- Regulatory framework of the Russian Federation

- Legislative acts and GOSTs

- Certification of ventilation equipment

- Air duct materials in gas boiler rooms

- Brick exhaust ducts

- Ceramic ventilation pipes

- Steel air ducts

- Regulations

- Rules and regulations for installing a gas boiler in a private house

- Features of installing a gas boiler in a private house according to SNIP in 2018

- Types of fuel for boilers

- Requirements for the installation of a boiler room in a private house

- Requirements for a gas boiler

- Principle of operation

- Boiler room

- Embedded

- Attached premises

- Installing a gas boiler in the kitchen

- Requirements for a boiler room in a private house, depending on the type of boiler

- Fire safety

- Types of roof boilers

- BMK

- Embedded

- Glazing area of a private house according to SNiP

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (p. 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If, during the commissioning tests, defects in the ventilation system and technical inconsistencies with the design documentation are revealed, the commissioning of the heating system will be refused.

The tasks of the gas service inspector include visual inspection of the equipment, checking the safety functions, control and making control measurements of carbon monoxide. If necessary, the owner of the premises may require the inspector to provide certificates of permission to work with an anemometer or SRO

Ventilation provides a constant intensive supply of fresh air. The functioning of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These NPAs include:

- Federal Law No. 384;

- Government Decree No. 1521 on mandatory enforcement of 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on security measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, therefore, when installing ventilation equipment for arranging a gas boiler house, one should follow their latest revisions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified at the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SPs:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on the microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Based on these regulations, design documentation should be drawn up. So that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the stage of project development.

Certification of ventilation equipment

When buying extractor and fresh air supply devices, check their documents. For ventilation equipment sold on the territory of the Russian Federation, a declaration of conformity is mandatory.

This document confirms that the devices comply with all current requirements of the Customs Union, as set out in the following technical regulations:

- TR TS 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on the electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of products and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler house. It contains all technical specifications of the product.

But voluntary certification requires additional investment, so it is often saved on it.In accordance with Federal Law No. 313 and Government Decrees No. 982 and No. 148, mandatory certification of ventilation equipment has been abolished.

Air duct materials in gas boiler rooms

Properly selected material for the duct ensures longer ventilation operation.

In accordance with the current standards, the following can be used as a material for organizing ventilation of rooms with gas equipment:

- brick;

- ceramics;

- asbestos;

- galvanized and stainless steel.

It is undesirable to use plastic for air ducts, because. this reduces the fire resistance of structures. In some regulations (for example, paragraph 7.11 of SNiP 41-01-2003) indicates that air ducts can be partially made of combustible materials.

When using plastic elements, it must be remembered that the presence of combustible elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employees

When using plastic elements, it must be remembered that the presence of combustible elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employees

Regardless of what material will be used, all ventilation ducts passing through cold areas must be insulated. In these places, draft may decrease, condensate may form, and the ventilation duct of the boiler room with a gas boiler may freeze and cease to perform its functions. That is why it is better to stretch pipes along a warm contour, excluding the possibility of their freezing.

Brick exhaust ducts

Brick is short-lived, because. due to temperature differences, condensation forms on its surface, leading to the destruction of the material. If brickwork is taken as a material for the mine, then the chimney is assembled from single-circuit galvanized metal pipes, the thickness of which depends on the temperature of the emitted gases.

Ceramic ventilation pipes

Air ducts made of ceramics are versatile, easy to use and durable. The principle of their assembly is similar to the technology of ceramic chimneys. Due to the high gas density, they are resistant to strong pollution of various types and aggressive chemical environments.

But in such hoods it is necessary to install steam traps, because. Ceramic absorbs moisture well. Structurally, such an extract consists of 3 layers:

- ceramic inner layer;

- middle insulating layer of stone and mineral wool;

- outer expanded clay concrete shell.

This ventilation system cannot have more than three elbows. At the bottom of the ceramic chimney, a drip and a revision are installed.

Steel air ducts

Steel exhaust channels are convenient and practical.

A metal chimney in a gas boiler room may have a rectangular or rounded cross-sectional shape, but in this case, the width of one of its sides should not exceed the width of the second by 2 times

A metal chimney in a gas boiler room may have a rectangular or rounded cross-sectional shape, but in this case, the width of one of its sides should not exceed the width of the second by 2 times

When installing a steel ventilation system, you must adhere to the following recommendations:

- The segments are collected using the pipe-to-pipe method.

- Wall brackets are fixed in increments of no more than 150 cm.

- The length of the horizontal segments should be no more than 2 m, unless forced draft is provided in the system.

According to the standards, the thickness of the steel walls should be at least 0.5-0.6 mm. The temperature of the gas that boilers produce is 400-450 C, which is why thin-walled metal pipes can quickly burn out.

Regulations

A boiler room in a private house is an object of increased explosion and fire hazard. The standards provide for measures aimed at increasing the reliability of these premises, preventing accidents and destruction of building structures in the event of a gas leak.

When designing and installing gas heating, they are guided by:

- instruction MDS 41.2-2000 for the placement of boilers;

- SNiP 2.04.08-87 p.6.29-48;

- SP 41-104-2000 chapter 4;

- SP 42-101-2003 item 6.17-25;

- SP 62.13330.2011 point 7;

- SP 60.13330.2012 clause 6.6;

- SP 55.13330.2011 clause 6.12.

The standards are developed for boiler houses, where automated factory-made units serve as a source of thermal energy. They are designed for a maximum coolant temperature of 115°C and a network pressure not exceeding 1 MPa. Rostekhnadzor issues a special permit for the use of equipment on the territory of the Russian Federation.

Rules and regulations for installing a gas boiler in a private house

The norms regulate design solutions and layout when placing gas equipment in country estates:

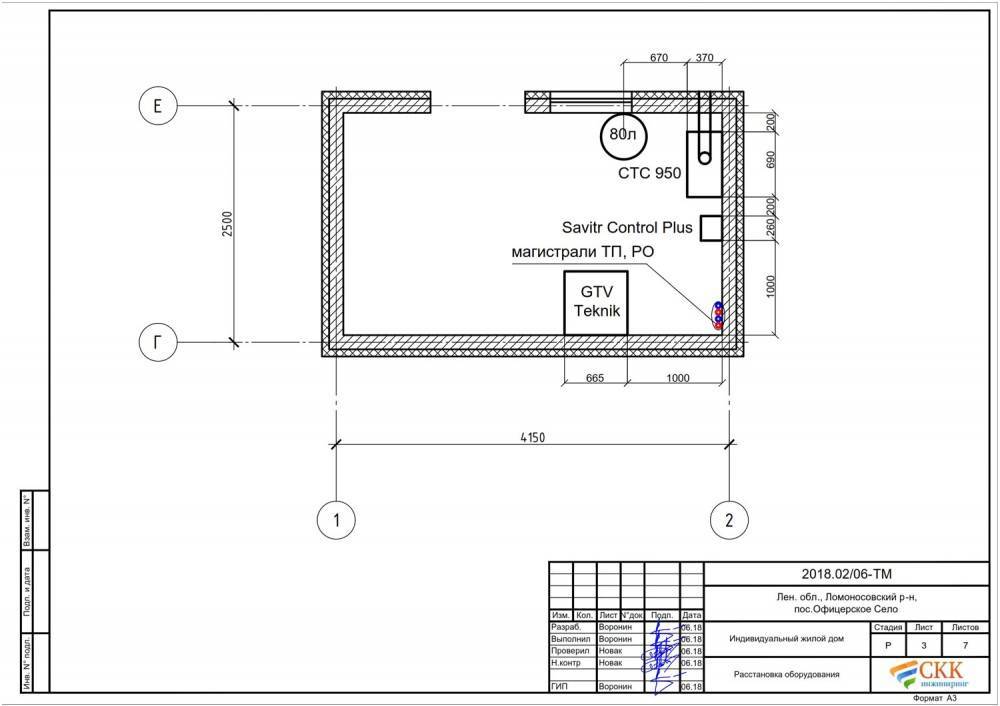

Boilers are not allowed to be installed in a room with a height below 2.5 m. The minimum volume of the furnace is regulated - 15 m³. With these characteristics, the area of the technical room is 6 m². The recommended size for easy maintenance of the heat generator is 7-10 m².

If additional equipment is installed in the room or the room is used for domestic purposes (laundry, ironing), the area is increased to 12 m².

The boiler room in a private house is fenced off from neighboring rooms with walls or partitions made of non-combustible materials. Finishing should also not support combustion.

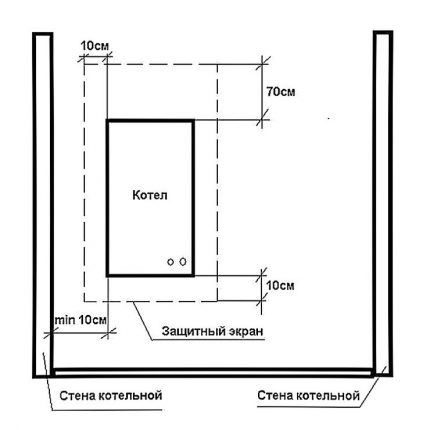

In wooden houses belonging to objects of increased fire hazard, the boiler is installed at a distance of 400 mm from the walls. This restriction applies to wood furniture and other flammable items.

If screens made of asbestos cardboard sheathed with roofing steel are used, the distance can be reduced by 2 times. In this case, the condition must be observed - the protection is 25 mm away from easily combustible structures and extends beyond the horizontal dimensions of the equipment by 150 mm, beyond the upper surface - by 300 mm.

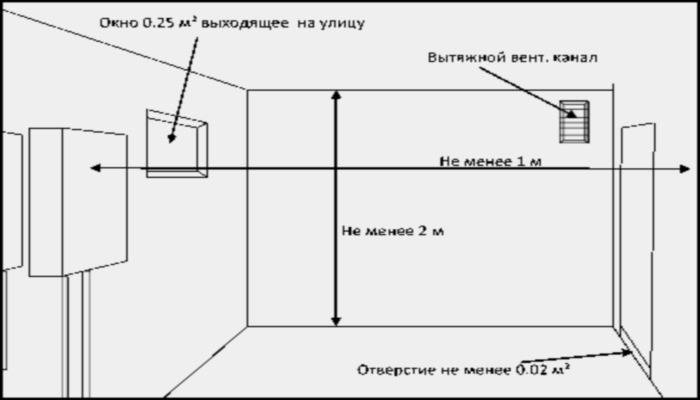

Natural lighting is a mandatory standard for boiler rooms. Norms do not limit the height of windows and do not dictate their geometric shape. The glazing area is calculated taking into account the volume of the room. It is 0.03 m² per 1 m³ of the boiler room.

For a room with a volume of 15 m³, the required glazing size is 0.45 m². This is the area of \u200b\u200bthe middle opening 60x80 cm. The norm does not provide for good lighting. Clearance is needed to perceive the shock wave in case of a possible explosion and to save building structures from destruction.

With a glass thickness of 3 mm, its minimum area is 0.8 m², 4 mm - 1 m², with 5 mm - at least 1.5 m².

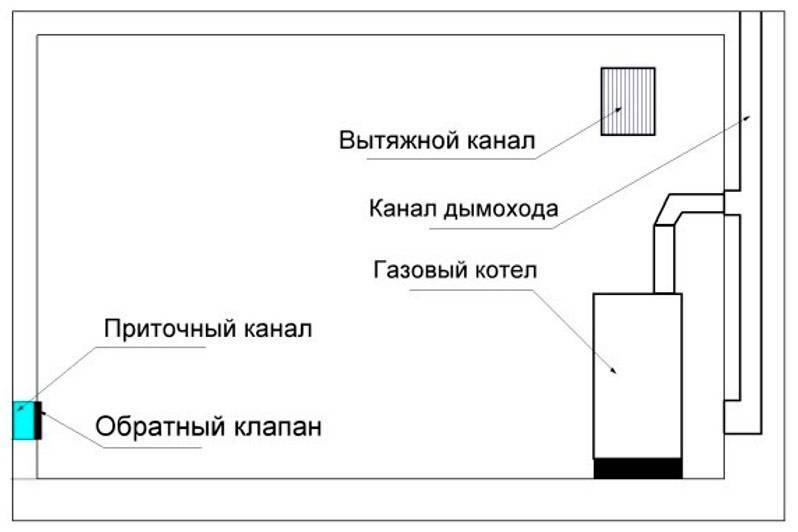

The boiler room is provided with natural ventilation and smoke removal. Depending on the model of the unit, it may be forced. The chimney pipe is brought to a mark above the roof level.

The location of the boiler room is taken into account in space-planning solution at home. All technical premises are located on the north or east side. In the southern and western parts of the building, it is better to plan living rooms.

For convenient maintenance, it is recommended to group the boiler room with other rooms containing technical equipment - a bathroom, a kitchen, a garage.

The boiler room provides for the supply of water and the possibility of its removal when draining from the system. It is forbidden to install an electrical panel nearby so as not to cross the electrical wiring and water communications.

Features of installing a gas boiler in a private house according to SNIP in 2018

Regardless of its location, in order to equip this room, there are special requirements and standards that are dictated by SNiP and safety regulations. All these requirements depend on the technical parameters of the boiler and other equipment.

To date, there is a large selection of heating boilers that can be installed in a private house. They are distinguished not only by manufacturing companies and pricing policy, but also by manufacturing materials, installation methods, the number of circuits and the type of fuel used.

Types of fuel for boilers

Here you can highlight:

- gas;

- diesel;

- electricity;

- solid fuel (coal, wood, coke, peat).

Boilers are classified by location into:

- Embedded.

- Attached.

- Stand alone.

A built-in boiler room will be called if it is located in one of the rooms of the building. Some boilers make noise during their operation, so not all of their representatives are conveniently located in the house. Very often, the requirements of SNiP do not allow installing a boiler indoors, and therefore, when redeveloping a house or changing a heating system, owners are faced with a situation where they have to build either an extension or a separate building, where all the conditions for a boiler room are created.

Requirements for the installation of a boiler room in a private house

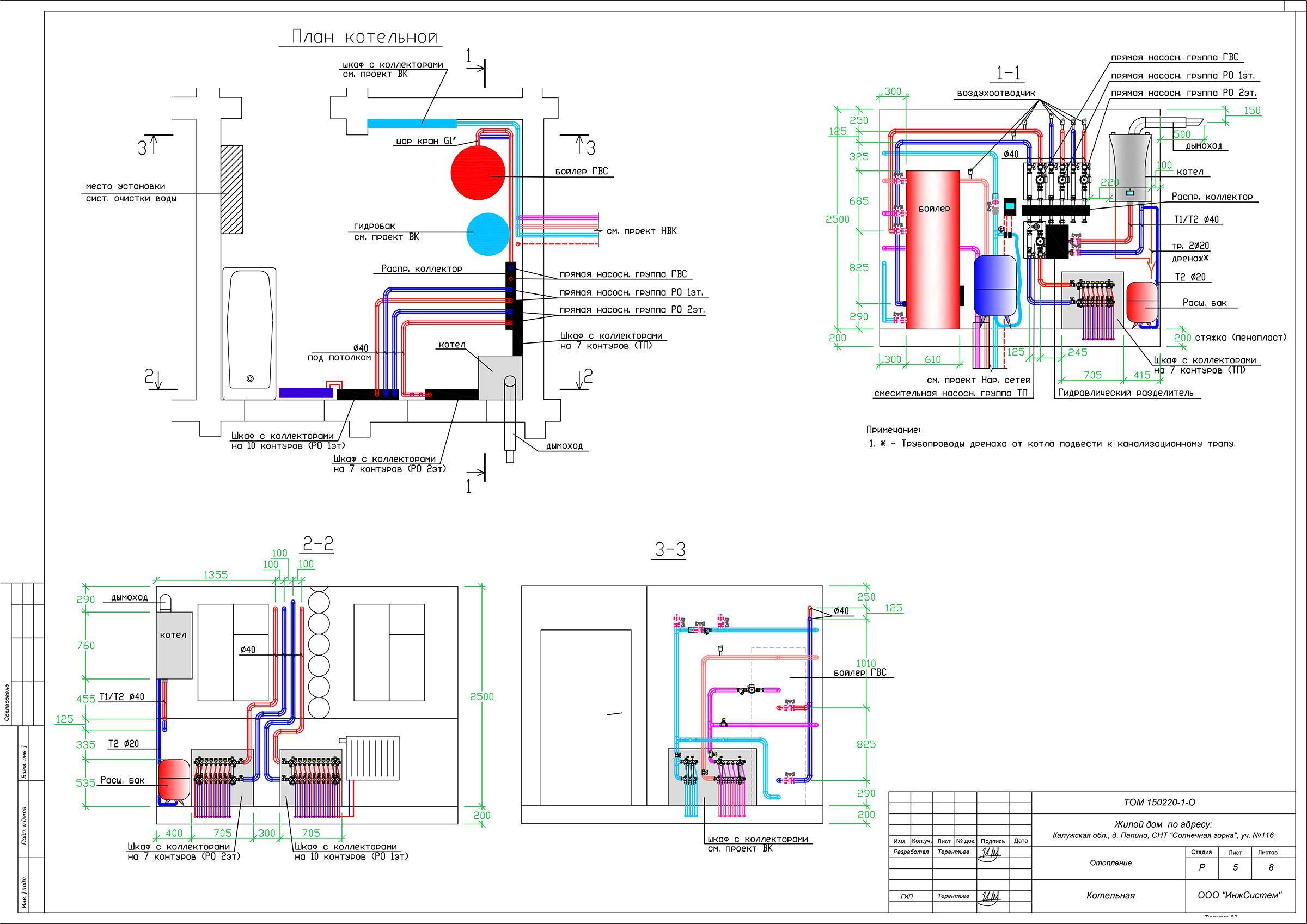

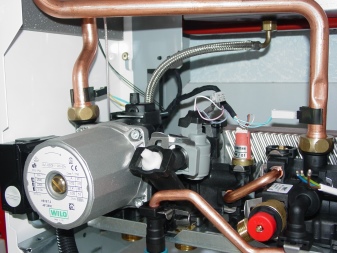

The boiler room will consist of:

- heating boiler;

- boiler;

- distribution manifold;

- expansion tanks;

- boiler safety groups;

- boiler make-up and automation systems;

- pipeline;

- chimney;

- shutoff valve.

Each of these equipments carries a functional significance.

The heating boiler generates heat for the heating system. In the process of how the fuel is burned, it heats the coolant, and hot water is supplied to the radiators and the boiler. The boiler is designed to heat water and supply it for various kinds of consumer needs.

Expansion tanks are used to compensate for the increased water pressure in the coolant or hot water supply.

The distribution manifold is responsible for the circulation and distribution of the coolant throughout the system and regulates its temperature. The chimney removes the products of combustion. The boiler feed system monitors the coolant pressure, and automation is an electronic device that is responsible for the operation of the entire system.

If the area of the building to be heated is large enough, and one system cannot cope with this, then no more than two boilers can be used for one room.

Chimney and supplyexhaust ventilation must comply with the design and correspond to the power of the boiler used.

According to the requirements, when building a boiler house in a private house, it is advisable to use brick or concrete

When facing walls and floors, it is necessary to take non-combustible materials (such as tiles, mineral plaster, metal sheets).

In order to prevent unwanted fires and explosions, it is prohibited to store combustible materials and substances in the boiler room.

The door separating the boiler room from the house must be fire resistant.

The requirements state that all equipment in the boiler room needs free access for maintenance, so it is important to design the room taking into account the free space.

Requirements for a gas boiler

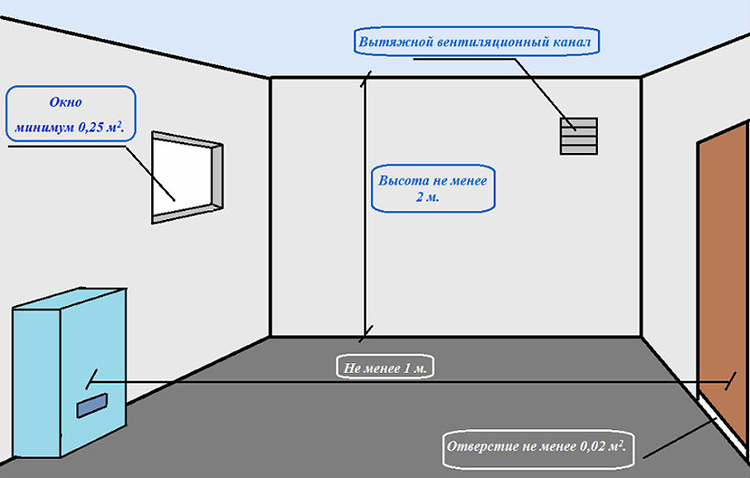

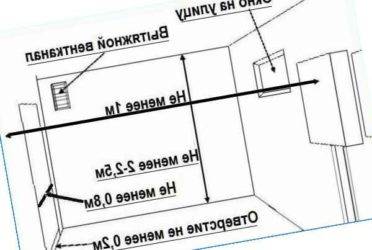

The requirements of SNiP for a gas boiler room clearly dictate that the ceiling height in this room should be at least 220 cm, and its volume should be 15 cubic meters, or 6 squares. At least one window should be provided in the boiler room, the glass area of which is at least 0.5 square meters. Constant ventilation is required, so the presence of special holes built into the door directly from the street plays an important role.

A sewer pipe must be connected to the room to drain emergency discharges, as well as to drain condensate from the chimney. The chimney must be periodically cleaned, so it must be provided with an additional channel for cleaning, and the pipe should be led out above the roof ridge.

These are general requirements for a gas boiler house, but there are many documents with detailed detailed provisions on how everything should be arranged correctly. Therefore, there are two options:

contact the control authorities and find out specific information about your boiler room in order to install it yourself;

it is advisable to give this matter into the hands of professionals, since the installation of a boiler room in a private house (and it does not matter whether it is gas or some other) is a very serious and unsafe matter.

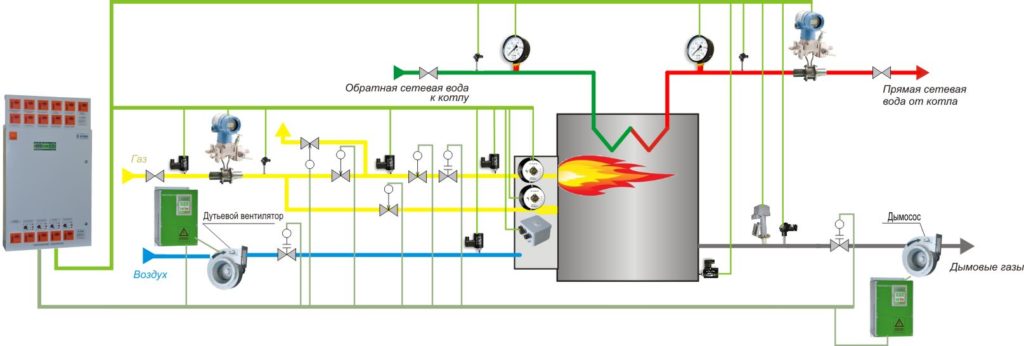

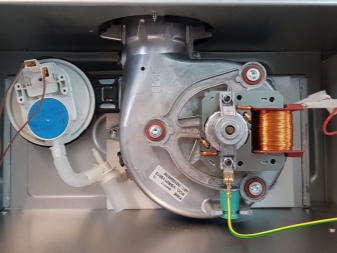

Principle of operation

There is nothing super complicated here. The gas boiler itself is connected to the main gas pipeline or (through a reducer) to the cylinder. Be sure to provide a valve that allows you to turn off the gas supply if necessary. Even the simplest boilers include:

-

a burner in which fuel is burned;

-

a heat exchanger through which heat is supplied to the coolant;

-

combustion control and monitoring unit.

More complex options use:

-

pumps;

-

fans;

-

liquid expansion tanks;

-

electronic control complexes;

-

safety valves.

If there is all this, the equipment can work in a fully automated mode for quite a long time. The boilers are guided by the readings of the sensors. Obviously, when the temperature of the heating medium and/or room air falls, the start-up of the burner and the circulating pump is initiated. As soon as the required temperature parameters are restored, the boiler plant is turned off or switched to the minimum mode.

In large boiler houses, gas comes only from the pipeline (supply from cylinders is technically impossible in such volumes). Be sure to provide a water treatment and softening system at a large heating facility. Additionally, after filtration, oxygen is removed from the water, which can be very detrimental to the equipment. Air is blown into a large boiler by a fan (since its natural circulation does not provide all the needs), and combustion products are removed using a smoke exhauster; water is always pumped by pumps.

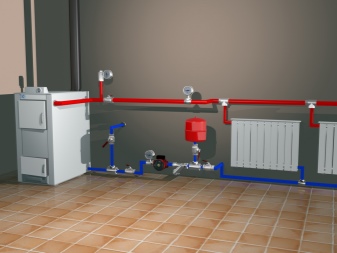

The coolant enters:

-

industrial installations;

-

heating batteries;

-

boilers;

-

warm floors (and after going all the way, it returns to the starting point - this is called a closed cycle).

Boiler room

Gas equipment is connected directly to the boiler room. Regarding the house, furnaces can be located:

- inside - built-in;

- nearby on a separate foundation - attached;

- at some distance - separate.

In accordance with the location, certain requirements are imposed on the premises aimed at ensuring safety during operation.

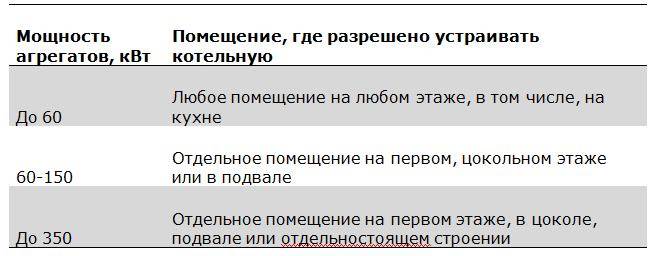

Embedded

Inside the house, according to SNiP, it is allowed to install gas equipment with a capacity of up to 350 kW. Boilers up to 60 kW can be placed in any room. As a rule, this is a kitchen or a household room. More powerful heat generators are located on the first or basement floors, in the basement.

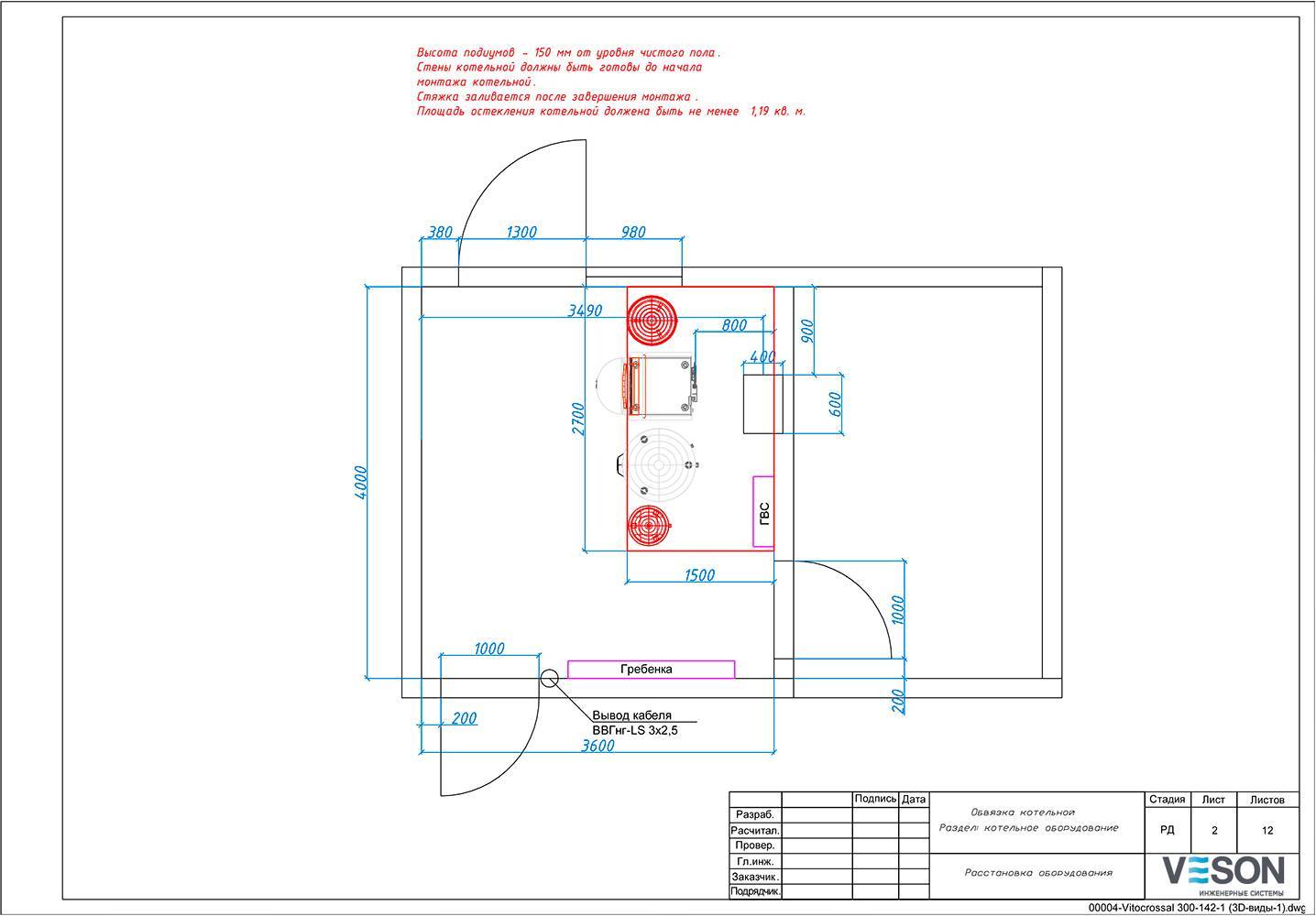

The ceiling in the room should not be lower than 2.5 meters. Ventilation is calculated for a three-fold replacement of air within an hour, that is, the cross section of the ventilation ducts must provide the rate of natural circulation of the amount of air equal to three times the volume of the room.

The size of the window opening, minus the bindings, must comply with the explosion safety requirement. In accordance with it, the area of easily dropped structures, in this case, glazing, is calculated from the condition of 0.03 m² per 1 cubic meter of the room.

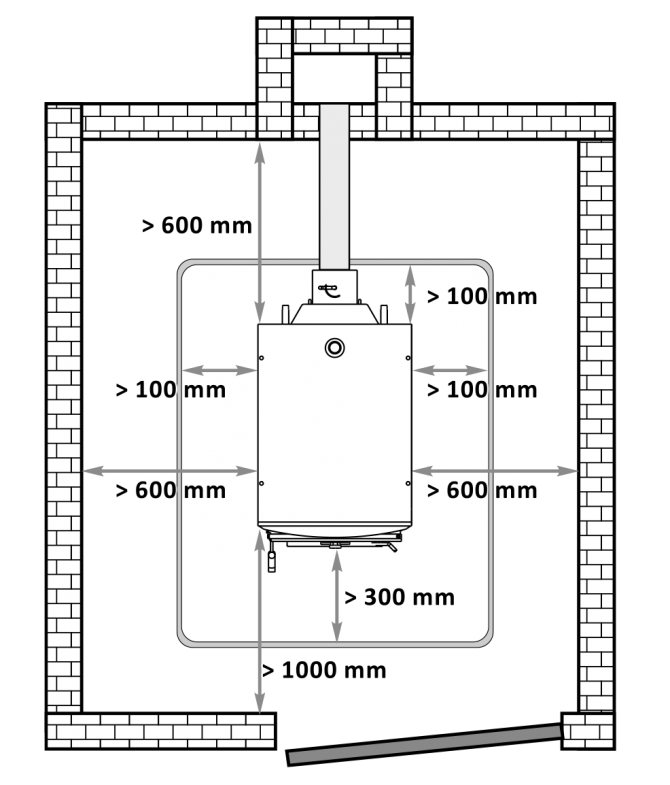

With a power of a thermal unit over 150 kW, the room is equipped with a separate exit. Regardless of the characteristics of the boiler, a passage along the front is left at least 1 m.

Attached premises

An attached boiler room with thermal units with a capacity of up to 350 kW is placed along the blank wall of the house. At least 1 meter away from the nearest door or window opening. The design of the furnace should not be rigidly adjacent to the foundation, walls and roof of a residential building.

The material for the walls of the boiler room is selected taking into account the minimum fire resistance limit - 0.75 hours. The structures should not burn or support combustion.

The height of the boiler room inside is at least 2.5 m. The equipment is placed so that it is convenient to maintain it. The size of the free area in front of the boiler is 1x1 meter.

Attached premises are equipped with a separate exit to the outside. The door should open to the street.

Natural lighting is a must. Glazing area - not less than 0.03 m³ per 1 m³. The hood must support an hourly three-time air exchange.

The door leading to the residential building is made of fireproof materials. It must comply with the third type of fire safety.

Installing a gas boiler in the kitchen

When installing a gas stove, a water heater and a boiler with a power of up to 60 kW in the kitchen, the following requirements are imposed on the room:

When installing gas-using equipment, they are guided by the manufacturer's passport. The walls must be made of non-combustible materials, and the distance to the unit must be at least 20 mm.

It is allowed to install boilers near walls made of combustible materials, provided that the surface is protected with asbestos sheet 3 mm thick and roofing steel or plaster. In this case, at least 30 mm recede from the enclosing structures. The insulation is removed from the dimensions of the equipment in height and width by 10 and 70 cm.

The floors under the boiler also protect against fire. Sheets of asbestos and metal are laid on them in such a way that their borders exceed the dimensions of the body and protrude 10 cm from all sides.

Requirements for a boiler room in a private house, depending on the type of boiler

Each fuel is different, and what is relatively safe in one situation can be a disaster in another. This must be understood and it is normal to relate to the fact that each type of boiler equipment adds at least five additional items to the list of basic requirements for a boiler room. Let us consider in more detail the most commonly used heating boilers.

Gas boiler in a private house

We can say that this is the most demanding boiler room for manufacturing - literally everything is important here. Firstly, this is the volume of the room - with a minimum ceiling height of 2.5 m, its volume should not be less than 15 m³. There are even restrictions on the floor area, which should not be less than 6m²

All this is due to possible gas leaks and ventilation of the room. Secondly, the window - its area must be at least 0.5 m². Thirdly, the width of the door is not less than 800mm. Fourthly, a chimney with an additional channel for cleaning, raised above the roof ridge by at least 0.5 m. Fifthly, the presence of sewage for collecting condensate - accordingly, it will be necessary to install collectors for this condensate on the ventilation and chimney. In general, there is a lot of everything here, and add the requirements for the installation and piping of the boilers themselves. And yet - gas services require the installation of a special device in the boiler room called a gas detector

There are even restrictions on the floor area, which should not be less than 6m². All this is due to possible gas leaks and ventilation of the room. Secondly, the window - its area must be at least 0.5 m². Thirdly, the width of the door is not less than 800mm. Fourthly, a chimney with an additional channel for cleaning, raised above the roof ridge by at least 0.5 m. Fifthly, the presence of sewage for collecting condensate - accordingly, it will be necessary to install collectors for this condensate on the ventilation and chimney. In general, there is a lot of everything here, and add the requirements for the installation and piping of the boilers themselves. And yet - gas services require the installation of a special device in the boiler room called a gas detector.

Electric boiler houses.Electricity is the safest fuel to use to heat your home. It is so safe that it is not even allowed to build a separate room for the equipment of such a boiler room. The furnace can be located directly in the house, since there will be no exhaust and any other harmful emissions. The only thing that is required here is to correctly make the wiring - grounding of electric boilers must be mandatory.

Solid fuel boilers. No less demanding than gas furnaces. Firstly, this is an unrestricted access to the boiler. Secondly, the presence of a steel floor at least around the boiler, at a distance of up to 1m from each side. Thirdly, for each kilowatt of boiler power, a window with an area of 0.08 m² is required. Fourthly, the size of the boiler room in a private house - its area should not be less than 8m². Naturally, a chimney with an equal section along its entire length and special openings for cleaning. In addition, if you plan to fire the boilers with coal, then all electrical wiring must be airtight, because coal dust explodes at a certain concentration.

Diesel boilers. Here, in general, everything is without problems - permits are not even required for the arrangement of such boiler houses. In fact, it is quite possible to arrange a diesel boiler room in the basement of a private house.

In principle, this is all of the basic requirements - of course, there are some other details that are due to individual factors. They are usually indicated in the design or permit documentation, and they cannot be ignored in any way - if they are not observed, your furnace will not pass the commissioning stage.The main thing here is to understand that all these requirements do not arise from scratch and are primarily due to security.

Fire safety

The furnace area must be kept clean, and there must be sufficient artificial lighting inside to provide good illumination of work and public areas. It is prohibited to store any flammable materials in such premises. If the pipes freeze, they can only be heated with steam or hot water. The use of open flames is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems, they must be checked and cleaned at intervals:

- Annually in August - cleaning the smoke channels from soot pollution, checking the draft.

- Quarterly - cleaning of brick chimneys.

- Annually inspect the integrity of the ventilation ducts.

Entrance doors of the furnace should open outwards. Windows are required to have easily removable packages. A protective solenoid valve, a fire alarm and room gas sensors are installed at the gas pipeline inlet to the furnace.

Types of roof boilers

The most acceptable option for placing such a boiler house is a flat roof structure. For these sources of heat supply, installations are provided: built-in and block-modular boiler house (BMK).

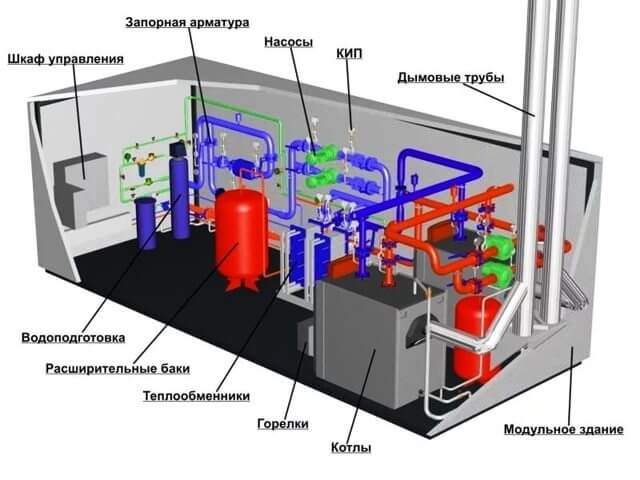

BMK

Block-modular gas-fired boilers are supplied in a complete factory set. They come to the customer in essence with 100% readiness, therefore they are launched as soon as possible. Modern rooftop boilers operate throughout the year in automatic mode for heating and hot water and do not need permanent operational personnel.

All boiler equipment is selected according to the design technological parameters and complies with the current legislation in terms of ensuring safe operation. The block includes boilers taking into account peak power, pumps for heating and hot water, fans and smoke exhausters, chimneys, primary thermal process control devices and an automatic control system. BMK is equipped with high-quality insulation and reliable supply and exhaust ventilation.

Embedded

An integrated roof boiler in an apartment building is built according to an individual project, in which each element of the thermal scheme is carefully calculated to create a safe and efficient heating system.

The boiler room is most often made of prefabricated sandwich structures or standard reinforced concrete products. The assembly of the thermal scheme of the boiler house is carried out on site, due to precisely selected equipment, developed schemes of the built-in boiler house, according to the design specifications for equipment and materials.

The assembly is carried out by the customer of the object or, under a separate agreement, with the installation organization. The scheme of a rooftop boiler house in a built-in apartment building includes gas boilers, taking into account the reserve, pumping equipment, a smoke exhaust and ventilation system, chemical water treatment and instrumentation.

Typically, such boiler houses are mounted within a few days, then the process of setting up the boiler equipment and the final stage of commissioning the boiler room begins.

Glazing area of a private house according to SNiP

Once upon a time, now it seems that a long time ago, rarely did any of us think about how many windows and what area should be made in a residential building.The glazing area of the house as an indicator was of little concern to anyone. The more windows and the larger they are, the better, so we thought.

After all, natural gas, which was used to heat our homes in the 80s and 90s, cost mere pennies. Why was it necessary to think about any energy saving, if it as the concept did not exist at all.

However, times are changing, and so are the prices for natural gas for heating a residential building. Since 2010, gas for the population has risen in price by almost 1.5 times and will rise in price by another half in the coming years. If earlier gas heating was cheap, now it can be called relatively cheap, compared to other types of energy carriers that are becoming incredibly expensive - diesel fuel and electricity.

It became completely impossible to heat the house with gas with the old approach to the construction of the house. In this regard, the New Building Norms and Rules regulate the energy efficiency of the house and special cases regarding the insulation of enclosing structures, the humidity regime of the premises and other parameters.

Including the modern SNiP regulates the glazing area of the house, which was built by a private developer. That is, not household and public buildings, not administrative and social premises, but private ones. It clearly indicates that it is unacceptable to carry out glazing of a private house without calculating the thermal resistance of windows, stained-glass windows, bay windows and glazed verandas.

Consider how the glazing area of a private house is regulated by SNiP (document text):

Firstly, for any regions and for any types of windows, regardless of the glazing area, the norm is set for the temperature of the inner surface of the glass in the room. It cannot be lower than +3C.

This encourages choosing more efficient glasses with a large number of hermetic chambers for cold regions. While in the warm regions of the country, you can get by with a smaller number of cameras and a simpler design of double-glazed windows.

Glazing standards in this case are the same for any region of residence. But the glazing area may be different according to the norms for different regions. And this is the second paragraph of the document.

If you live in a region where the heating season is measured at 3500 degree-days (degree-day table here), then your windows must have a heat transfer resistance of at least 0.51 sq. m * C / W. In this case, you can make any area of glazing in your home. But if you have chosen not so effective windows, then the glazing area of your house cannot be more than 18 percent of the area of \u200b\u200bthe entire facade according to SNiP.

The same applies to colder regions. For regions with 3500-5200 degree-days of the heating season, the normalized resistance to heat transfer of windows is set at 0.56 sq.m * C / W, for regions with the heating season of 5200-7000 degree-days - 0.65 sq.m * C / W , and for regions with a heating season over 7000 degree-days - 0.81 sq. m * C / W. In this case, the glazing area is not standardized. If the standards are not met, then the glazing area should also be no more than 18 percent of the total facade area.

Also, the Building Regulations and Rules establish the recommended area of skylights - no more than 15 percent of the area of the room under them. That is, if you have a skylight over a living room with an area of 30 square meters, then the glazing area of the skylight should not exceed 4.5 square meters.

Dormer windows should not be more than 10 percent of the area of the attic rooms in which these windows are installed. That is, if the entire attic has an area of 100 sq.m., and the illuminated rooms, that is, rooms with windows, have an area of \u200b\u200b80 sq.m. (they excluded the corridor and the flight of stairs), then the area of the attic windows can be 8 sq.m.