- Tips & Tricks

- Soldering

- How to properly lubricate a faucet

- Types of sealing tapes

- Anaerobic adhesives sealants

- Couplings

- Docking pipes made of metal and plastic

- Flange connection of gas pipes

- GOI polishing paste Archimedes Norma

- Table 1. Abrasive GOST 3647-80

- What is polishing ability

- Lapping order

- The order of lapping is as follows:

- Linen

- Which seal is better to choose for installing a heating system

- Purpose and variety of thermosealants

- Main technical properties of the sealing tape

- Rules for soldering copper

- Soldering large parts

- Soldering wires or wire

- Soldering dishes or soldering holes in copper

- Methods for checking the tightness of connections

- Features of the installation of threaded fittings

- Step by step installation instructions

- Metal pipe connection without thread

- Sealing with linen thread

- The question of packaging

Tips & Tricks

Professional craftsmen share several recommendations on how to make the sealing of threaded connections the simplest and most durable.

- Do not be afraid that the uncured sealant will come out from the inside of the pipe. It will not harden and during the operation of the water supply system it will simply be washed off with water. Anaerobic gels are completely harmless, but it is still better to leave the faucet open for a while so that the excess sealant is completely removed.

- When screwing connections treated with thread sealant, it is not necessary to tighten the threads with wrenches. The maximum effort of the hands will be quite enough, but you really need to wrap it with all your might.

- If the pipe is fragile, then you do not need to try to unwind the joint treated with sealants. Heat must be applied immediately. 170 degrees will be enough.

- If possible, it is best to refrain from using sealants for temporary installations. Dismantling the connections will require a lot of time and effort, which is not fully paid off. It is best to resort to the use of sealant threads or linen for temporary use.

For the features of thread sealant, see the following video.

Soldering

Equipment for soldering polyethylene pipes

Equipment for soldering polyethylene pipes

It would be more correct to say butt soldering. It is also used for polyethylene pipes. The condition for its implementation will be the mobility of the two articulated parts. Otherwise, the process will be broken. In terms of efficiency, it is not inferior to electrofusion. To carry out the work you will need a modular unit. Its components are a hydraulic unit, a cutter, a soldering iron and a centralizer. To use it correctly, proceed as follows:

- Inserts are mounted in a special vise according to the size of the pipe being processed.

- The pipes are clamped. Do not be zealous, if you overtighten the bolts, then the end will lose the shape of a circle, which will lead to problems.

- Soldered areas are cleaned of dirt and dust.

- A construction knife or other device eliminates chips on the chamfer, if any.

- On the hydraulic block, the valve slowly opens before the movement of the components on the centralizer begins. The pressure value is marked as working.

- The parts are bred, a trimmer is inserted between them. It starts and shifting is done again. After a few turns of the knives, the device can be picked up.

- To check the correctness and evenness of the joint, the nozzles are shifted again and inspected well.

- Joints are degreased with a solvent or alcohol wipe.

- The soldering iron is heated up.

- After reaching the set temperature, it is installed between the parts.

- The pressure for soldering is set according to the table and the centralizer modules are shifted again. They are held in tension until the formation of an influx of 1 mm.

- After that, the pressure is released, and they warm up for a few more seconds.

- Parts move apart and the heater is removed. Within 5 seconds, they must be reconnected under power for another 5 seconds. After that, the force is removed and the cooling time is waited.

Until the end of the time period indicated for cooling, in no case should the vise be removed or the pipes tilted in any way. This may lead to depressurization.

How to properly lubricate a faucet

The general algorithm for repairing any gas valve comes down to the following steps:

- Shut off the gas supply.

- De-energize the mains in the switchboard. If for some reason access is blocked there, then turn off all electrical appliances and lamps from the sockets.

- Remove all flammable materials and utensils (including matches, solvents, etc.).

- Close the kitchen door and open the window.

- Dismantle the faucet.

- Plug the riser pipe with a damp cloth.

- Apply lubricant.

- Remove the rags and assemble the faucet.

- Ventilate the room.

Dismantling the crane requires experience and extreme accuracy.If you need to lubricate the gas line on the stove, you will have to remove the turntables (flags) and the front or top panel below them. The faucet device will open.

For stoves of the Hephaestus type, it is not necessary to raise the panel with burners - the front cover is removed by itself, while it is quite simple, because it is attached to self-tapping screws. The valves are fixed with flanges with two screws - to remove them, you will need a Phillips screwdriver.

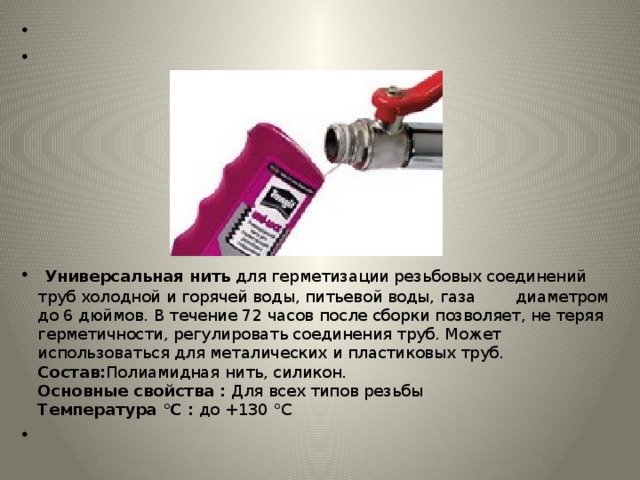

Types of sealing tapes

This material is produced in the form of winding on a coil up to 10 meters long. It is successfully used for winding on pipe threads in pressure systems, including plumbing, gas and heating.

Its purpose in joints is a deformable filler that acts as a thread lubricant, contributing to an increase in tightness. This seal is available in 3 types:

- type 1 - for use in pipeline systems for the transportation of aggressive liquids, used using purified petroleum jelly;

- type 2 - for pumping strong oxidizing agents, which prohibits the use of an additional sealant in the form of oils;

- type 3 - used for transporting relatively pure liquids and gases, the use of lubrication is excluded.

Anaerobic adhesives sealants

This material has good viscosity and liquid consistency. They can find a long time in the open air without changing their properties. When they enter threaded joints where there is no air, they polymerize without shrinkage. The result is a very strong and solid substance, similar in properties to plastic. It provides excellent sealing and completely fills the gap in the thread, regardless of the pressure of the liquid or gas in the pipes.An important advantage of anaerobic adhesives is that they turn into a solid substance only in threaded connections, and in the open air they remain liquid and do not clog equipment and valves. They can be easily removed from the surface. This material is widely used in industry.

Anaerobic adhesives can be easily applied directly from the packaging. When carrying out bulk work, it is worth using dispensers. Different types of adhesives have different polymerization times of the substance, from 3 minutes to several hours. The choice of a particular adhesive depends on the technical task. If you need a quick installation, then you should use an adhesive with a short curing time. In a situation where the connection needs to be adjusted, then you can choose an adhesive that takes on its final shape after a while.

A joint sealed with anaerobic adhesive can be disassembled using conventional tools. After curing, the adhesive is non-toxic, which makes it suitable for use in the food industry. The operating temperature of anaerobic sealants is from -55 to +150 degrees Celsius. Some types of glue can withstand up to +200 degrees. When briefly exposed to higher temperatures, they can continue to do their job without changing properties.

The cost of anaerobic adhesives is higher than other types of sealants. However, they fully work out the declared price. The reliability of the connection using anaerobic adhesive is much higher than any other material. Each owner chooses for himself what is more important for him: confidence and reliability or the likelihood of large losses in the event of a system breakdown.

The undoubted advantages of an anaerobic adhesive-sealant include ease of use, sealing threads regardless of force, easy installation of the system due to lubricity, ability to withstand more gas or liquid pressure, better value for money, preservation of liquid form in the open air.

The disadvantages of this substance include the impossibility of using in an oxidizing and oxygen environment and at low temperatures due to an increase in polymerization time. This composition can be used exclusively on dry threads and is not recommended for the installation of pipes with a diameter greater than M80.

Couplings

When repairing gas and water systems or laying new ones, the question arises: what is the best way to connect the risers and seal the joints that have appeared.

If we are talking about detachable connections, then it is best to connect the risers with the help of couplings. They can be used both in the form of fittings and as adapters, if the linear dimensions, including the diameters of threaded pipe connections, are different.

- reliability;

- availability and breadth of assortment;

- speed, ease of assembly and disassembly;

- low cost.

Depending on the types of risers, similar connecting fittings are produced. Sealant is selected in the same way. If metal fittings are most often sealed with tow with oil paint, then FUM tape and synthetic sealant, in particular an anaerobic sealant, are best suited for plastic parts.

Docking pipes made of metal and plastic

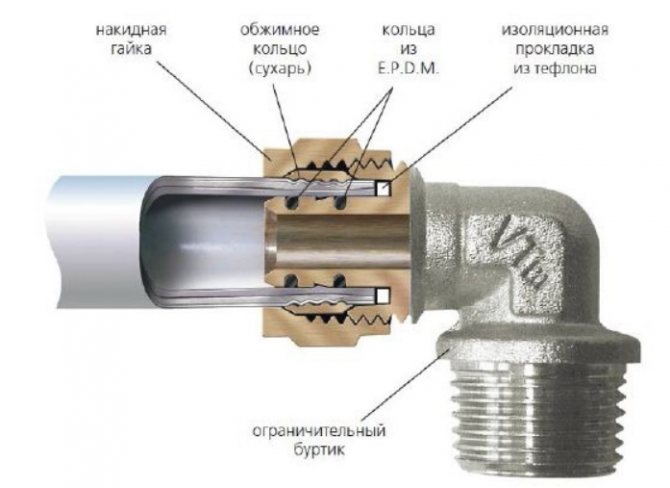

The popularity of polymer pipes in household mains often requires their connection to existing metal pipes. For this, special adapters are used. The most common of these are fittings called "American" or "nipple".

The American adapter consists of two parts. At one end of the metal part, an external or internal thread is applied, depending on the type of cutting of the pipe to be connected. At the other end is an external thread. The second part is made of plastic, ending with a union nut with an internal thread. Both parts are connected to each other by screwing the nut onto the thread of the metal element. Joint sealing - through a sealing gasket inside the union nut.

American adapter connecting metal and plastic

The first part of the adapter is screwed into the metal pipe to be connected, and the outlet pipe is welded by polymer welding to the plastic pipeline.

A nipple fitting is a polymer sleeve, inside of which a threaded metal part is soldered. It provides a joint with a steel pipe, and the sleeve itself is welded to a plastic pipeline.

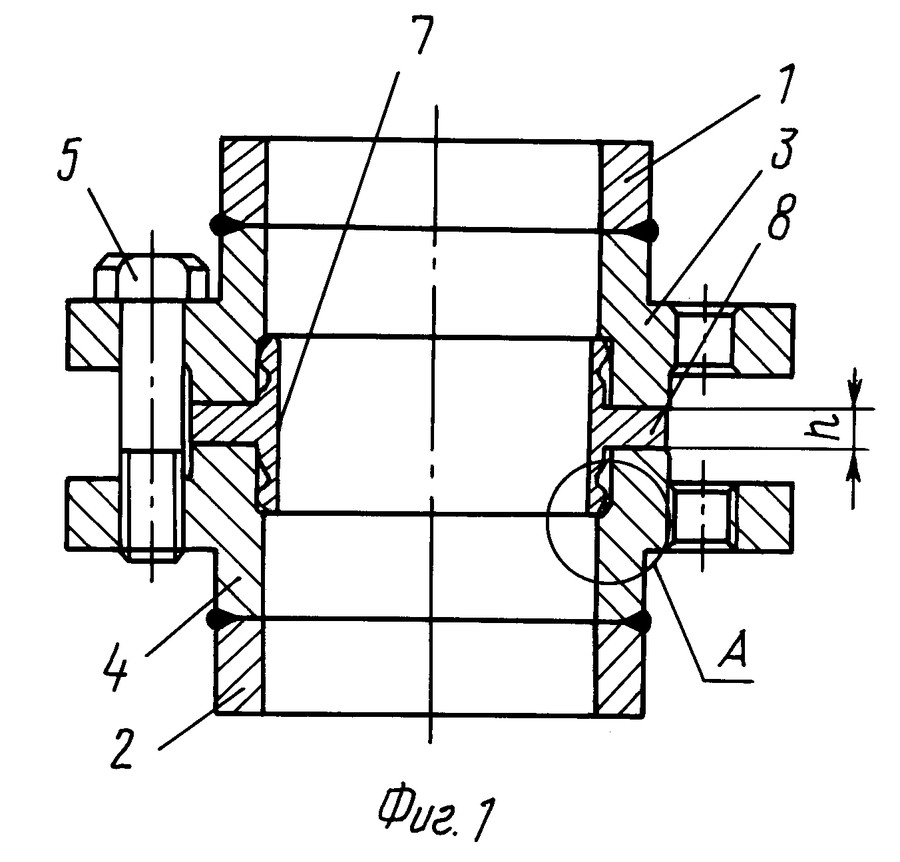

Flange connection of gas pipes

Flange connection is the most common type of detachable pipe connection.

Flange connection is the most common type of detachable pipe connection.

Due to the simplicity of design, ease of disassembly and assembly. But at the same time, there is a high cost of work and a low reliability of the connection compared to welded.

And if the pressure of the transported medium changes, then a gas leak may occur.

The flange connection consists of:

- from 2 flanges;

- fasteners - studs, bolts, nuts;

- O-ring or gasket.

Most often used technical rubber gaskets, asbestos cardboard or sheet paronite.

Hello dear readers. The question of how to seal the threads on a gas pipe is quite relevant. After all, this is a very vulnerable area. This is where most of the leaks occur.

GOI polishing paste Archimedes Norma

Paste GOI polishing Archimedes Norma means for polishing metals, glass and plastic. It can also be used to prepare the surface for polishing. The paste allows both manual and mechanical use on all types of paint. The paste is designed to remove: oxidized surface layer; pigmented areas of paint; coating defects; scratches and scratches; stubborn traces of insects.

Table 1. Abrasive GOST 3647-80

| Groups | Rooms | Groups | Rooms |

| grain | Grain size µm | grain | Designation |

| Sanding grain | Grinding powders | ||

| Glass, corundum, or a mixture | |||

| 63 — 50 | M63 | ||

| 50 — 40 | M50 | ||

| Micro grinding powders | |||

| 25-28 | M28 | ||

| 18-20 | M20 | ||

| 12-14 | M14 | ||

| 10 | M 10 | ||

| 7 | M 7 | ||

| 5 | M 5 |

| Percent composition. | rough | Medium | Thin |

| Chrome oxide | 81 | 76 | 74 |

| silica gel | 2 | 2 | 1,8 |

| stearic acid | 10 | 10 | 10 |

| split fat | 5 | 10 | 10 |

| oleic acid | — | — | 2 |

| bicarbonate soda | — | — | 0,21 |

| kerosene | 2 | 2 | 2 |

Rice. 3 . Abrasive powders and paste GOI.

What is polishing ability

The standard test for polishing ability is carried out as follows - chaotic movements of a hardened steel or brass plate are carried out chaotically on a cast-iron plate measuring 400 by 450 mm. in total giving 40 meters of a way at a certain pressure. Rough paste removes approximately 40 microns of metal. medium, about 5 microns, thin 0.25 microns.

Lapping order

Plug valves are produced in 3 types: with a cast-iron body and a brass stopper, with a brass body and a brass stopper, and completely from cast iron.

The order of lapping is as follows:

- If the valve is twisted from the pipe, then the body is clamped in a yew with little force, so as not to damage the body, with a large cone diameter upwards:

- The GOI medium paste is diluted with kerosene and evenly applied with a brush to the cork body;

- The knob is connected to a special threaded hole at the bottom of the cone;

- The cork is inserted into the body and rotated several times with light pressure;

- Why is 5 - 6 movements made with the hand by about 180 °, if there are no serious grooves on the cork or body, then this is quite enough;

- Remove and inspect the cork, if black furrows of the paste appear on it, it is necessary to wipe the parts and repeat the attempt until the blackness disappears;

- Then carefully wipe the cork and body dry. Apply several chalk longitudinal strips to the cone, insert the plug and turn it, then inspect, the chalk notches should be evenly distributed over the entire surface of the mating parts;

- After that, the mating surfaces are thoroughly wiped again and, after applying the sealing lubricant for gas valves, are assembled. You need to tighten the threaded holes with tow or fum. tape is better with sealing grease. Sealing grease for gas taps can be bought at a specialized plumbing store or ordered from numerous online resources.

Finally checked for leaks with soapy water, bubble inflation is not allowed.

In order for the faucet to work properly, it is necessary that the rotation of the plug in the faucet body occurs without effort, ensuring reliable sealing. For these purposes, special sealing and anti-friction compounds are used.Sealing lubricants have a harder concentration and are used to seal mating parts. Anti-friction lubricants are less viscous and are designed to separate moving parts. Lubricants must provide reliable operation when heated up to 300C. Solid substances such as graphite or fluoroplastic chips are added to the sealing composition. Anti-friction lubricants can be based on grease or silicone.

Linen

Linen thread is an old, but proven method of compaction. In addition, you can buy it in plumbing stores.

Before you buy, you need to consider some factors:

- what is the thickness of the strand;

- whether there is an unpleasant odor or particles of debris;

- Is the thread elastic enough?

It should also be borne in mind that flax is not suitable for all piping systems. Water and temperature lead to decay, and in the heating system it will burn out in a short time.

Modern sealing pastes are better at promoting rust on connection fittings and gas pipes.

Minium iron is usually the most used material. Do-it-yourself pasta is cheap and cheerful. To do this, take white and pour in a little drying oil, stir the mixture until it becomes similar in consistency to sour cream.

It should be applied in a small, thin layer directly on the thread itself. Evenly distributing and drying the material. Red lead white works best with steel pipes.

Due to the fact that the upper layer of iron is oxidized, insoluble compounds do not let ozone molecules through, according to the principle of magic.

Purchase ready-to-use hermetic pastes in specialized stores:

Gebatout 2 (paste based on mineral fillers and synthetic polymers). Pastum GAS (corrosion inhibitor, fillers).

Multipak (natural paraffin oil with inclusion of minerals). Unipak (natural minerals, fatty acids). The absence of the above funds is not a problem at all.

The working process is as follows: we separate part of the flax from the entire skein, two matches in thickness. We wind on a threaded connection, starting from the base of the pipe and to the end.

After that, we coat the formed structure with paste, this is necessary so that the joints hold tightly together.

Which seal is better to choose for installing a heating system

To date, the main criteria for choosing the best technology for sealing threads in heating system connections are the experience and materials that need to be worked with.

So, when working with cast-iron radiators and valves, the best option for them is to use a linen strand with plumbing paste or silicone heat-resistant sealant.

For small-diameter connections up to 25 mm from branded fittings, it is recommended to use FUM tape or adhesive sealant.

To install taps or connect steel, aluminum or bimetallic radiators, you can use the entire arsenal of ways to seal connections.

The only point that you need to pay attention to is that when installing copper pipelines, you must carefully study the instructions for the sealant in order to exclude the incompatibility of the composition of the adhesive and non-ferrous metal.

Purpose and variety of thermosealants

It should be noted that it is difficult to do without sealant in many areas of human life, from everyday life to the industrial sector. After all, what do we do if it is necessary to eliminate gaps, for example, between a wall and window frames? That's right, we go to the store and buy silicone. But will a simple glue perform all its functions when exposed to very high temperatures? The answer to this question is unequivocal - no. Of course, their temperature regime is quite large, and in individual cases it can reach 200 ° C, but often this is not enough. And not all sealing substances retain their properties even at this temperature.

So, a heat-resistant sealant is used to isolate joints on "hot" objects. These include DHW pipelines, open-hearth furnaces, chimneys, fireplaces, engines, including automobile engines, elements of turbines, compressors, pumps, as well as units operating on steam, in chemical and gaseous media. Such sealants are divided into silicone and silicate.

The first high-temperature sealant is a paste-like substance of red, brown and red-brown hue. Its main component is silicone rubber, and thanks to iron oxides, the desired heat resistance is achieved. Such sealants are divided into neutral and acidic. The latter have limitations in use, since the acid released during solidification negatively affects stone, concrete and metal surfaces. Therefore, such "aggressive" compositions are applicable for working with wood, glass, plastic and ceramics. Neutral ones have no restrictions, because in this case, safe alcohol-containing liquids and water are released during vulcanization.

In addition to the composition, silicone sealants are also divided depending on the scope of application.

- Food options do not contain toxins and are absolutely safe for human health.

- Sanitary hot melt glue has found its application in medicine.

- Heat-resistant sealant for the engine is resistant to aggressive components, antifreeze, oils and other auto chemicals, as well as increased plasticity. This hot melt usually has a red color.

- High-temperature sealants for furnaces are also very popular. They are used in industry and in everyday life for jointing furnace structures.

- Universal compositions can treat almost all surfaces and joints in the heat affected zone.

Silicate sealants are more heat resistant and can withstand up to 1500 ° C, therefore they are used in structures in contact with open fire. They are based on sodium silicate. Because of the color, such sealants are also called black. It is most advisable to use them for processing cracks in fireplaces, chimneys, ovens, furnaces, including open-hearth, heating boilers, etc.

Main technical properties of the sealing tape

The FUM tape has the following characteristics:

- Reduced coefficient of friction. The fluoroplastic seal, in addition to plasticity, is slippery, which simplifies fitting fittings.

- Thermal stability, allowing to withstand temperatures up to 260 degrees without destruction and loss of sealing properties. In addition, fluoroplastics are very effective dielectrics.

- Strength and plasticity.Seals made of this material work stably at pressures up to 10 MPa, and are able to withstand short-term loads up to 42 MPa, for example, those that occur during hydraulic shocks in pipeline systems. The service life of a seal made of FUM tape (fumka) is determined at 13 years. Decomposes faster when exposed to light, but this is not for our case, you just need to take this factor into account when organizing the storage of the material.

- chemical passivity. Not subject to destruction under the influence of acids and alkalis, which is determined by the uniform distribution of fluorine atoms over the surface of the product. Solvents capable of destroying this sealant have not yet been invented. Resistant to decay processes.

How to use FUM tape for gas and plumbing pipes correctly, we will consider in more detail.

Rules for soldering copper

When it is necessary to solder a copper product or a product containing copper components, it is impossible to give an unambiguous answer as to how and what is the best way to do this. The choice of method and tools depends on many factors, such as the size and weight of parts, their composition. The load to which already soldered products must be subjected is also taken into account. There are several soldering methods, and it is better to know them all in order to choose the most suitable one if necessary.

Soldering large parts

Scheme of capillary soldering of copper.

If you need to solder massive or large parts that cannot be heated to the desired temperature with a soldering iron, a torch and copper solder are used. The flux in this case is borax. Strength copper-phosphorus solder higher than standard tin.

A thin layer of flux is applied to the mechanically cleaned pipe or wire.After that, a fitting is put on the pipe, also mechanically cleaned. Using a gas burner, the junction is heated until the flux-coated copper changes color. The flux should become silvery in color, after which you can add solder. The solder melts instantly and penetrates into the gap between the pipe and the fitting. When drops of solder begin to remain on the surface of the pipes, the solder is removed.

Do not overheat the pipes, as this does not contribute to the appearance of a greater capillary effect. On the contrary, copper heated to blackness is less solderable. If the metal begins to blacken, the heating should be stopped.

Soldering wires or wire

Zinc chloride solder should not be used to solder thin copper wires, as this will destroy the copper. If no flux is available, in this case you can dissolve an aspirin tablet in 10-20 ml of water.

Scheme of copper welding in an inert gas environment.

Copper wire or parts made of wire of various sections can be easily heated to the desired temperature using a soldering iron. The temperature regime should be the one at which the solder melts, tin or lead-tin, and soldering is also performed by it. Fluxes must contain rosin or be made from rosin, soldering oil or even rosin itself can be used.

The surface of the wire is cleaned of dirt and oxide film, after which the parts are tinned. This process involves applying a thin layer of flux or rosin to the heated copper, and then solder, which is distributed over the surface as evenly as possible with a soldering iron.The parts that need to be connected are connected and heated again with a soldering iron until the already solidified solder begins to melt again. When this happens, the soldering iron is removed and the joint cools down.

Parts can be clamped in a vice so that the distance between them is 1-2 mm. Flux is applied to the parts and heated. Solder is brought to the gap between the hot parts, which will melt and fill the gap. The melting temperature of solder for soldering in this way must be lower than the melting temperature of copper so that the parts do not deform. The part cools down, then it is washed with water and finished, if necessary, with sandpaper until smooth and uniform.

Soldering dishes or soldering holes in copper

When soldering dishes, pure tin is used, the melting point of which is higher than that of tin or lead-containing solder. Sometimes, for soldering large parts, hammer soldering irons are used, heated on an open fire with a gas burner or blowtorch. In the future, everything happens according to the standard scheme: cleaning, fluxing and tinning, joining parts and heating with a soldering iron. It is for this soldering iron that pure tin solder is convenient.

From the inside, the fitting, as a rule, has a border that prevents it from being threaded through the pipe. It can be removed with a coarse file if the fitting needs to be pushed onto the pipe further than intended and the unnecessary hole must be soldered in this way.

Methods for checking the tightness of connections

The tightness of the gas pipeline is checked by sections.In the situation with apartment buildings, a segment is selected from the place where fuel is injected into the building to taps for household equipment.

Plugs are placed at the ends of the section. The pressure in the pipes exceeds the standard values by 25%. The pressure drop is a reason to check the connections.

The integrity of joints, branches and equipment connection points is checked in two ways:

- With a gas leak indicator.

- By applying a soap solution, emulsion.

In the first case, a digital, sound or color signal of the device will notify you of the danger. In the second, you need to monitor the appearance of bubbles. Their presence indicates a violation of the integrity of the connection.

Features of the installation of threaded fittings

Thanks to various types of threaded fittings, the pipeline is able to perform the most complex bends and turns.

The most common way to connect metal / plastic structures is an “American” fitting. Such an element, which has a coupling and thread at the ends, allows you to easily and quickly dock dissimilar parts

The most popular device for the junction of polymer and metal elements is the American fitting, which is available in various sizes. A convenient device with a plastic sleeve and metal thread is extremely easy to assemble, allowing you to create a reliable tight connection in a short time.

Step by step installation instructions

To connect a metal pipe to a polypropylene or other plastic pipe, you must:

Using a special soldering iron, weld the fitting sleeve to the end of the polymer pipe, and then wait for the joint to cool.

Bring the metal part to the other end of the "American" and then tighten the thread. To seal the joint, it is advisable to additionally wrap it along the thread with one or two layers of FUM tape, tow or linen fiber (you can additionally cover it with silicone).

The fitting must always be tightened by hand: the use of tools is undesirable and even dangerous.

Special equipment does not allow you to fully control the applied forces, which can lead to damage to the part.

After completing the work, it is important to check the strength of the resulting fastening. To do this, just turn on the water and make sure there is no leakage.

If moisture is still filtering through the joint, you can try to tighten the bolt a little more. With further flow of water, it is necessary to unwind the thread again and carry out all the manipulations again.

The shape of the finished connection can be changed by softening the plastic part with a building hair dryer, and then making the bend necessary for the project.

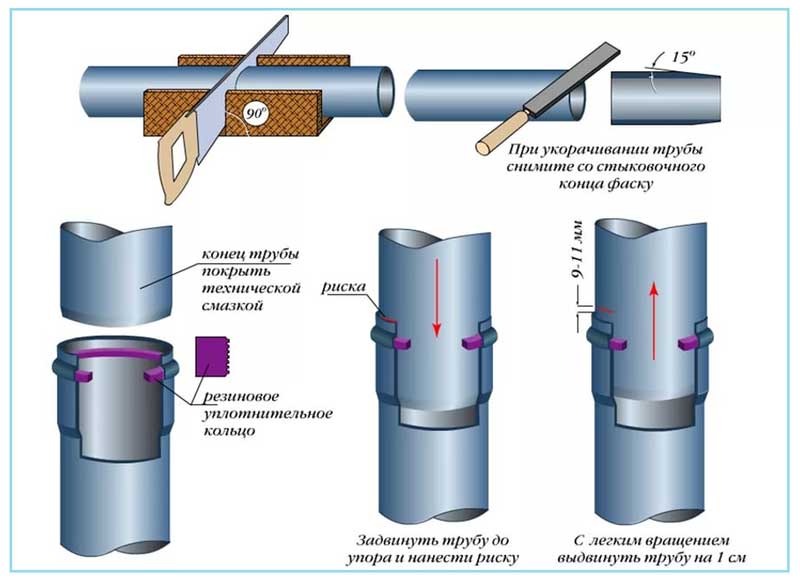

Metal pipe connection without thread

There are situations when a plastic pipe must be connected to a metal counterpart that does not have a thread.

The thread on the pipe can be applied using a special tool - a threader. In specialized stores you can find both mechanical and electrical models of such a device.

A similar problem can be solved with a special tool called "threader" or "thread cutter", with which you can apply grooves to a part made of steel or cast iron.

There are two fitting options:

- Electric, which includes several cutters designed for pipes of different diameters.Such models are comfortable and easy to use, but have a high cost.

- A manual threader is much cheaper, but working with it requires more physical strength and certain skills.

You can read more about how to cut threads on pipes in our article.

When using thread cutters, you should follow a few simple rules:

The tool cannot be operated if the pipe is a short distance from the wall.

The electric threader heats up quickly, so you will need to rest periodically when machining multiple items.

When working with a hand jig, it is important to alternate movements, making a half turn forward and a quarter turn back, until you have cut the thread to the desired length.

For threading a pipe, it is necessary to thoroughly clean the pipe, if necessary, remove the existing paint and grind off the metal flows. Then carve with an electric or carved tool.

The cut grooves are well cleaned and lubricated with solid oil, oil or other lubricant, and then used for connection with a fitting.

Sealing with linen thread

This method is the oldest. This is how pipe joints were sealed in Soviet apartments. If there are no other sealants in the store, then flax and plumbing paste will certainly be found. But this seal has a number of significant drawbacks:

- According to the rules, flax is used in combination with drying oil and red lead. Lead prevents corrosion of the joint, and drying oil fills the pores of flax like a polymer.But finding high-quality ingredients is quite difficult, so red lead is often replaced with iron, which only accelerates the oxidation of metal components. Some craftsmen get out of the situation by using silicone-based automotive sealants.

- The complexity of laying linen thread on the thread. What is so easy for experienced plumbers can cause a lot of difficulties for a non-specialist. It is unlikely that it will be possible to wind flax correctly on the connection the first time, and any error in performing this operation will lead to the fact that the seal will not last very long.

- Len does not tolerate changing working conditions very well. Therefore, in heating systems, its strands will collapse much faster. Also, this type of seal does not respond well to aggressive environments.

- The high hygroscopicity of the material leads to its swelling, due to which insufficiently strong joints can simply burst. For example, it is not recommended to use flax when sealing aluminum radiators.

The question of packaging

The packaging of gas connections is a defensive measure against leaks. For the process you need: flax and paste for investing threaded connections.

- A small strand is plucked from the linen used.

- If there are no notches on the thread, they need to be made. A special tool is used.

Thanks to the notches, the linen does not come off while screwing the thread.

- Winding starts from the end of the thread. Continues towards its end. Flax should cover the top of the thread quite a bit.

This volume is enough for the flax to be fixed in the joint.

It turns out a neat connection.

- Linen is wrapped in paste.

- The finished connection is screwed.

- The reciprocal element of the American is strung on (a key is used here) and wrapped in a heating apparatus (radiator).

- Result.