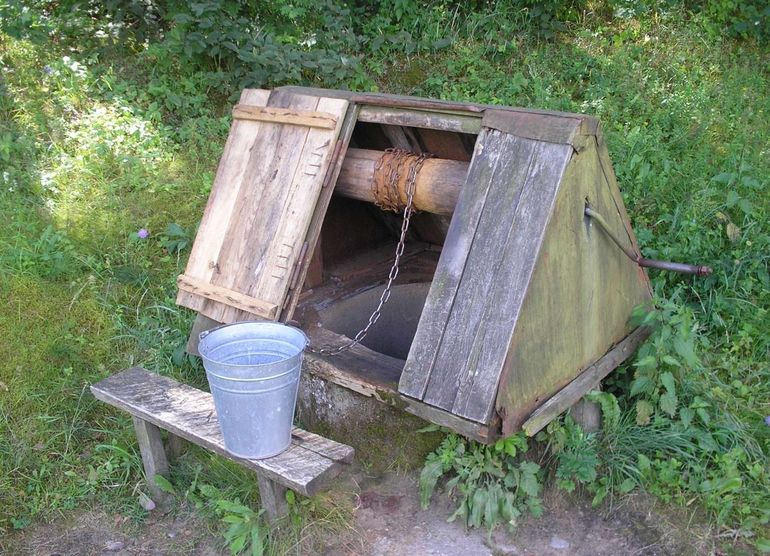

- Sand pulls through a layer of gravel backfill

- Myths and reality

- How many stages of purification should well water go through?

- Causes of cloudy water in the well

- Violation of the tightness of the well rings

- Change in the composition of the aquifer

- The problem of stagnant water

- Well design defects

- Pump installation error

- Quicksand

- Cleaning and disinfection of artesian wells

- Why self-cleaning is impractical

- Cleaning wells in the Kyiv region - who to trust

- What to do with yellow water in a well

- Measures to prevent pollution of sources

- How to clean the well from silt and sand with your own hands?

- Bailer

- Vibrating pump

- Deep electric pump

- Well Cleaning Safety

- Video - System and filters for cleaning water from a well in a country house from iron

- Perform disinfection

- Cleaning and disinfection

- Maintaining good sanitation

- Cleaning and disinfection of wells

- The main causes of cloudiness

- WAYS TO SOLVING THE PROBLEM

- How to choose a filtration system for a summer residence

Sand pulls through a layer of gravel backfill

The most common cause of sanding is a faulty filter.

If the well is made according to all the rules, then its bottom is a tightly welded end.The old regulations stated that the weld end could be replaced with a conical point oak chop. However, at present, in the vast majority of cases, instead of brewing, gravel is simply poured into the pipe, similar to how it is done when arranging wells. However, the problem is that water flows into a well and a well at completely different speeds.

The grid of any well becomes clogged after some time. Its resistance begins to exceed the resistance provided by the gravel backfill. Water arrives through the backfill and brings sand into the well. At the same time, grains of sand can have completely different sizes - from the smallest to very large.

In addition, if such a well is equipped with a high power pump, during its operation, the gravel plug may have less resistance than even a clean filter grid. In such circumstances sand begins to pass very quickly into the well through the gravel pack. And it can be pulled up to the level of the pump, i.e. pretty high.

Quite often, this phenomenon is accompanied by the fact that the clay, liquefied under the constant influence of the water flow, will no longer hold the gravel backfill. And because of this, muddy water with a clay admixture will go.

Myths and reality

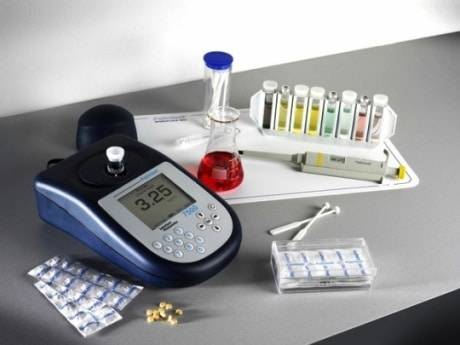

It is believed that in deep wells the water is always clean. However, this assertion is debatable. Whether the water is drinkable and clean can only be answered after laboratory tests.

The purity of the water "feels on the palate": pure water is sweetish and pleasant to the taste. This is not true. The water in each well has its own taste, someone likes it from one well, someone from another. A sweetish taste usually indicates an excess of lead oxide.Experts warn that in most cases in the laboratory it turns out that the water is not of the best quality. Often the water is unsafe and needs cleaning.

Cloudy water doesn't mean it's dangerous. This is not true. If the water is cloudy, “perch water” (ground water) has got into it, in which there are always a lot of various organic compounds and microorganisms.

You can fight turbidity with filters. This is true. For example, if the water has an unpleasant odor and brown flakes, it means that it contains an excess of iron. There are so many iron particles that they literally rust when exposed to oxygen. Iron filters solve this problem. If the water is too hard, this problem can also be solved with the help of filters. Hard water forms limescale and accelerates the wear of household appliances. Ion exchange filters are used to soften water. If the water has a blue-green tint, this is evidence of increased acidity of the water. In such cases, carbon filters are used.

With the help of filters, you can purify any water. This is not true. Not all filters help. To find out if the water is not dangerous, it is necessary to do a laboratory analysis.

The arrangement of reverse osmosis will eliminate the unpleasant smell of water. Not quite true. If the water has acquired the smell of clay or earth, you must first mechanically clean the well, then install osmosis and activated carbon filters.

If serious contamination is found in the water, the well cannot be used, even if filters are installed. This is true. First you need to clean the water. After submitting water samples for analysis, you will receive the result and recommendations.After that, you will find the best cleaning method, carry out cleaning procedures, make sure that the water is clean, and only after that you can use the water as usual.

With regular water purification, you can not worry about your health. Not certainly in that way. In some cases, cleaning will help for a short time, it happens that the well needs repair. Often it is necessary to strengthen the rings with staples. It may also be necessary to seal the joints with a solution of cement with liquid glass.

You can disinfect the water in the well with ultraviolet light. This is true. There is an alternative method of purifying well water - by ultraviolet irradiation. This is a less time-consuming process, but it is also carried out only after mechanical cleaning of the well.

More about this in the video:

How many stages of purification should well water go through?

Filtration and modern methods of water disinfection consist of several stages. The use of special purification, consisting of several stages, makes it possible to make water recommended for consumption.

Choosing water filters, it is necessary to take into account the indicators obtained in the analysis.

When filtering water coming from a reservoir, several stages of purification are performed:

- First you need to clean the water from the well mechanically. For this, a water filter in the form of a mesh structure is used. These devices help to retain various impurities: clay compounds, silt and rust.

- Then the water from the well is purified using a special electrochemical treatment. The process is to treat contaminants that are dissolved in the water.

- Turbid water from the well is removed by catalytic clarification. Contaminants accumulate on the filter.They can then be removed by washing.

- At the final stage, sorption purification of water is carried out. For this, filters are selected, which include carbon fibers. At the same time, well water becomes clean and specific odors are eliminated from it.

Causes of cloudy water in the well

The owners of their own water intakes consider the extracted water to be better than from the central main. Partially they are right: it is spring, is not subject to chlorination and did not travel a long way through the old pipeline. This is so if it is transparent and does not contain unwanted impurities.

There are times when muddy water is in the well. Consider the reasons why this happens, and what can be done to correct this situation.

Violation of the tightness of the well rings

If the soil in the area is mobile, heaving, when lining the mine, they did not waterproof the joints between the rings or did it poorly, then over time, liquid with clay and other soil particles will begin to ooze from the joints and cracks. This will cause the water in the well to turn yellow.

The solution to the problem is to re-seal the seams and cracks with a hydraulic seal, and treat them with coating cement waterproofing from above. It is impossible to use bituminous mastics, sealants, polyurethane foam, epoxy resins in drinking water intake structures - they will spoil the water.

The procedure for sealing seams and cracks in a mine well made of concrete rings:

- Examine the walls.

- Remove loose concrete.

- Expand and deepen the seams so that it is convenient to fill them with a hydroseal. Remove concrete dust and crumbs.

- If the reason for the depressurization of the seams is the displacement of the rings from the effects of movement or swelling of the soil, then it is necessary to fasten the elements of the shaft with metal brackets. Below the level of soil freezing put 2 brackets each, above - 4 each.

- Dilute a small portion of the hydroseal with water according to the instructions. The amount of the composition is taken based on a few minutes of work. The tool hardens quickly - from 3 to 8 minutes.

- Insert the seal into the gap and spread with a spatula.

If a strong leak is detected, then the hydroseal is taken dry in the hand (with a glove), placed directly into the seam or crack and wait for several minutes. There are special ultrafast hardening compounds designed to seal pressure leaks. They freeze in 30-50 seconds.

Change in the composition of the aquifer

Sometimes pollution does not enter the well through the seams between the rings. They can poison the aquifer itself, thanks to which the structure is filled with water. This happens if there is an enterprise near your site that drains its industrial effluents into a natural reservoir, destroying it and the territory adjacent to it.

After all, new portions of water from the feed layer will return the problem that has arisen. It remains only to hope for a filter system that should be placed on the water path from the source to the place of its final consumption.

The problem of stagnant water

Understanding why there is muddy water in the well, you can find another reason in the form of its stagnation. As you know, it must be in constant motion:

- if the source of water supply is rarely used, this contributes to its stagnation, the organic compounds in it begin to decompose and change its composition;

- this is accompanied by the appearance of an unpleasant odor and the manifestation of turbidity;

- it cannot be used as a drink, and it is unlikely that you will want to do this.

The appearance of color, unpleasant odor and taste occurs due to the development of bacteria of putrefactive formations. It can be cleaned by pumping and disinfecting the shaft.

Well design defects

The design of the well should be protected as much as possible.

If there is no canopy, a “house” above the well, or it is installed incorrectly, then garbage, foliage, etc. gets into the mine. Sunlight creates optimal conditions for the development of bacteria, in the most neglected cases, the walls become overgrown with mosses.

The water, as if stagnant, turns green and smells unpleasant. After cleaning, a reliable cover and a canopy are installed over the structure, or defects in existing fixtures are eliminated.

Pump installation error

Sometimes a pump installed too close to the bottom (at a distance of less than 70 cm) raises sand, silt, etc. when turned on. The reason may also be the excess power of the device. If the reinstallation of the water-lifting equipment did not help, then it is necessary to replace it with a device of a different design or less powerful.

Quicksand

To protect the structure and prevent pollution, a shield made of fine metal mesh or wood is installed at the bottom: aspen, bog oak, fir, larch, juniper. A bottom filter made of sand, gravel, pebbles or special minerals - shungite, zeolite, jadeite - is poured over the shield.

Cleaning and disinfection of artesian wells

Timely cleaning of wells for water is the key to the normal operation of the equipment, sufficient debit and safe composition of the resulting water.With the help of purification, various substances accumulated during the long use of the well are removed from the water: organic (alcohols, aldehydes, phenols, acids, nitrogen, hydrocarbons) and mineral (sand, clay, salts, mineral acids). Our company cleans both old and new artesian springs.

Well cleaning methods

To clean deep wells from various contaminants, two main methods are used - mechanical and chemical. Let's consider them in more detail.

-

Mechanical method - used when cleaning the well from debris, sand that has fallen from above. Several approaches are used:

-

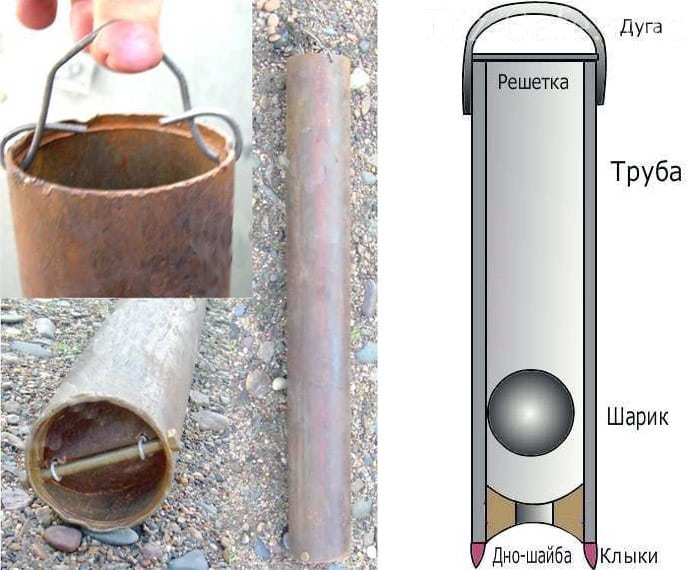

Cleaning with a bailer, a metal pipe with a check valve. It is one of the simplest methods, as well as the most secure. This process does not damage the filter system, but is very labor intensive.

-

Pumping out with a pump. This method is advisable only with a small blockage, at the first stage of contamination. To remove a dense crust of dirt, this method is not used, as it is ineffective.

-

Hydraulic cleaning. Water is pumped under pressure up to 10 atmospheres. This method involves the use of professional equipment and only by qualified specialists.

-

Air purge. This procedure is carried out by special compressor equipment that pumps air into the well shaft. As a result of this process, silt and sand are pushed to the surface.

-

-

The chemical method helps to get rid of more complex deposits - silt, lime, rust.

-

Cleaning the well with acid is very rarely used.

-

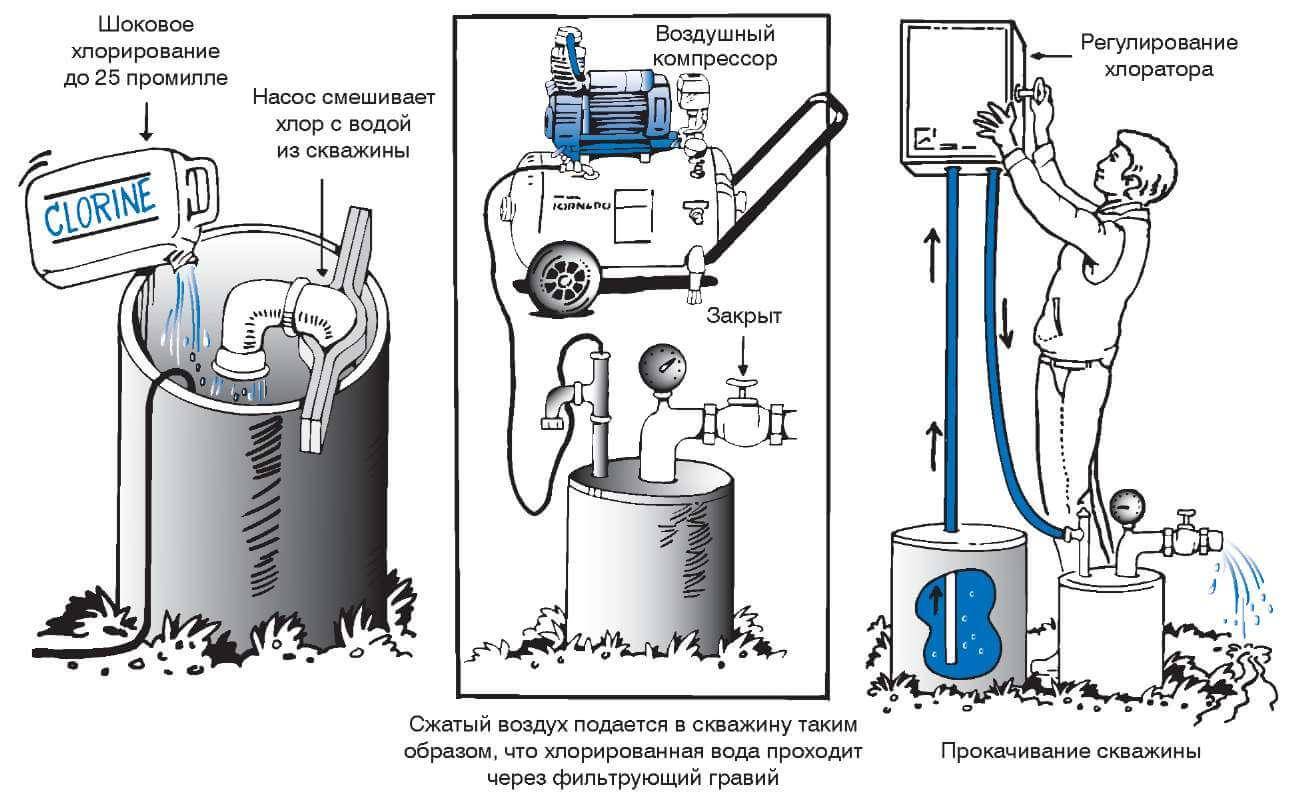

Chlorine disinfection.Water contamination with bacteria can be eliminated by treating the water source with a bleach solution at a percentage of 100 mg of chlorine per 1 liter of water for 2 hours. The water chlorination solution should provide 50% more water supply.

-

Why self-cleaning is impractical

Pollution of the water supply system can be triggered by various problems - improper installation of equipment, insufficient cleaning during operational pumping, or the wrong choice of pump. Without professional diagnostics, it is impossible to identify the true cause of the blockage, so get rid of it yourself.

Cleaning wells in the Kyiv region - who to trust

Cleaning of artesian wells should be carried out only by qualified craftsmen using professional equipment. Inexperienced professionals may confuse well cleaning with workover work, assuming that they are the same process, although they are not. Repair means the restoration of the integrity of the structural parts of the equipment, underground and surface, the tightness of gaps, joints, pipes, the serviceability of the mechanisms of the pumping system. Cleaning involves the removal of debris, sand, foreign matter from the source of water supply and disinfection.

Performing all repair and cleaning work on your own can lead to the termination of equipment performance. Therefore, you should trust the professionals, in Kyiv and the Kyiv region, our company will help you quickly and efficiently solve the problem.

The cost of work depends on several factors, the main of which are the volume and complexity of cleaning.We guarantee the prompt execution of works of any complexity for cleaning and disinfection of wells of various depths, providing a guarantee of quality and loyal prices for services. If it is necessary to clean the wells from any kind of pollution.

What to do with yellow water in a well

Yellow water in the well is not yet a sentence. Sometimes the corrosive metal that was used in the construction of the mine becomes the cause of trouble. It is enough to remove the "foreign body", and the problem will disappear by itself. However, in most cases, efforts will have to be made to obtain high-quality water suitable for drinking, cooking and washing clothes.

The easiest way to get clean, clear water is to settle. This method is applicable if consumption volumes are small and a pump is not used. Otherwise, you will have to install and constantly monitor the filter system.

Mechanical cleaning will help only in the presence of physical impurities, but not chemical ones. It will turn out to defend and filter the water into which clay, sand or other components have been mixed. They appear as a result of a strong flood, intense rains that set the groundwater in motion.

It is more difficult when it comes to the composition of water containing a large amount of iron oxide or humic acid salts. As long as the compound is in the soil, where oxygen access is limited, yellowness does not manifest itself in any way.

Even control drilling does not always give an objective picture - samples can be completely transparent. The characteristic taste and color of rust will appear when it is too late to change something - the well has been dug and is functioning.

To avoid wondering why well water turns yellow, we recommend that you do the following:

- assess the composition of soils, get advice on the location of nearby peatlands or swamps, including drained ones;

- drill a control well and extract a water sample;

- contact a specialized laboratory and conduct a chemical analysis of the liquid.

If the results confirm the presence of iron oxide, this is not a reason to refuse to build a well. Be sure to record the indicators of salt content - in the future, the information will be useful when choosing filters. The higher the oxide concentration, the more multicomponent the cleaning process will be.

Measures to prevent pollution of sources

In order to avoid frequent cleaning of the well from bacteria, it is necessary to take some measures in a timely manner:

it is not recommended to leave the well in an open state, the chance of various debris getting inside increases;

penetration of direct sunlight into the mine is unacceptable, this creates a favorable environment for the reproduction of bacteria;

the mine should be as far as possible from places of pollution, the minimum distance to the sewer should be 20 m;

there must be sealed walls of the mine, this will protect it from getting inside surface and groundwater;

carefully approach the choice and location of pumping devices, they should not raise soil particles from the bottom;

avoid draining the extracted water back into the mine, this will contribute to the contamination of its contents;

regularly monitor the quality of water, at the first suspicion of its deterioration, contact specialists;

timely carry out maintenance of the well shaft and pumping equipment;

special attention should be paid to the bottom of the mine;

it is important to decide whether it is necessary to install a filter and which one, in some cases it can degrade water quality.

How to clean the well from silt and sand with your own hands?

Bailer

Cleaning of silt and sand with a bailer.

Bailer is a device for mechanical cleaning of wells. It is a short pipe with a stop valve at the end. The latter has the form of a ball or a lid.

The device suspended on a cable is lowered to the bottom and raised to a distance of 0.5 m. Such actions are performed several times. When the pipe moves, the cover or ball moves, contaminated liquid enters the cavity.

When the pipe is lifted, the ball closes the hole, so the pumped sand or clay does not fall back. After completion of work, the device is removed. After that, the quality of the extracted resource is checked.

Vibrating pump

This method is used for physical contamination. This is due to the principle of operation of vibration equipment. The fluid is sucked in by a rubber piston that is in constant motion. Unlike other types of pumps, vibration pumps can operate in a highly polluted environment. The device is placed at a height of 20 cm from the bottom and launched. To facilitate the work, tying a steel bar helps to prevent the deepening of the pump.

In the presence of additional equipment, it is also included. The liquid supplied by the device is settled in the tank and returned to the well through the hose. This helps to remove dirt from the bottom. The vibration pump will remove sand and clay from the well.

Deep electric pump

Deep equipment does not create vibration, so the filter layer will have to be cleaned separately.For this, an auxiliary apparatus is used - a mechanical baking powder. He is hung on a nylon rope and lowered to the bottom of the mine. The device removes a layer of sand and clay from the bottom. After purification, the water is analyzed for the presence of contaminants.

Well Cleaning Safety

This type of work is classified as risky, so the well should be cleaned taking into account the necessary safety measures.

-

Cleaning activities must be carried out using a safety rope. If a person descends into the well, then a group of two or three assistants should watch this.

- The head is protected by a special helmet, and the legs are protected by high rubber boots.

- If, when diving more than 3 meters, it becomes difficult to breathe, dizziness and signs of drowsiness occur, then you should immediately get up.

-

Disinfection and cleaning of the bottom should be carried out in a respirator. It is also acceptable to use a gas mask.

- Such work is contraindicated for persons with diseases of the heart or respiratory organs.

- When at the bottom of the well, do not stand under a rising or falling bucket.

Video - System and filters for cleaning water from a well in a country house from iron

Well water purification

Well disinfection

Well water purification

Water purification system from iron pollution

Filter for water treatment from the well

How to purify water from the well

Neglecting to clean the well is a health risk!

Well water analysis

Pump for pumping water. Mechanical water purification involves cleaning the entire structure of the well

Cleaning the bottom of the well

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

The terrible smell of rotten eggs says only one thing - there is an excess of hydrogen sulfide masses in the water

Muddy water in the well

Polluted water in the well

Green water in the well

Repair of a well from concrete rings

Photo of factory filters for a well

Sample bag for laboratory analysis

Example of a water sample analysis result

Water filter pitcher

Well water filter

Preparation of bleach solution

Before disinfection, it is necessary to clean the walls of the well from plaque.

The solution (in this case, potassium permanganate) is poured into the well

At the end, the well must be covered with a lid.

The first clear signs of chlorine poisoning are: sharp chest pain, dry cough, vomiting, pain in the eyes (lacrimation)

The use of a safety rope is mandatory

Perform disinfection

Cleaning and disinfection

As we can see from the plan, the actual disinfection is divided into two stages: the treatment of the well and the maintenance of a sanitary condition. Below we will consider all the methods used for this in detail.

Seams treated with sealant

The well processing instruction provides for the following actions:

First, we need to pump out or scoop out water, and preferably to the very bottom. This can be done using the simplest pump.

We subject the drained well shaft to mechanical cleaning. To do this, we go down and scrape off hundreds of walls, everything that is scraped off - salt deposits, bacterial plaque, algae colonies, etc. After processing, we should have clean concrete rings of the well.

Next, we arm ourselves with a shovel and collect silt, sand and the top layer of a gravel filter from the bottom.Using a bucket on a rope, we raise the collected material to the surface and lay it out on a flat area covered with a tarpaulin or non-woven material for washing.

After washing, add shungite or silicon to the gravel

These minerals will help soften the water, which is also very important.

The extracted silty gravel must be washed

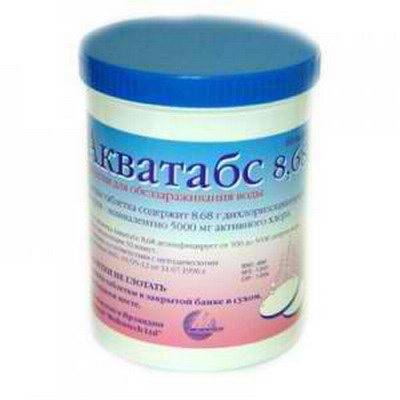

Next, we begin chlorination of water in the well:

- We dilute bleach in cold water (20 grams of lime per liter of water or 500 ml of "Whiteness" per bucket).

-

The resulting composition is applied to the walls of the well with a brush or paint sprayer.

- In the course of work, we must use a respirator, and when we have to go down to great depths, then a gas mask.

- If the composition remains - pour it to the bottom. All the same, water will arrive within a few hours and the reaction we need will pass.

- We close the well with polyethylene for at least two days.

- After this period, open the lid, ventilate the mine and wash the walls with a hose.

- The accumulated water is pumped out twice and drained. It can only be used for technical purposes: it is not suitable for drinking or irrigation.

After pumping out, it is necessary to check the composition of the liquid: if it still gives off bleach, the pumping must be repeated. It is also advisable to boil water for at least two weeks before drinking.

Maintaining good sanitation

If the analyzes show that, despite our efforts, the level of pollution remains above the permissible level, it will be necessary to carry out systematic treatment of the water itself.

Most disinfectants contain chlorine.

This is done in this way:

- If you are looking for how to disinfect well water, then the easiest way is to use bleach.To do this, we calculate the approximate volume of the aquifer of our well in liters (this is easy to do if the level of the water table is known).

- Based on the volume obtained, add 2 to 5 milligrams of active chlorine per liter of water to the water. As a rule, a liter of bleach solution (1%) is enough for high-quality disinfection.

- After adding the reagent, the water must be thoroughly mixed, and only then it should be taken. The use of an aerator gives good results: due to the saturation of the liquid with oxygen, the activity of chlorine increases, and the amount of solution introduced can be reduced by at least half.

Tablets with bactericidal action

Potassium permanganate or special disinfectant tablets can also be used instead of bleach. They are quite convenient to use (no need to suffer with the preparation of a solution of the desired concentration), but their price is very high. However, if you can afford it - buy boldly!

In any case, it is necessary to constantly monitor the quality of the water, and, if necessary, immediately carry out a complete cleaning.

Cleaning and disinfection of wells

All water wells have one significant drawback - they are subject to various pollution as they are used. The first signs that an artesian well needs cleaning are the appearance of sand in the water or a decrease in pressure. The water may include hard rock particles called slurry. They can settle on the filtration system and interfere with normal water supply.

The chemical composition of water must meet the regulated norms and state standards.It is checked after operational pumping and after the installation of an artesian well. Very often, these results can differ significantly due to unsuccessful construction pumping, the intake of an insufficient amount of water, provided for by the requirements of SNIP, without taking into account the unorganized process of using the well.

The chemical composition of water must meet the regulated norms and state standards.It is checked after operational pumping and after the installation of an artesian well. Very often, these results can differ significantly due to unsuccessful construction pumping, the intake of an insufficient amount of water, provided for by the requirements of SNIP, without taking into account the unorganized process of using the well.

Our employees, thanks to their high level of qualification and many years of experience in drilling, diagnostics and cleaning of wells, carry out the most accurate analysis of the state of the well. Also, experts will calculate and offer the most cost-effective and efficient way to clean water sources.

Our staff quickly and efficiently performs any tasks, thanks to professional equipment, a full range of necessary tools and related materials. All work is carried out taking into account the surrounding landscape, trying as much as possible not to disturb or damage the surrounding area.

The main causes of cloudiness

Before you start cleaning, you need to find out what exactly caused the cloudiness. The main causes of water pollution include:

- ingress of soil particles due to depressurization of the walls;

- active development of microorganisms, for example, when exposed to direct sunlight;

- improper use and care of the device;

- stagnation during very rare operation of the well;

- a faulty pump, which during operation raises silty masses from the bottom;

- harmful chemicals entering the groundwater;

- decomposition of organic compounds accidentally found in the mine;

- mixing well water with sedimentary moisture falling from above due to the lack of a cover;

- improper arrangement of the above-ground part of the structure.

After determining the cause of the pollution of the well, you can begin cleaning work. They can be done on your own or you can seek help from specialists.

Soil particle pollution

If the turbidity of the water is caused by the ingress of soil or sand particles into it, a mechanical filter will help. If the dirt seeps along with the perch, it is necessary to put in order the broken sealing of the butt joints.

To clean a dirty well, you need to act in a certain order. It must be dried first. To do this, the contents are completely pumped out of the shaft using a pump.

A person in special clothes must descend into an empty well with a cable. Using a brush with a hard bristle or a special scraper, he will clean the inner surface of the accumulation of silt masses and dirt.

Layers removed from the walls and bottom must be collected in a bucket and lifted out. Cleaned surfaces should be treated with a disinfectant to remove harmful microorganisms and odors. All butt joints or cracks caused by under water pressure, - seal with a moisture-resistant compound.

How to make a clay castle? If the clay castle was not equipped during the digging of the well, the water will inevitably be polluted by precipitation. Therefore, it is necessary to provide protection from rain. A ditch 1 m wide must be dug around the above-ground head of the well. The minimum depth is 0.5 m.

In the prepared ditch, it is necessary to tightly lay the clay in several layers. Each layer is carefully compacted. Crushed stone or other bulk material is poured over the clay. The final layer is a cement mortar. With its help, a slope is formed from the mine to the side.This will ensure the runoff of rain and melt water from the structure.

Pump problems

Sometimes turbidity in the well is observed during pump operation. This occurs when the device malfunctions or is incorrectly installed. After checking and reinstalling, the pump can be connected.

If turbidity occurs again, you need to purchase a different type of pump - with a different liquid suction pattern. When buying a device, it is necessary to take into account the chemical composition of the water in the well. You can check it in the laboratory of Rospotrebnadzor.

Silting water

If the cloudy water has a yellow or greenish tint, then it is silting. This is due to an incorrectly laid and/or partially destroyed bottom filter.

In this case, it is necessary to drain the well. Then disassemble the bottom filter and extract it in parts to the surface. If bulk materials have become unusable, they must be updated.

Partially damaged gravel or crushed stone should be sorted out and washed. After that, the material can be reused, adding new masses if necessary. The bottom filter must be laid out again, carefully observing all the rules for its installation.

Water stagnation

If the well is rarely used, the water in it stagnates and becomes cloudy. In this case, it is necessary to drain its trunk. Thoroughly clean the bottom and walls of debris, silt, mucus and treat with a disinfectant solution. When the shaft is full, you need to add a solution of bleach.

To avoid stagnation, you need to periodically use the well. Additional cleaning will be provided by installing a special filter purchased at the store.

ferruginous water

With an increased iron content, well water becomes yellowish and acquires a metallic taste.If it settles, a precipitate will surely appear, resembling rust in color.

It is not dangerous to health, but it is unpleasant to drink it. The taste of dishes prepared with its use deteriorates noticeably. Special filters equipped with cartridges will help to correct the situation. to remove iron.

WAYS TO SOLVING THE PROBLEM

There are three ways to solve the problem of an inactive fund.

First, the use of innovative types of maintenance and repair equipment.

Secondly, the use of innovative technologies for oil production and carrying out the pilot project.

Thirdly, optimization of organizational work. Innovative production equipment includes equipment with intelligent diagnostic systems, packers and shut-off valves, and equipment with anti-flight devices.

Innovative types of PRS equipment include diagnostic equipment (video cameras, thermal imagers), special fishing tools, and coiled tubing equipment.

One of the options for optimizing organizational work can be the path proposed in the letter that Deputy Energy Minister Sergei Kudryashov, on behalf of Deputy Prime Minister Igor Sechin, sent to the management of Soyuzneftegazservis. The document, in particular, notes that "the parameters of the operation of a single well are directly dependent on the functioning of the entire technical and technological complex of the field." The deputy minister also refers to the complexity and "inexpediency" of tax accounting for oil produced at each individual well. According to Mr. Kudryashov, the conclusion of “operator and other agreements” with service companies can become a way out of the situation.

Within the framework of these agreements, it is possible to use the forces and means of service companies that are armed with special methods and special equipment for bringing wells out of inactivity, increasing the profitability of oil production, and increasing THD.

How to choose a filtration system for a summer residence

It is extremely important to choose the right filter in private well water treatment house. Taking care of your health, it is recommended to give it to the laboratory for testing.

After that, you will know exactly its real composition for the presence of salts, iron, etc. As a result, it will be easier to choose the appropriate device.

You may need to buy a comprehensive fluid treatment. In this case, you must be prepared for serious costs. If the water is too hard, a fine filter is bought. When choosing, it is worth considering an important factor: whether an established water supply system under pressure is necessary. As a result, the water will be of high quality.