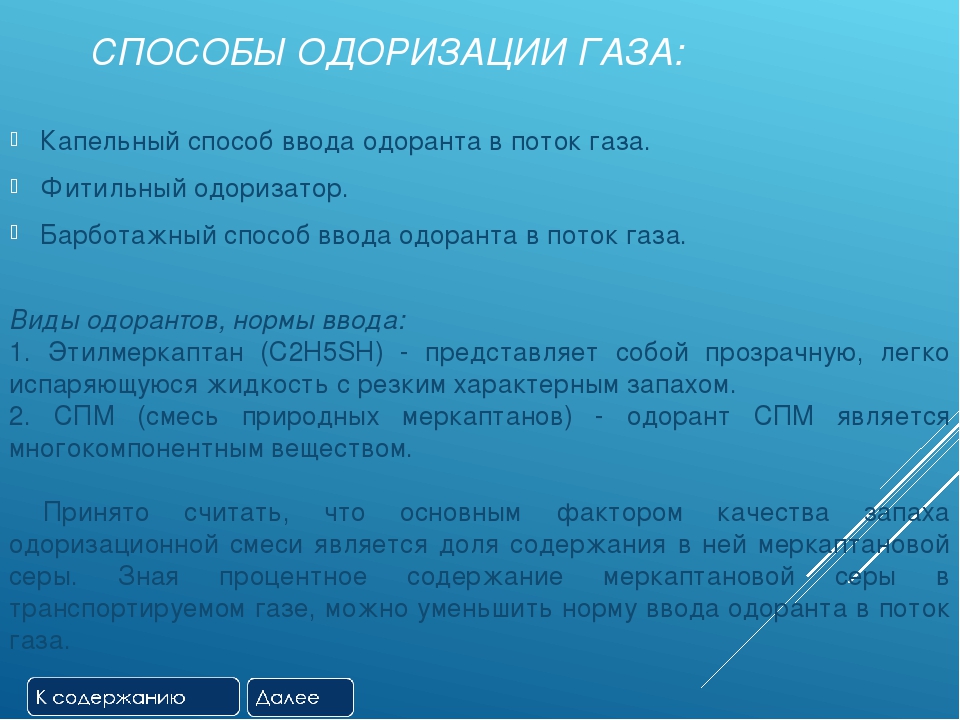

- Norms and composition of odorizing substances

- Properties and composition of odorants

- Possible changes in the regulated norms of odorants

- CLEANING FROM HYDROGEN SULFIDE AND CARBON DIOXIDE, GAS DRYING AND ODORIZATION

- GAS DISTRIBUTION STATIONS

- Odorization

- GDS OPERATION

- General provisions

- Repair work

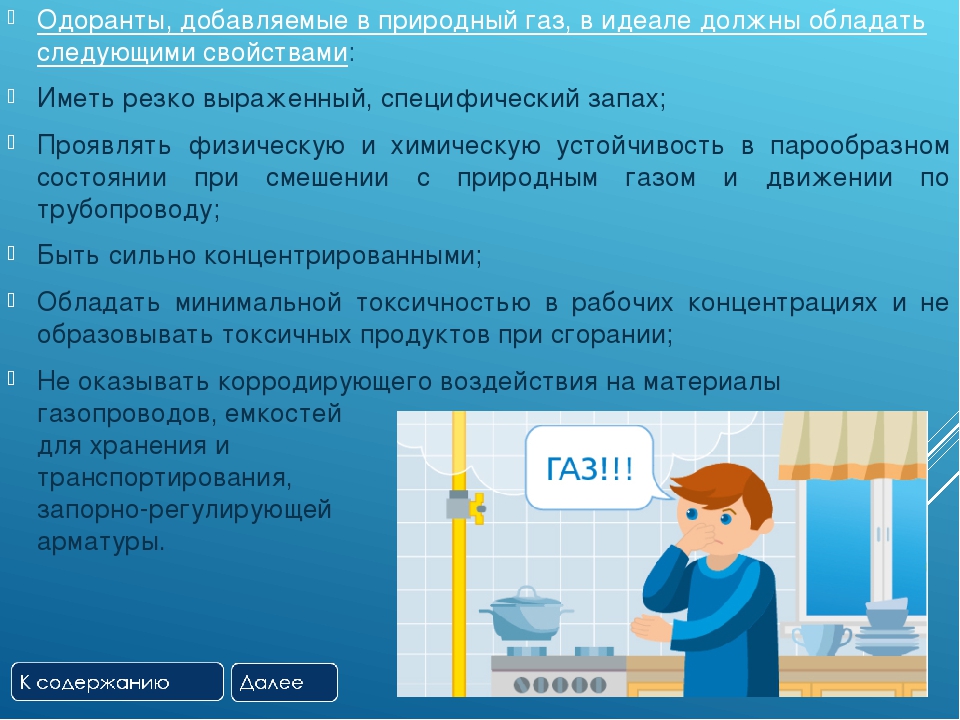

- What are the properties of odorants for natural gas

- Odorization - natural gas

Norms and composition of odorizing substances

Natural gas should be detected by smell in the air when its concentration is not more than 20% of the lower explosive limit, which is equal to 1% of the volume fraction of organic compounds. What to do if you have apartment smells of gas, we will describe in detail in the next article.

The amount of odorant in the gas supplied to the consumer depends on the chemical composition of the mixture.

The Regulation on the technical operation of the GDS of main gas pipelines VRD 39-1.10-069-2002 states that the rate of input of ethyl mercaptan is 16 g per 1,000 m³ of gas.

This odorant was one of the first industrial additives that was used in the territory of the former USSR, but EtSH has several significant drawbacks:

- exhibits easy oxidation;

- interacts with iron oxides;

- has a high toxicity;

- dissolves in water.

The formation of diethyl sulfide, to which ethyl mercaptan is prone, reduces the intensity of the smell, especially when transporting over long distances. Since 1984, almost throughout Russia, a mixture of natural mercaptans has been used, which includes isopropyl mercaptan, ethyl mercaptan, tert-butyl mercaptan, butyl mercaptan, tetrahydrothiophene, n-propyl mercaptan and n-butyl mercaptan.

The odorant complies with TU 51-31323949-94-2002 "Natural odorant of Orenburggazprom LLC". The norm for this multicomponent additive does not differ from the recommended amount of ethyl mercaptan.

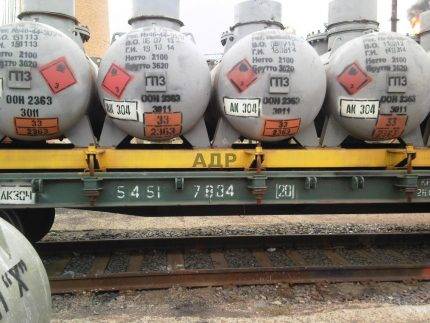

Loading drums for filling with odorant, transportation of dangerous goods, its rearrangement on the site must be carried out exclusively by mechanized means. This is done to ensure that there is no damage to the containers, each of which must also be marked

Loading drums for filling with odorant, transportation of dangerous goods, its rearrangement on the site must be carried out exclusively by mechanized means. This is done to ensure that there is no damage to the containers, each of which must also be marked

The so-called mercaptans are produced on the basis of hydrogen sulfide, sulfur and sulfides. But modern production is based on the use of sulfur-free compounds, for example, in Germany they produce an environmentally friendly product called Gasodor S-Free.

GASODOR S-Free odorant is based on ethyl acrylate and methyl acrylate, which, when burned, form water and carbon dioxide. Despite good performance, some polymeric materials can cause a sharp decrease in the concentration of acrylates, and as a result, a decrease in the intensity of the gas odor

GASODOR S-Free odorant is based on ethyl acrylate and methyl acrylate, which, when burned, form water and carbon dioxide. Despite good performance, some polymeric materials can cause a sharp decrease in the concentration of acrylates, and as a result, a decrease in the intensity of the gas odor

This odorant has a sharp specific smell, remains stable even during long-term storage, does not change its quality when the temperature changes.

The additive is also highly valued for the fact that it does not dissolve in water.When testing, which confirmed the suitability of the substance, at one of Gazprom's domestic facilities, an odorant concentration of 10-12 mg/m³ was used.

Ethanthiol is transported in road and rail tank cars, cylinders, containers. The maximum allowable storage volume is 1.6 tons in cylindrical ground tanks, the filling factor should be 0.9-0.95

Ethanthiol is transported in road and rail tank cars, cylinders, containers. The maximum allowable storage volume is 1.6 tons in cylindrical ground tanks, the filling factor should be 0.9-0.95

Crotonaldehyde is considered as a potential odorant. A flammable liquid with a pungent odor, belongs to the second hazard class in terms of the degree of impact on the body.

It has several significant advantages over ethanethiol:

- there is no sulfur in the composition;

- less toxic effect;

- has little volatility under normal conditions.

The maximum level of emissions from crotonaldehyde does not exceed the maximum allowable rate and is 0.02007 mg/m3. The possibility of practical use of the substance as an odorant has not yet been studied in detail.

Properties and composition of odorants

Ethylmarkaptan began to be used back in the days of the Soviet Union and it was manufactured in Dzerzhinsk. It was found that it has a low chemical stability, which is expressed in its rapid oxidation. The latter substance is always present in the pipeline. They form another chemical element called diethyl disulfide. This element, in comparison with ethylmarcaptan, has a weak odor intensity, so it is necessary to increase its concentration, respectively, and costs. Speaking about this substance, it is necessary to answer that it is quite toxic.

Another fairly common SPM.Its main producer is a gas processing plant located in Orenburg. It contains many individual components such as ethyl mercaptan, iso-popyl mercaptan and butyl mercaptan. There are 7 of them in total and all of them have a different mass fraction in the substance. 16 g of SPM is introduced per 1000 m3. As a foreign odorant, mercaptan is used, which is created during the chemical synthesis of sulfur, sulfide and other substances, but with a smaller molecular fraction.

The international standard, which was followed by most manufacturers and consumers, has recently been changed. If earlier sulfur compounds, which have a boiling point of 130 degrees, were used as odorants, now sulfur-free compounds have begun to be widely used. They have the following properties:

- ecological purity of the product. Compounds that have sulfur are not emitted into the atmosphere;

- stronger and more persistent smell;

- compliance with epidemiological standards;

- high intensity;

- low concentration;

- the substance is stable even during long-term transportation or storage;

- unchanging properties, even during large temperature fluctuations;

- does not dissolve in water.

One example of such odorants is Gasador. He was recognized as suitable in our country, after all the tests were passed. They were carried out at the Severgazprom LLC enterprise.

Possible changes in the regulated norms of odorants

Over the past few years, the number of well-reasoned proposals for the abolition of rigid regulated norms has increased dramatically

If individual standards are set for all facilities, which take into account such factors as the length of the gas pipeline, as well as the composition of the substance and its quality, this will give an additional impetus to the use of different odorants

The quality of natural gas odorants is affected by:

- The length of the pipeline gas pipeline can adversely affect the quality of ethyl mercaptan. During the chemical reaction of the elements of the composition of the odorant, as well as the elements of the pipeline, there is a decrease in the intensity of the gas. Therefore, an enterprise that transports natural gas has to increase the amount of odorant introduced.

- The quality of the smell of the mixture depends on the mass fraction of sulfur. If you know what percentage of the element is contained in the transported natural gas, you can change the amount of odorant introduced into the total flow. At the same time, the presence of a large amount of impurities can affect the deterioration of its quality. So, moisture has the most negative effect on the quality, which leads to the appearance of condensate in the pipeline, which will entail the dissolution of a certain amount of odorant.

- Ingredients of the composition and their quality. Speaking about the qualitative composition, we cannot leave the topic of transporting odorants in our country. Due to the fact that black steel is often used for this purpose, which reacts with the transported substance, the odorant loses its qualities quite strongly during transportation. This is also affected by temperature fluctuations that arise due to the large length of highways passing through the whole country.In addition, a significant decrease in the actual quality of some elements of the odorant occurs due to fluctuations in the ratio of its components, which occurs through the fault of the manufacturer.

CLEANING FROM HYDROGEN SULFIDE AND CARBON DIOXIDE, GAS DRYING AND ODORIZATION

29.1. For everybody

production process, technological regulations should be developed,

agreed and approved in the prescribed manner by Mingazprom.

29.2. enterprise management,

manufacturer is obliged to ensure strict compliance with the approved

technological regulations with the maximum use of modern means

technological control and automatic process control.

29.3. Operation is prohibited

enterprises without an approved technological regulation or according to

technological regulations, the validity of which has expired.

29.4. Persons responsible for the violation

of the current technological regulations are subject to strict disciplinary

responsibility, if the consequences of this violation do not require application to these

to persons of more severe punishment in accordance with the current legislation.

29.5. operation,

inspection and repair of devices and tanks of separation and purification plants

from hydrogen sulfide and carbon dioxide, dehydration and odorization of gas are carried out in

in accordance with the Rules for the Design and Safe Operation of Vessels,

working under pressure from Gosgortekhnadzor.

29.6. Coating, cleaning and repair

equipment are carried out according to the schedule approved by the management of LPUMG and PO.

29.7. Opening, cleaning and

flushing of devices and individual units is carried out in accordance with the current

instructions under the direction of the person responsible for the operation of the installations.

29.8. hot work on

areas where dust collectors and gas cleaning and drying devices are installed,

perform under the supervision of the head (deputy head) of LPUMG in

in accordance with the Standard Instructions for the production of hot work on existing

main gas pipelines, gas gathering networks of gas fields and SPGS,

transporting natural and associated gas.

29.9. taken from the apparatus and

pollution communications (especially those containing pyrophoric compounds)

must always be under a layer of liquid and not in contact with air to avoid

spontaneous combustion. These contaminants must be incinerated offsite.

installations in specially designated pits, followed by backfilling them with earth.

29.10. operating procedure,

opening, cleaning and repair of the main and auxiliary technological equipment,

operation of instrumentation and instrumentation, handling extracted from separation plants

pollution, purification from hydrogen sulfide and carbon dioxide, dehydration and odorization of gas

determined by the relevant instructions.

29.11. After installation or repair

devices and equipment of installations, commissioning should be carried out under

the guidance of a responsible engineering and technical worker, for whom

fixed equipment.

29.12. Gas quality control

carried out according to OST 51-40-74 and GOST 20061-74.

29.13. By quality

gas indicators are accepted by the supplier at delivery points.

Samples for quality control

are selected according to GOST 18917-73. The frequency of sampling is determined in each

in a separate case by agreement between the supplier and the consumer.

29.14. Gas quality is controlled

according to the test methods specified in OST 51.40-74. In case of non-compliance

gas quality requirements of this OST are repeated periodic

measurements within 8 hours only for indicators that gave negative results.

The results of repeated measurements are final. In controversial cases

establishing quality indicators of gas, joint control

measurements by representatives of both parties. Measurement results are documented

bilateral act. The procedure for resolving disputes by indicators

gas quality is established by agreement between the supplier and

consumer.

29.15. The supplier guarantees

compliance of natural gas quality with the requirements of OST 51.40-74, subject to

Rules for the technical operation of main gas pipelines.

29.16. Natural gas fire and

explosive. Composition-specific ignition limits and temperatures

natural gas are determined in accordance with GOST 13919-68.

29.17. Gas moisture content

is determined using a TTR-8 moisture meter or a similar device.

GAS DISTRIBUTION

STATIONS

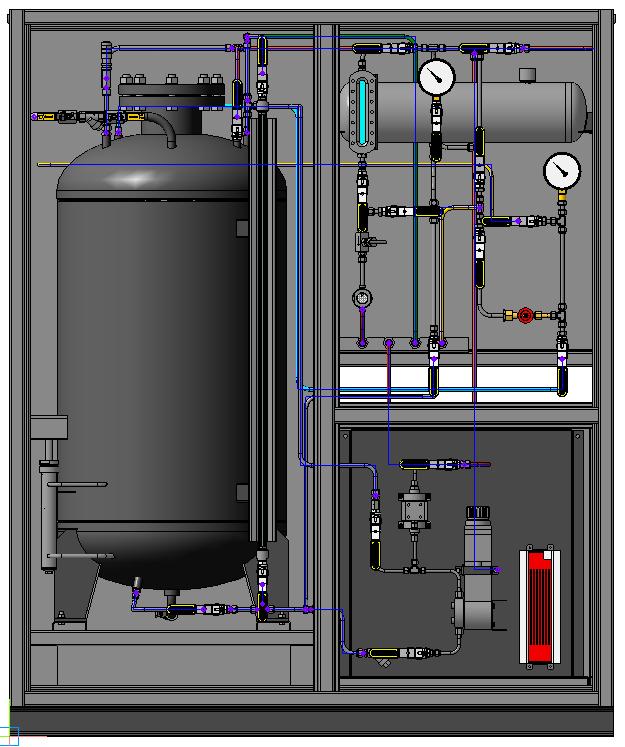

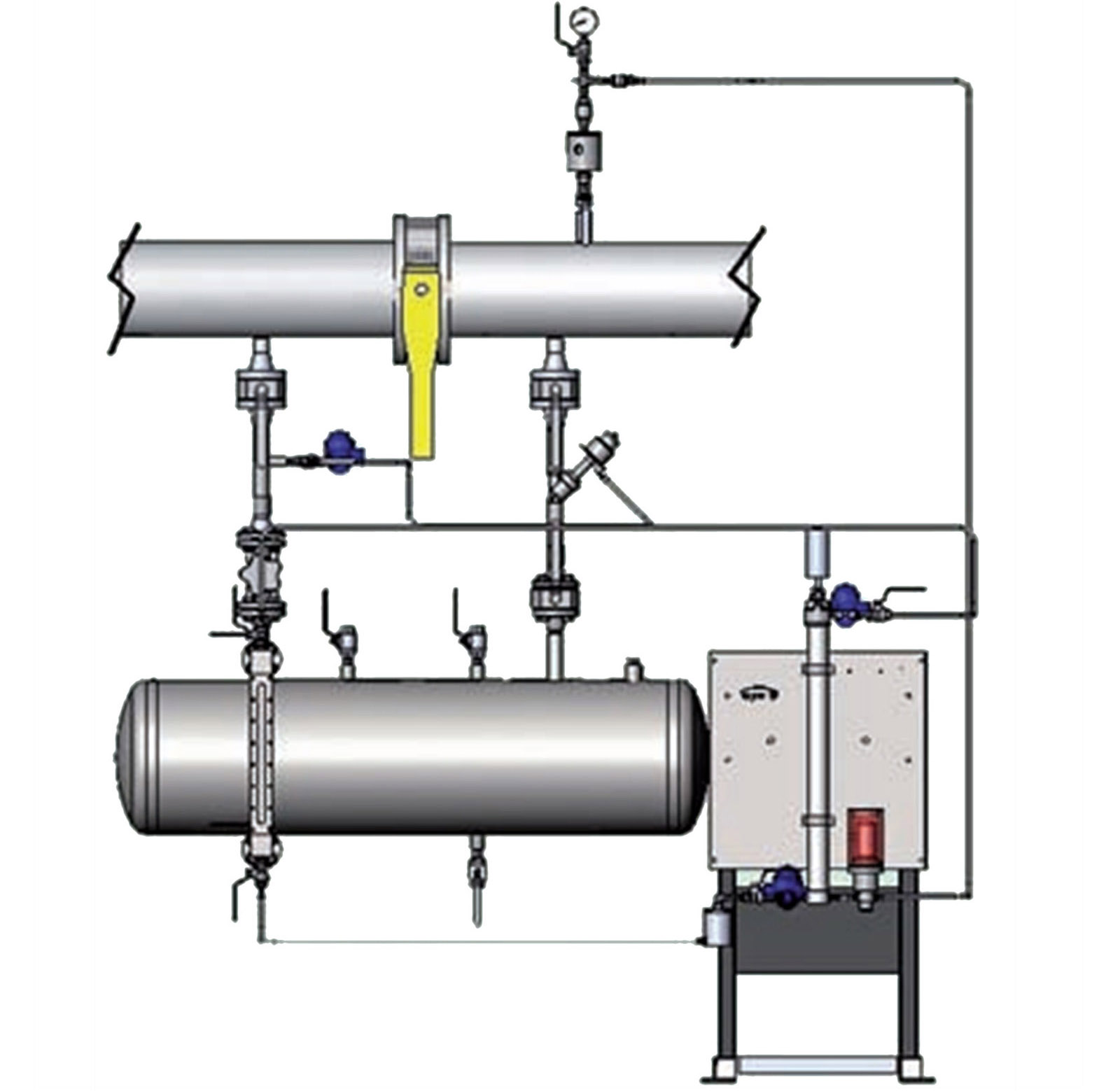

Odorization

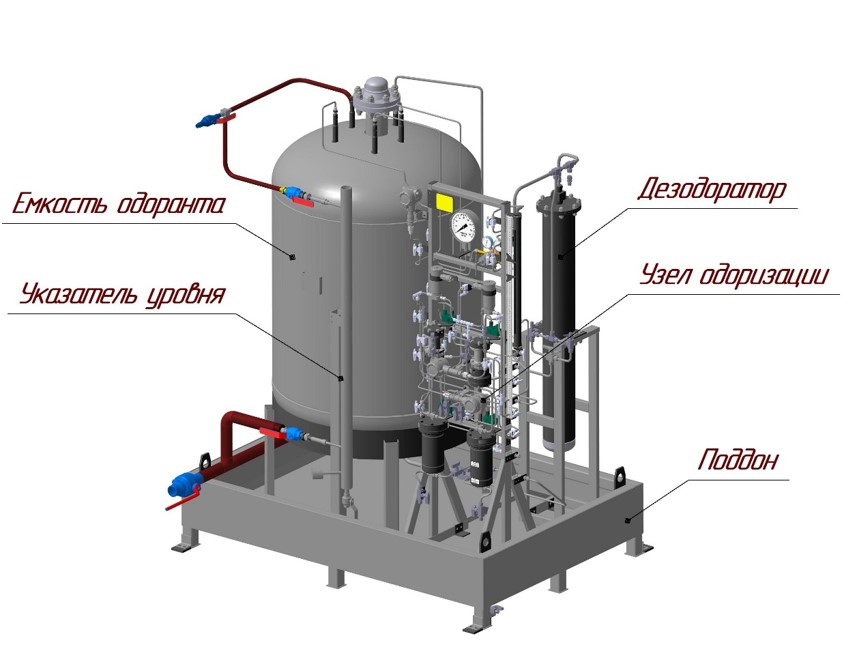

Odorization allows you to more quickly detect gas leaks.

Odorization to the value set above is carried out at each point of the transport network using a centralized odorization unit.

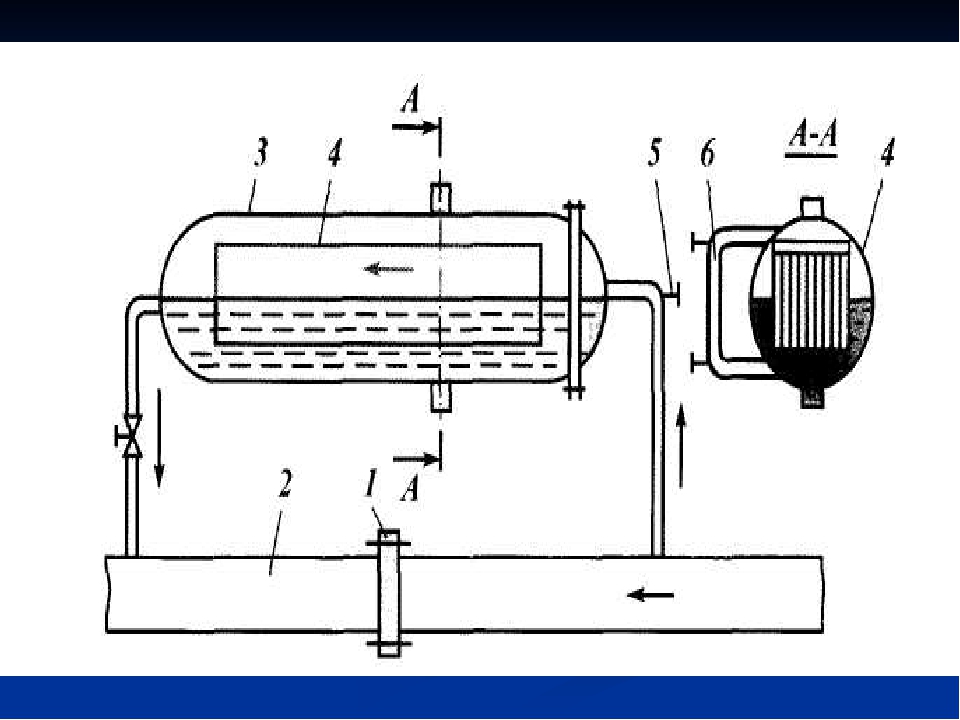

Odorization is carried out by adding a small amount of a liquid with good volatility and a sharp specific odor to the combustible gas.

Odorization, a mandatory technological operation in the preparation of natural gas, is carried out, as a rule, by supplying liquid odorants to the gas.

Odorization should be carried out by automatic introduction of an odorant, the amount of which is proportional to the gas flow rate.

Odorization is the process of giving natural gas an artificial smell; necessary for safety purposes, makes it easy to detect even the smallest gas leak.

Odorization of gas in the gas supply system of Leningrad is an extremely important measure to ensure proper sanitary and hygienic conditions and the safety of using combustible gases in everyday life and industry.

Gas odorization is carried out at the outlet pipeline from the GDS. Gas supplied to domestic consumers must be odorized. Gas supplied to industrial plants may not be odorized.

Odorization of gas containing hydrogen sulfide is not performed.

Odorization of gases is carried out using special liquids with a strong odor. The most commonly used odorant is ethyl mercaptan. In this case, the smell of gas should be felt when its concentration in the air is not more than 1/5 of the lower explosive limit. In practice, this means that natural gas, which has a lower explosive limit of 5%, should be felt in indoor air at 1% concentration. The smell of liquefied gases should be felt at 0 5% - their concentration in the volume of the room.

Odorization of gases is carried out using special liquids with a strong odor. The most commonly used odorant is ethyl mercaptan, which contains up to 50% sulfur. The amount of ethyl mercaptan added to gases is taken at the rate of 16 g for every 1000 m3 of natural gas. In practice, this means that natural gas, which has a lower explosive limit of 5%, should be felt in indoor air at 1% concentration.

Odorization of gases is carried out using special liquids with a strong odor.The most commonly used odorant is ethyl mercaptan, which contains up to 50% sulfur. The amount of ethyl mercaptan added to gases is taken at the rate of 16 g for every 1000 m3 of natural gas. In this case, the smell of gas should be felt when its concentration in the air is not more than Vs part of the lower explosive limit. In practice, this means that natural gas, which has a lower explosive limit of 5%, should be felt in indoor air at 1% concentration. The smell of liquefied gases should be felt at 0 5% concentration in the volume of the room.

| Technological scheme of gas purification from hydrogen sulfide and carbon dioxide with ethanolamine solution. |

Odorization of the gas is necessary because the hydrogen sulfide-free gas does not have the odor required for leak detection. Therefore, as mentioned above, an odorant is introduced into the gas. Ethyl mercaptan (C2HB8H) commonly used for this purpose is a clear, easily evaporating liquid with a pungent characteristic odor. In addition to ethyl mercaptan, captan, tetrahydrothiophene, pentalarm, etc. can be used as an odorant. Odorization can be carried out at the head facilities of the main gas pipeline, but more often gas is odorized at gas distribution stations, using drip, bubbling and injector odorizing plants for this purpose.

Odorization of gases is carried out using special liquids with a strong odor. The most commonly used odorant is ethyl mercoptan, which contains up to 50% sulfur. The amount of ethyl mercoitane added to the gases is taken at the rate of 16 g for every 1000 m3 of natural gas.At the same time, according to GOST 5542 - 50, the smell of non-toxic gases should be felt when their content in the air is not more than Vs of the lower flammability limit, and the smell of toxic gases - when they are contained in the air in quantities allowed by sanitary standards.

GDS OPERATION

General

provisions

31.1. Complex of planned

preventive, repair work and measures to ensure uninterrupted and

trouble-free operation, elimination of emergencies, flow measurement

gas and its accounting at the gas distribution station, is carried out by the personnel of the maintenance and preventive group

GDS at LES LPUMG in accordance with these Rules and the Rules for technical

and safe operation of the GDS.

31.2. General management of the GRS

carried out by the head of the LES LPUMG, directly - senior engineer (engineer)

GRS.

31.3. Responsibility for

condition, repair and maintenance of special facilities at the GDS in accordance with

technical operation and safety requirements (ECP,

power supply, instrumentation and A) are carried out by specialists of the relevant services of LPUMG.

31.4. Admission of a new entrant

at the enterprise, an employee is allowed to work independently at the GDS only

after they have been instructed in occupational health and safety at

workplace and training in the amount provided for by the Regulations on the procedure

training and testing knowledge on labor protection of workers, employees and

administrative and technical personnel at enterprises and organizations

Ministry of the gas industry and the Rules for technical and safe operation

GRS.

31.5. Forms of GRS service in

depending on the operational complexity factors contained in the Rules

technical and safe operation of the GDS, the following are established:

a) centralized

maintenance personnel, when the complex of preventive and repair works on

GRS is carried out once a week by operational and maintenance personnel

repair and preventive group of GRS;

b) periodic - with

service (with one or two operators) GDS per shift by one operator,

periodically visiting the SDS to perform the necessary work in accordance with

job description;

c) watchkeeping - with round-the-clock

shift duty at the GRS of duty personnel.

Repair work

31.6. Repair of technological

systems, devices and equipment of the gas distribution station is carried out in the volumes and on time,

All pages<<19>>

Advertise on this site

What are the properties of odorants for natural gas

Natural gas does not smell, therefore it is not perceived by the olfactory organs. To detect its leakage, it is necessary to use special sensors or use a substance in the composition of the gas that can give it a certain smell, which will be felt even with a small amount.

- 1 Concentration of a substance to detect a leak

- 2 Properties and composition of odorants

- 3 Possible changes in the regulated norms of odorants

- 4 Safety requirements for the transportation of the SPM odorant

Methane, which is the main element of natural gas, causes severe poisoning in humans and can lead to death. An environment in which there is a high concentration of it, in the presence of an open flame, may ignite or explode.Sensors are not capable of doing this effectively enough because a really large gas leak must occur for them to work. This problem is solved by odorants for natural gas.

Odorants are special substances that are introduced into natural gas and allow you to quickly feel the presence of gas in the room. Their mixing with natural gas is called odorization and is carried out at special stations. Odorants have such qualities as:

- a strong unpleasant odor that is easily recognized by the olfactory organs;

- high stability, which ensures a stable dosage;

- high concentration, allowing to consume a smaller amount of the substance;

- low level of toxicity, ensuring the safety of operation;

- minimal corrosive effect on all elements of the system.

Finding a substance that will have all of the above properties is almost impossible. Moreover, it must meet all the requirements set forth in a special instruction issued in 1999 by Gazprom specialists.

Particular attention is paid to the safety of production, storage and transportation of odorants.

Odorization - natural gas

Orenburg field, can - be used for natural gas odorization.

Efficiency tests were carried out before the start of industrial trials of shale odorant natural gas odorization ethyl mercaptan with the determination of its content by the nephelometric method with silver nitrate at various points in the gas network. It was found that the strength of the smell of gas and the amount of odo - ranta in it are not the same.The absence of smell in some places of the network was noted even earlier even with a 2-3 times increase in the consumption of odorant, which is apparently explained by the unsaturation of gas pipelines and the presence of stagnant sections with insufficiently effective gas exchange.

At the end of the experiments with ethyl mercaptan, a transition was made to natural gas odorization slate odorant. Sample 5 was tested first with a maximum degree of odorization of 30 g/1000 nm of gas.

The safety rules in the gas industry of the Gosgortekhnadzor of the USSR establish that the degree natural gas odorization should be checked at least 3 times a month. In this case, samples must be taken at different places in the gas network, mostly remote from those points through which gas enters the network.

For odorization of artificial gases rich in carbon monoxide, the specified rate natural gas odorization should be higher and determined empirically.

Such an amount of ethyl mercaptan is extremely large and exceeds the usual consumption rates for it. odorization of natural gases about 15 times.

Such an amount of ethyl mercaptan is extremely large and exceeds the usual consumption rates for it. odorization of natural gases about 15 times.

With the currently regulated odorization rate of 16 mg/m3 of gas, for natural gas odorization Russia currently needs 2,720 tons of odorant.

To facilitate the detection of fistulas during pneumatic testing of an ethylene pipeline, the compressed air was odorized with methyl mercaptan, commonly used for natural gas odorization.

Taking into account the reduction in the smell of gas during transportation, it is recommended, in addition to organoleptic test methods, to improve and develop new chemical methods for controlling the degree of natural gas odorization.

For control, the following test was carried out: in a sealed room-chamber with a volume of 41 5l3, equipped with an agitating fan and usually used to control the degree natural gas odorization, 166 liters of gaseous propane-butane were released, which was 0 4 vol. % camera.

Commercial odorant sulfan contains from 82 to 105% MM, from 10 to 426% DMS, from 0 to 66% DMDS, not more than 34% turpentine, the rest is methanol. Norm natural gas odorization 20 g per 1000 m3, while achieving a good odorizing effect. Sulfan odorant has high performance properties: reduced viscosity at low temperatures, lower sulfur content compared to other odorants.

The light fractions of the stable condensate of the Orenburg field contain up to May 2. Currently natural gas odorization in Russia, it is carried out by adding SPM odorant to it.

Therefore, for natural gas odorization in 2030, 4,080 tons of odorant are needed.

| Controlled pressure regulator. |