What do indicator signals mean?

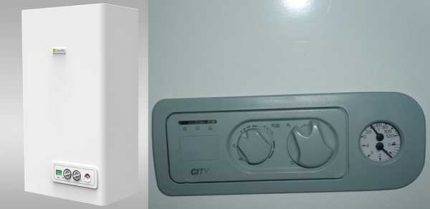

In some models of Beretta gas boilers, such as Beretta City, the appearance of failures in the operation of the units can be judged by the signals of red, yellow and green indicators.

The indicators are two or three light diodes located on the central panel, which start flashing with different intensity when a particular failure occurs.

In some models of Beretta gas boilers, errors and malfunctions are signaled by indicator lights located on the control panel.

In some models of Beretta gas boilers, errors and malfunctions are signaled by indicator lights located on the control panel.

Blinking green indicator can mean the following:

- 1 time / 3.5 sec - the equipment is switched to standby mode, the fire is extinguished;

- 1 time / 0.5 sec - the boiler is stopped due to a breakdown;

- 1 time / 0.1 sec - the unit is switched to the auto-regulation system;

- the indicator lights up and does not blink - the boiler is working normally, the fire is on.

Beretta City can stop on its own due to a breakdown in cases of receiving a signal from pressure and smoke exhaust sensors.

The boiler may stop working for 10 minutes, during which the correct parameters should be restored.During this time, the system will automatically scan. A detailed guide on how to check the Beretta gas boiler sensor readings should already be included in the self-diagnosis system.

The indicators on the panel of the Beretta boiler can give signals in various combinations and with different intensities. The type of light signal depends on what error occurred during the operation of the unit

The indicators on the panel of the Beretta boiler can give signals in various combinations and with different intensities. The type of light signal depends on what error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator lights up and does not blink - if after the suspension the operation of the boiler is not adjusted, the unit goes into emergency mode;

- the indicator flashes - the limit temperature sensor is triggered. Sometimes you can eliminate the error using the mode switch.

Simultaneous flashing of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator lights up and lights up continuously when the preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified specialist to repair the Beretta gas boiler.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified specialist to repair the Beretta gas boiler.

To eliminate all the above problems with Beretta gas boilers, it is strongly recommended to use the services of masters of authorized service centers and organizations with which an agreement has been concluded for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to even more serious damage, which will result in expensive repairs and a long stop of the autonomous heating system.

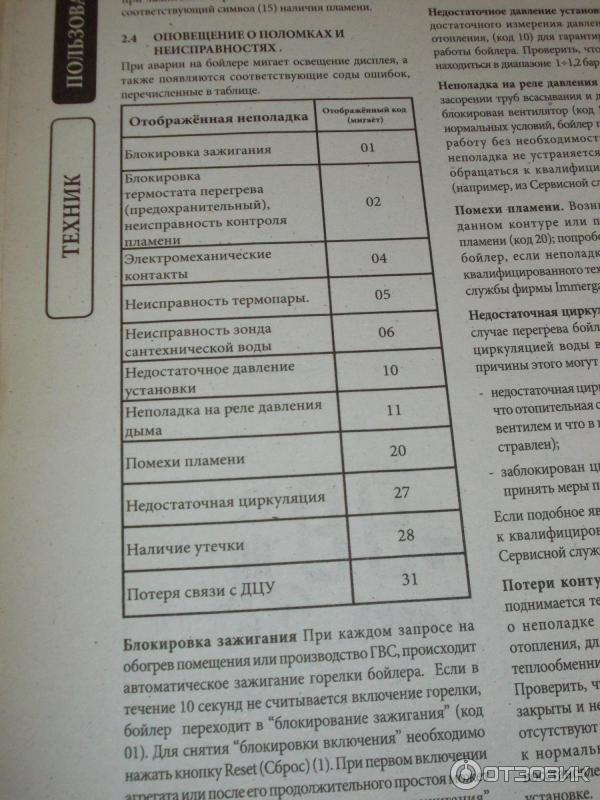

Overheating of the heat exchanger of the Gazeko gas boiler. The unit stops working.

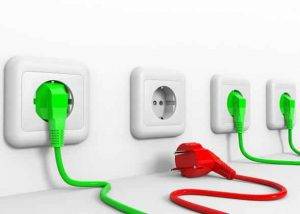

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

Checking the polarity in the plug-socket connection: turn the plug 90 degrees and insert it back into the socket or stabilizer.

-

Checking the signal circuits from the EPU to the NTC sensor: short circuit, wire break, insulation melting, broken contact, but often visual inspection is not enough - you need to pull it out of the plug sockets and check the condition of the lamellas: oxides. Checking the performance of the NTC sensor: depending on the model, there are NTC sensors overhead, in a sleeve and submersible.

DHW temperature sensors differ only in housing, but the principle of operation is identical: they are thermistors (a semiconductor whose resistance depends on the ambient temperature).

The performance test is carried out with a multimeter in the measurement mode R (a diagram for a specific sensor can be found in the instructions).

The simplest test is to determine the resistance at room temperature (25 C). If R \u003d 8.1 - 8.6 kOhm, the device is working and the cause of the error e06 is not in it. A slight deviation of the value (±0.2) is allowed, taking into account the measurement error. At R = 0, the sensor is rejected (breakdown of the p / n junction).

The water supply tap in the system is closed: you need to check the position of the controls of the taps, valves on the main and bypass. Most likely, the heating circuit pipe is blocked in some area.

The coarse filter on the main line is clogged: it gradually becomes clogged with deposits from the heating system, and if the mesh has not been washed for a long time, then dirt can cause an error.

Air in the system: the accumulation of bubbles moving along the pipes along with the coolant reduces the flow rates, causing the pump to malfunction.

It is necessary to bleed air from the system, it is not worth relying entirely on the air vent in the boiler pump, over time it wears out and does not work out the air discharge so effectively, in such a case it is good to have an additional air vent at the highest point of the system (2nd floor) which is additionally mounted on the battery instead of the Mayevsky tap, if there is none, then you can manually bleed the air through the Mayevsky taps (until water appears).

The boiler pump is faulty: problems with the pumping device also cause an error, while the pump may work, but not in the set mode: hence the decrease in circulation rate and overheating of the main heat exchanger.

You also need to check the rotation of the impeller: when the unit is turned off, a washer is removed that closes the air bleed hole. In the center, the tip of the motor shaft with a horizontal slot is visible.

In a working pump, the axle turns easily. Difficulty in its rotation is evidence of incorrect operation of the pump.

The three-way valve or the servo drive is faulty: when the boiler mode was changed from DHW to RH, the valve did not switch.

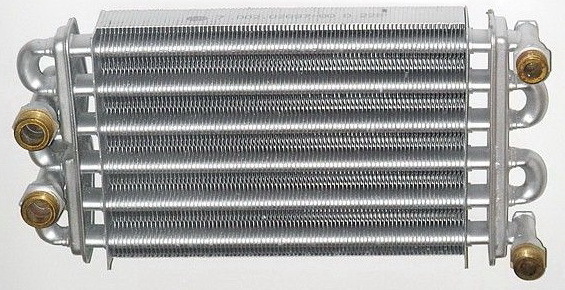

The boiler heat exchanger is clogged: maintenance needs systematic maintenance, and if the deadlines are not met, the quality of the coolant (degree of purification, hardness index) is not taken into account when organizing work, overheating is inevitable over time.

To clean the TO, you need to use professional equipment (booster) or rinse the TO yourself using special liquids.

About Baxi gas boilers

Baxi gas boilers have been present on the heating equipment market for quite a long time, and have shown themselves from the best side. These heaters are quite reliable and easy to maintain, and are assembled from high quality components. Baxi have an adjustable flame level, which allows you to more accurately maintain the desired temperature. Adjustable flame allows you to operate the boiler in a sparing mode, since the number of switching on and off the boiler is significantly reduced. This feature allows the burner nozzle to last much longer, and also increases the life of the heat exchanger. All this is because the adjustable flame reduces the frequency of heating and cooling of the heat exchanger, which has a positive effect on its service life.

Also, heating devices of this brand are famous for their efficiency, and they save not only gas, but also electricity. Baxi boilers are equipped with several temperature sensors that are located inside the boiler. But it also provides for the installation of remote temperature sensors that can be installed from the side of the street. With such an arrangement of sensors, the boiler itself will respond to changes in the air temperature outside the window, and select the most optimal mode of operation.

Despite the many innovative technologies that are used in the heating devices of this brand, Baxi boilers are famous for their light weight and compactness. Even the floor units of this manufacturer are quite light and small. Baksi boilers are incredibly reliable, since all systems of this device are controlled by an electronic control unit.The electronics monitors all parameters of the boiler, and if the slightest malfunction occurs, the boiler stops working, and the error code is displayed on the liquid crystal display. Each code encodes information about a particular malfunction, and decoding this code allows you to quickly identify the malfunction and eliminate it. Errors are of the following names.

About gas equipment in general

Gas boilers every year replenish the list of household appliances of each apartment or country house, have already become an integral part of the modern heating system. In almost every new building, a wall-mounted gas boiler has already been installed according to the project. Of course, double-circuit boilers have a number of advantages: they are compact, safe, economical and operate under the control of smart automation. Let us consider in more detail modern gas boilers using the example of Baksi.

These boilers are compact and easy to operate, a wide range of models allows you to choose equipment for a small apartment and a country house. The most popular BAXI models are: main four, eco four, luna. Boilers from different manufacturers have the same principle of operation and scheme of operation, the differences are only in power, technical design and equipment.

To install gas equipment, first of all, the requirements for the room in which the boiler will be installed must be met. Basically, we are talking about boilers with an open combustion chamber, where air is taken directly from the room in which they are installed, so good air exchange, ventilation, absence of exhaust devices, etc. must be ensured.In some EU countries, such boilers are already banned, because failure to comply with installation requirements leads to disastrous consequences.

For apartment buildings, boilers with a forced smoke exhaust system and a closed combustion chamber are mainly used. They are safer and more unpretentious in operation. The word unpretentiousness may not be entirely appropriate here, but in the context we are talking about the fact that any unit is equipped with an advanced system of self-diagnosis and accident prevention and, subject to the requirements, is absolutely safe.

In the future, in principle, nothing supernatural is required from the user: annual maintenance and proper response to problems reported by the boiler security system. There is nothing complicated here - everything is described in sufficient detail in the instruction manual.

Error e01

Malfunction e01 of Baksi boilers indicates a malfunction in the ignition system. This error is generated by the Baxi sensor, which controls the flame. The error code can be reset by hand, and for this you need to hold down the "R" button. After 3-5 seconds after pressing and holding this button, the boiler should start. If the flame did not appear and error e01 is displayed again on the screen, then only one thing will help in this situation - calling a boiler repairman. An error with this code can be caused by several reasons. This may be a failure of the ignition system, as well as incorrect operation of the electronic control unit. There have also been cases that this malfunction occurred due to an incorrectly adjusted gas valve. This error can also be caused by:

- weak draft in the chimney;

- weak gas pressure.

Let us consider in more detail the causes of the error e01 on Baxi boilers, and how to eliminate it. This error is sometimes very difficult to correct, since many factors can cause it. This malfunction is associated with the difficulty of ignition. On some models of boilers from this manufacturer, there is also a flame sensor in the electrode, and this bundle sometimes does not work correctly.

When the ionization current that passes from the electrode through the burner to the ground loop without any obstacles, then the ignition works without any deviations. The control board fixes the parameters of the ionization current. If its strength is in the range from 5 to 15 microamps, then this can be considered the normal mode of operation of the ignition system. When for some reason the ionization current deviates from the norm, the electronic control unit of the boiler records these deviations, and the gas the Baksi boiler is blocked with an error e01.

Also, this error appears if the contact of the electrode with the control board is broken. Also, if an error e01 occurs, you immediately need to check the gas pressure in the line. On natural gas, the pressure should not be lower than 2 mbar, and on liquefied gas - 5-6 mbar. Also, the pressure can be adjusted with a special nut, which is located on the gas valve. It is also necessary to thoroughly check the operation of this valve - measure the resistance of the coils with a multimeter. The first coil should have a resistance of 1.3 kOhm, and the second - 2.85 kOhm.

The conductor that connects the gas valve to the electronic board may contain a diode bridge, which may also fail.This is a feature of some models of Baksi boilers and the diode bridge must also be checked with a multimeter. You also need to check the resistance of the electrode itself. It should not exceed 1-2 ohms. Also, the edge of the electrode must be at the right distance to the burner. This distance should be 3 mm.

Error e01 can also appear if ignition occurs, but the flame immediately goes out. This may be due to the fact that the polarity on the 220 volt plug is reversed. By turning the plug 180 degrees, you can get rid of ignition problems. These problems can also be caused by a ground fault. The voltage between the phase and neutral phase, and the ground must be the same. The voltage between zero and ground should be no more than 0.1 volts. If this parameter is violated, then this may be the cause of the e01 malfunction.

You also need to make sure that the gas line is isolated from the boiler. This line may carry a small electrical potential, which can cause a malfunction of the heater. For insulation, a special dielectric spacer is used, which is placed between the gas pipe and the boiler.

Conclusions and useful video on the topic

To eliminate failures and errors during the operation of the Beretta gas boiler, it is necessary to understand the principle of its operation:

Recognize Beretta boiler errors The video below will help:

An example of determining and eliminating a Beretta gas boiler error:

p> If your Beretta gas boiler began to produce this or that error, it is not recommended to let things take their course and pull with repairs or adjustments. But before contacting the gas workers, it would be nice for the owner of the equipment to figure out what the equipment error is.

Knowing the cause of the identified failure will help the owner find the best solution to the problem when communicating with the authorized service master.

Do you want to talk about how you yourself determined the breakdown of a gas boiler of the Beretta brand by indication or code? Is there any useful information that may be useful to site visitors? Please leave comments in the block form below, ask questions, post photos on the topic of the article.

![How to fix the e26 error on a gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/f/7/b/f7b6f5f4ce5671d05f57db208e06d5b5.jpeg)

![How to fix the error e04 boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/a/8/0/a801a6f29c8bf835d483677dbb11974e.jpeg)

![How to fix error 10 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/a/9/4/a94730d7193be260e5155c9bf706dcb8.jpeg)