mode is set. It displays the actual room temperature next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating.

Setting the Timer Mode

The "Timer" mode is necessary to set the time to stop the operation of the gas boiler in the range from 0 to 12 hours. The unit will work for half an hour, turning off for the time of the specified interval.

To set the "Timer" mode, hold down the "radiator" button until the "clock" symbol appears. When the icon is flashing, use the "+" and "-" keys to set the interval time. The set value is saved, the “hours” stop flashing, and the display shows the actual air temperature.

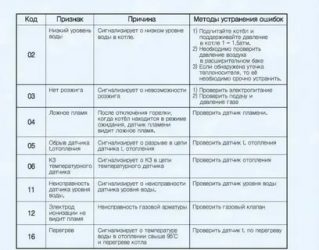

Malfunctions of the gas boiler Navien

In order for you to be able to repair Navien gas boilers on your own, we have compiled this guide. It will provide invaluable assistance in eliminating breakdowns and failures. Let's see what self-diagnosis systems can tell us - we will present the error codes of the Navien boiler in the form of a list:

Despite the huge number of possible breakdowns, most of them do not pose a serious problem and are solved fairly quickly and with little money.

- 01E - overheating occurred in the equipment, which was evidenced by the temperature sensor;

- 02E - in Navien boilers, error 02 indicates an open in the flow sensor circuit and a decrease in the coolant level in the circuit;

- Error 03 in Navien boilers indicates the absence of a signal about the occurrence of a flame. Moreover, the flame can burn;

- 04E - this code is the opposite of the previous one, as it indicates the presence of a flame in its absence, as well as a short circuit in the flame sensor circuit;

- 05E - an error occurs when there is a malfunction in the temperature measurement circuit of the coolant in the heating circuit;

- 06E - another temperature sensor failure code, indicating a short circuit in its circuit;

- 07E - this error occurs when the temperature sensor circuit in the DHW circuit malfunctions;

- 08E - an error of the same sensor, but diagnosing a short circuit in its circuit;

- 09E - error 09 in Navien boilers indicates a malfunction of the fan;

- 10E - error 10 indicates problems with smoke removal;

- 12E - the flame in the burner went out;

- 13E - error 13 indicates a short circuit in the flow sensor of the heating circuit;

- 14E - code for the lack of gas supply from the main;

- 15E - a rather ambiguous error indicating problems with the control board, but without specifically indicating the failed node;

- 16E - error 16 in Navien boilers occurs when the equipment overheats;

- 18E - malfunctions in the smoke exhaust system sensor (sensor overheating);

- 27E - electronics registered errors in the air pressure sensor (APS).

There are no repair instructions supplied with the boilers, since the repair work should be carried out by a service company. But nothing prevents us from repairing a faulty node on our own, without resorting to the help of specialists. Let's see how Navien boilers are repaired at home.

The Navien boiler does not reach the set temperature

In order to prevent the appearance of scale, install a system for cleaning and softening tap water - the costs will not be the biggest, but you will extend the life of your boiler.

First you need to clean the heat exchanger of the Navien gas boiler. At home, this is done with citric acid, toilet bowl cleaners, or special products (if available). We remove the heat exchanger, fill it with the selected composition, and then rinse it under high water pressure.

In a similar way, the heat exchanger of the DHW circuit should be cleaned if the Navien boiler does not heat hot water. In the most advanced cases, the exchanger must be completely replaced.

The Navien boiler quickly gains temperature and cools down quickly

A very complex error indicating some kind of malfunction or imperfection in the heating system. Try to correct the situation by adjusting the speed of the circulation pump, make sure that there is no air in the system. It is also necessary to check the filter and the clearance of the heat exchanger. In some cases, it may be necessary to replace the coolant.

How to fix error 03 in Navien boilers

For some reason, the electronics do not receive a signal about the presence of a flame. This may be due to a lack of gas supply or a malfunction of the flame sensor and its circuit. Sometimes an error appears after carrying out any work on the gas line. Another possible reason is that the ignition does not work. Troubleshooting:

- We check the presence of gas supply;

- We check the performance of the ignition;

- We check the ionization sensor (it could be dirty).

When using liquefied gas, it is recommended to check the operation of the reducer.

If there is no malfunction in the Navien gas boiler, error 03 may occur with some problems with grounding (if any).

Decryption

The error informs about the presence of a flame when the burner of the Navien boiler is not working.Such a signal is called false, parasitic.

Procedure

Restart. The instability of the supply voltage is the cause of failures and the appearance of fault codes for technical devices equipped with electronic self-diagnosis circuits. Pressing the reset button (restart) on the remote control of the Navien boiler will remove error 04.

Turning on and off the remote control panel for the Navien boiler

Grounding check. Unreliable contact, R lines ˃ 4 Ohm initiate error 04. This requirement also applies to general house wiring (Navien boiler manual, section 6).

Checking the pressure of "blue fuel". A value exceeding that specified in the Navien boiler passport as a working one causes error 04 to appear. With an autonomous gas supply, it is easy to determine by the pressure gauge of the reducer: when using LPG 275 ± 25 mm of water. Art. If the object is connected to the main pipe, it is enough to light the burners of the gas stove. Everything is required to ensure maximum energy consumption. By the tongues of the flame it is easy to determine whether the pressure is normal or too high.

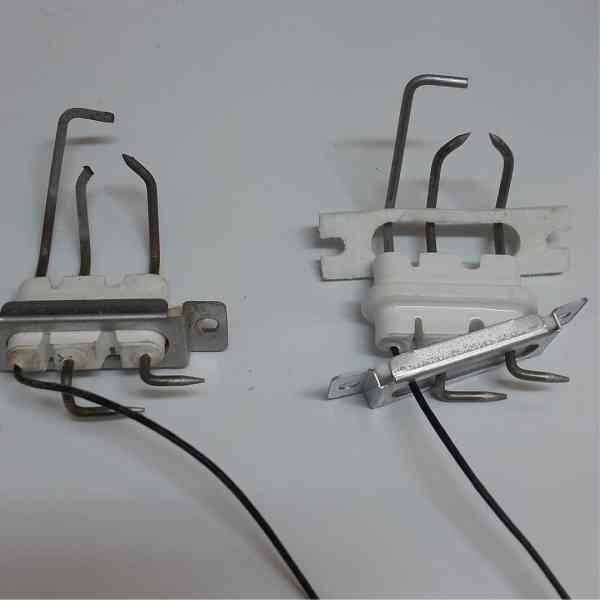

Check the electrode group. The cause of error 04 is the effect of the spark during ignition of Navien on the ionization sensor. It happens when the insulator is defective, the location of the sensitive elements (wires) is incorrect: they can be knocked down with careless maintenance of the heat exchanger, combustion chamber. The malfunction is caused by the short circuit of the signal line, dampness. The latter is typical for Navien boilers when put into operation after a long period of inactivity in an unheated room. It is not difficult to visually assess the condition of ceramics, wires, and dry the boiler cavity with a fan.

Boiler ignition electrode used and new Navien

Navien gas valve check. Leakage in fitting causes error 04 on the console display.The pressure at the boiler inlet is measured with the valve on the pipe closed: you need a pressure gauge (the norm is 130–250 mm of water column). The defect of the assembly is associated with its mechanical part: self-repair is impractical - replace or call a service technician.

Navien boiler gas valve

A malfunction of the electronic board is the last probable cause of error 04. It is not difficult to replace the unit on your own - it is screwed to the rear wall of the unit, and the installation locations of wires and cables should not be confused (ports differ in size and configuration). Given the cost of the module, you should make sure that it is he who causes error 04, and this requires professional diagnostics of the boiler. You can not do without a representative of the repair organization.

Navien boiler error 10

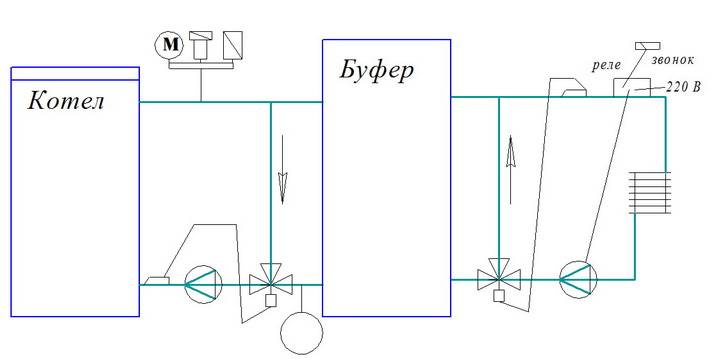

This error is related to the smoke exhaust system of the gas boiler. The products of combustion must be removed; for this, a fan is provided in the boilers. To control the operation of the fan and determine the presence of an acceptable draft for the operation of the boiler, a differential relay is used, which is connected to the turbine with two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Causes errors 10 may be a clogged chimney, back draft or incorrect connection of the air pressure control sensor to the fan. For the latter case, it is necessary to check that the yellow tube is connected to the bottom of the fan, and the transparent tube to the top, and the tubes themselves are not damaged, deformed or condensed inside.

Increased resistance in the chimney can occur due to direct gusts of wind or clogging of the chimney (bird nest or cobwebs, frost in winter). That's right, the place for the chimney to take into account the direction of the winds of a particular region at the design stage and the chimney should not be led to the leeward side of the house.

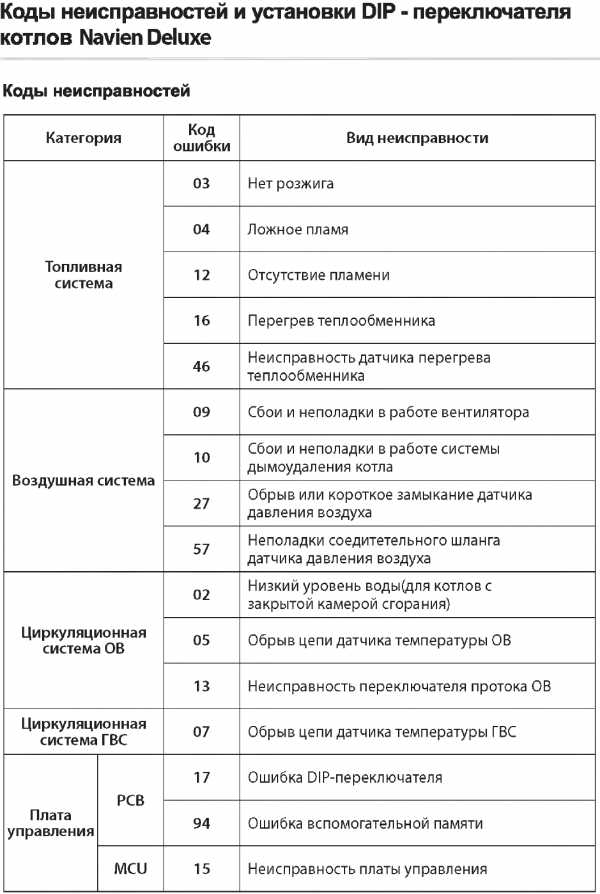

We stopped at the most common failures in the operation of Navien boilers, but in fact there are significantly more error codes. Ways to check and troubleshoot is the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

|---|---|

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from ionization electrode |

| 04 | Incorrect signal from the flame sensor or short circuit. Make sure that the ionization electrode is not in contact with the boiler or burner body, diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and compliance with the temperature table, make sure that the connection between the sensor and the control board is reliable. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of resistance on temperature on the sensor, make sure that the sensor is connected to the control unit. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (reference value approx. 23 ohms). Make sure that there is 220 V voltage at the fan terminals. There may be a malfunction of the control board circuit (Navien board diagnostics is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. Sticking of the sensor, or malfunction of the control unit. |

| 15 | Control board internal error (diagnosis and repair required) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient circulation of the coolant (see error 02), clogging of the heat exchanger or a malfunction of the thermostat itself. Operation occurs at 98 degrees, shutdown of the accident when it cools down to 83 degrees. |

| 27 | Open or short circuit in the air pressure sensor circuit |

![How to fix error 18 on a gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/d/7/2/d721b269a97dd59a9e1e1bc7a3c8bbe7.jpg)

![How to fix error 16 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/4/d/0/4d047bd1cbbca427bfcd4e6c029d48ec.jpeg)

![How to fix error 09 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/f/8/e/f8e812bbd6895c74107078f6c6619899.jpeg)

![How to fix error 09 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/6/4/9/649fb48212bea3d41cf7954f8a745c75.jpeg)

![How to fix error 16 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/c/0/b/c0ba0c1356f37b85925a1069257f2763.jpeg)

![How to fix error 15 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/1/0/7/107f59b9c60e26bac3882c947cfb2a96.jpeg)

![How to fix error 10 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/a/6/a/a6a0b149d7728da0976701227a699d0d.jpeg)