- Mounting

- What to choose: one-pipe or two-pipe heating system

- Modernization of single-pipe heating systems

- The principle of operation of a single-pipe heating system

- Mounting Features

- Advantages and disadvantages

- One-pipe and two-pipe water heating systems

- Two-pipe system with bottom wiring

- Advantages and disadvantages of a two-pipe system with bottom wiring

- Features of mounting a two-pipe system with bottom wiring

- Comparative analysis

- Types of heating systems with gravity circulation

- Closed system with gravity circulation

- Open system with gravity circulation

- Single pipe system with self-circulation

- Two-pipe system with self-circulation

- Two-pipe heating system

- pros

- Minuses

- open tank

Mounting

- Do not save too much money and time on the installation of the heating system.

- The heating main includes 2 pipes. One way the coolant is supplied to the radiators, and the other way it returns to the boiler.

- The pipe supplying water to the batteries must be higher than the one that gives water to the boiler.

- Do not save on radiator valves, bypasses and other devices that improve the operation of the heating system.

- Do not allow the line to have sharp corners that could create traffic jams or resistance.

- The supply pipe must be well insulated, then there will be minimal heat loss.

- The expansion tank should also be installed in a warm place.

Boiler installation. This is the very first step. It is best when it is in a separate place. There must be good ventilation to ventilate the products of combustion. Around it, it is necessary that the walls and floor are fireproof. In addition, the apparatus must always have free access for convenient maintenance and control.

A pipe is diverted from it to the expansion tank.

Circulation pump. It is mounted after the boiler. Together with it, a manifold cabinet with all necessary equipment is installed.

Pipe wiring. They are carried out from the boiler to the places where the batteries are located.

At this stage, it is important to be very careful and carefully connect the pipes.

Connecting radiators. 2 pipes are connected to each device. At the top, a pipe is mounted supplying the coolant, and at the bottom, carrying away the cooled water

The batteries themselves are mounted under the window on the brackets. From the window sill, the battery should be at a distance of about 100mm, from the wall 20-50mm, from the floor 100-120mm. Shut-off valves are mounted on the sides of the radiator, thanks to which the battery will be turned off without disturbing the operation of the entire system. After completing the installation of radiators, carefully check the tightness of their connections with pipes.

At the top, a pipe is mounted supplying the coolant, and at the bottom, carrying away the cooled water. The batteries themselves are mounted under the window on the brackets. From the window sill, the battery should be at a distance of about 100mm, from the wall 20-50mm, from the floor 100-120mm.Shut-off valves are mounted on the sides of the radiator, thanks to which the battery will be turned off without disturbing the operation of the entire system. After completing the installation of radiators, carefully check the tightness of their connections with pipes.

What to choose: one-pipe or two-pipe heating system

There are only two types of heating systems: one-pipe and two-pipe. In private homes, they try to install the most efficient heating system.

It is very important not to sell too cheap, trying to reduce the cost of buying and installing a heating system. Providing heat at home is a lot of work, and in order not to have to reinstall the system, it is better to understand it thoroughly and make “reasonable” savings.

And in order to draw a conclusion about which of the systems is better, it is necessary to understand the principle of operation of each of them. Having studied the advantages and disadvantages of both systems, both from the technical side and from the material side, it becomes clear how to make the best choice.

Modernization of single-pipe heating systems

A technical solution that makes it possible to regulate the operation of each individual heater has been developed.

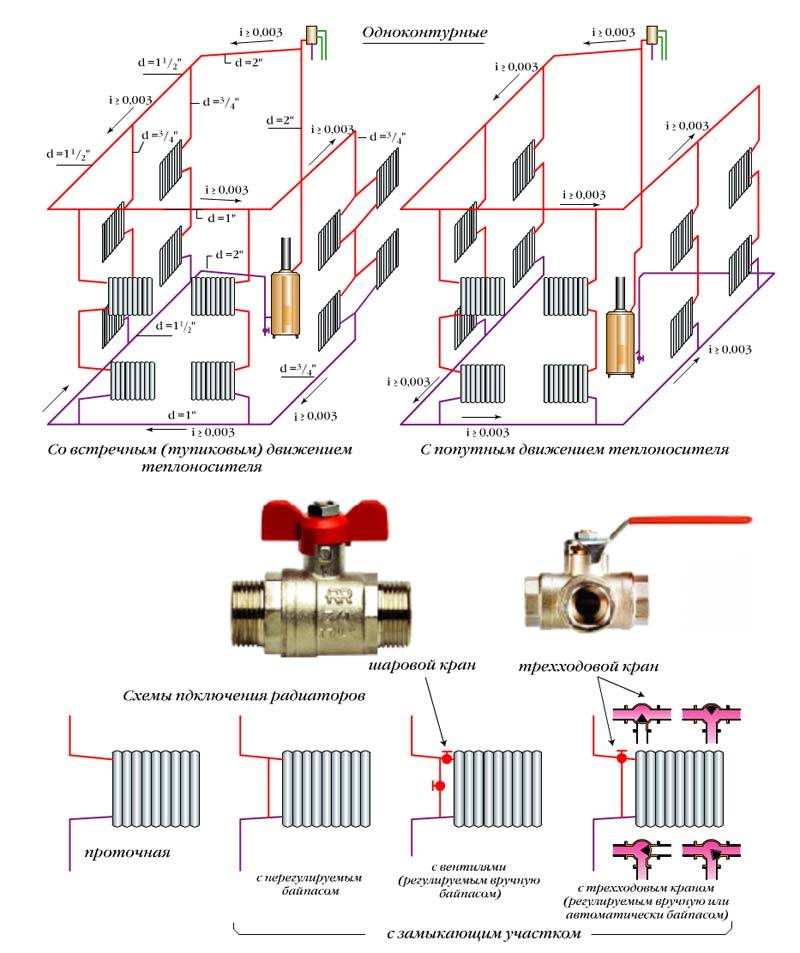

It consists in connecting special closing sections (bypasses), which make it possible to embed automatic radiator thermostats in heating. What other benefits are possible with the installation of bypasses? We will talk about this in detail later.

Bypass (appearance)

Bypass operation diagram

The main advantage of such a modernization is that in this case it becomes possible to regulate the heating temperature of each battery or radiator. In addition, you can completely shut off the coolant supply to the device.

Due to this, such a heater is repaired or replaced without shutting down the entire system.

Bypass is a bypass pipe equipped with valves or taps. With the correct connection of such fittings to the system, it will allow you to redirect the flow of water through the riser, bypassing the repaired or replaced heater.

It is not difficult to understand that the task of installing such devices into the system with your own hands is hardly possible to solve, even if detailed instructions are available. In this case, one cannot do without the participation of a specialist.

A heating system with one main riser should be equipped with heating devices that have improved characteristics in terms of reliability. Any devices in a one-pipe system must withstand increased pressure and high temperature.

The principle of operation of a single-pipe heating system

The single pipe heating structure consists of a single main piping. It supplies the coolant to the convectors installed in series and discharges it after exhaustion. At the same time, the temperature of the liquid gradually decreases towards the finish point. A classic system of this type does not provide for the presence of individual temperature controllers on the batteries.

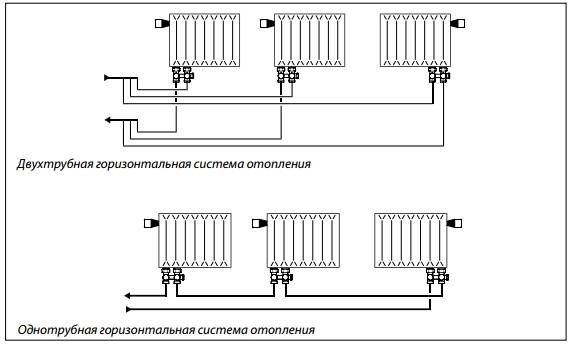

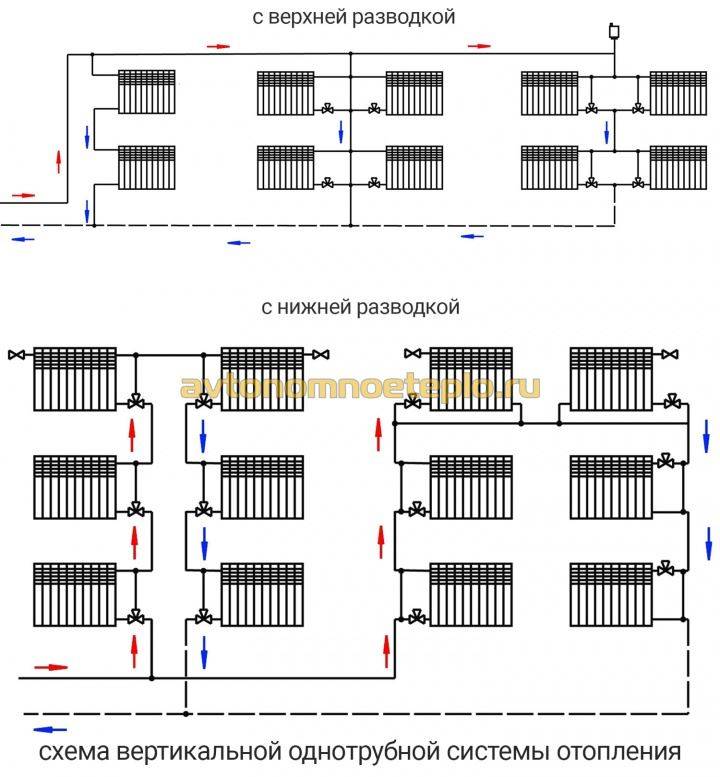

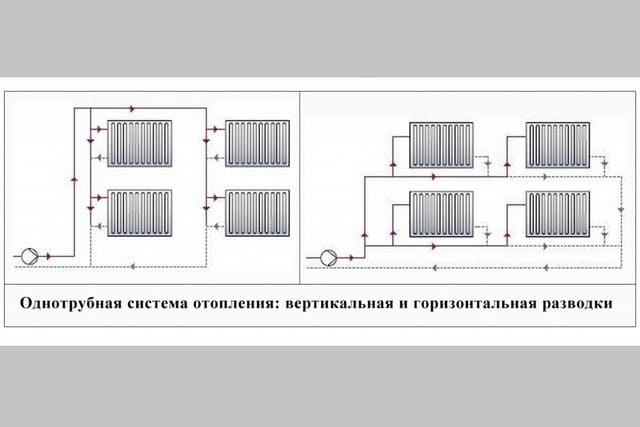

The horizontal single-pipe piping scheme is a chain of radiators connected to a horizontal heat pipe. The vertical contour is used in multi-storey buildings.

The liquid passes through the main pipeline upwards with the help of a hydraulic pump and returns downwards, overcoming the chain of radiators. Due to the successive dilution of the hot liquid, the waste on the lower floor is always cooler than on the last one.

The vertical and horizontal scheme includes a boiler, radiators, an expansion tank for pressure stabilization, prevention of liquid overheating and water hammer, a water supply system, which includes drain valves, inlets, valves and bypasses.

The bypass is a backup fluid path in case of an emergency. This is a piece of pipe connecting the supply and discharge pipes of the convector. Bypass allows the use of batteries with automatic thermostats, which significantly increases the efficiency of this type of heating.

The circuit with a lower connection provides for the supply of liquid to the convector from below and works only if there is an accelerating manifold or a hydraulic pump. With the top supply, the liquid enters the radiator from above, and flows out diagonally from the bottom. There is no bypass in this scheme.

Mounting Features

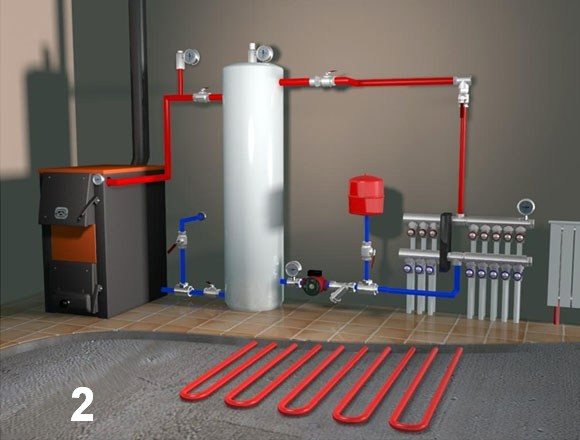

The heating boiler is installed in the basement or basement. An expansion tank of a closed type is also placed here. For a bottom-wired structure, the supply heat pipe is laid along the floor of the first floor or basement, and a vertical main pipe is already connected to it, going to the upper floors.

In a building with an upper wiring, the liquid is immediately supplied to the highest point located in the attic or under the ceiling of the upper floor. An open expansion tank is also installed here. Then, through convectors connected in series, the waste liquid returns to the heating device.

The modern single-pipe design provides for the presence of tees and bypasses at the connection point of each heating radiator.If it is planned to move the coolant by gravity, the line should have a slope of 3-5º per linear meter of the pipe. If the movement of fluid in the system is forced, the slope should be 10 mm per linear meter.

Since the circulation hydraulic pump operates at a temperature not higher than + 60ºС, it is mounted after the last heating radiator, at the entrance of the return line to the boiler.

Convectors are connected in sequential order. For each, a Mayevsky crane is installed for air release, a shut-off valve, a plug.

To check the reliability of the connections, the assembled system is filled with air or water under pressure, and only after that - with the selected coolant for adjusting the control elements.

Advantages and disadvantages

- Cooling of the heat carrier during transportation, which does not allow uniform heating of all premises of the building.

- The number of coolants in the circuit is limited to 10. More units will make the design inefficient.

- To ensure the operation of a single-pipe structure in a multi-storey building, a powerful hydraulic pump capable of pumping water through a battery circuit is required. His work is often accompanied by water hammer, due to which leaks are possible.

- To increase efficiency, the installation of a single-pipe type system is carried out using additional nodes. For example, jumpers are installed on each floor to balance the temperature and the number of sections for convectors on the lower floors is increased.

Advantages:

- The presence of bypasses, balancing valves, ball valves and shutoff valves allows you to repair a damaged unit without shutting down the entire circuit.

- Profitability. Installation of the system requires 2 times less materials.

- Ease of design and installation, which also reduces the cost of the project.

- Compactness.

One-pipe and two-pipe water heating systems

There are also single-pipe and two-pipe water heating systems. In a single-pipe system, radiators are connected to the heating system in series, in two-pipe systems in parallel.

That's all about the basic principles of water heating! Warmth for your home.

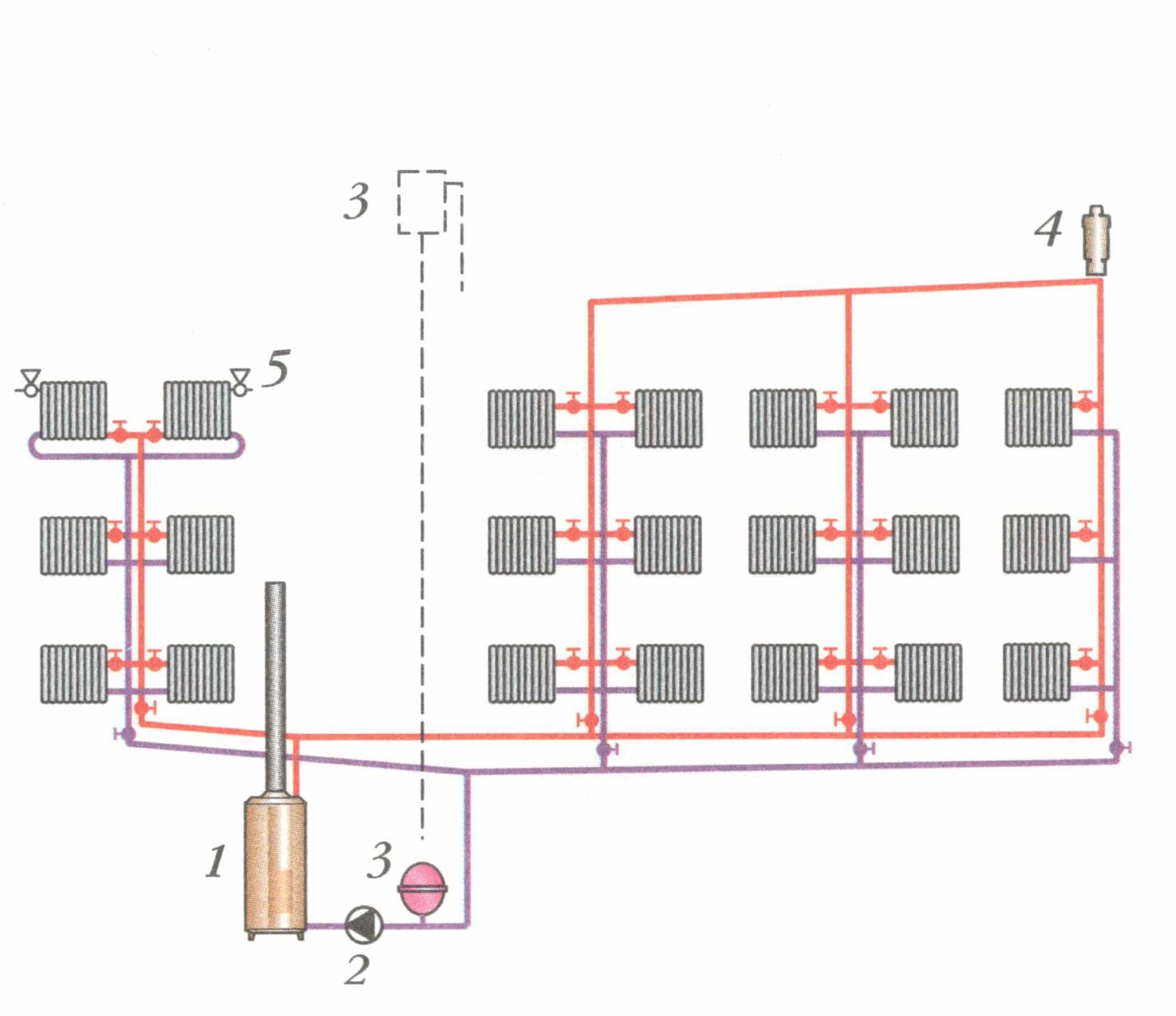

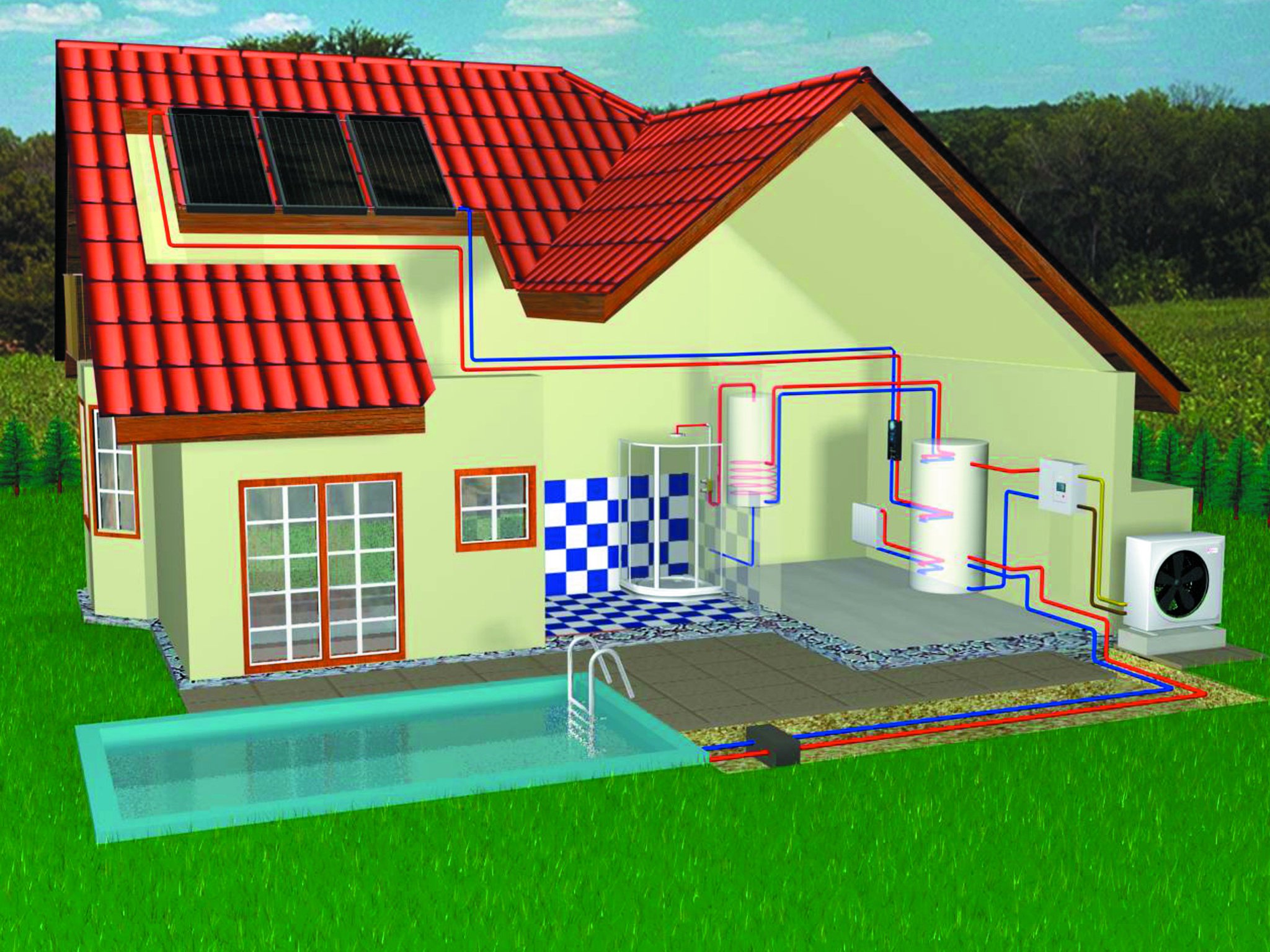

Several visual designed drawings of water heating systems:

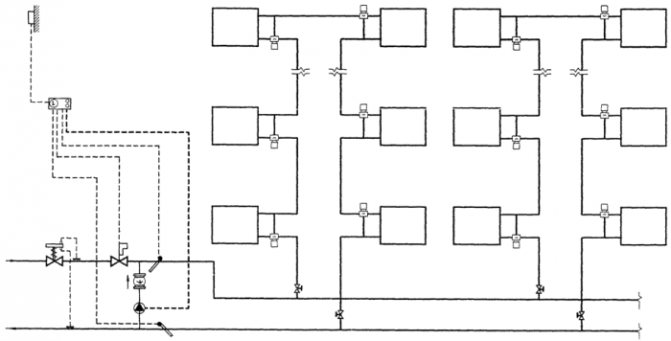

Closed, two-circuit closed water heating system with a DHW tank with Expansomat

Closed, two-circuit closed water heating system

Closed single-circuit heating system

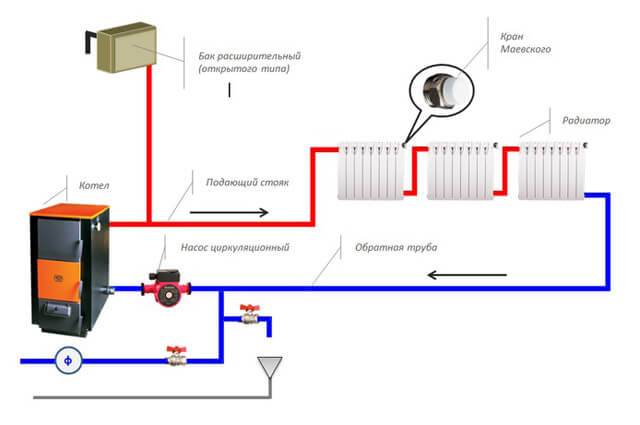

Open water heating system with artificial circulation and expansion tank

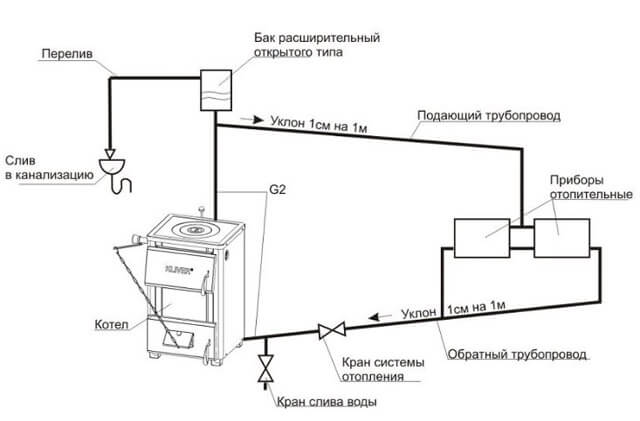

Open water heating system with natural circulation and expansion tank

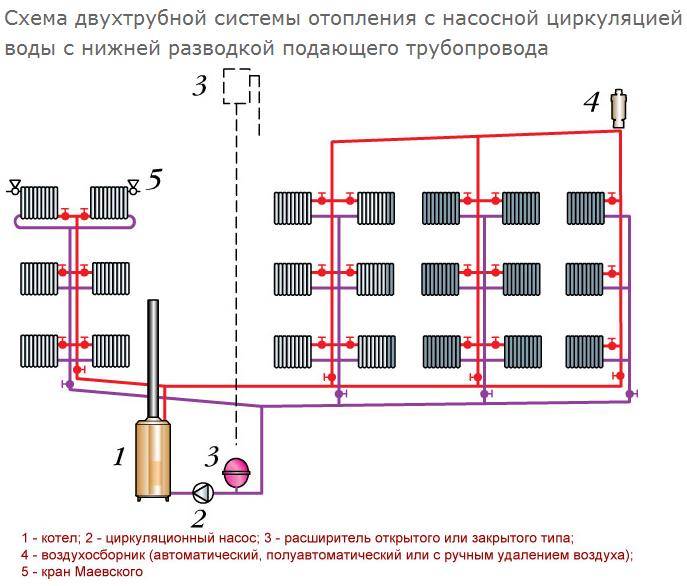

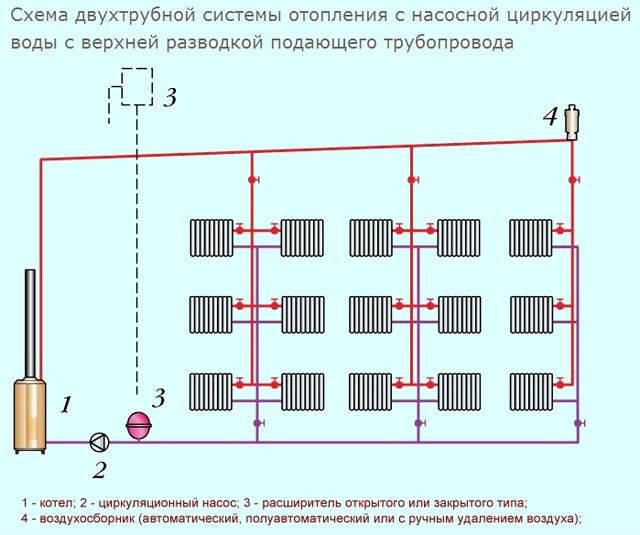

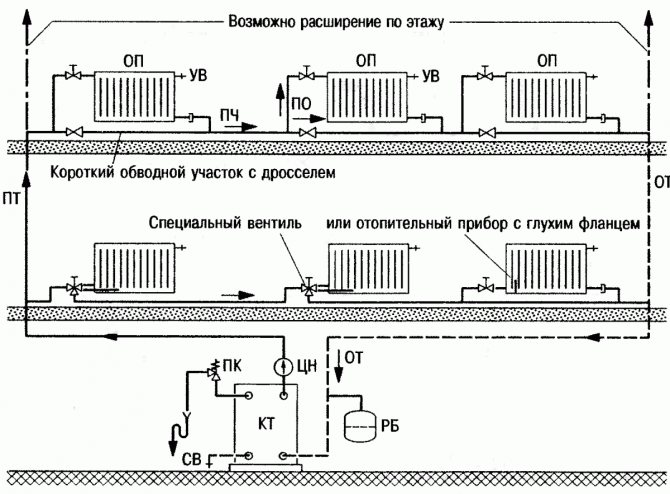

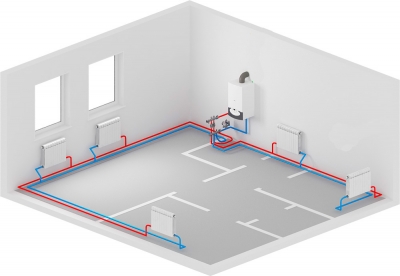

Two-pipe system with bottom wiring

Next, we will consider two-pipe systems, which are distinguished by the fact that they provide an even distribution of heat even in the largest households with many rooms. It is the two-pipe system that is used to heat multi-storey buildings, in which there are a lot of apartments and non-residential premises - here such a scheme works great. We will consider schemes for private houses.

Two-pipe heating system with bottom wiring.

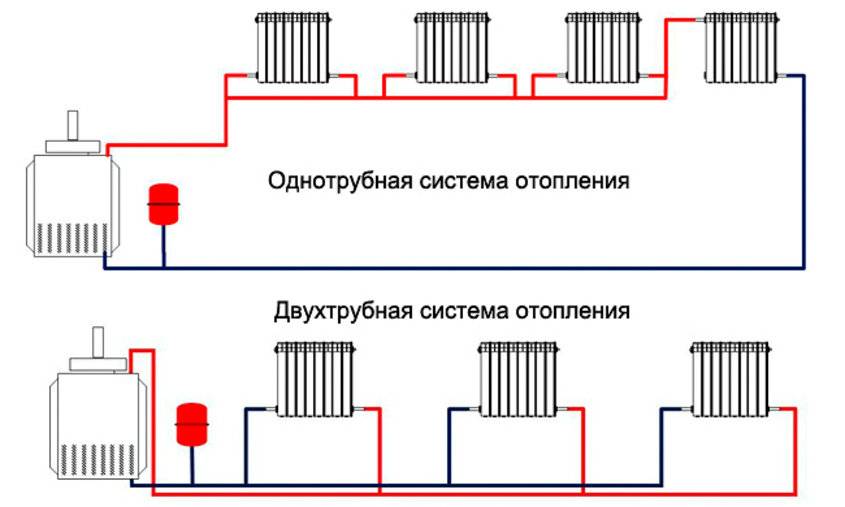

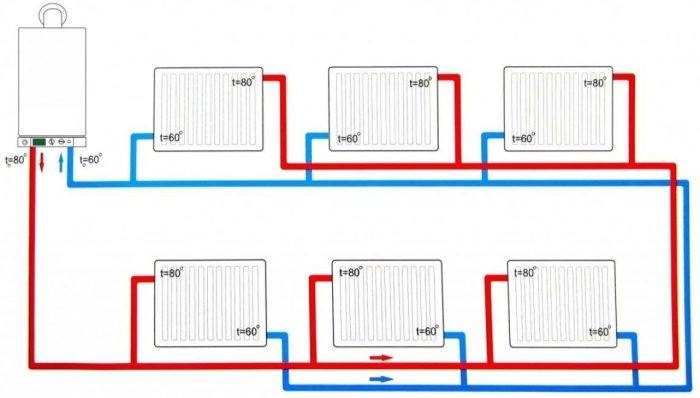

A two-pipe heating system consists of a supply and return pipes. Radiators are installed between them - the radiator inlet is connected to the supply pipe, and the outlet to the return pipe. What does it give?

- Uniform distribution of heat throughout the premises.

- Possibility to regulate the temperature in the rooms by completely or partially blocking individual radiators.

- Possibility of heating multi-storey private houses.

There are two main types of two-pipe systems - with lower and upper wiring. To begin with, we will consider a two-pipe system with a bottom wiring.

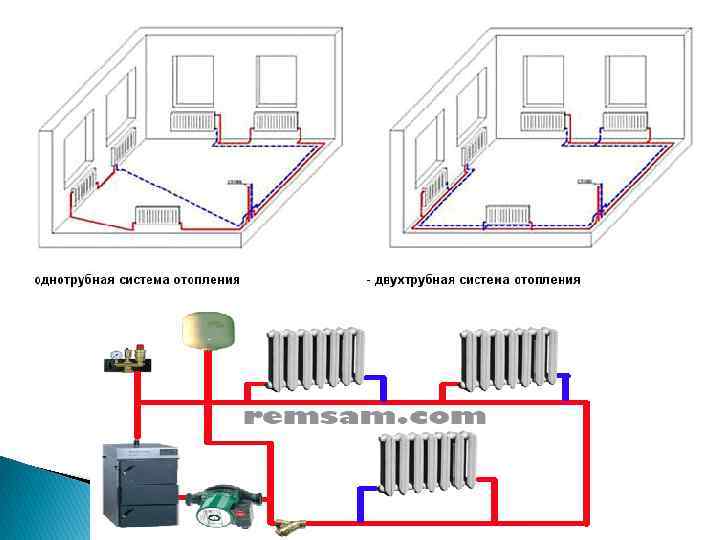

Lower wiring is used in many private homes, as it allows you to make heating less visible. The supply and return pipes pass here next to each other, under the radiators or even in the floors. Air is removed through special Mayevsky taps. Heating schemes in a private house made of polypropylene most often provide for just such a wiring.

Advantages and disadvantages of a two-pipe system with bottom wiring

When installing heating with a lower wiring, we can hide the pipes in the floor.

Let's see what positive features two-pipe systems with bottom wiring have.

- The possibility of masking pipes.

- The possibility of using radiators with a bottom connection - this somewhat simplifies installation.

- Heat losses are minimized.

The ability to at least partially make heating less visible attracts many people. In the case of the bottom wiring, we get two parallel pipes running flush with the floor. If desired, they can be brought under the floors, providing for this possibility even at the design stage of the heating system and the development of a project for the construction of a private house.

If you use radiators with a bottom connection, it becomes possible to almost completely hide all the pipes in the floors - the radiators are connected here using special nodes.

As for the disadvantages, they are the need for regular manual removal of air and the need to use a circulation pump.

Features of mounting a two-pipe system with bottom wiring

Plastic fasteners for heating pipes of different diameters.

In order to mount the heating system according to this scheme, it is necessary to lay the supply and return pipes around the house. For these purposes, there are special plastic fasteners on sale. If radiators with side connection are used, we make a tap from the supply pipe to the upper side hole, and take the coolant through the lower side hole, directing it to the return pipe. We put air vents next to each radiator. The boiler in this scheme is installed at the lowest point.

It uses a diagonal connection of radiators, which increases their heat transfer. Lower connection of radiators reduces heat output.

Such a scheme is most often made closed, using a sealed expansion tank. The pressure in the system is created using a circulation pump. If you need to heat a two-story private house, we lay pipes on the upper and lower floors, after which we create a parallel connection of both floors to the heating boiler.

Comparative analysis

In a single-pipe line, there is only one pipe - the supply pipe. A two-pipe system has not one, but two pipelines: supply and return. Between themselves, they are connected by heating devices and radiators as jumpers. Each scheme has its advantages: a two-pipe one is more convenient to manage - liquid of the same temperature flows into each radiator, so they heat up evenly around the entire perimeter.

A single-pipe system with a lower connection is only with forced circulation, with the exception of one exception, when a gravity method is organized in the presence of an accelerating manifold. Then the liquid from the boiler is directed vertically down, then to the collector, and then through the devices connected in parallel into the circulation ring.

The differences between the upper wiring and the lower wiring are as follows: it does not have bypasses, the supply pipe is connected at the top of the radiator, the outlet pipe is at the bottom. In this case, the radiators are connected from top to bottom, water is also supplied. This scheme is more suitable for the option with natural circulation and does not have a supply riser. Valves and taps are not mounted on the batteries, therefore it is impossible to adjust the temperature regime separately in any room.

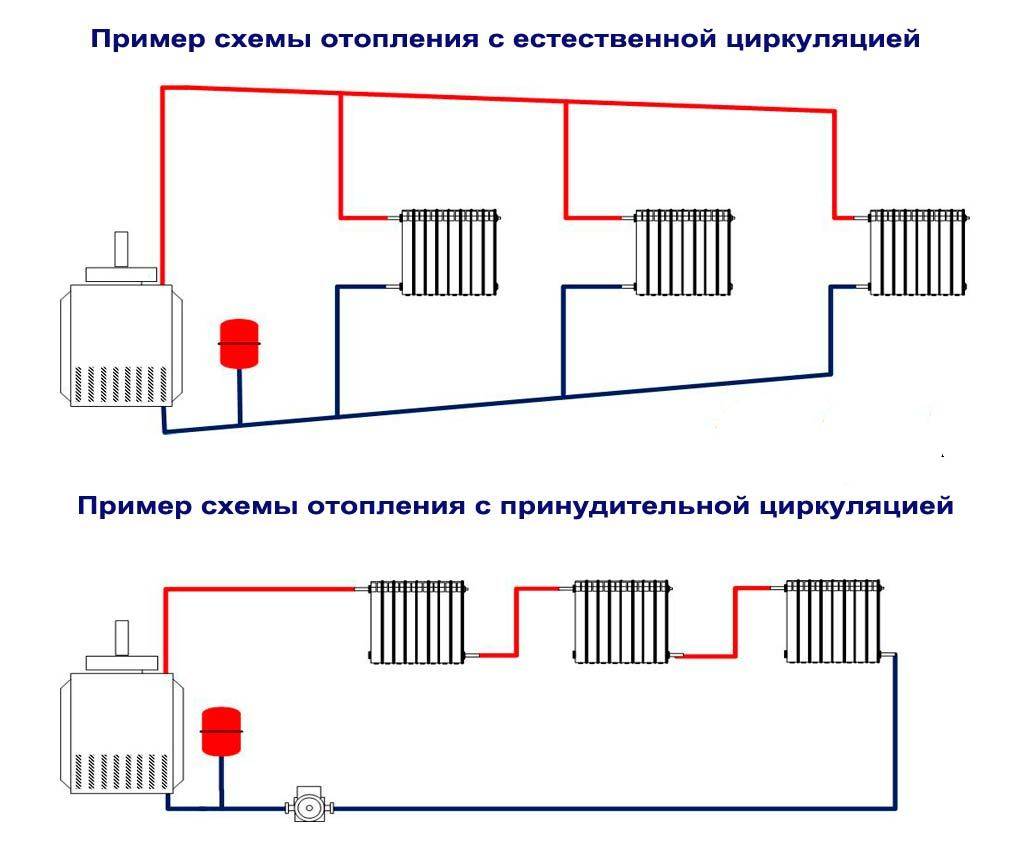

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of the coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is required to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the pipe diameter, etc. You may need the help of a professional when doing the calculations.

Closed system with gravity circulation

In the EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet been widely used. The principles of operation of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands, water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container is a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs, and the gas squeezes the water out of the tank.

Otherwise, closed-type systems work like other natural circulation heating schemes. As disadvantages, one can single out the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a capacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantages of an open system is the possibility of self-manufacturing containers from improvised materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the ingress of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing the system is also a frequent "guest" in open circuits. Therefore, radiators are installed at an angle, Mayevsky cranes are required to bleed air.

Single pipe system with self-circulation

This solution has several advantages:

- There is no paired pipeline under the ceiling and above the floor level.

- Save money on system installation.

The disadvantages of such a solution are obvious. The heat output of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a single-pipe heating system of a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often redone (by installing pumping equipment).

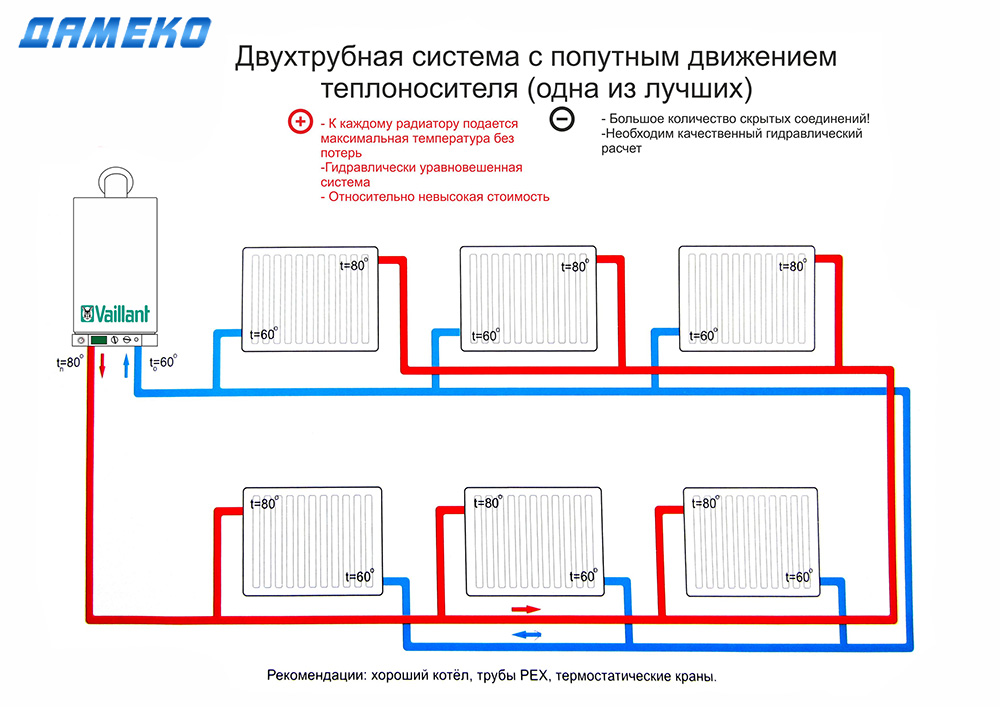

Two-pipe system with self-circulation

Two-pipe heating system in private house with natural circulation, has the following design features:

- Supply and return flow through separate pipes.

- The supply pipeline is connected to each radiator via an inlet.

- The battery is connected to the return line with the second eyeliner.

As a result, a two-pipe radiator type system provides the following advantages:

- Uniform distribution of heat.

- No need to add radiator sections for better warm-up.

- Easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe schemes.

- Lack of strict rules for installing a two-pipe system. Small deviations regarding slopes are allowed.

The main advantage of a two-pipe heating system with lower and upper wiring is the simplicity and at the same time the efficiency of the design, which allows you to level errors made in the calculations or during installation work.

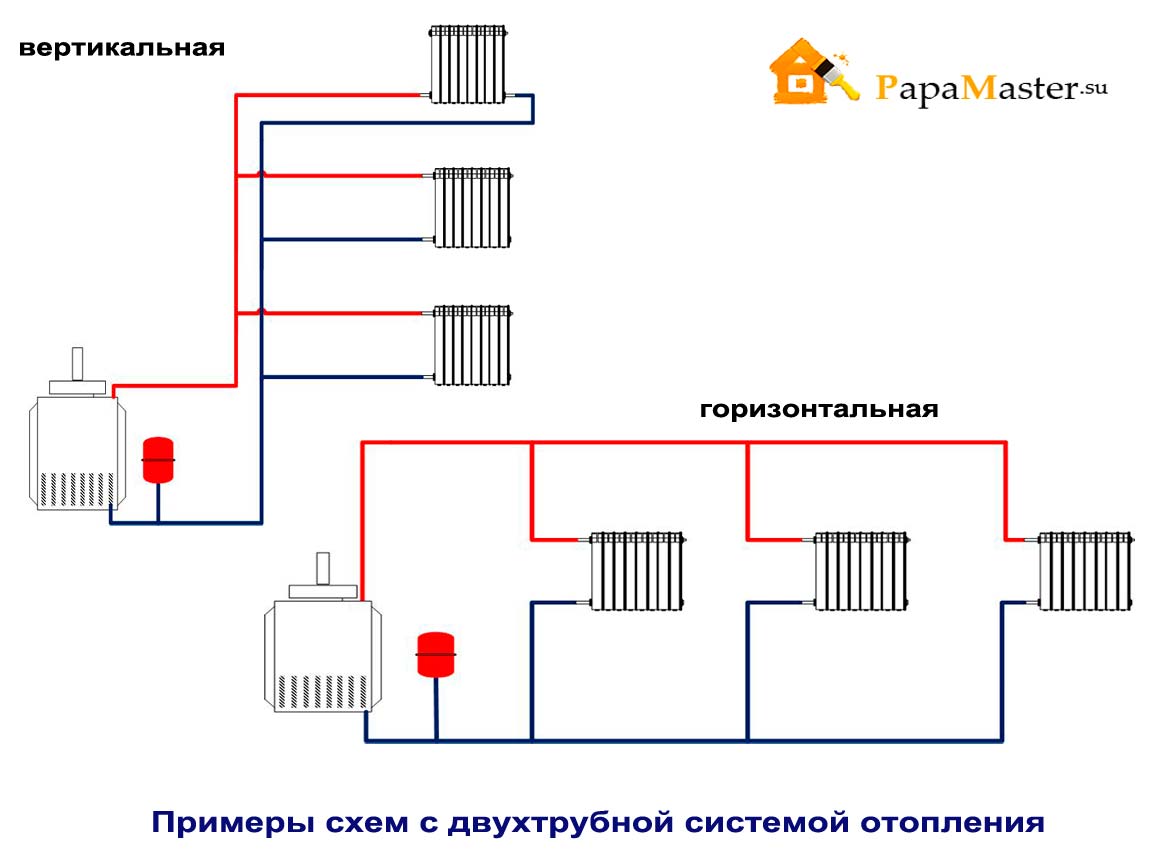

Two-pipe heating system

The main design difference of this scheme is two circuits through which the coolant circulates. The first is intended for supplying hot liquid to radiators, the second - to return the cooled coolant to the boiler. In this case, too, a vicious circle is obtained. It is a pair of interconnected contours that is the most “repulsive” moment for many owners of private houses. The long length of the mains, the difficult wiring are the reasons for the dislike for two-pipe structures.

Two-pipe heating systems are also open or closed. The difference between them is the presence of different designs of the expansion tank. Closed structures are more practical, easy to use. They use membrane containers as a tank, their difference is complete safety. They allow you to add to the circuit (or turn off) heating devices or entire branches, greatly simplify the adjustment of the system.

There are two main types of connection of elements of a two-pipe structure - vertical and horizontal. In the first case, the pipes are connected to a vertical riser for each floor separately. This option is convenient, almost ideal for two- or three-story houses or cottages. Air congestion in this case, the owners are not afraid.

Horizontal wiring, which has an upper (in the attic, under the ceiling) or lower (in the basement, under the floor) location, is usually used for single-story buildings of large footage. Or for large buildings with several floors, if floor adjustment is required. Air locks are eliminated with the help of Mayevsky cranes, they are installed on radiators.

Now there is another type of system - radiant heating. In this case, the distribution of hot liquid goes through the manifold.It is possible to adjust: both the speed of movement and the temperature of the coolant.

pros

Which heating system is better: one-pipe or two-pipe? If we keep in mind the quality of heating, then the second option has a great advantage: it is the uniform heating of all radiators, regardless of their distance from the boiler. Other pluses include:

- thermoregulation, which can be foreseen at the design stage of the heating system;

- parallel connection of elements, enabling a relatively simple replacement of each of them;

- the ability to add new radiators if you want to increase the heating efficiency;

- a chance to extend the heating structure in any direction: both horizontal and vertical;

- easy elimination of any technical errors directly during installation;

- simple repairs, easy maintenance of radiators.

Minuses

The biggest disadvantage of this system is the higher cost of the work. But there are other reasons to think about the expediency of its implementation. These include:

- a large number of communications, they will have to be hidden, which means that new costs are inevitable, because of this, difficulties in maintenance may arise;

- the need for forced circulation by an electric pump;

- exactingness to the author when drawing up a rather complex project;

- installation, which takes much more time, takes a lot of effort;

- the need to purchase a large number of pipes for wiring, valves that regulate the supply of coolant to each radiator.

open tank

An open expansion tank is a partially or completely open tank connected to the circuit in its highest section, immediately after the boiler.To prevent the liquid from overflowing over the edges of the vessel, there is a special pipe closer to the top: it serves to drain excess water into the sewer or into the street. When organizing the heating of one-story buildings, the compensating capacity is mainly installed in the attic. In order to avoid freezing of water in winter, the walls of the tank are additionally insulated.

Such heating systems are called open. Most often we are talking about non-volatile or combined heating. In this case, the coolant comes into direct contact with air: this leads to its natural evaporation and enrichment with oxygen.

Open circuits are characterized by the following disadvantages:

- Precise observance of slopes (if gravity systems are used). This will allow the air seeping into the pipes to exit through the tank into the atmosphere.

- The need for constant monitoring of the water level in the tank. From time to time, the volume of the coolant has to be replenished, since part of it evaporates through the open top.

- Do not use non-freezing fluids that release toxic substances when evaporating.

- Oxygen saturation of the circulating fluid provokes corrosion processes inside metal steel heating radiators.

Strengths of open systems:

- It is possible not to carry out regular checks of the pressure level in the pipeline.

- Small leaks in the circuit will not prevent him from properly heating the home. The main thing is that there is enough liquid in the pipes.

- To make up for the loss of coolant, it is allowed to use a simple bucket. This is done by simply adding water to the expansion tank to the required level.