- Final word

- The principle of operation of water heating

- Two-pipe heating assembly technology

- Features of two-pipe heating

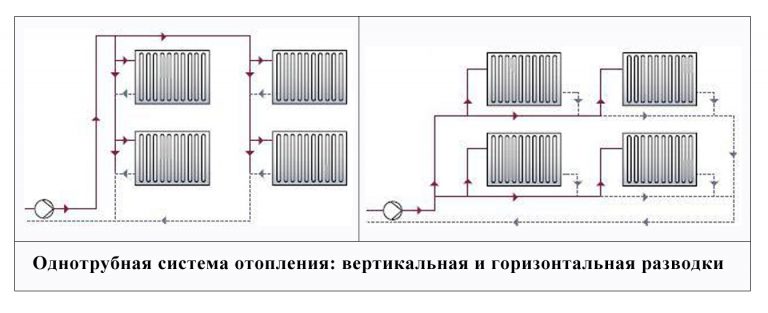

- Single pipe heating system

- Installation of a horizontal single-pipe system

- Features of installing a vertical system

- Two-pipe heating system

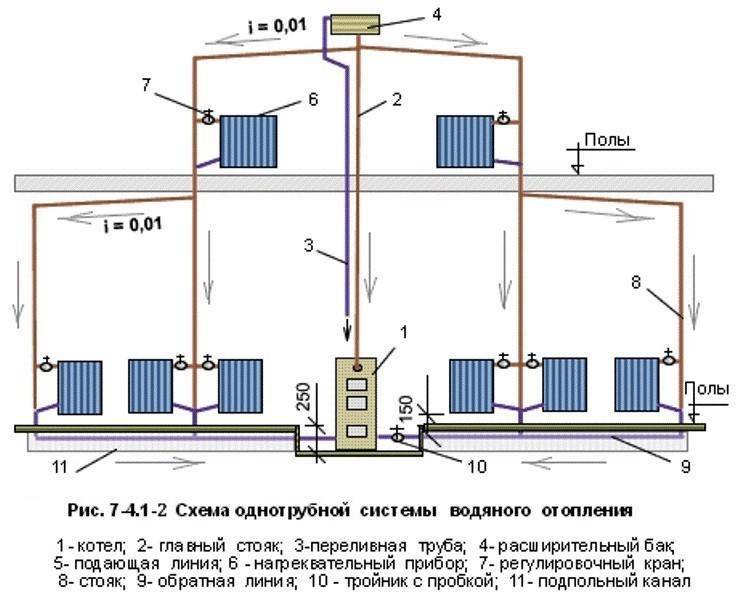

- Elements and general arrangement of a single-pipe system - briefly about the main

Final word

As can be seen from the materials presented above, the single-pipe heating scheme of a private house is a fairly convenient and simple heating option. It is used everywhere, including in apartment buildings.

Over many years of operation, this method of heating has successfully proved its simplicity and efficiency, and in the case of low-rise buildings, the use of a horizontal gravity flow scheme allows you to save electricity and not depend on external factors when heating a house.

Thus, combining the lowest cost, average efficiency, ease of maintenance and the ability to make changes at any stage - the presented option is, of course, the market leader.

Of course, there are more advanced options, such as air heating, or infrared floors, but whether they are really needed in your case, or simple and understandable one-pipe heating is exactly what you need - of course, you decide.

However, whichever option is chosen, remember one thing: you do not need to save on the materials used in the work, the performance of the entire system depends on the quality of each specific link. Do not forget Mayevsky taps to bleed air locks from radiators, filters and separators, make sure that the pump and expansion tank are really reliable, add a pressure gauge to monitor the state of affairs in the circuit in real time.

Spend a little more time and money to be completely sure that your heating will not let you down.

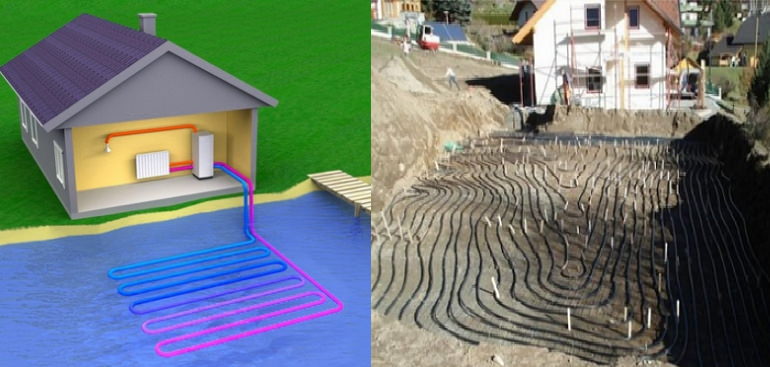

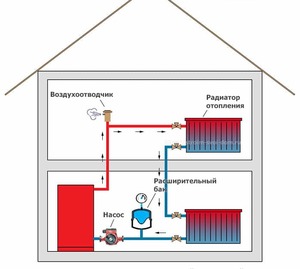

The principle of operation of water heating

In low-rise construction, the most widespread is a simple, reliable and economical design with a single line. The single-pipe system remains the most popular way to organize individual heat supply. It functions due to the continuous circulation of the heat transfer fluid.

Moving through the pipes from the source of thermal energy (boiler) to the heating elements and back, it gives up its thermal energy and heats the building.

The heat carrier can be air, steam, water or antifreeze, which is used in houses of periodic residence. The most common water heating schemes.

Traditional heating is based on the phenomena and laws of physics - thermal expansion of water, convection and gravity. Heating up from the boiler, the coolant expands and creates pressure in the pipeline.

In addition, it becomes less dense and, accordingly, lighter. Pushed from below by heavier and denser cold water, it rushes upwards, so the pipeline leaving the boiler is always directed as far as possible upwards.

Under the action of the created pressure, convection forces and gravity, the water goes to the radiators, heats them up, and at the same time cools itself.

Thus, the coolant gives off thermal energy, heating the room. The water returns to the boiler already cold, and the cycle begins anew.

Modern equipment that provides heat supply to the house can be very compact. You don't even need a special room to install it.

A heating system with natural circulation is also called gravity and gravity. To ensure the movement of liquid, it is necessary to observe the slope angle of the horizontal branches of the pipeline, which should be equal to 2 - 3 mm per linear meter.

The volume of the coolant increases when heated, creating hydraulic pressure in the line. However, since water is not compressible, even a slight excess will lead to the destruction of heating structures.

Therefore, in any heating system, a compensating device is installed - an expansion tank.

In a gravity heating system, the boiler is mounted at the lowest point of the pipeline, and the expansion tank is at the very top. All pipelines are sloped so that the coolant can move by gravity from one element of the system to another

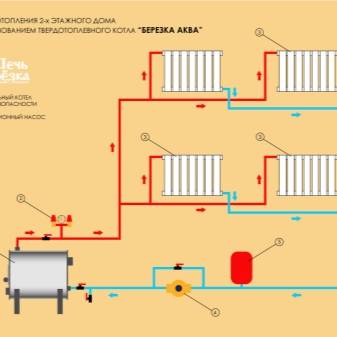

Two-pipe heating assembly technology

Gone are the days when, in order to “weld” heating, bulky equipment was required, and most importantly, a lot of experience in using it. Today, anyone can relatively inexpensively purchase the necessary set of tools and mount the system with their own hands. Of course, some skills are required, but the main thing is desire.

When performing work, the sequence of actions should be as follows:

Installing the boiler, it is from him that all subsequent manipulations must begin. It is better to choose a separate room as the installation site, which must meet the requirements for the installation of gas equipment. If heating involves natural circulation, then the boiler must be placed as low as possible.

An expansion tank is installed. In contrast to the boiler, the highest point is selected for it. In this case, it is better to install it in a heated room. When placed in attics and cold attics, you need to take care of insulation. It is advisable to think over, at least a primitive, alarm about the water level.

Next to the boiler, on the outlet pipe, a pump is mounted

It is important to follow the direction of the arrow. She should look at the heater.

Radiators are installed with air vents installed.

According to a pre-designed scheme, a pipeline is mounted. With natural circulation, one should not forget about the obligatory slope.

Radiators are connected to the pipeline.

Connection to water supply and sewerage

This is necessary to fill the system and emergency discharge of water from it.

Now you can check the system for leaks.

With natural circulation, one should not forget about the obligatory slope.

Radiators are connected to the pipeline.

Connection to water supply and sewerage. This is necessary to fill the system and emergency discharge of water from it.

Now you can check the system for leaks.

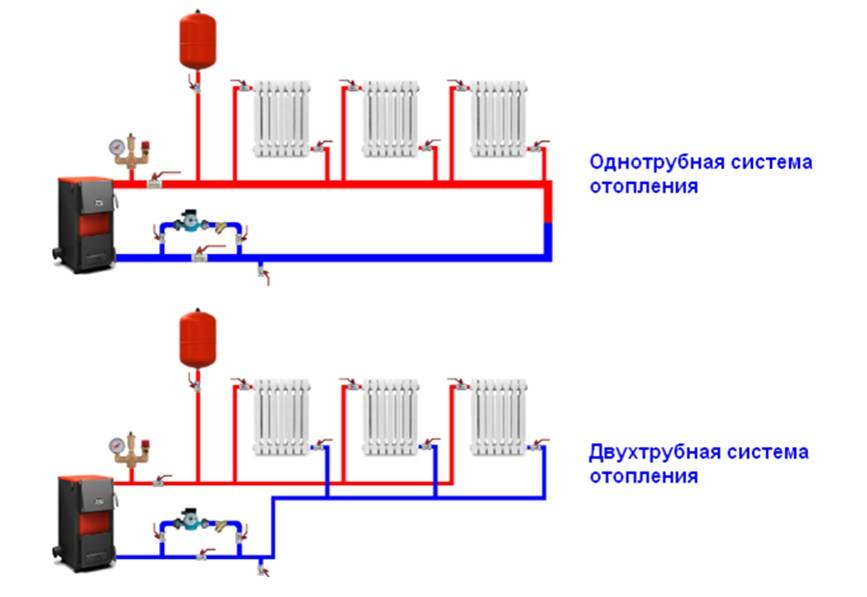

Features of two-pipe heating

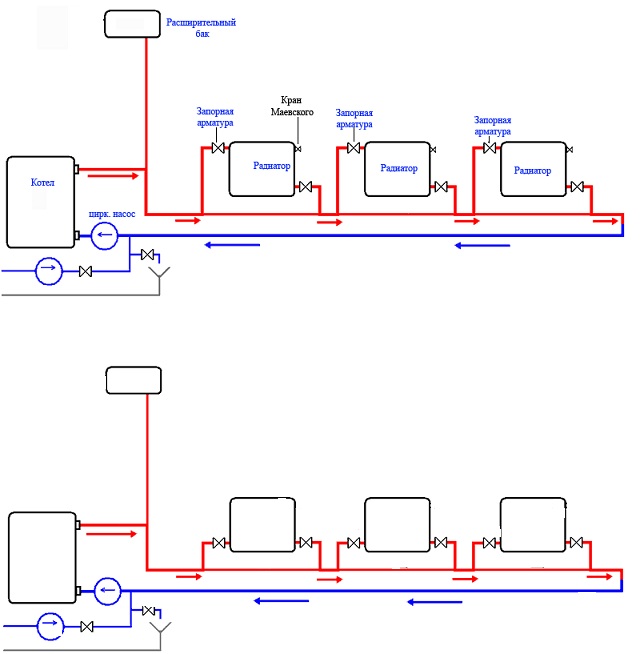

Any heating system with a liquid heat carrier includes a closed circuit connecting radiators that heat the room and a boiler that heats the coolant.

Everything happens as follows: the liquid, moving through the heat exchanger of the heater, is heated to a high temperature, after which it enters the radiators, the number of which is determined by the needs of the building.

Here, the liquid gives off heat to the air and gradually cools. Then it returns to the heat exchanger of the heater and the cycle repeats.

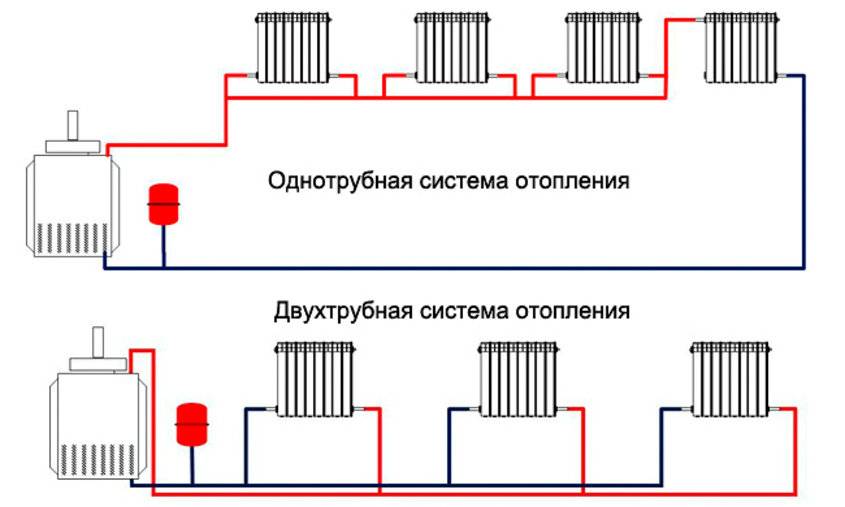

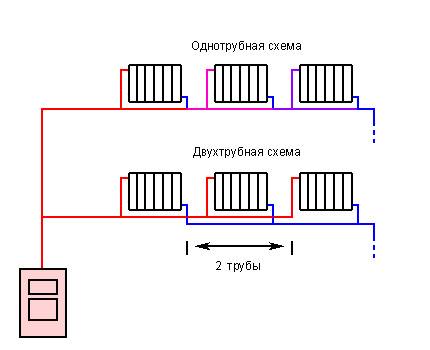

The circulation is as simple as possible in a single-pipe system, where only one pipe is suitable for each battery. However, in this case, each next battery will receive the coolant that came out of the previous one, and, therefore, colder.

A distinctive feature of the two-pipe system is the presence of a supply and return pipe suitable for each radiator

To eliminate this significant drawback, a more complex two-pipe system was developed.

In this embodiment, two pipes are connected to each radiator:

- The first is the supply line, through which the coolant enters the battery.

- The second is the outlet or, as the masters say, the “return”, through which the cooled liquid leaves the device.

Thus, each radiator is equipped with an individually adjustable coolant supply, which makes it possible to organize heating as efficiently as possible.

Since the supply of heated coolant to the devices is carried out almost simultaneously by one pipe, and the collection of cooled water by another, two-pipe systems are distinguished by an optimal thermal balance - all the batteries of the system and the circuits connected to it operate with almost equal heat transfer

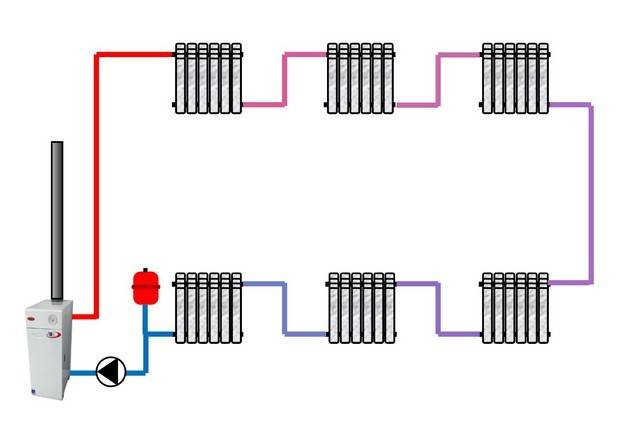

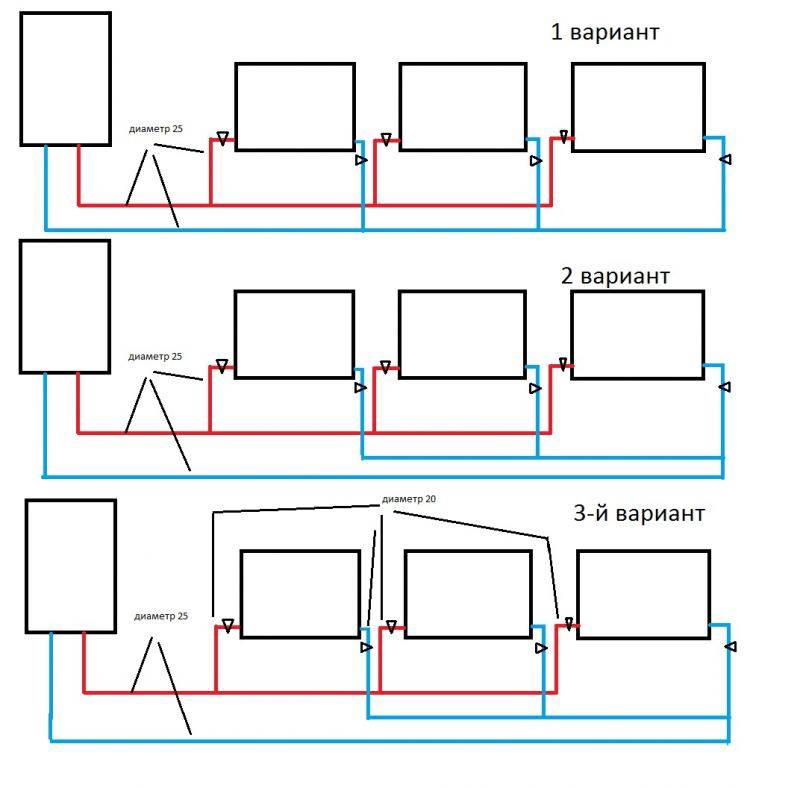

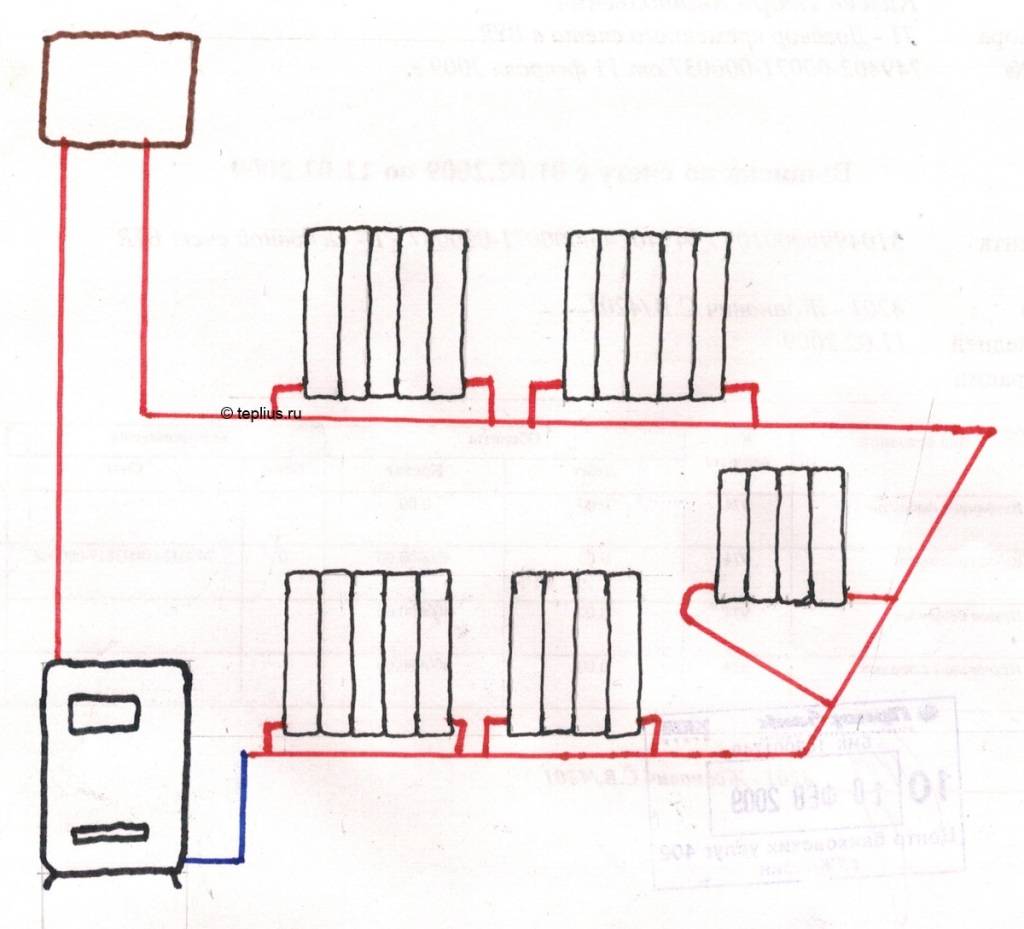

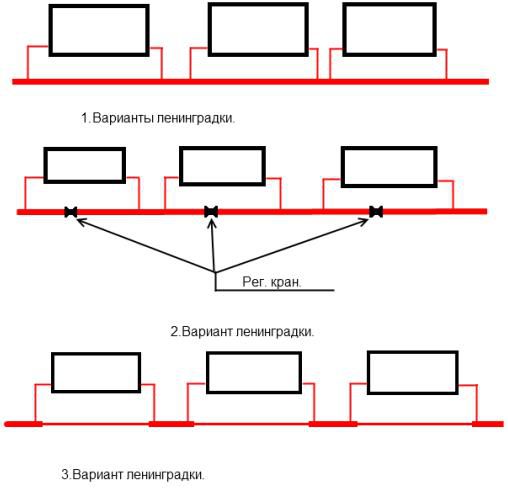

Single pipe heating system

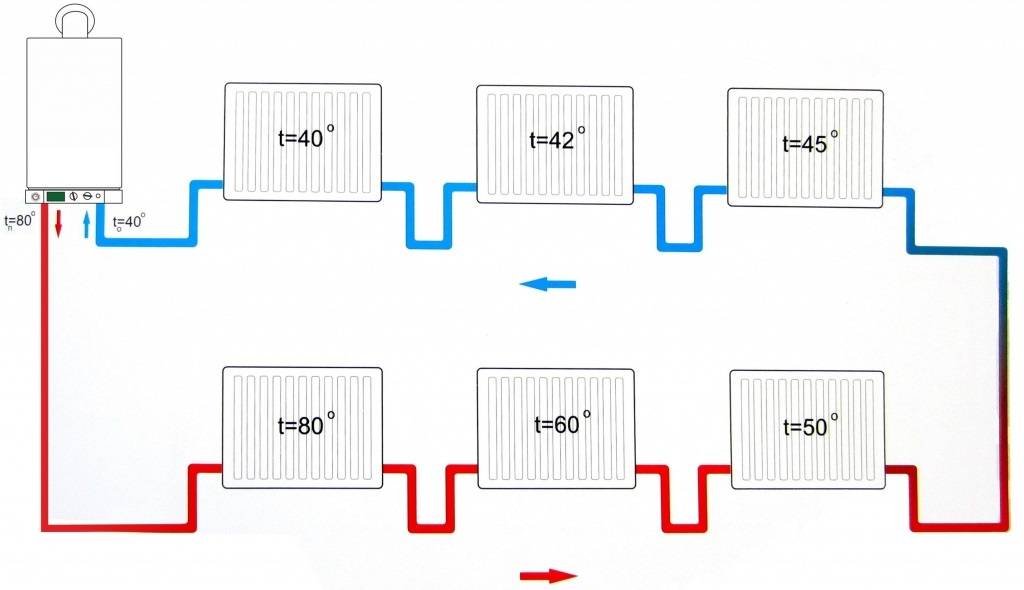

A single-pipe heating system of the Leningradka type has a fairly simple device scheme. A supply line is laid from the heating boiler, to which the required number of radiators is connected in series.

After passing through all the heating elements, the heating pipe returns to the boiler. Thus, this scheme allows the coolant to circulate in a vicious circle, along the circuit.

The circulation of the coolant can be either forced or natural. In addition, the circuit can be a closed or open type heating system, this will depend on the source of coolant you have chosen.

To date, a single-pipe Leningradka scheme can be mounted taking into account the requirements of modern construction for private housing. At your request, the standard scheme can be supplemented with radiator regulators, ball valves, thermostatic valves, as well as balancing valves.

By installing these add-ons, you can qualitatively improve the heating system, making it more convenient for controlling the temperature regime:

- Firstly, you can reduce the temperature in those rooms that are rarely used or not used at all, while it is always recommended to leave the minimum value to maintain the room in good condition, or vice versa, increase the temperature in the children's room;

- Secondly, the improved system will allow lowering the temperature in a separate heater without affecting or lowering the temperature regime of the next one following it.

In addition, it is recommended to include a scheme of taps on bypasses for connecting heating radiators to the one-pipe system of Leningradka.

This will make it possible to repair or replace each heater independently of the others and without the need to shut down the entire system.

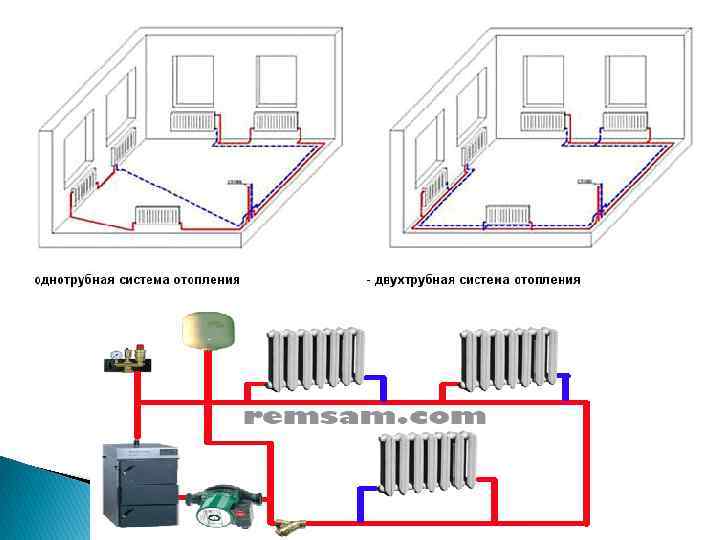

Installation of a horizontal single-pipe system

Set horizontal Leningradka heating system quite simple, but it has its own characteristics that should be considered when planning a private house:

The line must be installed in the plane of the floor.

With a horizontal installation scheme, the system is laid either in the floor structure, or it is laid on top of it.

In the first option, you need to take care of reliable thermal insulation of the structure, otherwise you cannot avoid significant heat transfer.

When installing heating in the floor, the flooring is mounted directly under the Leningradka. When installing a one-pipe heating system on the floor, the installation scheme can be processed during construction.

The supply line is installed at an angle in such a way as to create the necessary slope in the direction of movement of the coolant.

Heating radiators must be installed at the same level.

Before the start of the heating season, air bubbles are removed from the system using Mayevsky taps, which are installed on each radiator.

Features of installing a vertical system

The vertical connection scheme of the Leningradka system, as a rule, with forced circulation of the coolant.

This scheme has its advantages: all radiators heat up faster, even with small diameter pipes in the supply and return lines, however, this scheme requires a circulation pump.

If the pump was not provided, the circulation of the coolant is carried out by gravity, without the use of electricity. This suggests that water or antifreeze moves due to the laws of physics: the changed density of a liquid or water when heated or cooled provokes the movement of masses.

A gravity system requires the installation of large diameter pipes and the installation of a line at an appropriate slope.

Such a heating system does not always organically fit into the interior of the room, and there may also be a danger of not reaching the main line to the destination.

With a vertical pumpless system, the length of the Leningrad can not exceed 30 m.

Bypasses are also provided in the vertical system, allowing dismantling of individual elements without shutting down the entire system.

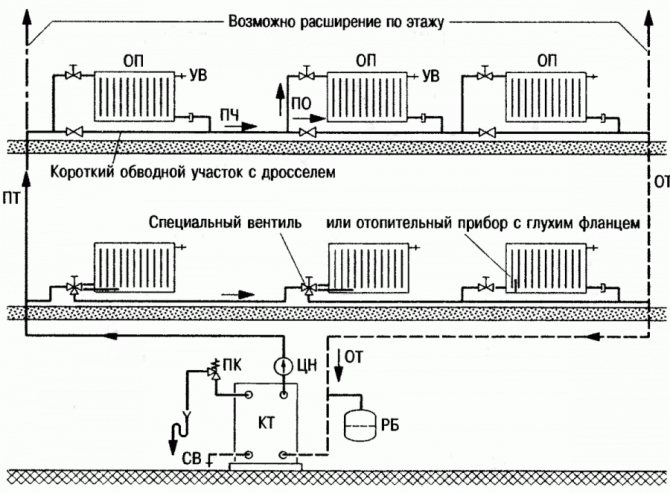

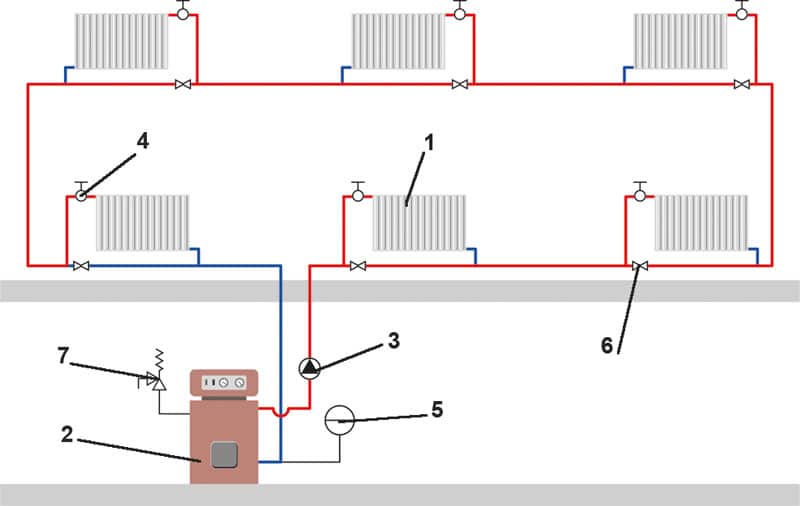

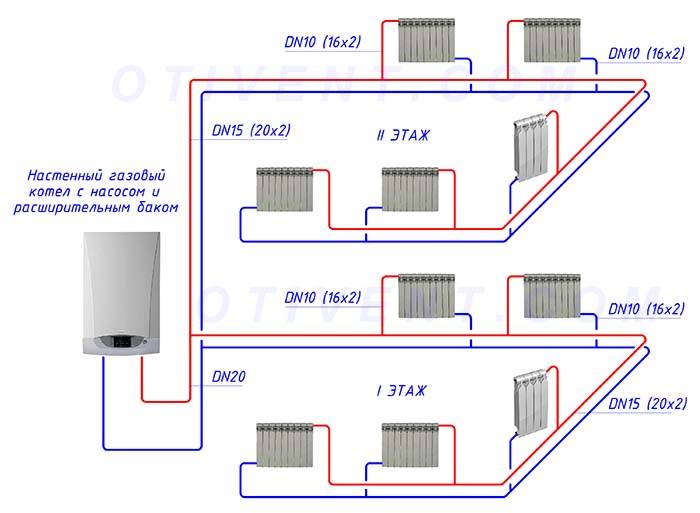

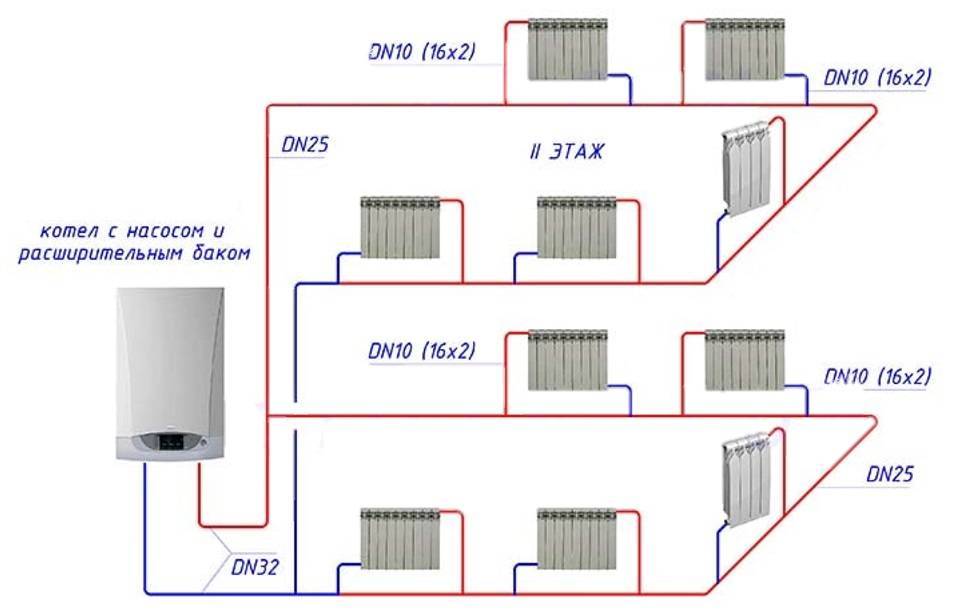

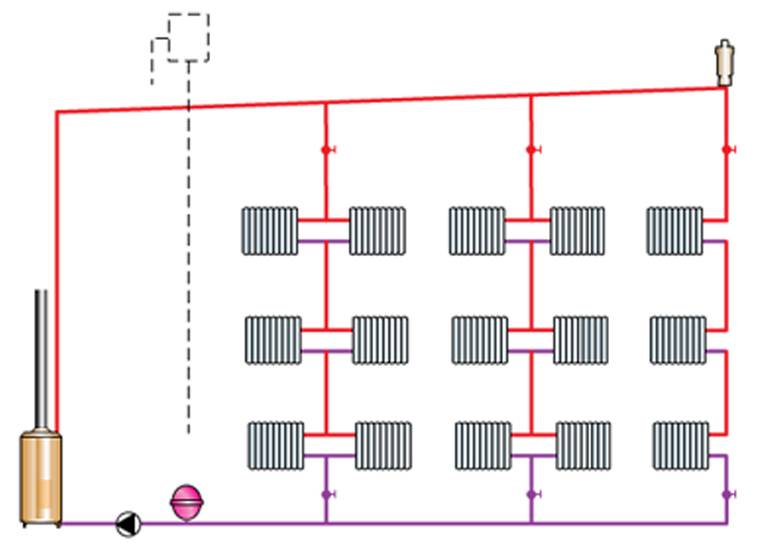

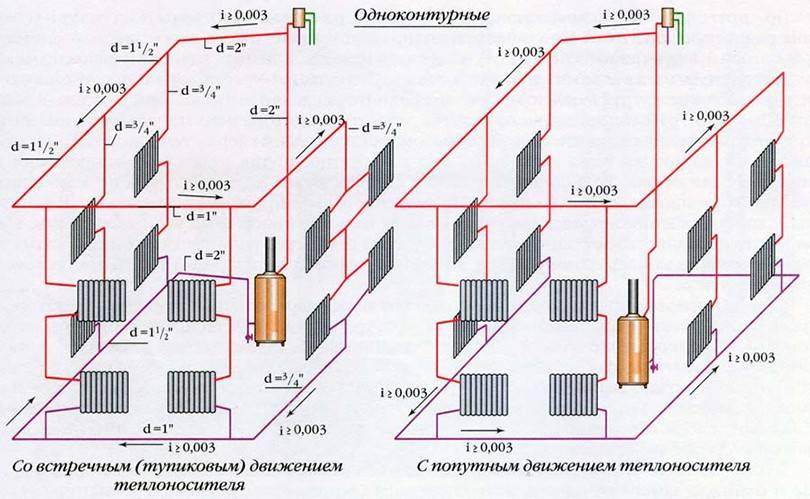

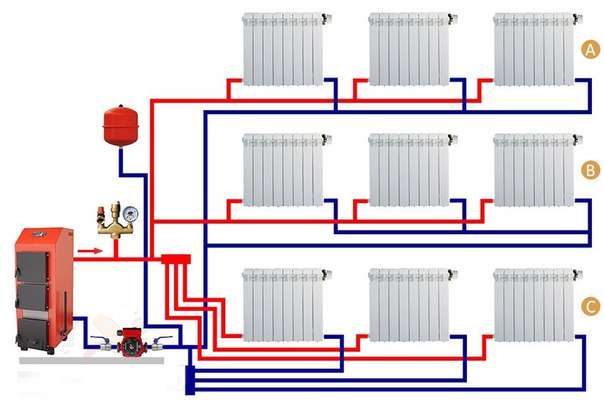

Two-pipe heating system

The scheme of a two-pipe system with forced circulation is distinguished from a single-pipe system by the presence of another route for the cooled coolant. It flows parallel to the main system, and cold water from the radiators enters it.

The scheme of a two-pipe system with forced circulation is distinguished from a single-pipe system by the presence of another route for the cooled coolant. It flows parallel to the main system, and cold water from the radiators enters it.

During the design of a two-pipe system, it is necessary to correctly form the layout of the pipelines. The direct and opposite two-pipe line must be installed in the same way with each other, however, not more than 15 cm apart, in addition, this system can be with one direction of movement of the coolant, with different vectors, and besides, it can be dead-end. Most of all, the model with one-way orientation is chosen.

Peculiarities:

- Small pipe diameter - from 15 to 24 millimeters. This will be enough to form the necessary pressure characteristics;

- Possibility of designing both horizontal and vertical piping;

- A huge number of rotary components will affect the hydrodynamic data of the system for the worse. Therefore, they should be made as small as possible;

- When selecting a hidden connection, an inspection hatch is installed in the pipe connection areas.

In any forced system, a bypass must be provided in the circulating pump assembly. It is designed for gravitational movement of the coolant in the event of power outages and connections.

The operation of the pumping equipment must guarantee normal circulation in the system. To do this, it is necessary to correctly calculate its performance and efficiency.

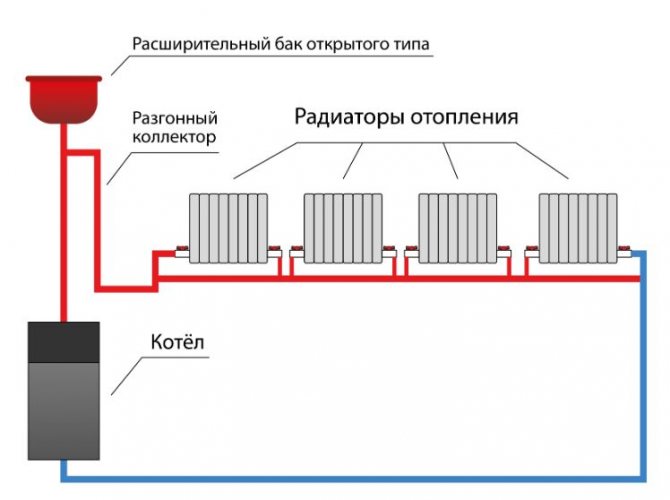

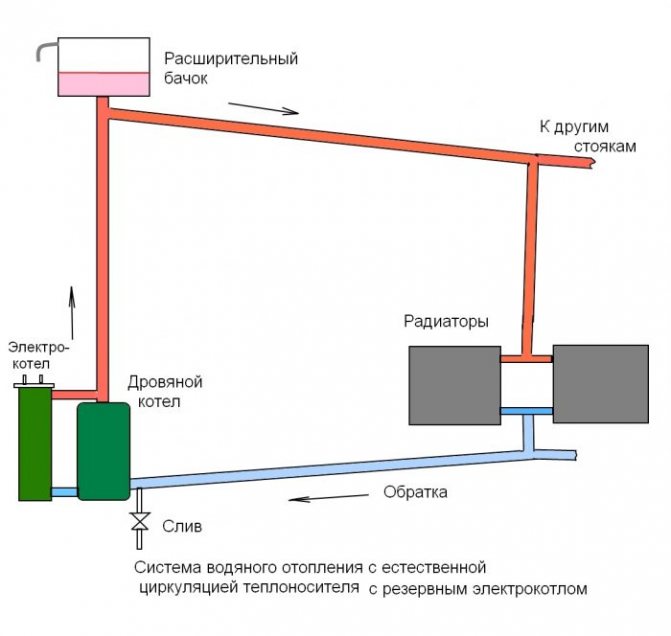

Elements and general arrangement of a single-pipe system - briefly about the main

The considered heating circuit is a closed circuit. It integrates:

- special equipment necessary for stable circulation of hot water;

- pipeline (main);

- expansion tank;

- batteries;

- heating unit (for example, solid fuel boiler).

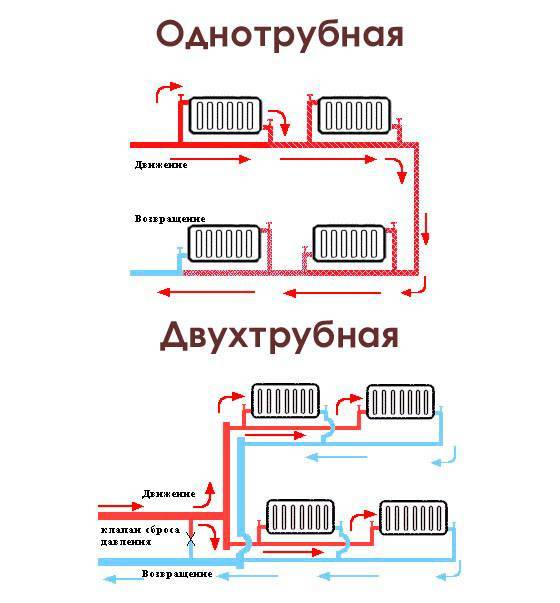

The circulation of the coolant in single-pipe systems can be forced or natural. In a natural process, the coolant moves due to the fact that the water in the system is characterized by different density indicators. The scheme in this case is:

- hot water, which has a lower density than cold water, is forced out last into the system;

- the heated liquid rises to the top point along the riser, and then it begins to move along the main pipe;

- from the main pipe, the coolant flows to the radiators.

For the operation of such a scheme, it is required to provide a 3-5-degree slope of the highway. This is not always realistic. If you have a fairly large house with an extensive heating system, natural circulation is not suitable for it. For each meter of the length of the highway, in this case, it will be necessary to provide for a height difference of 5–7 cm.

When using forced circulation, which involves the installation of a special pump, the slope of the line is taken to be minimal. It is enough that it provides a height difference of about 0.5 cm per meter of pipe. The pump is placed in front of the entrance to the heating unit - on the return line of the circuit. The circulation device generates a pressure that is sufficient to maintain the coolant in the batteries in the required temperature range.

Circulation device for maintaining coolant in batteries

The pump is powered by electricity. If your light is turned off, it will not function. Naturally, the whole system will stop. It's easy to avoid this. Just put a special pipe into the system with your own hands. It is called an accelerating collector.It raises hot water to a height of 1.5–1.8 m and guarantees heating even when the electricity is turned off.

Note! At the top of the collector, a line outlet is necessarily made. It is connected to an expansion tank, which performs an important function - it corrects the pressure in the system

The expansion tank eliminates the risk of an extreme increase in the load on the boiler and all heating elements. It is open and closed.

Open type dilators are now rarely used. In them there is an active interaction of oxygen with hot water. This leads to corrosion and early failure of metal batteries and tubular products.

In closed tanks, air does not come into contact with water. In such designs there is a membrane flexible element. On one side of it, an outlet is made for hot water, on the other, air is pumped with high pressure. Closed expanders are mounted anywhere in the system (an open tank is always installed at the top of the manifold).