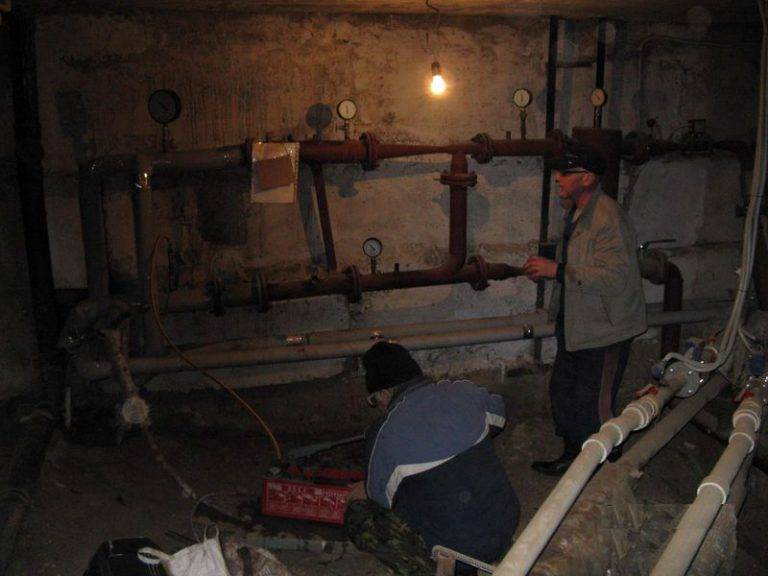

- Diagnostic methods

- Heating system test equipment

- The essence of pressure testing

- What is flushing and pressing

- The procedure and technological features of the pressure testing of the heating system

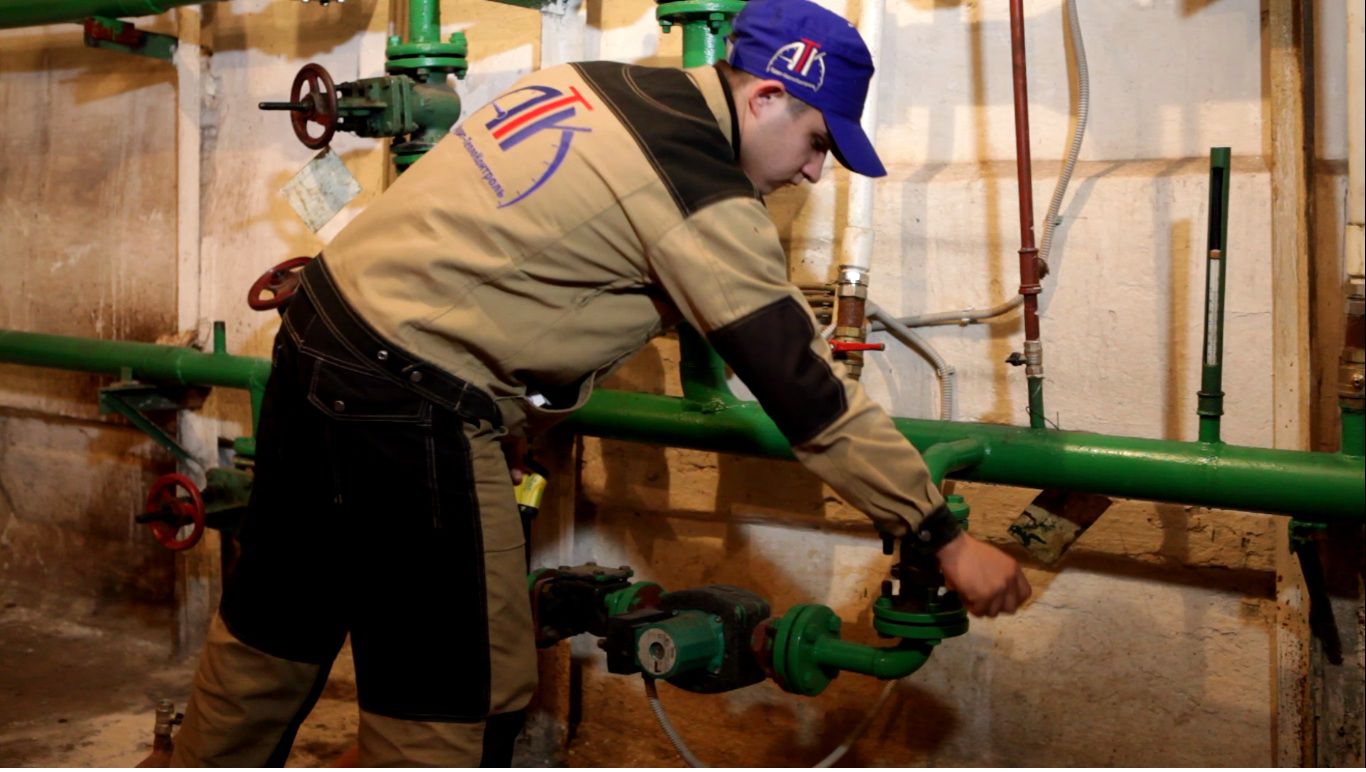

- How it's done?

- The procedure for organizing cleaning work

- Crimping process

- Types and reasons for holding

- Test tools

- Basic Rules

- Crimping process

Diagnostic methods

- The water test is the main method by which all circuits are tested. In this case, water must be pumped into the lower part of the pipes through a tap. It is allowed to pump liquid both by automatic and manual pressure pump. The advantage of this method is that it is very easy to perform all the work, and the efficiency of leak detection is at a height. The fact is that traces of liquid will immediately appear on the pipes.

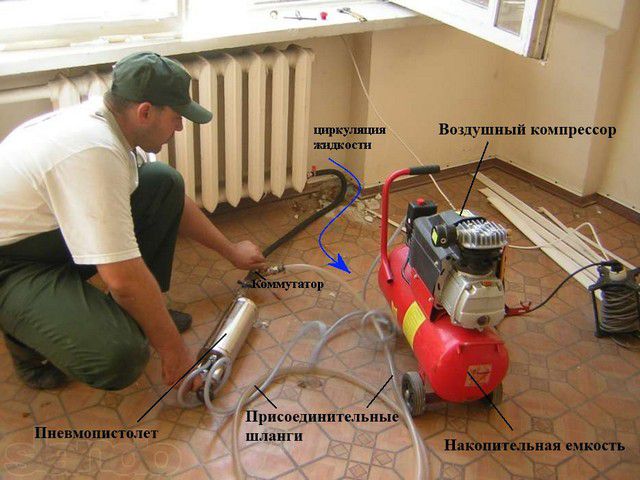

- Testing with air is not a very effective method, since it is quite difficult to detect leaks. But it is allowed to use such a technique at negative temperatures - the air will not freeze after all. A compressor is used to force air into the system. It is connected by means of an adapter to the pipeline. In order to find the place of the leak, you need to listen. Once you find the approximate location of the leak, use a soap solution.

Heating system test equipment

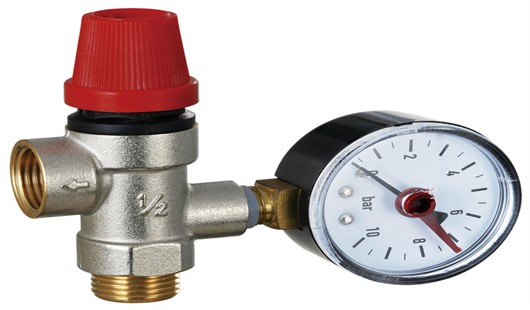

Most often, a pressure tester is used to perform a hydraulic test. It is connected to the circuit to regulate the pressure in the pipes.

A huge number of local heating networks in private buildings do not need high pressure, so a manual pressure tester will suffice. In other cases, it is better to use an electric pump.

Hand-held devices for testing heating systems develop a force of up to 60 bar and more. Moreover, this is enough to check the integrity of the system even in a five-story building.

The main advantages of hand pumps:

- Acceptable cost, which makes them affordable for many consumers;

- Small weight and dimensions of manual presses. Such devices are convenient to use not only for personal purposes, but also for professional use;

- Long service life without failures and breakdowns. The device is so simply arranged that there is nothing to break in it;

- Suitable for medium and small heating equipment.

Branched and large circuits in large areas, multi-storey buildings and production facilities are checked only with electrical appliances. They are able to pump water at very high pressure, which is unattainable for manual devices. They are equipped with a self-priming pump.

Electric pumps develop force up to 500 bar. These units, as a rule, are built into the main line or connected to any opening. Basically, the hose is connected to a tap through which the pipe was filled with coolant.

Pressure testing of heating is a very complex technological procedure. That is why you should not do it yourself, it is better to use the services of professional teams.

(2 votes, average: 5 out of 5)

Brief excerpts from normative documentation, rules and SNiP for pressure testing of heating.

Analyzing the statistics of the questions you ask and realizing that many questions on pressure testing of the heating system for the majority of our audience remain incomprehensible to you, we decided to make a selection from the necessary points and the Rules for pressure testing, approved by the Ministry of Fuel and Energy of the Russian Federation and SNiP.

All SNiPs and rules contain information on more than 100 pages, which are sometimes difficult to understand, therefore, in order to make it easier for you to see and, if necessary, refer to the required paragraph of a particular regulatory document, we have processed the applicable regulatory documents and in a brief form posted on the site. Explanations to the Rules and SNiP can be found in the article: "Norms and rules for pressure testing of the heating system"

The essence of pressure testing

Pressure testing of a water pipeline (as well as any other systems for pumping liquid or gaseous media) is the most important in the pipeline construction process, especially in such industries as the chemical or oil and gas industry, hydraulic engineering, housing and communal services. Along with checking the value of allowable compression in the pipes, an analysis of the stress-strain state of the pipes is also carried out, which makes it possible to estimate the resource of their durability.

Pressure testing of a water pipeline (as well as any other systems for pumping liquid or gaseous media) is the most important in the pipeline construction process, especially in such industries as the chemical or oil and gas industry, hydraulic engineering, housing and communal services. Along with checking the value of allowable compression in the pipes, an analysis of the stress-strain state of the pipes is also carried out, which makes it possible to estimate the resource of their durability.

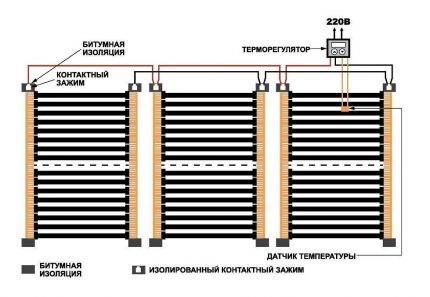

Some pipe manufacturers, such as the Rehau brand, develop their own original methods for crimping their products. For these purposes, Rehau sells a special electro-hydraulic tool, with which you can test the pipeline immediately after its installation.The test method is local: a pressure test pump is connected to the sealed area, which creates the necessary internal air pressure. The stability of indicators is established by a manometer.

What is flushing and pressing

Flushing and pressure testing of heating systems is carried out in cases where the layer of deposits in the pipes becomes too large for them to continue to function. As a preventive measure, such events are rarely carried out, since this pleasure is quite laborious and expensive. For hydropneumatic flushing, acid solutions are used, which remove plaque from the pipeline walls to the outside. Metal particles cling to the inner walls of the pipes, thereby reducing their diameter. It leads to:

- increase in pressure;

- increase in the speed of the coolant;

- decrease in efficiency;

- increase in costs.

What is pressure testing of a heating system - this is an ordinary test, according to the results of which one can say whether it is safe to use such equipment or not, and also whether it can withstand the necessary loads. After all, no one wants to become a victim of circuit depressurization and be a patient in the burn department. Pressure testing of the heating system is carried out in accordance with SNiPs. It is a mandatory procedure. After it, a document is issued confirming the technical serviceability of the circuit. Here are the main cases when pressure testing of the heating system is carried out:

- when assembling a new circuit and putting it into operation;

- after the repair work;

- preventive checks;

- after cleaning pipes with acid solutions.

Pressure testing of the heating system is carried out in accordance with SNiP No. 41-01-2003 and No. 3.05.01-85, as well as the rules for the technical operation of thermal power plants.

From these rules, it is known that such an action as pressure testing of a heating system is carried out either with air or liquid. The second method is called hydraulic, and the first is called manometric, it is also pneumatic, it is bubble. The rules for pressure testing the heating system state that water tests can only be carried out if the temperature in the room is above five degrees. Otherwise, there is a risk that the water in the pipes will freeze. Pressurization of the heating system with air removes this problem, it is carried out in the cold season. In practice, hydraulic pressure testing of the heating system is used more often, as everyone is trying to complete the necessary planned work before the heating season. In winter, only the elimination of accidents, if any, is performed.

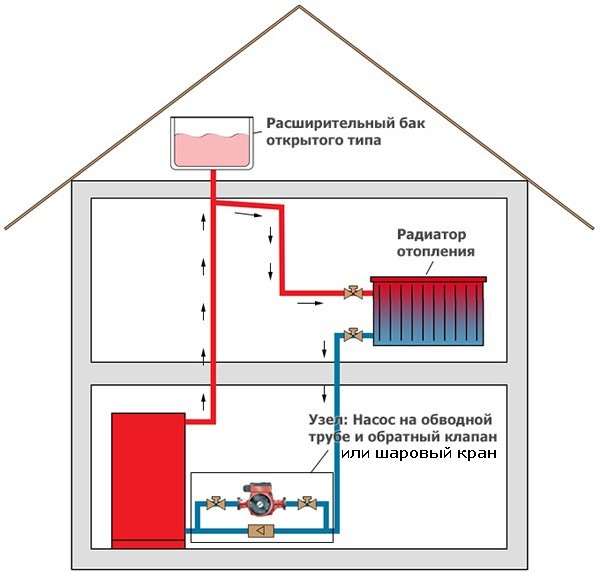

It is possible to start pressure testing of the heating system only when the boiler and expansion tank are cut off from the circuit, otherwise they will fail. How is the heating system pressure tested?

- all liquid is drained from the circuit;

- then cold water is poured into it;

- as it fills, excess air descends from the circuit;

- after water has accumulated, a pressure supercharger is supplied to the circuit;

- how the heating system is pressurized - the amount of atmospheres gradually increases. In this case, the maximum test pressure should not be higher than the tensile strength of the various elements of the circuit;

- high pressure is left for a while and all connections are inspected. It is necessary to look not only at the threaded connections, but also at the places where the parts of the circuit are soldered.

Pressurizing the heating system with air is even easier.Just drain all the coolant, close all outlets in the circuit and bring air into it. But in this way, it is more difficult to determine the malfunction. For example, if there is liquid in the pipes, then at high pressure it will seep through a possible gap. It is easy to identify visually. But if there is no liquid in the tubes, accordingly, there is nothing to go out except air. In this case, a whistle may be heard.

And if it is inaudible, while the pressure gauge needle indicates a leak, then all connections are smeared with soapy water. To make it easier, you can check not the entire system, but by dividing it into segments. In this case, it is easier to carry out pressure testing of heating pipes and determine possible places of depressurization.

The procedure and technological features of the pressure testing of the heating system

It is customary to carry out hydraulic tests of heat supply systems with different pressing pressures depending on the purpose of the system and the type of equipment used. For example, a heat input unit into a building is pressurized with a pressure of 16 atmospheres, heat supply systems for ventilation and ITP, as well as heating systems for multi-storey buildings - with a pressure of 10 atmospheres, and heating systems for individual houses - with a pressure of 2 to 6 atm.

The heating systems of newly erected buildings are pressed by 1.5-2 times greater pressure from the worker, and the heating systems of old and dilapidated houses are pressed by underestimated values in the range of 1.15-1.5. In addition, when pressure testing systems with cast-iron radiators, the pressure range should not exceed 6 atm., But with installed convectors - about 10.

Thus, when choosing a crimping pressure, you should carefully read the passports for the equipment.It should not be higher than the maximum pressure of the “weakest” link in the system.

To begin with, the heating or heat supply system is filled with water. If a low-freezing coolant is poured into the heating system, then pressure testing is carried out first with water, then with a solution with additives. You should be aware that, due to the lower surface tension, ethylene glycol or propylene glycol-based heat transfer fluids are more fluid than water, therefore, in case of minor smudges on threaded connections, they should sometimes only be slightly tightened.

When preparing a functioning heating system for the heating season, the working coolant must be drained and refilled with clean water for pressure testing. The filling of the heating system is usually carried out at the lowest point of the boiler room or heating unit through a drain ball valve. In parallel with filling the heating system, air must be bled through auto-air vents on risers, upper branch points or through Mayevsky taps on radiators. To prevent airing the heating system the filling of the system is carried out only "bottom-up".

Then the pressure of the system is increased to the calculated one with the control of the pressure drop on the measuring pressure gauges. In parallel with pressure control, a visual inspection of the entire system, pipeline units, threaded connections and equipment is carried out for leaks and drops at the seams. If condensation forms on the system after filling with water, the pipelines must be dried, and then further inspection should be carried out.

Heating devices and sections of pipelines hidden in building structures are subject to mandatory inspection.

The heating system is maintained under pressure for at least 30 minutes, and if no leaks are detected and no pressure drop is recorded, then it is considered that the pressure testing system has passed.

In some cases, a pressure drop is permissible, but within the limits not exceeding 0.1 atmosphere, and provided that visual inspection does not confirm the formation of water leaks and leakage of welded and threaded joints.

In case of a negative result of hydraulic tests, repair work is carried out with further repressurization.

Upon completion of the test work, an act of pressure testing is drawn up in the form specified in the main regulatory documents.

How it's done?

After it became clear what needs to be done, the methods become obvious.

When pressing, the following operations are sequentially performed:

- The pipeline section is hermetically cut off from other engineering systems. The choice of method is individual for each case.

The valves in the elevator unit are closed, the heating system ring is cut off by the valves. In the case of sewers, pneumatic rubber plugs are used.

They look like this

- A pipe pressure test pump is connected to the pipeline under test. This device can be manual, electric, or have its own internal combustion engine.

The choice of a particular device depends on the required pressure and on the volume of the pipeline.

So, for pressure testing of the heating system of a private house, a simple hand pump with a capacity of 3 liters per minute can be used; for pressure testing of heating mains with their volumes, the same pumps are used that provide circulation in them.

Before us is the simplest manual crimping machine

You can pressurize the pipe with air.But it's much longer

- Water is injected into the pipeline under test at a pressure exceeding the calculated working pressure. For systems of heating and water supply pipes, this is usually 6-8 kgf / cm2.

For heating mains and main water pipelines 10-12 kgf/cm2. Cast iron sewerage is checked with an overpressure of no more than 2 atmospheres, plastic - no more than 1.6.

The presence of leaks is easy to track by pressure drop: even the cheapest pipe presser is equipped with a pressure gauge.

Where possible, it is best to check for leaks visually as well. In the presence of leaks after their elimination, repeated pressure testing is carried out.

The procedure for organizing cleaning work

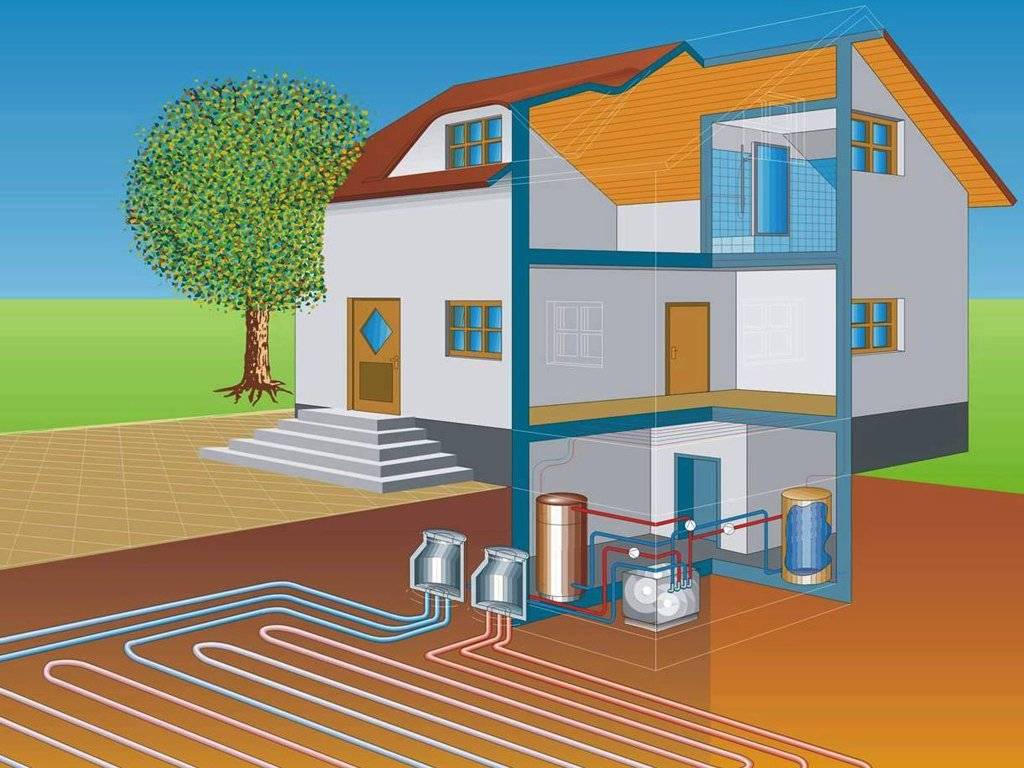

The heat carrier in the pipes is water, which has various contaminants that settle and compact on the walls of the pipelines. They interfere with the normal circulation and functioning of the coolant, cause blockage of pipes and heating radiators.

The flushing organization must:

- pre-inspect the equipment;

- draw up an act on covert transactions;

- choose a cleaning technology;

- draw up an estimate for flushing the heating system and a contract;

- perform work;

- carry out secondary pressure testing of equipment;

- fill in the act form.

The act of flushing the heating system is an important document certifying the completion of work for specialized organizations involved in such services.

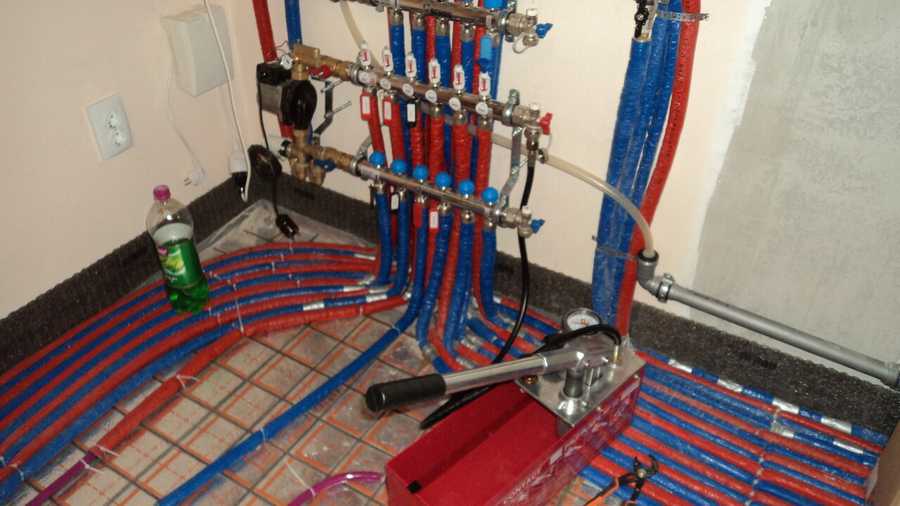

The process of pressing heating pipes.

Pressure testing of equipment is carried out with water or air. It must ensure that the work is done correctly.

One of the methods for assessing the technical condition of equipment is pressure testing, which reveals all malfunctions before work begins. The pressure must be greater than the standard, but not less than 2 atmospheres.

To check with air, a pump and a special pressure gauge are used that measure the pressure in the system. If the pressure does not change, then the equipment is sealed, and if it decreases, you need to look for the place where the leak occurs and fix the problem.

An act is drawn up for various hidden operations: dismantling of radiators, separation of flanges, preparatory work. Next, the cleaning technology is selected, but in most cases the hydropneumatic method is used.

The estimate for flushing the heating system includes the price of fuel, depreciation of equipment, reagents.

Then a contract is drawn up, which specifies the main points of cooperation:

- service cost;

- calculation procedure;

- deadlines;

- the amount of fines in case of non-fulfillment of obligations;

- obligations and responsibilities of the parties;

- procedure for terminating the contract.

After the cleaning is completed, a secondary pressure test is carried out and the operability of the equipment is checked. The form of the washing act is filled in, where the customer evaluates the quality of the service.

Documentation is carried out immediately after the completion of work. If the terms of the contract are not met and the quality of the service does not satisfy the customer, the document is not signed until all defects and malfunctions are eliminated.

Crimping process

Pressure testing of heating systems of a private house begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If shut-off valves lead to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler, depending on the pressure that you apply to it.Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of the boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off with the help of shut-off valves or temporary jumpers are installed - drives.

Next, the process is:

If the system was in operation, the coolant is drained.

A pressurizer is connected to the system. A hose extends from it, ending with a union nut

This hose is connected to the system in any suitable place, even in place of the removed expansion tank or instead of a drain cock.

Water is poured into the capacity of the pressure test pump, and pumped into the system with the help of a pump.

The device is connected to any available input - on the supply or return pipeline - it does not matter

Remove all air from the system before pressurizing. To do this, you can pump the system a little with the drain valve open or lower it through the air vents on the radiators (Mayevsky taps).

The system is brought to operating pressure, maintained for at least 10 minutes

During this time, all the remaining air descends.

The pressure rises to the test pressure, a certain period of time is maintained (regulated by the regulations of the Ministry of Energy). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

During crimping, the pressure level is controlled. If, during the test, its fall does not exceed the norm (registered in SNiP), the system is considered serviceable.If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start the pressure test again.

As already mentioned, the test pressure depends on the type of equipment and system being tested (heating or hot water). The recommendations of the Ministry of Energy set forth in the "Rules for the technical operation of thermal power plants" (clause 9.2.13) are summarized in a table for ease of use.

Test equipment table

Correspondence table for different pressure units

On the other hand, SNIP 3.05.01-85 (clause 4.6) has other recommendations:

- Tests of heating and water supply systems should be carried out with a pressure of 1.5 from the working one, but not lower than 0.2 MPa (2 kgf / cm2).

- The system is considered serviceable if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm).

Which rules to use is an interesting question. While both documents are in force and there is no certainty, so both are eligible. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast-iron radiators is no more than 6 atm, respectively, the test pressure will be 9-10 atm. Approximately also it is necessary to be determined with all other components.

Types and reasons for holding

Based on what tasks are set, there are three main types of pressure testing of the heating system in multi-apartment and private houses:

- Primary. Before the heating system is ready for operation, it must be diagnosed without fail. This is done after all the details are connected (radiators, heat generators, expansion tank). However, before the pipelines are hidden behind the sheathing frames or, for example, filled with screeds.The main role is given to checking the quality of the assembly.

- Next (repeated). In order to prevent hydraulic testing of the system, experts advise to perform annually. The best time is when the heating season is over and the system has been subject to scheduled maintenance. The main task here is to prepare for the next winter and minimize the risk of an emergency.

- Extraordinary (emergency). The act of pressure testing of the heating system must be carried out if any part of the system has been repaired, for example, the radiator, boiler, etc. have been dismantled. It is considered that after the system has been flushed or started up after a long period of inactivity, it should also be pressure tested.

Test tools

To test the system for resistance to high pressure, a special device is used, which is called a pressure tester. It is a pump capable of creating pressure inside the system up to 60 or 100 atmospheres, depending on the type of mechanism. There are 2 types of pumps: manual and automatic. They differ only in that the second option stops pumping itself if the pressure has reached the desired level.

The pump consists of a tank into which water is poured and a plunger pump with a handle that moves it. On the body of the mechanism there are taps to block the supply of pressure and pressure gauges to regulate the pressure. Also on the tank there is a tap that allows you to drain the water that remains in the tank.

The principle of operation of such a pump is similar to a conventional piston analogue, which tires are inflated with. The main difference lies in the cylindrical piston made of steel.It is tightly fitted inside the case and a minimum gap is made, which makes it possible to build up pressure up to 60 atmospheres.

Manual blower

For hand pumps, the biggest disadvantage is that such pressure testing of pipes will take a very long time due to pumping the system with water. This process can take several hours, as large systems that have radiators will need to be filled manually.

Automatic devices work on a similar principle, but when the pressure limit is reached, they turn off themselves. They also require electricity to operate, so manual ones are more suitable for places where there is no power supply yet. Automatic pumps can deliver pressures up to 100 bar and industrial devices up to 1000 bar.

Electric version of the compressor

Basic Rules

If you follow the instructions, all work will be of high quality and safe.

In this case, all indicators must be taken into account, for example:

- The temperature in the room should be positive.

- The pressure must not exceed the limit.

- The pressure itself should be 50% more than the working one. In the event of a decrease in pressure, it is necessary to carefully inspect the pipes and find a leak. After it must be eliminated and the test continued.

- During the pressurization period, all boilers must be turned off.

More about the requirements and errors when pressure testing heating:

> In addition to pressure testing, thermal testing is mandatory. To do this, you need to test the system with water heated to + 60 ° C for eight hours.All tests and work carried out must be included in the report, as well as indicate in it any additional troubleshooting work.

During pressure testing, it should also be borne in mind that if there are cast-iron radiators, work is carried out at a pressure of 6 atmospheres, and for convectors - not less than 10. It is for this that you must first study the equipment passports. Before work, the pipes are pumped with water and pressure tested, and then the procedure is repeated with additives.

After all the work done, it is necessary to drain all the water and fill it with clean water. To prevent air from entering the system, water is pumped from the bottom up. But if the air still remains, it must be bled off with the help of air vents, which are located on the water supply risers.

How to pressure test the heating system:

The next step is to start heating and test it for an hour. If during this period of time no leaks and pressure drops were detected, and all radiators warmed up equally, we can safely say that the building is ready for winter. It happens that during the test the pressure may decrease by 0.1. If in this case it was not possible to detect leaks, then the further state should be monitored.

Crimping process

Pressure testing of heating systems of a private house begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If shut-off valves lead to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of the boiler, you will have to rely on the serviceability of the taps.If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off with the help of shut-off valves or temporary jumpers are installed - drives.

Next, the process is:

- If the system was in operation, the coolant is drained.

- A pressurizer is connected to the system. A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even in place of the removed expansion tank or instead of a drain cock.

-

Water is poured into the capacity of the pressure test pump, and pumped into the system with the help of a pump.

- Remove all air from the system before pressurizing. To do this, you can pump the system a little with the drain valve open or lower it through the air vents on the radiators (Mayevsky taps).

- The system is brought to operating pressure, maintained for at least 10 minutes. During this time, all the remaining air descends.

- The pressure rises to the test pressure, a certain period of time is maintained (regulated by the regulations of the Ministry of Energy). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

- During crimping, the pressure level is controlled. If, during the test, its fall does not exceed the norm (registered in SNiP), the system is considered serviceable. If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start the pressure test again.

As already mentioned, the test pressure depends on the type of equipment and system being tested (heating or hot water).The recommendations of the Ministry of Energy set forth in the "Rules for the technical operation of thermal power plants" (clause 9.2.13) are summarized in a table for ease of use.

| Type of equipment tested | Test pressure | Test duration | Permissible pressure drop |

|---|---|---|---|

| Elevator units, water heaters | 1 MPa(10 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with cast iron radiators | 0.6 MPa (6 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with panel and convector radiators | 1 MPa (10 kgf/cm2) | 15 minutes | 0.01 MPa (0.1 kgf/cm2) |

| Hot water supply systems from metal pipes | working pressure + 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 10 minutes | 0.05 MPa (0.5 kgf/cm2) |

| Hot water systems from plastic pipes | working pressure + 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 30 minutes | 0.06 MPa (0.6 kgf/cm2), with a further check within 2 hours and a maximum drop of 0.02 MPa (0.2 kgf/cm2) |

Please note that for testing heating and plumbing from plastic pipes, the holding time of the test pressure is 30 minutes. If during this time no deviations are found, the system is considered to have successfully passed the pressure test. But the test continues for another 2 hours

And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf / cm2)

But the test continues for another 2 hours. And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf / cm2).

Correspondence table for different pressure units

On the other hand, SNIP 3.05.01-85 (clause 4.6) has other recommendations:

- Tests of heating and water supply systems should be carried out with a pressure of 1.5 from the working one, but not lower than 0.2 MPa (2 kgf / cm2).

- The system is considered serviceable if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm).

Which rules to use is an interesting question. While both documents are in force and there is no certainty, so both are eligible. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast-iron radiators is no more than 6 atm, respectively, the test pressure will be 9-10 atm. Approximately also it is necessary to be determined with all other components.