- Invention for clearing blockages

- Grease trap function

- The principle of operation of the device

- Classification by material of manufacture

- The main features of the grease trap cleaning process

- Popular Brands

- How is grease traps cleaned?

- Consequences of neglecting to clean the grease trap

- How often should a kitchen hood be cleaned?

- Ready-made products for cleaning the hood from grease

- Folk methods for cleaning fat

- Device Features

- Maintenance and control of the separator

- Price

- Where to buy a grease trap for sewerage?

- In Moscow

- In St. Petersburg

Invention for clearing blockages

A grease trap can be a real salvation for those who are constantly faced with clogged sewers in the kitchen. The device consists of several parts, performs a specific task, acting in a special way.

Grease trap function

The device, called a grease trap, has one task - to separate fat from water. The device is attached to the sewer pipes and prevents the formation of fatty plugs.

Greaser under the kitchen sink allows you to always keep the pipes clean

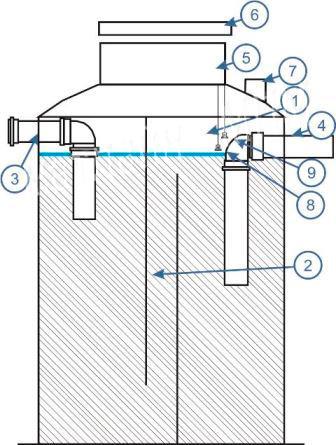

The grease trap functions conscientiously due to the special components:

- inlet pipe;

- septum;

- outlet pipe in the form of a tee.

All elements that contribute to the screening of fat from water are enclosed in a plastic box.In this case, the nozzles for the inlet and outlet of water are installed so that they are partially outside the housing.

The principle of operation of the device

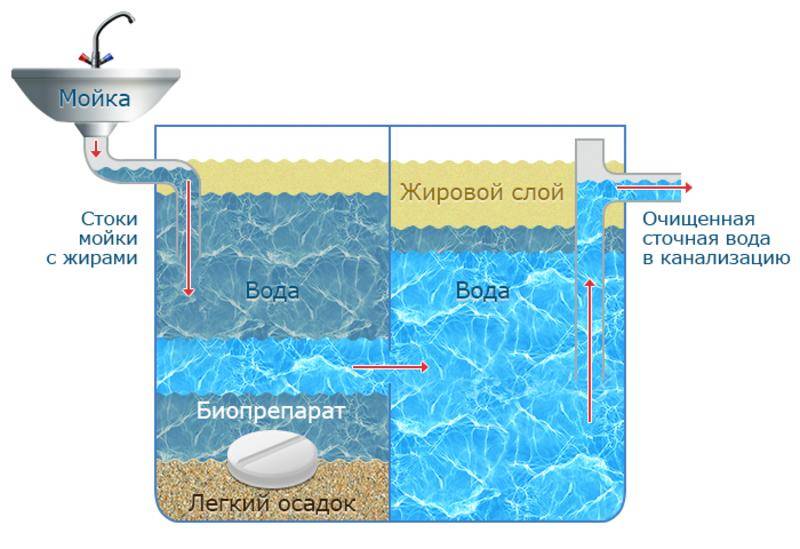

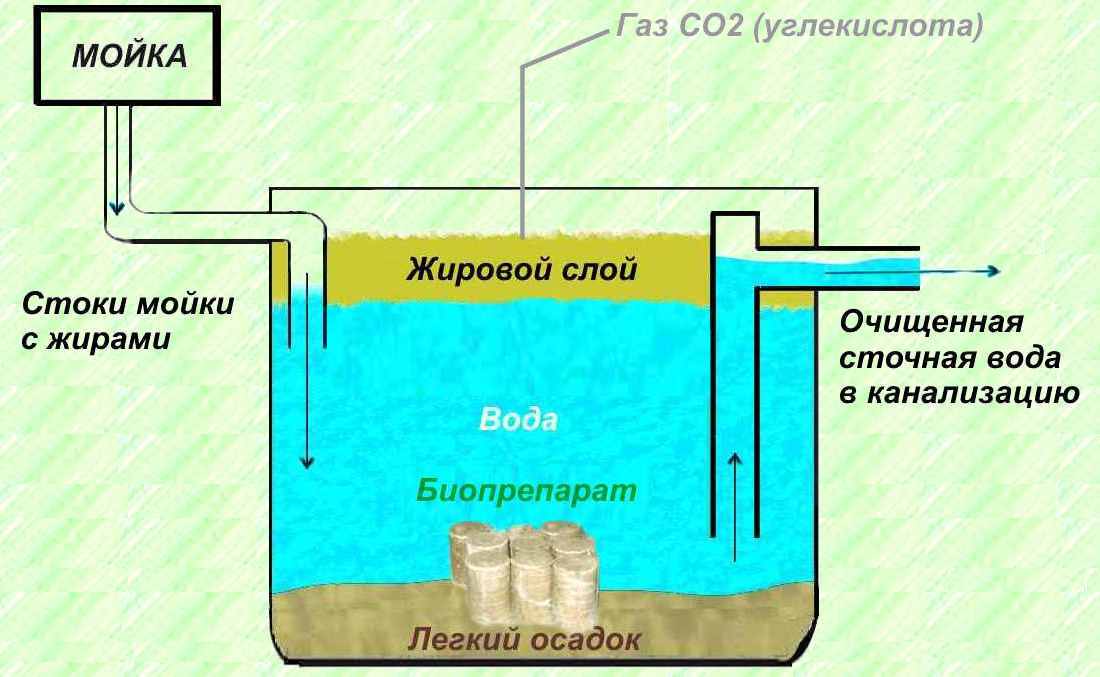

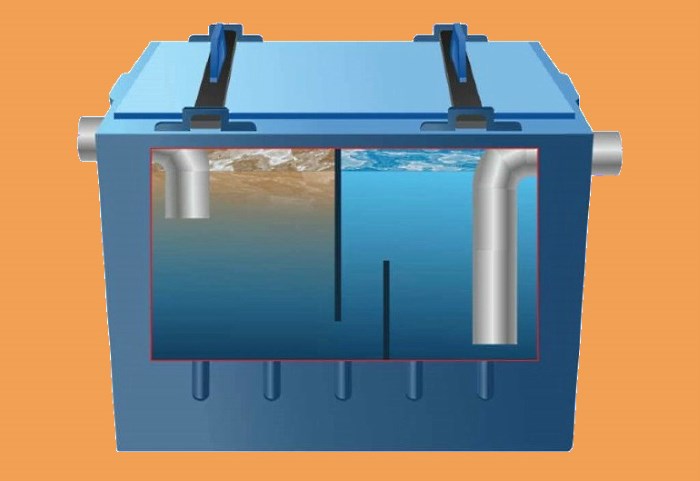

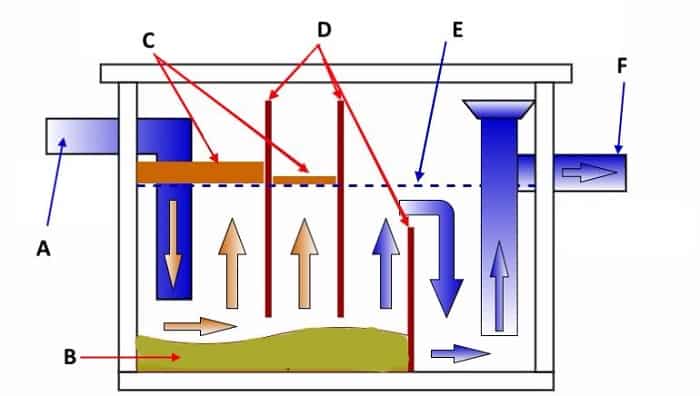

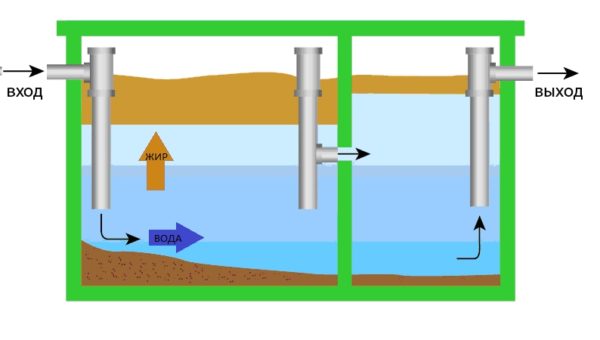

The grease trap functions as follows:

- The inlet pipe receives the liquid flowing from the sink in the kitchen.

- The primary chamber is filled with dirty water. The collected liquid is partially cleaned, while the fat is carried upwards, where it will remain due to the installed partition. The height of this barrier is limited, it occupies only two thirds of the size of the box.

- Through the partition, water, freed from fat, enters the next compartment of the body.

- From the second chamber, the liquid flows along the bottom of the box into the outlet pipe in the form of a tee. From there, the purified water is sent to the sewer pipe.

Due to the special movement of the liquid, the fat is blocked in the drawer.

As a result of the passage of water through special sections, fat is collected on the surface of the working medium, the volume of which remains unchanged.

It's interesting: how make a pit do it yourself - options structures and installation steps

Classification by material of manufacture

Russian and foreign manufacturers of grease traps are used in the manufacture of:

- Resistant plastic, often used for kitchen appliances, grease trap.

- Fiberglass.

- Stainless steel.

Consider the properties of materials and how they affect the performance of grease trap equipment:

- Plastic equipment for catching fats has been in operation for a long time, more than 30 years.

- Resistant plastic is environmentally friendly, it can not adversely affect the environment.

- Plastic devices of grease traps for washing are easy to maintain: washing, cleaning surfaces from grease with improvised tools.

- From plastic it is easy to make equipment for grease traps of special dimensions, according to the sketches of the customer.

- For restaurants and cafes, the warrant of equipment for fat traps made of plastic is excellent, where high performance is not needed, the change of visitors is not fast.

The modern brand of plastic separators for trapping fats is the model of the company from Russia "5th element".

Fiberglass fat traps are represented on the market for equipment of this type by the Eco-J model, which is manufactured by Ecoline.

Properties:

- Grease traps made of fiberglass endure exposure to aggressive chemical environments.

- Excellent equipment of this type adapts to the installation site, easy to mount outdoors or indoors.

- Grease traps made of fiberglass are reliable, light weight, easy maintenance.

Grease traps made of stainless steel are produced by the ASO Group company, which are installed at catering establishments with high productivity. This is expensive, but high performance equipment.

Characteristics of stainless steel grease traps:

- Stainless steel grease trapping equipment for sewerage is installed, without restrictions (room, street).

- The increased hygienic properties of the material fit perfectly into any restaurant interior.

Important! A lot of companies are making galvanized steel grease separators, they are strong but cannot have the properties of stainless steel separators.

The main features of the grease trap cleaning process

Remove blockages using a manual or offline method.The most suitable method is chosen after a thorough check of the volume of fat accumulations on the surfaces, the size of the installation and its performance. To eliminate fat deposits on the walls of grease traps, an aqueous solution consisting of chemical preparations is used. First of all, you need to remove the accumulated clots. Otherwise, chemical treatment will be useless. To eliminate serious problems with blockages, you will need to disassemble the entire system, manually strain and clean all parts of the device.

The extraction of oil-fat deposits from the "trap" is carried out in special areas, which are called landfills. Therefore, you can not worry about the fact that the disposal will be performed incorrectly.

Popular Brands

Known for well-known brands. EuroREK (raw material from Wavin Labko) is a European manufacturer that has been operating in Russia for over 15 years. Grease traps are strong, stable and durable. Material - fiberglass.

Helyx operates throughout the Russian Federation. Works since 2007. It produces only industrial grease traps. Suitable for pub, cafe or restaurant. The manufacturing plant is located in the Tver region. They also manufacture fiberglass products.

Flotenk has been on the market for over 12 years. High quality and stability. It has 2 factories in Russia of the European level: one in St. Petersburg, the second in the Sverdlovsk region. Service life more than 50 years.

Evo Stok (Russian products) uses reinforced plastic or polypropylene. The products are suitable for both household and for industrial premises.

It is worth noting the Russian products "The Fifth Element". It produces household and industrial grease traps. Warranty 5 years. For a private house, this is a very good choice with an optimal cost.

How is grease traps cleaned?

The grease trap must be kept clean by regular cleaning. The frequency of cleaning depends on the capacity of the grease trap and the contamination of the wastewater. If cleaning is not carried out for too long, a large amount of dirt accumulates in the grease trap, and it loses its protective ability and may fail completely.

Also, fat is a favorable habitat for various bacteria, and can become a source of a sharp unpleasant odor. Household grease traps are cleaned quickly and easily, it is enough to periodically collect excess grease from the surface. The grease trap is completely disconnected from the sewer system, after which it is cleaned with a special spatula, usually it is included in the delivery, after which it is treated with chemicals. Due to the small volume of grease trap tanks, this procedure should be carried out once a week. After the procedure, it is necessary to connect the grease trap and check the entire system for leaks.

To clean workshop grease traps, Ecolife uses its own know-how - the so-called small sludge pump. The device was created by the hands of Ecolife specialists and has proven itself in practical use.

Consider the process of cleaning a standard grease trap using the example of one of our regular customers. The Perekrestok chain of stores has its own workshops for the preparation of semi-finished and finished products. Periodically, they carry out scheduled cleaning of grease traps.

|  |

| Works on cleaning grease traps and waste removal are carried out at night so as not to interrupt the business processes of the enterprise. | A fully staffed team with all equipment, materials and tools arrives at the site. |

|  |

| Small sludge pump of the original Ecolife design is designed for automatic pumping out of grease traps with reloading of the contents into special containers. | Small sludge pump with vacuum installation. The unit is equipped with wheels and handles for transportation, dimensions allow passage in narrow corridors. |

|  |

| One of the grease traps of the semi-finished products workshop | Grease trap with open lid. (All photos are enlarged by clicking) |

|  |

| Pumping out the contents of the grease trap takes a few minutes. | The grease trap is empty and ready to be cleaned with a reagent. |

|  |

| Preparation of a pump-action sprayer with a sprayer for work. | The reagent is poured for cleaning interior walls grease trap. |

|  |

| The reagent is applied to the walls of the grease trap. | Cleaned grease trap from the inside. |

|  |

| The grease trap is filled with water and is ready to go. The work was done quickly and efficiently. | The pumped-out contents are taken out on the cart. "Walking wheels" allow you to climb stairs. |

See other Our works

|

| Own sludge suction machine for pumping out and removing solid waste from industrial grease traps. |

To clean industrial grease traps, Ecolife uses a special technique - a sludge suction machine.

All fat accumulated in the grease trap is drawn through a hose into a special container. Industrial grease traps require less frequent cleaning than household ones, usually once every 3 months.

All pumped fats are transported to special landfills for waste disposal.The customer is provided with all the necessary documents and acts on the disposal of fat at the landfill.

Ecolife company has all the necessary licenses to carry out activities for the collection, transportation, processing, disposal, neutralization, disposal of waste of I-IV hazard classes.

Consequences of neglecting to clean the grease trap

The minimum that will happen if you do not periodically clean and maintain the grease traps is the loss of protective functions. Devices may stop working properly, which will subsequently lead to sewage problems (drainage will stop passing through pipes). This happens due to the accumulated pollution in them, which harden and turn into stone particles. It is they who most often cause accidents in the pipes of the sewer system; it cannot be installed indoors (with the exception of household models that are specifically designed for installation under a sink).

Repair of equipment, grease traps, sewers and other systems is expensive and takes a long time. This results in significant financial outlays. You will have to spend money on fixing the problem, but at the same time the company will incur losses, because it will not be able to temporarily perform its work normally. Plus, food processing plants, restaurants, cafes, and other catering establishments do not have legislative authority to dispose of waste from fat and oil pollution traps. Therefore, it is better to order a turnkey service for the enterprise.

How often should a kitchen hood be cleaned?

The frequency of cleaning the kitchen hood depends on the frequency of cooking.With regular cooking, you will have to wash and clean the structure above the stove once every three months. If you cook infrequently, then the frequency of cleansing can be reduced to 1 every six months or even a year.

Provided regular cleansing of fat, the cleaning process will not take much time. If you know some tricks or use special detergents, then even old-fashioned fatty deposits will be easy to remove.

Ready-made products for cleaning the hood from grease

Now let's figure out how to wash extractor hood in the kitchen. The easiest way to do this is with ready-made tools:

- Soda is in every home. Prepare a soda solution - take a glass of soda for 2 liters of water. Pour the solution into a container of a suitable size to fit the parts of the hood. After boiling the solution, soak the contaminated elements in it for half an hour. After that, the fat will easily go away.

- You can rub the fatty coating on the body with lemon juice or a solution of citric acid. After 20 minutes, the surface is rinsed with water. If necessary, parts can be soaked in a solution of citric acid (4 tablespoons per 1 liter of water).

- Laundry soap removes many impurities. It is enough to grate a small bar of soap and dissolve the shavings in hot water. The parts of the hood are kept in the resulting solution for 20 minutes. Then they are well rubbed with a sponge or brush.

- Acetic essence dissolves greasy deposits and adhering dust. It is enough to moisten a cloth in the essence and wipe the surface. After a quarter of an hour, the parts are rinsed with water. To soak the filters, you can prepare an vinegar solution. To do this, the essence is mixed with water in a ratio of 1 to 2. The filter is soaked for 20 minutes, and then washed.

- To clean the hood, you can use a regular kitchen dishwashing detergent.It dissolves fat well. The surface can be washed with a sponge soaked in the product, or the parts can be soaked in a solution with the addition of dishwashing gel.

- Compositions for cleaning stoves and ovens are also suitable for this purpose. Place the filter on a flat surface, such as a baking sheet, and then apply the cleaning agent to it with a sponge. After half an hour, the part is intensively rubbed with a stiff brush and rinsed with warm water.

- Gel-like pipe cleaner "Mole" is used if no other compounds and cleaning methods help. The gel is applied to contaminated surfaces and left to act for 30 minutes. When the gel begins to act, fat deposits will foam. After that, the part does not even have to be rubbed with a brush, it is enough to rinse well under running water.

- The kitchen appliance can be washed with ordinary bleach. Apply the solution with a brush and leave to act for 10 minutes, then rinse well with water.

If everything is already tired and you don’t know what else to play, then you can try downloading 1xBet slot machines and enjoy new experiences with the popular bookmaker.

You can also use a steam generator to dissolve fat. After that, the fatty deposit is easily washed off by any of the above means.

Folk methods for cleaning fat

If you do not know how to wash the grid from hoods in the kitchen, then you can prepare an effective means for dissolving fat at home. To prepare it, you will need citric acid, soda, ammonia, salt, vinegar, alcohol and laundry soap.

We prepare the tool as follows:

- we collect cold water in a five-liter pan;

- three on a coarse grater half a piece of laundry soap and throw into the water;

- then pour in half a bottle of ammonia, hydrogen peroxide or silicate glue;

- then add 1-2 tablespoons of citric acid, salt or soda ash;

- at the end, you can add half a tablespoon of alcohol or vinegar.

After dissolving all the ingredients, put the filter or other parts that need to be washed in the pan. We wait 15-20 minutes for the fat to dissolve well, remove the grate and rinse it under running water. During washing, the surface can be rubbed with a brush or sponge.

Device Features

The purpose of this type of equipment is to prepare wastewater for release into the public sewer network, which, according to the law, is associated with strict standards regarding the mass fraction of fats allowed in wastewater.

The capacity of the grease trap is located along the path of effluents in the sanitary collector from public catering establishments (restaurants, canteens, cafes, chebureks), industrial premises for the manufacture of food products and private houses.

underground structure

The reservoir performs the following functions:

- separates, collects and removes oil and grease from drains;

- protects treatment tanks, own and public sewerage from the formation of fatty plugs;

- prevents blocking of highways in certain sections, which can lead to a serious accident. Settling on the inner walls of pipes, fat eventually reduces their diameter and patency, causing blockages;

- ensures compliance with the current standards for the content of harmful impurities in the effluent in the form of fat;

- increases the cost-effectiveness of maintaining the sewerage system.

Plastic compact version

Quite stringent requirements have recently been imposed on the state of wastewater regarding the content of fats in them at the legislative level. To ensure their observance and avoid penalties from the inspection authorities, the grease traps are understaffed with a sorption filter. This makes it possible to obtain an output of fat products of no more than 1 mg/l.

Sorption filter for drains

In addition to this, devices with an underground location, regardless of type and modification, are equipped with the following means:

- a meter with a sound accompaniment unit to control the level of fat;

- sediment level control device;

- a device for signaling the filling of the tank;

- automated system for the collection and removal of fat;

- automated sludge disposal system.

For the operation of equipment in regions with a predominance of low temperatures with a shallow location of the tanks, the body of the grease traps is made in a warmed form.

The principle of operation of the device

Maintenance and control of the separator

Maintenance of a grease trap is not the most pleasant procedure, but it is much more unpleasant to clean clogged sewer pipes.

The frequency of cleaning the household separator depends on several parameters:

- the volume of the grease trap tank;

- family diet, which determines the composition of wastewater;

- the temperature of the water used.

Due to these factors, the frequency of cleaning the separator can vary from several weeks to several months.

Before cleaning the grease trap, it is necessary to open windows for cross-ventilation and wear protective gloves, because harmful bacteria multiply during the decomposition of fats.

Close attention to the level of effluents must be paid in the first weeks of operation.It is necessary to periodically open the lid of the grease trap and check the level of solid waste

If the bottom layer of fat sinks to the level of the outlet, then it can become clogged, which will lead to overflow of the tank and flooding of the room.

It is desirable to remove the fat mass at the moment it reaches the level of 4-5 cm above the bottom edge water outlet pipe. To remove fat, you need to open the tank lid and pull out the upper viscous layer with gloves, a bucket or other improvised device.

After the inspection of the grease trap, you can rinse it with hot water for several minutes.

When the approximate period of safe operation of the grease trap has already been established experimentally, you can look into it much less often.

Price

The price depends on the capacity of the model, as well as the availability of additional equipment. The simplest models for domestic use can cost 4,000 rubles. Industrial have prices from 25 to 500 thousand rubles.

Where to buy a grease trap for sewerage?

You can find such devices in plumbing stores, as well as order from organizations selling equipment for the food industry.

In Moscow

In Moscow, grease traps are available in the following stores:

- LLC "Septic" Address: st. Gorbunova, 12 building 2 building 4. Phone: 8 (495) 215-17-79.

- Stroyservis-AVF LLC. Address: Andropova avenue, 42 building 1. Phone: 8 (495) 565-35-00.

- LLC "The Fifth Element" Address: 2nd Entuziastov St., 5 building 3. Phone: 8 (800) 500-12-19.

In St. Petersburg

You can buy grease traps in St. Petersburg in the following places:

- Matline North-West LLC. Address: Sofiyskaya st., 66. Phone: 8 (812) 647-49-00.

- Termite. Address: ave. Obukhov Defense, 141. Phone: 8 (905) 297-41-35.

- MegaLine.Address: 026 D Komendantskiy avenue, 4 building 2, lit. A. Phone: 8 (812) 448-68-21.

Since grease traps are simple in design, household models can be made with your own hands. But if you need a device that processes a large amount of waste, you should look at ready-made models that have additional equipment.