- Norms and rules for crimping

- In an apartment building

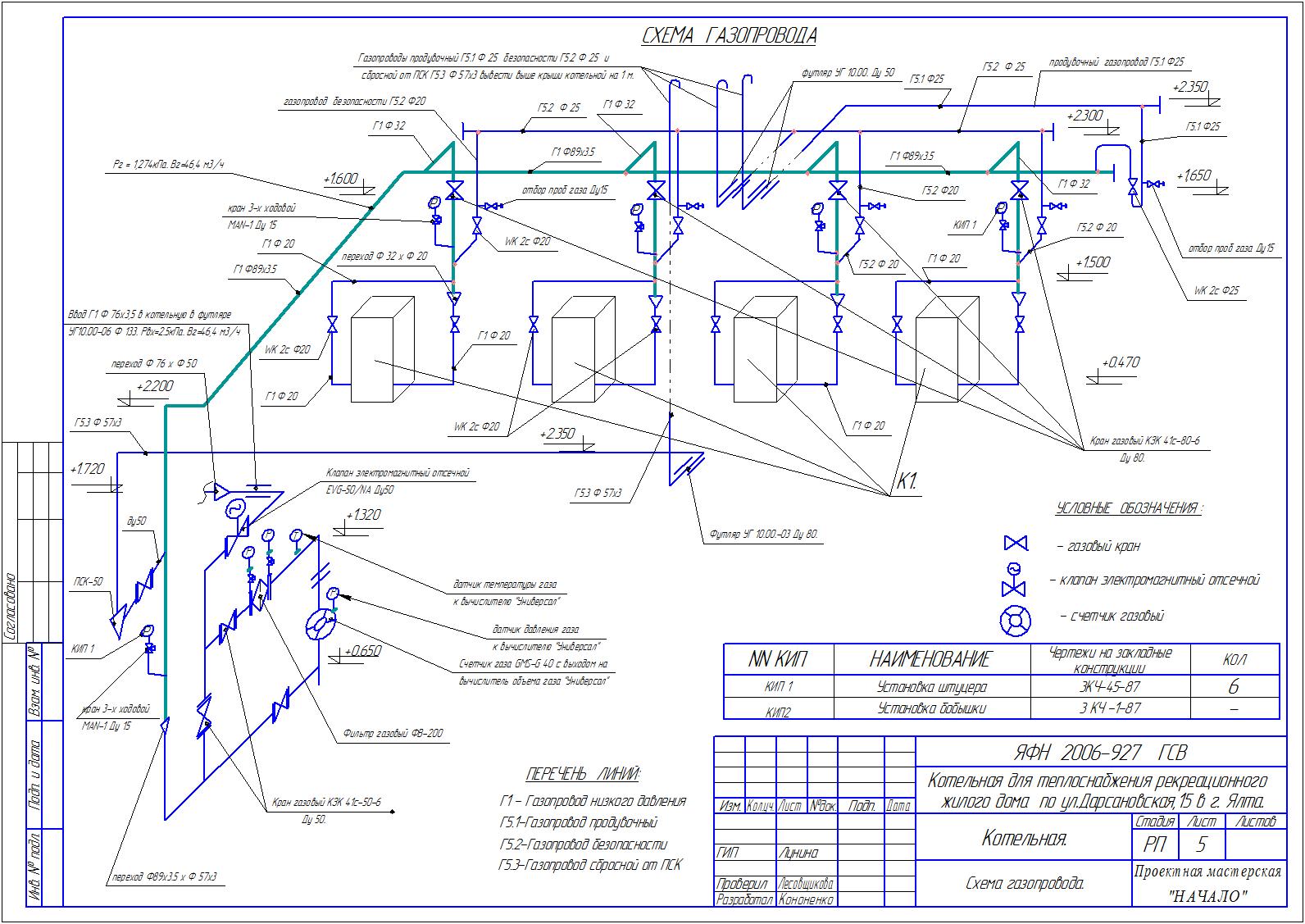

- Underground gas pipeline

- Internal low pressure gas pipeline

- Technical inspection of the gas pipeline by operators

- Flushing period for heating systems

- Gas pipeline tightness control

- An example of pressure testing of a private gas pipeline

- Pneumatic crimping

- System test pressure

- Preparatory work and activities

- Crimping process

- Such a high temperature will fall into both the tap and the batteries.

Norms and rules for crimping

Operating standards

Operating standards

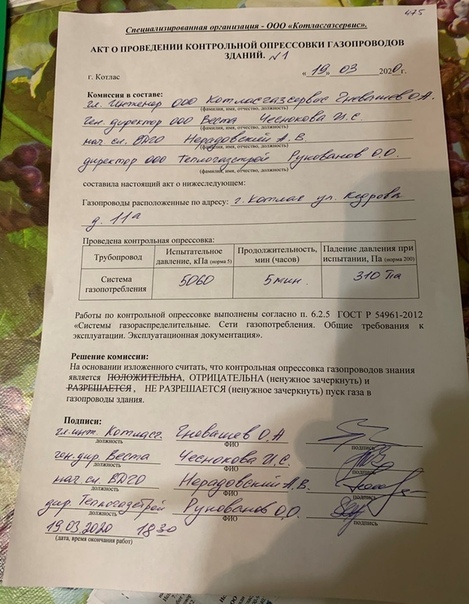

Control pressure testing of internal gas pipelines is regulated by GOST R 54983 2012. The general rules are the same for testing any part of the circuit under high and low pressure.

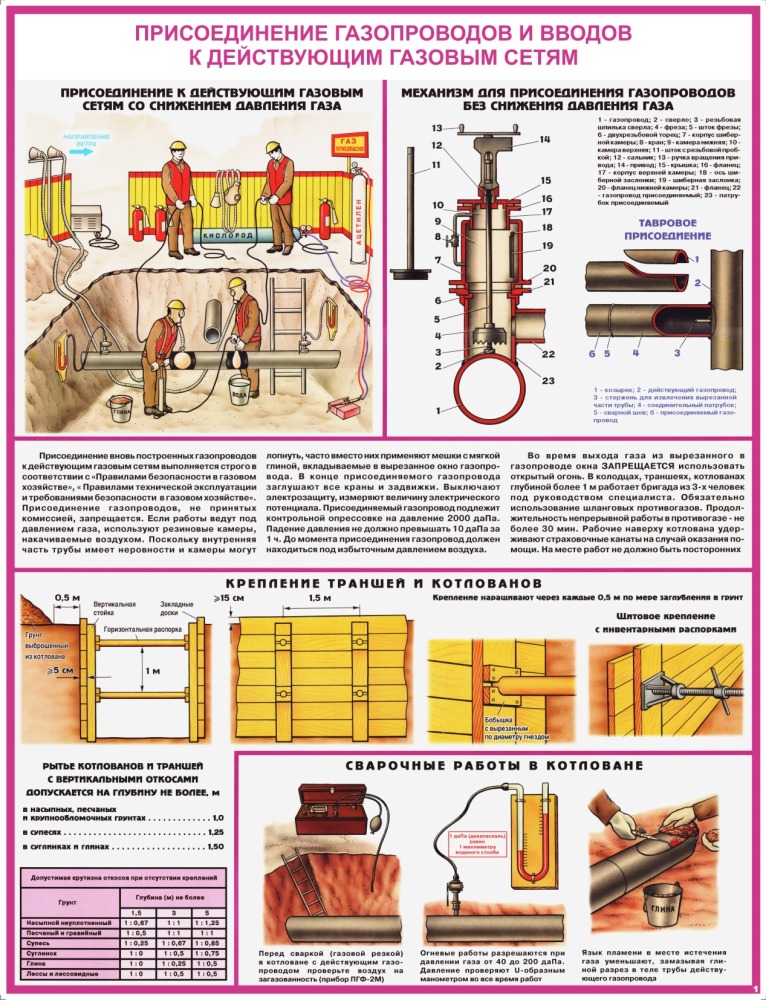

- Pressure testing of gas equipment and pipelines with air is performed before the line is cut into the central line.

- To check, air is pumped into the cut-in section of the gas pipeline under a pressure of 100 kPa and held for at least 60 minutes. Measure the pressure in the circuit with a manometer. The accuracy class of the device must be less than 0.6.

- If the circuit is sealed, the overpressure indicator is maintained until the end of the pressure test. If the pressure gauge detects a decrease in pressure, there is a leak in the pipe. According to SP 62.13330.2011, pressure testing is repeated six months after the control test.

In an apartment building

Crimping begins after an external inspection of the system within the apartment

Crimping begins after an external inspection of the system within the apartment

Pressure testing of the intra-house internal gas pipeline is performed after an external examination. After maintenance, the gas pipeline is checked for strength. Air is pumped into the circuit at a pressure of 1 kgm / sq. see So they check the pipeline from the switch at the entrance to the house or to the landing to the taps on holidays to the apparatus. A complex gas pipeline is checked by dividing it into separate sections.

If gas meters are installed in the building, they are turned off during pressure testing, and the sections are connected by a jumper. The test starts 3 hours after the pressure rise. The possibility of leakage is checked with a soapy solution. If defects are found, the commission fixes them.

Pressure testing of gas inner pipes includes a tightness test.

- The gas pipeline is filled with air under pressure of 400 mm of water st. with running meters and gas appliances. If there are no meters in the circuit, air is pumped under a pressure of 500 mm of water. Art. The gas supply system has passed the test if, within 5 minutes, the pressure drop does not exceed 20 mm of water. Art.

- When connecting new gas equipment to an existing gas pipeline in an apartment building, pressure testing is carried out with gas. The emulsion is applied to all torn and threaded connections to check for leaks.

- Automation devices are checked only for density. The air pressure during pressure testing reaches 500 m of water. Art.

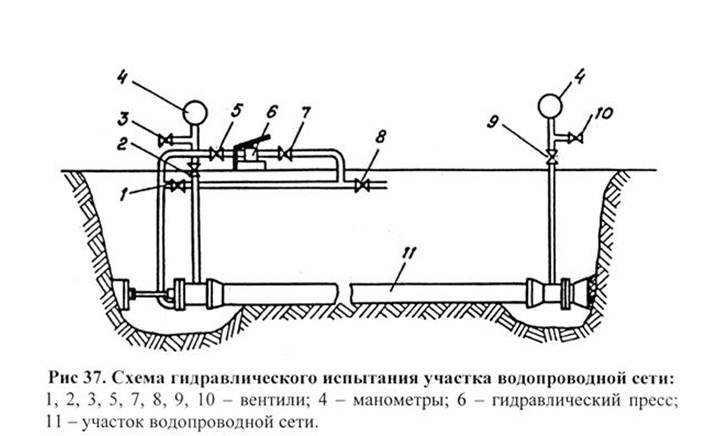

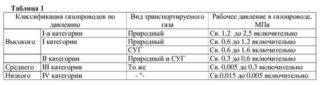

Underground gas pipeline

Each section of the underground gas pipeline from plug to plug is checked separately

Each section of the underground gas pipeline from plug to plug is checked separately

Pressure testing of an underground gas pipeline is carried out after installation in trenches and full or partial backfilling - at least 20 cm.Each section of the line, from end cap to end cap, is tested separately.

- Tests begin with air pumping under test pressure. Maintain the time required for temperature equalization.

- Measurements are performed with pressure gauges with an accuracy class of 0.4 or 0.6.

- The section of steel and polyethylene gas pipelines is pressure tested separately.

- Pressure testing of underground external gas pipelines laid in cases is carried out three times. For the first time immediately after welding and before laying. Then, after backfilling in the trench, and finally, together with the entire gas pipeline.

- Multilayer pipes are tested in 2 stages. First, they are tested for strength by pumping air for 10 minutes at a pressure of 0.1 MPa, and then they are tested for tightness at a pressure of 0.015 MPa.

Testing of special technical devices is carried out according to the standards for lines with the same pressure.

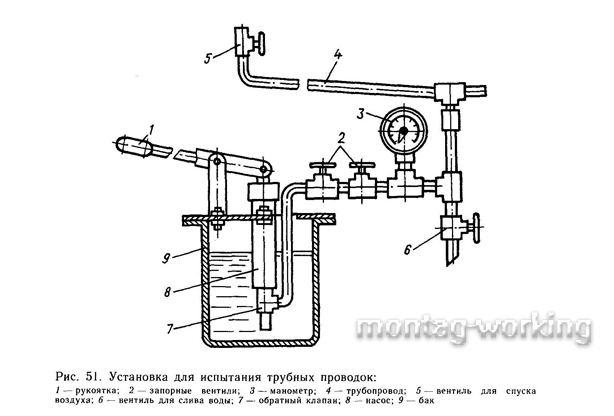

Internal low pressure gas pipeline

vacuum gauge

vacuum gauge

Pressure testing of the equipment and the internal gas pipeline is carried out with an air mixture under a pressure of 1000 mm of water. Art. The surveyed area is from the main tap to the switch in front of the burners. Testing lasts 1 hour. During this time, a pressure drop of 60 mm of water is allowed. Art.

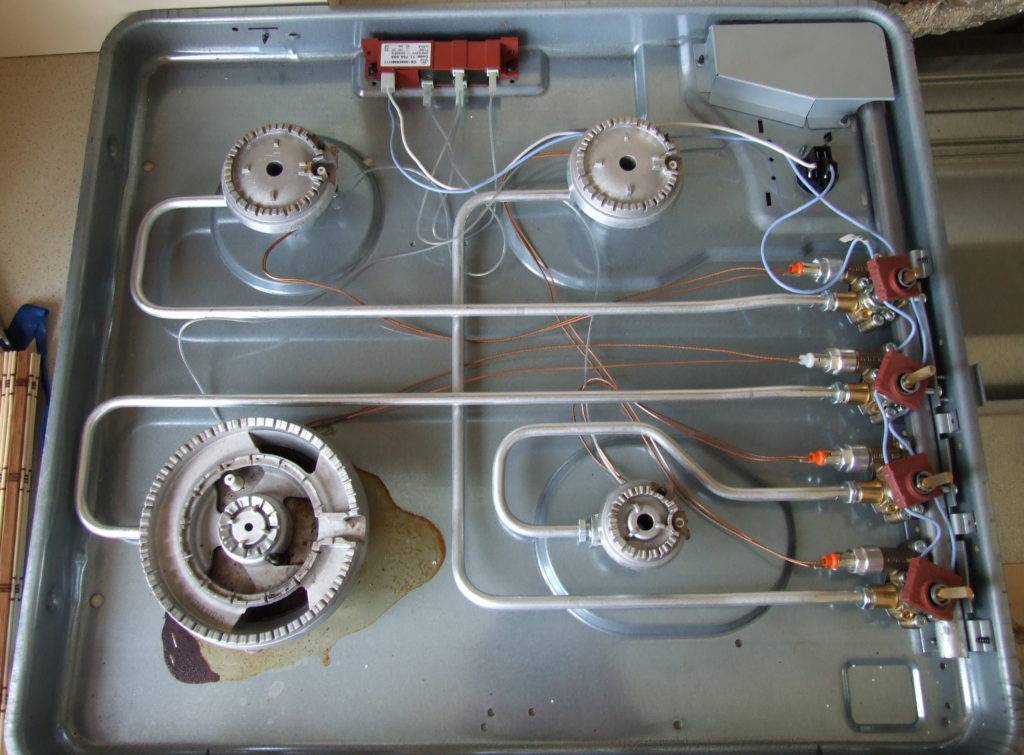

Pressure testing in an apartment building includes inspection and testing of household equipment.

- A pressure-vacuum gauge and any device with a variable volume will be connected to the nozzle of the gas stove. With its help, an excess pressure of up to 5 kPa is created.

- Open the valve of the burner to be checked and fill the tank with gas.

- Close the valve on the gas pipe. Gas is squeezed out of the container to create pressure.

- The burner tap is closed and the tightness is checked with a man-vacuum gauge: in 5 minutes the pressure can decrease by no more than 0.3 kPa.

- If the pressure drops faster, there is a leak. It is detected by applying a soap solution to the joints and threaded connections. After a leak is detected, turn the valve on the burner so that the gas pressure on it drops. Then one of the burners is lit, the gas is carefully squeezed out of the container and the pressure gauge and fixture are disconnected.

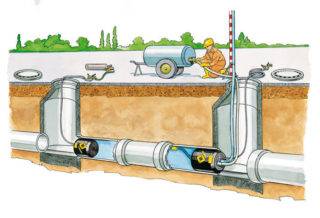

Technical inspection of the gas pipeline by operators

The gas pipeline is checked using special devices, in strict accordance with the production instructions. It is possible to achieve the most accurate survey results and carry out high-quality repairs that eliminate the possibility of an emergency situation with several weather indicators: thawed soil, heat and dryness.

Checking the tightness of the connecting nodes

The survey is carried out by a team, which includes at least three operators: two, walking in front, check the insulating coating, transfer to the third about possible places of leakage.

During the examination:

- the gas pipeline route is completely subjected to a thorough check for tightness;

- gas pipes and wells of the gas pipeline are checked for possible gas contamination;

- wells are subjected to a thorough inspection of existing wells, within a range of 15 cm from the gas pipeline, underground utilities: basements, collectors and mines.

The survey is carried out according to the scheme of the gas pipeline route, which should be with one of the operators. All identified problems, leaks are eliminated immediately, on an emergency basis.

It should be remembered that in order to ensure safety and improve the accuracy of research, work on the inspection of a gas pipeline located along a transport highway is carried out during a minimum traffic flow. Operators must wear special signal vests.

If defects and violations of the insulating layer of pipes are detected, a technical examination of this place is required. To carry out this procedure, it is necessary to dig a hole. Pit holes are also needed at points where, due to a large amount of industrial interference, it is impossible to use devices.

Also, to identify possible violations of the tightness of the gas pipeline, wells are drilled, in which special devices are used to establish the fact of leakage and accumulation of gas. It must be remembered that the use of fire in the study of the wellhead at the time of the presence of gas in it is possible only at a distance of at least 3 meters from structures and buildings.

A more technological way to check the gas pipeline system for tightness is its pressure testing.

Flushing period for heating systems

Temporary scheduled shutdown of the heating network does not imply a drain on the resource from the radiators.

This is due to the following reasons:

- the deposits will dry out, harden;

- after refilling, leaks will occur in the connecting areas.

Therefore, experts recommend draining water from the heating system of an apartment building only in summer, after the end of the cold period. The spent resource is discharged into the sewer through the drain valve. To speed up the flow of water, it is necessary to open the air locks on the radiators of the upper floors.The risers are cleaned first with cold, then heated water, while the liquid coming out of the pipes will carry mud, lime suspensions with it.

At the end of the procedure, the boiler is filled with water with the addition of chemicals that slow down the slagging of the heating circuit. The liquid level in communications should not rise above the control mark of the safety tank.

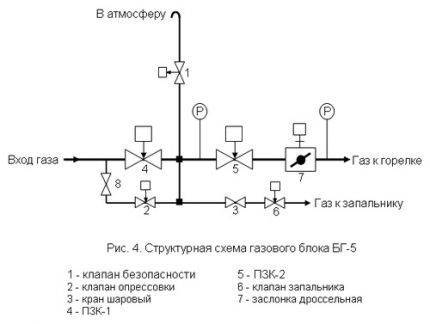

Gas pipeline tightness control

Only after obtaining a satisfactory result according to the procedures described above, it is possible to proceed with the pressing work. To do this, the system is connected to a special compressor and the pipes are filled with pressurized air. The design is then examined for deficiencies.

To perform pressure testing, air is injected into the system. If the required pressure level is maintained for a certain time, the test result can be considered positive.

If deficiencies are identified, they are eliminated, but if the system is completely sealed, it is connected to a common gas line. In the process of preparation, you will have to remove and install special plugs, rotary elements can be replaced with threaded connections. In general, the procedure for carrying out pressure testing should consist of the following operations:

- To disconnect the area to be treated from the main line, turn off the high-pressure valve and the low-pressure network tap.

- After that, plugs are inserted.

- When the flange breaks, shunt jumpers are used.

- To bleed the gas present inside the system, it is necessary to use a special sleeve made of rubberized fabric or perform this operation through a candle, which is usually installed on the condensate collector.

- The gas is flared, and if it is not possible to do so safely, it is moved to safe storage.

- Now you need to install adapters for connecting pressure gauges and a compressor.

- For pressure testing of systems of extended length, it is recommended to additionally use hand pumps.

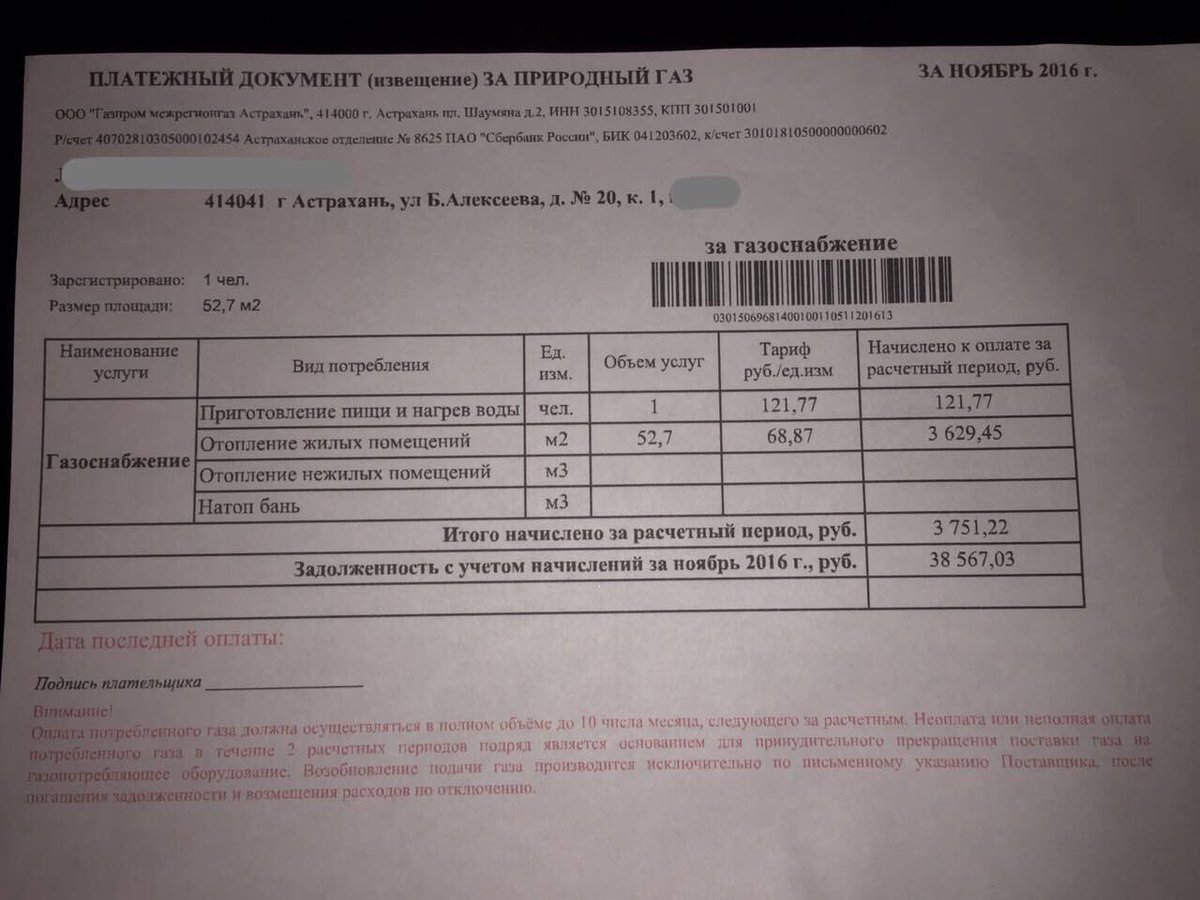

Usually, control pressure testing is performed under a working pressure of 0.2 MPa. The recommended pressure limit is 10 daPa/h. In some industries, it is recommended to use a pressure of 0.1 MPa for pressure testing of the internal gas pipeline, and the allowable drop rate is 60 daPa / h or less.

Pressure testing of gas pipes inside the house is carried out along the entire length of the system from the valve at the entrance to the house, to the connection to gas consumers, for example, to the boiler

At non-industrial facilities, including when arranging gas pipelines in residential premises, control pressure testing is performed at a pressure of 500 daPa / h. The allowable pressure drop in these cases is 20 daPa in five minutes. Tanks intended for storage of liquefied gas are pressurized at 0.3 MPa/h.

If the pressure inside the system remains stable during the control time, then the pressure test result is considered positive. If this situation is reached, then the specialists remove the hoses connecting the system to the air duct. At the same time, it is necessary to check the condition of the shut-off communications installed in the area between the air duct and the gas pipeline.After that, install the plugs on the fittings.

If during pressure testing it was not possible to achieve stable pressure indicators in the system, the result of the procedure is considered negative. In this case, a technical inspection of the system is performed to identify deficiencies and eliminate them. After that, the procedure is repeated to ensure the quality of the work performed.

Only after a stable pressure is established in the system, pressure testing can be considered completed. If the system status check is not satisfactory, permission to connect to the trunk will not be issued. The reason for the refusal to put the gas pipeline into operation may also be violations committed during the pressure test.

After pressure testing is completed, the pressure inside the structure is reduced to atmospheric level. Then the necessary fittings and equipment are installed, after which it is necessary to hold the system under working pressure for another 10 minutes. To check the tightness in the places of detachable connections at this stage, use a soap emulsion.

To eliminate the identified defects, in accordance with the rules, you must first reduce the pressure in the system to atmospheric. If, after unsuccessful pressure testing, welding work was performed, their quality should be checked by physical methods.

After pressure testing is completed, an appropriate act is issued, on the basis of which gas industry specialists connect to the main gas pipeline

The procedure is recorded in a journal with operational documentation. Upon completion of the inspection and pressure testing, the results of the work are reflected in the acceptance certificate.This document should be kept together with other technical documentation related to the gas pipeline. In addition, the results of pressure testing are recorded in the construction passport.

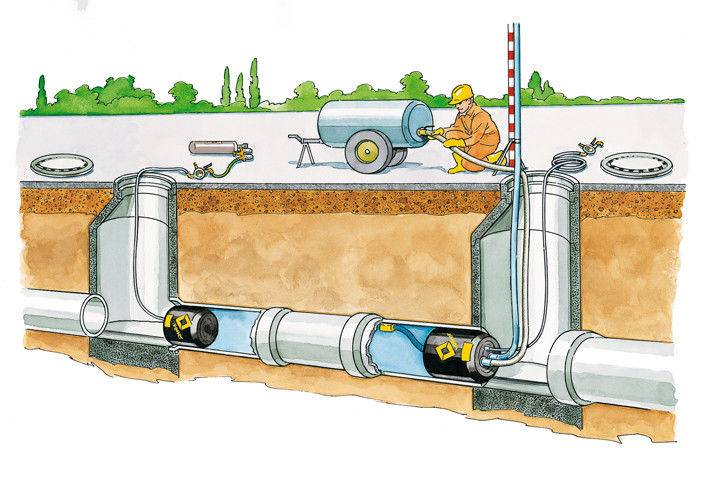

An example of pressure testing of a private gas pipeline

The working documentation specifies the diameter and design features of the gas pipeline, in accordance with which the fittings necessary for inserting control equipment are selected. The part of the pipe located underground is cut in such a way that some margin remains.

After that, a compressor is connected to the pipe and the gas pipeline is first purged. A powerful air flow blows out debris particles, water residues and other foreign contents from the system. After that, you need to install plugs at the ends of the gas system. At one end of the pipe, where there is a base inlet, a special adapter should be installed, which allows metal equipment to be attached to the plastic structure.

Pressure testing makes it possible to verify the tightness of the gas pipeline system and ensure its trouble-free operation for a long time

A manometer and a valve are installed here. After all the necessary devices are installed, air is supplied to the system in such a way that the pressure inside reaches the desired limit. Now you need to hold the control time to make sure that the pressure remains stable. The pressure gauge readings are recorded.

This is the simplest version of the procedure for checking a private gas pipeline for tightness. To perform such operations on high and medium pressure communications, it is required to use special high-precision equipment and invite specialists with the appropriate qualifications.

Pneumatic crimping

Crimping air is used quite rarely, most often when testing in private homes. Thus, the quality of the assembly of the system is checked in the absence of water or related equipment.

For testing, a compressor equipped with a pressure gauge is connected to a supply or drain cock. At the same time, the design of the pump and its drive do not play a role, the main thing is that its power is at a sufficient level. For safety reasons, excess pressure is not increased by more than 1.5 atm. Air valves are replaced with plugs.

The pressure holding time in the system is longer compared to a hydraulic test. This is due to the properties of gases, since the stabilization of pressure in the circuit is slow. Its value will initially inevitably decrease even with serviceable equipment. After stabilization of the air pressure, the shutter speed should be more than half an hour.

Despite the simplicity of the operations carried out during pressure testing, this is a responsible undertaking, which it is advisable to entrust to a qualified specialist.

System test pressure

To avoid an emergency, pressure testing should be carried out in accordance with the requirements of SNiP. This standard provides for a pressure for testing 50% higher than the working level, but not less than 0.6 MPa. The rules for the technical operation of thermal power plants recommend pressure testing under milder conditions: with an excess pressure of 25% higher than the working one, but not less than 0.2 MPa.

Thus, the working pressure is the base value for testing. In houses with no more than three floors, the value is less than 2 atm. and controlled by actuating a check valve.In houses with a large number of floors, this figure is higher and changes with an increase in the number of floors, it can reach 10 atm.

Normative documentation indicates that the pressure during the test is selected between the maximum and minimum. The minimum value is taken in the range of 20-30% above the working one. The maximum value is determined by the project.

In the general case, it is required to study the passport data of absolutely all devices and devices included in the heating system so as not to harm them during testing.

Preparatory work and activities

Pressure testing of a section of a gas network is considered the most technologically advanced method for identifying design flaws. Before starting this procedure, it is necessary to perform preparatory measures. This is required for safety reasons.

Before proceeding with pressure testing of the gas system, the person responsible for the execution of the work must study the technical documentation and compare it with the actual location of the gas pipeline

First, you should study in detail the technical documentation related to the object being examined. Based on this information, the location of such elements as:

- plug;

- a set of instrumentation;

- a set of special sensors;

- compressor.

With the employees performing pressure testing, a discussion is held of the regulations for the upcoming procedures, as well as briefing on compliance with the necessary safety rules. All control measures before putting a new gas pipeline system into operation are carried out by employees of the local gas industry.

The basis for pressure testing before the launch of a new gas pipeline is the corresponding application of the owner of a private house or other gasified facility. All other work on connecting to the main gas pipeline is also carried out by employees of the gas service.

Before starting pressure testing, the gas system is first purged with a jet of air under pressure in order to remove accumulated contaminants from the pipes.

Crimping work should be carried out in the presence of employees of the gas facilities, as well as representatives of enterprises that performed installation work on the arrangement of the external and internal gas network. At the same time, specialists should have an executive drawing of the structure. All activities are carried out in accordance with the operating instructions for the gas pipeline. Before pressure testing, it is necessary to blow the gas pipeline with air in order to clean it from possible contaminants.

Permission to start up a new gas network can only be obtained after a successful pressure test. The entire procedure should be supervised by only one person who is responsible for the safe conduct of work. This specialist must have the appropriate qualifications.

The installation and removal of gas plugs is usually the responsibility of the master of the gas section, and these operations are performed by employees with the appropriate clearance and qualifications of at least the fourth category.

The specialist responsible for carrying out pressure testing first checks the provided as-built drawings and the actual location of the elements of the gas pipeline, all devices and pipes.The data must match. Then a control inspection of the gas equipment is carried out, it is checked how correctly the measuring devices work.

After that, you should make sure that the protective devices are working properly, the alarm is connected correctly, the system is blocked in accordance with the settings. The condition and functioning of the shut-off valves of the boiler, burners, etc. are also checked. All operations for the control pressure testing of the gas pipeline must be formalized by issuing a work permit, which is issued additionally. Such a document can only be issued to qualified specialists.

Crimping process

Pressure testing of heating systems of a private house begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If shut-off valves lead to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of the boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off with the help of shut-off valves or temporary jumpers are installed - drives.

There are two important points: pressure testing can be carried out at an air temperature not lower than +5°C, the system is filled with water at a temperature not higher than +45°C.

Next, the process is:

- If the system was in operation, the coolant is drained.

- A pressurizer is connected to the system.A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even in place of the removed expansion tank or instead of a drain cock.

- Water is poured into the capacity of the pressure test pump, and pumped into the system with the help of a pump.

The device is connected to any available input - on the supply or return pipeline - it does not matter

Remove all air from the system before pressurizing. To do this, you can pump the system a little with the drain valve open or lower it through the air vents on the radiators (Mayevsky taps).

The system is brought to operating pressure, maintained for at least 10 minutes. During this time, all the remaining air descends.

The pressure rises to the test pressure, a certain period of time is maintained (regulated by the regulations of the Ministry of Energy). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

During crimping, the pressure level is controlled. If during the test its fall does not exceed the norm (written in SNiP), the system is considered to be correct.. If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start the pressure test again.

As already mentioned, the test pressure depends on the type of equipment and system being tested (heating or hot water). The recommendations of the Ministry of Energy set forth in the "Rules for the technical operation of thermal power plants" (clause 9.2.13) are summarized in a table for ease of use.

Type of equipment tested

Such a high temperature will fall into both the tap and the batteries.

For safety reasons during the test period hot water will be turned off all consumers connected to the district heating system. will also heating off schools, preschool institutions, healthcare institutions. During the tests for 5 - 6 hours, high temperature water will circulate in the heating systems of residential buildings.

Residents in whose apartments polypropylene pipes are installed should not worry, because even when a coolant at an elevated temperature is supplied to the internal system of the house, a displacement of network water from the supply and return pipelines must be provided, and the coolant will enter the heating system with a temperature of no higher than 95 degrees, and this is in accordance with the regulations.

It is also noted that sometimes during testing, management organizations arbitrarily turn off central heating systems in residential buildings, in addition to the safety-required shutdown of hot water supply. This is contrary to the test program and may adversely affect their conduct, causing an increase in pressure in pipelines and causing damage.

IMPORTANT: The leaders of the management company, HOA, housing cooperative need to complete the entire range of technical and organizational measures to prepare for temperature tests