- What to do: ways to purify water from iron

- How to prevent turbidity in the future?

- How to get rid of yellow water

- How to clean the well from silt and sand with your own hands?

- Bailer

- Vibrating pump

- Deep electric pump

- Circumstances and methods of counteraction

- Rust

- Sand

- Clay

- Tannin

- Is water that turned yellow due to dissolved iron dangerous?

- Causes of yellowing of water in the open air

- Muddy water comes out of the well: what to do?

- Ways to deal with poor quality water

- Turbid water: well cleaning rules

- Hydrogen sulfide and bacteria: disinfecting the well

- Pre-disinfection

- Mine cleaning

- Re-disinfection

- Expert answers

- Step-by-step cleaning with active chlorine

- First stage

- Second phase

- Third stage

- When is troubleshooting necessary and when not?

- Why is there muddy water coming out of the well?

- Vibration Pump Cleaning Method

- Conclusion

What to do: ways to purify water from iron

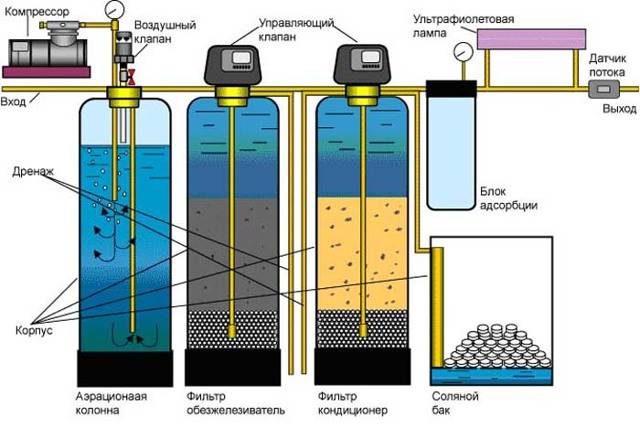

The modern filter market offers a variety of methods, from homemade, by settling water to high-tech systems of the new generation.

The most popular types of iron filters in the well:

- Reverse osmosis: a system that purifies water from absolutely all impurities, both harmful and beneficial. In this regard, it requires artificial mineralization of water after purification.Pros: cleaning efficiency. Cons: high cost of implementation and maintenance, the need to allocate free space, high water consumption (two-thirds of the original volume is drained), does not filter hot water.

- Ion exchange: effective against dissolved iron, but does not cope with oxidized iron, requires maintenance and replacement of reagents. Also softens water

- Titanium fine water filters. They are not consumed during operation, do not require replacement of cartridges - only cleaning in a solution of citric acid. They work with both forms of iron, filter cold and hot water, are compact (even fit under the sink). Appeared on the market 2 years ago, presented by TITANOF, the technology is patented.

How to prevent turbidity in the future?

Getting rid of cloudy water is a rather dreary process. Turbidity is easier to prevent than to get rid of.

All that is required is to follow the basics of a proper launch and not rush. Aquaristics generally do not like to rush, especially when it comes to the biological balance in the aquarium.

To prevent the appearance of turbidity, the following recommendations should be followed:

Run the aquarium only on natural soils.

Immediately from the moment of start-up, use filtering equipment, which must work around the clock

It is important that the filter matches the volume of the aquarium and contains high-quality fillers.

Use biostarters, this will not speed up the process of establishing the nitrogen cycle, but will prevent the water from becoming cloudy.

Do not use tap water without settling or using conditioners. Chlorine, which is contained in tap water, is detrimental to bacteria.

You need to populate the fish no earlier than two weeks from the date of launch

Shrimps or delicate fish species - not earlier than in a month.

Feed moderately only high-quality food.

Changes should be done in minimal quantities. The first replacement - not earlier than 10 days after launch, and not more than 20% of the aquarium volume. In the case of using nutrient soils, follow the manufacturer's recommendations.

By following these simple rules, turbidity will not be a cause for concern. You just need to remember that the aquarium becomes fully viable only after a month, until this moment it cannot be overloaded, because biological balance is the basis of any aquarium.

How to get rid of yellow water

Well cleaning schemes

Depending on why the water from the well is yellow, there are several options for eliminating this phenomenon.

Causes of yellow water and methods for its elimination:

- If the reason for the appearance of yellow water is numerous impurities of sand (see How to flush a well from sand: basic options) and clay, then they are dealt with by all known methods. Immediately in the well you need to place a device to inspect the walls of the structure. The reason may be breaks in the connection of the structure. If there are any, then you can eliminate them with your own hands using special hermetic means. They lubricate all pipe connections.

- It is also worth assessing the condition of the filter installations. If only natural filters in the form of gravel or crushed stone are used in the well, then they are replaced. To do this, the old layers are raked out from the bottom and new ones are filled in their place. After such procedures, the well is pumped until the H2O goes clean.

If additional filters are used, then their design has metal meshes, which do not allow particles to penetrate into the source. Their clogging quite often causes the appearance of yellow water. It is necessary to disassemble the grids and rinse them well under powerful pressure. After that, they are installed back and the entire system is flushed, as sand or clay could remain in it.

How to clean the well from silt and sand with your own hands?

Bailer

Cleaning of silt and sand with a bailer.

Bailer is a device for mechanical cleaning of wells. It is a short pipe with a stop valve at the end. The latter has the form of a ball or a lid.

The device suspended on a cable is lowered to the bottom and raised to a distance of 0.5 m. Such actions are performed several times. When the pipe moves, the cover or ball moves, contaminated liquid enters the cavity.

When the pipe is lifted, the ball closes the hole, so the pumped sand or clay does not fall back. After completion of work, the device is removed. After that, the quality of the extracted resource is checked.

Vibrating pump

This method is used for physical contamination. This is due to the principle of operation of vibration equipment. The fluid is sucked in by a rubber piston that is in constant motion. Unlike other types of pumps, vibration pumps can operate in a highly polluted environment. The device is placed at a height of 20 cm from the bottom and launched. To facilitate the work, tying a steel bar helps to prevent the deepening of the pump.

In the presence of additional equipment, it is also included. The liquid supplied by the device is settled in the tank and returned to the well through the hose. This helps to remove dirt from the bottom.The vibration pump will remove sand and clay from the well.

Deep electric pump

Deep equipment does not create vibration, so the filter layer will have to be cleaned separately. For this, an auxiliary apparatus is used - a mechanical baking powder. He is hung on a nylon rope and lowered to the bottom of the mine. The device removes a layer of sand and clay from the bottom. After purification, the water is analyzed for the presence of contaminants.

Circumstances and methods of counteraction

First of all, a complete analysis of the suspicious liquid is required. Then you can choose the most effective solution to the problem. Otherwise, you have the opportunity to "fight the windmills" without solving the real problem.

In addition, in the case of a regular color, it is better not to save money and find out what you plan to use for many years. Since the consumption of low-quality water creates a cumulative effect that slowly destroys the body.

Rust

Yellow water in the well is possible from an excess of iron and oxygen, the combination of which leads to the corrosion process. So, rust can pour not only from a public plumbing system, but also from a domestic underground source.

There are two situations:

- An increase in the amount of iron due to the proximity of red, bronze or another type of iron ore leads to an inevitable chemical reaction with oxygen and a subsequent change in the color of the liquid. As a result, it loses its taste and necessary qualities.

- The contact of oxygen with the metal of pipes and other elements of the water supply system from the well located at the bottom of the mine. It can be rings, filter mesh, fasteners.

In order to eliminate the result, the following instruction will help you:

Install a sealed polyethylene cap on the well. It will significantly limit the flow of oxygen inside, and without it, the corrosion process will not begin. Reagent water filtration through appropriate equipment

In this case, care must be taken, because if the ratio of reagents is incorrect, the well may become unusable for a long time. In addition, it is possible to carry out a simpler iron removal with your own hands:

We install a plastic or stainless steel tank in the attic.

- We bring a hose from the pumping station to it.

- We make an outlet a couple of centimeters above the bottom.

- We run water from it around the house.

- We fill the container with water and let it settle, as a result of which all the rust will precipitate, and clean will disperse around the house.2O.

Despite the fact that a certain amount of iron must necessarily be in the composition of water, since it accompanies the process of oxygen transfer through the human circulatory system, the excess must be removed.

Sand

When a well is drilled into a sandy aquifer, very small sand can be caught and will enter through the lower screen mesh. And then you also expect yellow water from the well.

In this case, it is possible to take the following measures:

- Install a coarse filtering system at the outlet. Also take into account the particle size and do not forget about the need for regular rinsing.

- Initially, install a depth filter for a well with a smaller grid. This is fully possible to foresee, knowing what type of well you are planning to drill.

Clay

If mistakes are made during drilling and installation of equipment, it is likely that the edge of the pipe with the filter will fall into the clay. In addition, this is facilitated by not strong backfilling of the bottom of the mine with crushed stone. Clay particles, getting into the liquid, will begin to color it in a brown hue.

To eliminate this trouble, you need to take two steps:

- It is good to pump the well, removing clay from it. The most optimal result will bring the option with two pumps:

- We immerse one apparatus to the bottom and draw a hose from it into a special container with a mesh to clean the liquid.

- We install the second pump on top of the surface and turn it on to transfer purified water from the container under pressure back to the mine.

- Such an unusual water hammer will help wash out the right amount of clay for its subsequent removal by a pump.

- Replace or reinforce the gravel bottom filter. It is he who creates favorable conditions for high-quality water intake.

So the trouble is completely eliminated, without disturbing you in the future, unlike sand and iron, which will need to be dealt with systematically.

Tannin

This substance or humic acid can be found in groundwater and is completely harmless to the human body. But in cooperation with many filtration systems, or rather with their cleaning components, they color the water in the ill-fated yellow color with all the ensuing consequences.

The solution to this problem will be the use of carbon filters.

Is water that turned yellow due to dissolved iron dangerous?

According to SanPiN 2.1.4. 1074-01 "Drinking water" safe iron content in water - 0.3 mg / l. And the daily requirement for adults is:

- 8-10 mg for men;

- 15-30 mg for women;

- 0.25-20 mg for children (depending on the age and sex of the child).

To determine the amount of trace elements in the water will help laboratory analysis of the contents of the well. It is not always possible to visually recognize whether there is an excess of iron. So, water remains transparent in the presence of ferrous iron in it. It is completely dissolved and will precipitate only after contact with air, oxidizing to ferric iron (rust). This is found after settling the well water for some time.

Constant consumption of water with a high iron content is very dangerous. Everyone is familiar with the term "iron deficiency anemia". Indeed, the mineral is involved in hematopoiesis, metabolism, and forms immunity. In total, from 2.5 to 4.5 g of this microelement should be constantly present in the human body. Micronutrient deficiencies are dealt with through dietary supplements.

It is much more difficult to remove excess iron (a dose of 200 mg for humans is toxic). Symptoms of deficiency and excess of it are very similar:

- increased fatigue;

- dry pale skin;

- tendency to arrhythmia;

- the risk of developing myocardial infarction;

- varicose veins and ulceration of the esophagus;

- high blood sugar and risk of diabetes;

- acceleration of skin aging.

Specific symptoms of high iron content:

- staining the palms of the hands, armpits, the inner surface of the limbs in yellow;

- yellowing of the whites of the eyes, tongue, palate (the doctor will determine an enlarged liver).

The accumulation of trace elements in the body contributes to the constant consumption of water with a high content. The trouble is that iron is one of the most essential substances for a person and, even without experiencing a shortage, the liver and spleen deposit it in case of a deficiency.But "thrifty" organs cannot stop the process of accumulation, and an excess of the mineral becomes the cause of a serious illness.

To get rid of the toxic effect of a microelement, it is urgent to consult a doctor. Diet changes are not enough. Very large doses of iron are deadly: a person's nervous system is affected, convulsions begin, then coma. To normalize the condition, emergency measures (bleeding) and long-term treatment may be required.

Causes of yellowing of water in the open air

Daily consumption of poor quality water will lead to a negative impact on the body, will have a consistent destructive effect.

There can be several reasons for the yellowing of water from a well:

- Rust is a consequence of the presence of metal in a humid environment. When it interacts with air, oxidation occurs, which affects its color. This can be caused by the presence of metal pipes.

- Iron with manganese spoils its natural appearance and smell, making it harmful to the human body.

- Sand, together with clay, is able to penetrate the filter, turning it yellow. This is a common occurrence in sandy soil.

- Tannin or humic acid comes into contact with the filters and turns yellow. The harm of these substances has not been established, but it is unpleasant to use it. This effect occurs in peat wells.

- Poor-quality equipment and cost savings in the construction of wells eventually lead to a decrease in the quality of the extracted water.

We have considered only the main reasons that can change the color and taste.

Now let's talk about the different time of manifestation of yellowness in the water we produce:

- The appearance of yellowness after a few hours.If initially the water had a transparent appearance, but after standing in an open space, it began to acquire yellowness, and after 24 hours a precipitate appeared - this indicates the presence of sand or iron fractions. The source of such pollution may be the presence of a nearby source of pollution in the form of an abandoned landfill.

- In the process of raising its water temperature. In the case of a set of clean water, when it is heated, the formation of yellowness indicates the presence of iron, manganese, clay and sandy fractions. It should not be consumed in its raw state, it should be boiled, carefully defended, and the sediment removed. The reason for this phenomenon may be low quality softeners, depressurization of the filter connection.

It is not recommended for consumption and use in household appliances. It indicates a detrimental effect on the human body and household appliances.

Muddy water comes out of the well: what to do?

After you eliminate the cause of the cloudy water environment in the well, the structure itself also needs to be cleaned. There are several ways to clean them:

- Bailer cleaning.

- Vibration pump cleaning.

- Mechanized well cleaning.

- Cleaning the well with a deep pump.

The first method of well cleaning is performed in several stages:

- A bailer sinks to the bottom of the structure. After it rises to a height of 40-50 cm, it plunges again with a sharp movement.

- This action is repeated four times.

- Then the half-filled bailer is lifted up, cleaned, and the cleaning procedure is repeated again.

Ways to deal with poor quality water

Turbid water: well cleaning rules

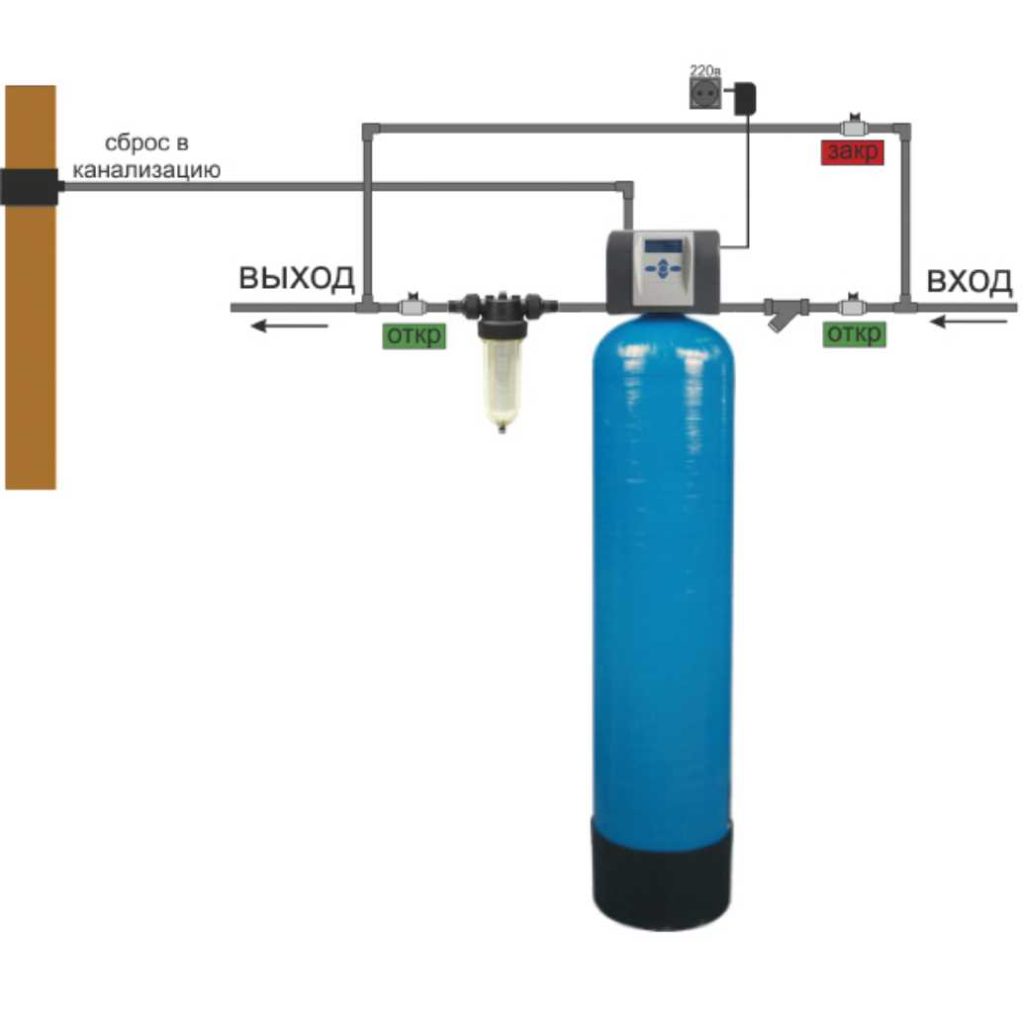

First, find out why the well is cloudy. If it becomes opaque due to particles of clay or sand, then a mechanical filter must be installed. If the top water is to blame for the turbidity, which seeps through the joints of the rings and brings dirt with it, then it is necessary to block its entrance. This is easy to check: the water in the well will become cloudy after it rains.

After finding out the reasons for the appearance of turbidity in the well, they carry out a complete pumping out of water to clean the bottom and install a bottom filter

To restore water quality, the following set of works is carried out:

- With the help of a pump, all the liquid is pumped out of the mine.

- They descend on a cable and clean all the inner walls of the rings from mud deposits, silt, etc., using a hard brush or scraper.

- Disinfect the entire concrete surface (as we say later).

- From the bottom, buckets scoop out silt and all the garbage that has fallen into the column.

- The joints of the rings and all cracks are carefully coated with sealant.

- They create a barrier to precipitation from the outside with the help of a clay castle.

Hydrogen sulfide and bacteria: disinfecting the well

Hydrogen sulfide is a waste product of bacteria, so it is better to deal with both problems in a complex way. First you need to disinfect the water in the well, choosing the best way to do it. It can be treated with chlorine and ultraviolet lamps. Ultraviolet is expensive but requires less preparation and does not change the taste of the water. Special installations are produced, which must be mounted indoors, as close as possible to the place of water consumption. But ultraviolet disinfection is best used as a preventive measure, because it does not improve the condition of the well itself.If the mine is already infected with bacteria, then it is better to clean it with chlorine, and after all the work, install an ultraviolet installation.

Consider how to properly clean the well and the water in it with active chlorine.

Pre-disinfection

- The exact volume of water in the column is calculated and active chlorine is poured into it (10 g of the substance per liter of water).

- They shake the water, immersing the bucket several times, raising it and pouring the water back.

- The shaft is closed with a lid and allowed to “brew” for 2 hours.

Chlorine lime disinfects water no worse than pure chlorine, but it needs to be infused and remove limescale from the solution

Mine cleaning

- Two hours later, complete pumping of water begins.

- The bottom and walls are completely cleaned of silt deposits, mucus, debris, etc. (all this must be buried away from the well).

- Repairs seams and cracks.

- Disinfect the inner surface of the mine. To do this, dilute 3 grams of pure chlorine or 15 grams of bleach in a liter of water and smear the walls with a brush, roller or spray with a hydraulic control.

- Close the well and wait for the column to be completely filled with water.

Silty layers at the bottom of the well must be cleaned out, otherwise the aquifer will be constantly diluted with decaying organic matter and have an unpleasant odor

Re-disinfection

- When the well is full again, fill it again with chlorine solution. Prepare the composition as follows: dilute a liter of water with 200 grams of bleach, let it brew for an hour. The upper part (before sediment) is poured out, and the lower part is poured into the well, mixed with a bucket and left for a day.

- A day later, the procedure is repeated.

- Completely pump out the water and rinse the rings with clean water, wiping them with a mop, brush or other device.

- Wait until the column is filled with clean water and pump it out again. This is repeated so many times until the smell of chlorine disappears, and its taste ceases to be felt in the water.

- Boil water for drinking for 2 weeks.

If the cleaned bottom of the well is covered with silicon gravel, then it will filter both organic matter and all heavy metals that enter with groundwater

To finally make sure that the quality of the water is restored, bring it for analysis to a special laboratory and only after the conclusion start using it for drinking. In order to avoid water pollution in the future, it is necessary to carry out well maintenance on time. You can learn about the rules for operating wells from this video:

Expert answers

Vedara:

it’s interesting for me to read the answers)) I’m so at work .. I pour it, it’s crystal clear, a tear .. and boiled ... yellow (((

GREAT CORN:

Maybe the pot is rusty?

E.S.:

High content of iron compounds.

Olga Oleinik (Maletina):

High iron content. When interacting with oxygen, iron forms an insoluble form and forms rust.

Roman Panteleev:

Possibly due to the high iron content. Use a special water filter with a high Fe content.

pechkin:

Why guess on coffee grounds? The one who drilled the well was obliged to conduct a water analysis. If you are screwed up, hand it over to the nearest laboratory of the plumbing system. Only water should be fresh no more than a day

Vladimir Petrov:

Try to pump the well and hand over the water for testing, everyone will tell you there. They will perform a complete water analysis and make recommendations.

Andrey Ponomarev:

When boiling, water-soluble forms of iron become insoluble - a precipitate (suspension) precipitates. pump the well

Alex Mishin:

What kind of water is available in your area - this will have to be used. Or use imported water, and this one - only for washing and watering. At the dacha, we carry water for drinking from a spring, and at home (a village in the Near Moscow Region) we carry it in bottles from work from the tap, the water in the Moscow Water Pipeline is good. I don’t want to buy “bottled water” (the level of literacy of manufacturers is amazing!) - I don’t want to: otvet.mail /answer/96566837 In your case, it is very likely that the water has a high iron content, and when boiled, it gives ferric hydroxide colloid - Fe (OH ) 3. "Home remedy" for cleaning water from iron is to pour it into a plastic barrel through a shower head and defend the rust flakes. Water analysis (chemical and biological) for its suitability for drinking is officially done at the Rospotrebnadzor Centers - before they were called Sanitary and Epidemiological Stations. Drillers are not required to do this.

Nikolai Potafeev:

Pump the well, there will be no problems.

◄Non-GMO►:

iron yes. But an excess of manganese is also possible; when boiled, the water also darkens. Take it to the laboratory for analysis, it costs about 2 thousand rubles.

Lesya:

Don't hesitate to drink it.

…….:

We had the same. I had to put in a filter. Iron exceeded the norm by 10 times, and manganese by 6 times (((

It's interesting: How to insulate a garage from the inside (video)

Step-by-step cleaning with active chlorine

Unlike ultraviolet radiation, active chlorine can have a negative effect on the human body.

When using it, it is important to strictly adhere to the dosage. These disinfection actions are carried out by specialists using personal protective equipment.

First stage

- First of all, you need to determine the volume of water in the well. For this, its depth and diameter of the mine are measured.

- After that, it is necessary to calculate the applied weight of the chlorine powder intended for filling into the well shaft. The calculation is made from the ratio of 10 grams of dry chlorine per liter of water.

- Chlorine is poured into the shaft and mixed well until completely dissolved. Why is water scooped up with a bucket, and poured back again. This is repeated about 5 times, it is desirable to pour the walls of the mine with a solution.

- After that, the well is tightly closed with a lid for 2 hours to expose the chlorine.

- After the specified time, the cleaning process itself begins. All water is taken from the mine. Its walls are thoroughly cleaned, mucus, moss and other debris are removed. Silt is selected at the bottom.

Second phase

- A mixture is prepared from the ratio: 3 grams of chlorine powder or 15 grams of bleach per liter of water.

- Using a roller, this solution is applied to the inner walls of the well shaft.

- Close the well with a lid and wait for it to fill with water.

Third stage

- A bleach solution is prepared at the rate of 200 g of bleach per liter of water.

- It settles for an hour, its lower part with sediment is poured into the well.

- With the help of a bucket, it is mixed with well water and closed for a day.

- A day later, this procedure is repeated.

- After that, all the contents are selected from the mine.

- With the help of brushes, the walls of the well are wiped and rinsed with clean water.

This completes the third stage of cleaning. Then several times the well is filled with water, followed by its pumping.This is done until the new water no longer smells of chlorine and gets rid of the unpleasant aftertaste. Over the next few weeks, water from such a well can only be drunk in boiled form.

When is troubleshooting necessary and when not?

You should not show excitement and immediately rush to do something when a whitish shade of water appears in your home pond, in the following cases:

- After starting a new aquarium in the first two, and with a large volume of water - up to four weeks. This is the time required for the formation of the living environment.

- With a sharp discharge of water onto unwashed soil and, as a result, small particles and turbidity are washed out of it. After a few days, they will settle, and the milky tint of the water will disappear by itself.

The aquarium needs help to fix the problem of whitish water resulting from:

The aquarium needs help to fix the problem of whitish water resulting from:

- bacterial outbreak;

- overpopulation of the aquarium with fish;

- insufficient filter performance;

- loosening the soil by fish in search of food.

Why is there muddy water coming out of the well?

| The reasons | signs | Cleaning methods |

| Biological | The presence in the water of the remains of rotting plants, the smallest algae, microorganisms, an unpleasant odor. | Mechanical method, filtration of water at the outlet of the well |

| Mechanical | The presence of sand, clay and other insoluble sediments in the water | mechanical way |

| Chemical | The presence of salts, chemical elements, gases in water, which is determined by chemical analysis, an unpleasant odor | Well water filtration |

Causes of biological contamination of the well:

- The appearance in the source of a large number of microorganisms and organic substances entering the well from the surface. Usually in this way water deteriorates in shallow mines.

- The rapid development of algae, due to which the liquid acquires a greenish tint.

- The presence of pathogenic microflora in the well leads to silting and flowering of water. The problem often occurs if the well is rarely used.

Chemical pollution occurs for the following reasons:

- Entry into the source of industrial effluents. Chemicals react with salts and elements dissolved in water, causing it to become cloudy.

- The presence of a large amount of iron in the liquid. Such pollution occurs even in artesian wells, in which the aquifer is located in calcareous rocks. The presence of iron and manganese can be determined by the yellowish or brown tint of the liquid. The color only appears on the surface when iron oxide reacts with oxygen.

To get complete information about why there is cloudy water in the well, take fluid samples to the sanitary and epidemiological station.

The liquid also loses transparency due to mechanical contamination, which occurs as follows:

- Washing out the bottom filter designed to retain solid particles. Gravel disappears due to non-compliance with the technology of building a well and installing casing pipes. Loss of backfill leads to the accumulation of large amounts of sand and limestone deposits in the well.

- The displacement of the soil can lead to the loss of the tightness of the mine and to the penetration of untreated groundwater into the cavity.

- Casing filter damage.

- The use of cheap dressing at the construction stage, or it was not enough.

- Using a vibration pump to pump out water. It also provokes the appearance of sand in the source. It is recommended to install a centrifugal unit in the well.

- If the casing pipe is not immersed in the aquifer.

- Pumping a small volume of fluid out of a well. In this case, a thick layer of clay and rust from the pipes collects at the bottom.

A very unpleasant cause of cloudy water associated with contamination of the source with clay. In new mines, it appears in such cases:

- The drilling of the shaft was carried out in violation of the method of supplying technical water to the mine. If, after opening the aquifer, the clay solution is not replaced with clean water, the soil will fall into the underground layers and disperse over a large area. It is not easy to remove it from there, washing out can last several days. The soil remaining inside provokes formation clogging, in which the pores are clogged, providing fluid access to the well.

- Clay can enter the trunk from the nearest reservoir, in which this soil is contained in large quantities. Therefore, it is not recommended to drill close to ponds if the soil around it has poor filtering qualities.

- Soil enters a shallow source due to poorly set casing or lack of cement plugs between the column and the shaft wall. Water from the surface flows along the outer side of the column and carries soil particles into the well.

- Fluid is pumped out with clay if the suction port of the pump is incorrectly positioned. When it is too low above the bottom, all the dirt that lies on the filter will come to the surface. To correct the situation, raise the device higher.

- When clay appears from a long-used well, check two versions - source contamination due to casing depressurization or filter failure. In both cases, complex repairs are indispensable.

Vibration Pump Cleaning Method

The fastest and most effective way to clean a well is to use a vibrating pump. The only negative is the inability to determine the distance to the bottom. However, this is not required in all cases.

The cleaning procedure is performed as follows:

- A hose is fixed to the water intake housing with a clamp.

- To prevent the hose from floating up after immersion in the column, a weight is attached to its lower end.

- As soon as the hose descends into the structure, it will touch the silt deposits. After that, it must be raised by 50-100 mm, and the unit turned on.

The speed of cleaning by this method significantly exceeds the cleaning efficiency of the previous method. However, please note that a vibrating type pump will not be able to lift large, heavy contaminants. Also, very rapid wear of the valve of the unit is observed.

Conclusion

If there are the first signs that the water quality has changed, you should immediately correct the situation. If the water smells unpleasantly like a bolt, this indicates that due to the depressurization of the system, groundwater got inside

It is also important to inspect and troubleshoot. If untimely eliminated, this can lead to severe poisoning.

Oxidation with reagents will help fight hydrogen sulfide or the smell of a rotten egg. If you smell iodine, stop drinking water and contact the laboratory immediately, as this may be due to industrial waste entering the water.