- Types of boilers and the principle of their operation

- Types of boilers, their advantages and disadvantages

- Classic boilers

- Gas generating (pyrolysis) boilers

- Features of long-burning boilers

- Solid fuel and electric heater

- The best solid fuel boilers for direct combustion

- Viadrus Hercules U22

- Zota Topol-M

- Bosch Solid 2000 B-2 SFU

- Protherm Beaver

- Mounting order

- What to look for when choosing a boiler?

- Types of equipment by design

- How to calculate power correctly?

- Regulator type and price tag

- The best solid fuel boilers for long burning

- Stropuva Mini S8 8 kW

- ZOTA Topol-22VK 22 kW

- ZOTA Topol-16VK 16 kW

- ZOTA Topol-32VK 32 kW

- Stropuva S30 30 kW

- Features of the operation of gas-generating boilers

- Device types

- 3 ZOTA Pellet 100A

- Scope of pyrolysis boilers

- What is a pyrolysis boiler

Types of boilers and the principle of their operation

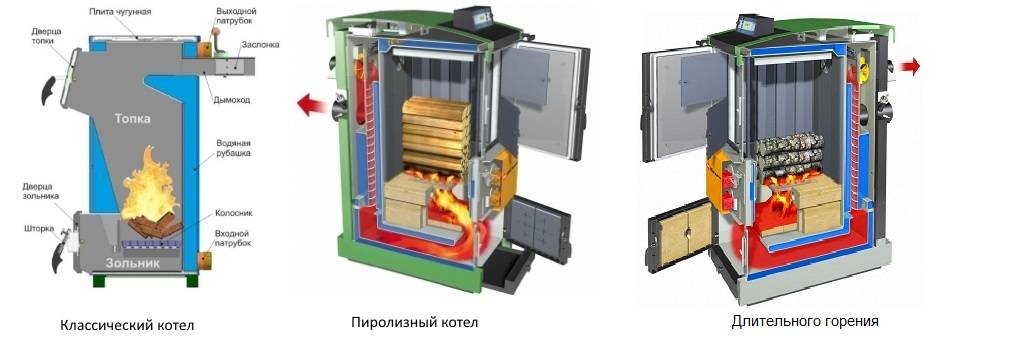

All boilers in operation solid fuel, subdivided into several types, which differ from each other in many indicators. But according to the main characteristics, they are divided into four types:

- Classic;

- Pyrolysis heating boilers;

- Long burning boilers;

- Automatic;

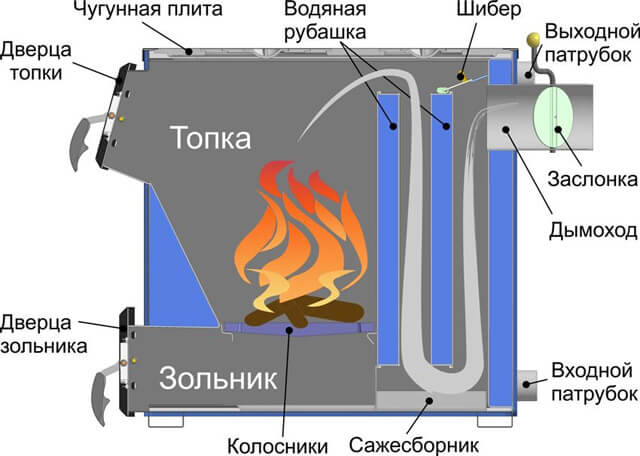

Classical boilers - the principle of operation of a classic solid fuel boiler lies in the fact that heat is given by fiery combustion of fuel.It has two doors, through one of which fuel is loaded, through the other - the boiler is cleaned of ash and other combustion products. They can run on two types of fuel - wood and coal.

Classical boilers - the principle of operation of a classic solid fuel boiler lies in the fact that heat is given by fiery combustion of fuel.It has two doors, through one of which fuel is loaded, through the other - the boiler is cleaned of ash and other combustion products. They can run on two types of fuel - wood and coal.

They differ in the material of manufacture of the heat exchanger; they can be made of cast iron or steel. Cast iron is a priority in terms of durability, its service life is more than 20 years. Among the shortcomings, one can note the fact that he is afraid of mechanical shocks and is very sensitive to temperature changes, which can lead to destruction. The steel heat exchanger is more resistant to temperature extremes and damage, but its service life is much lower - just over 6 years.

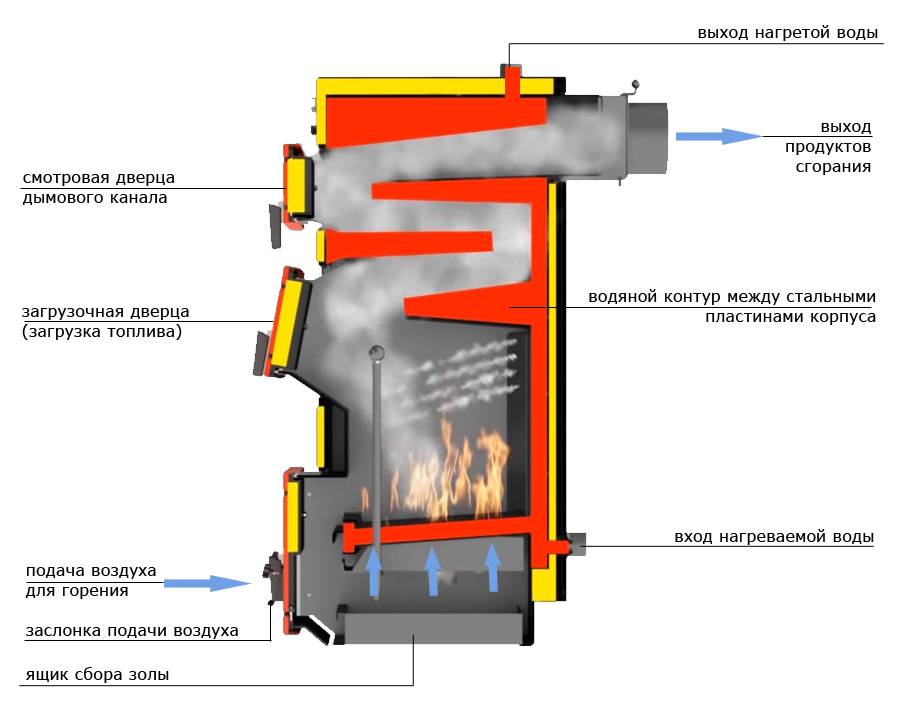

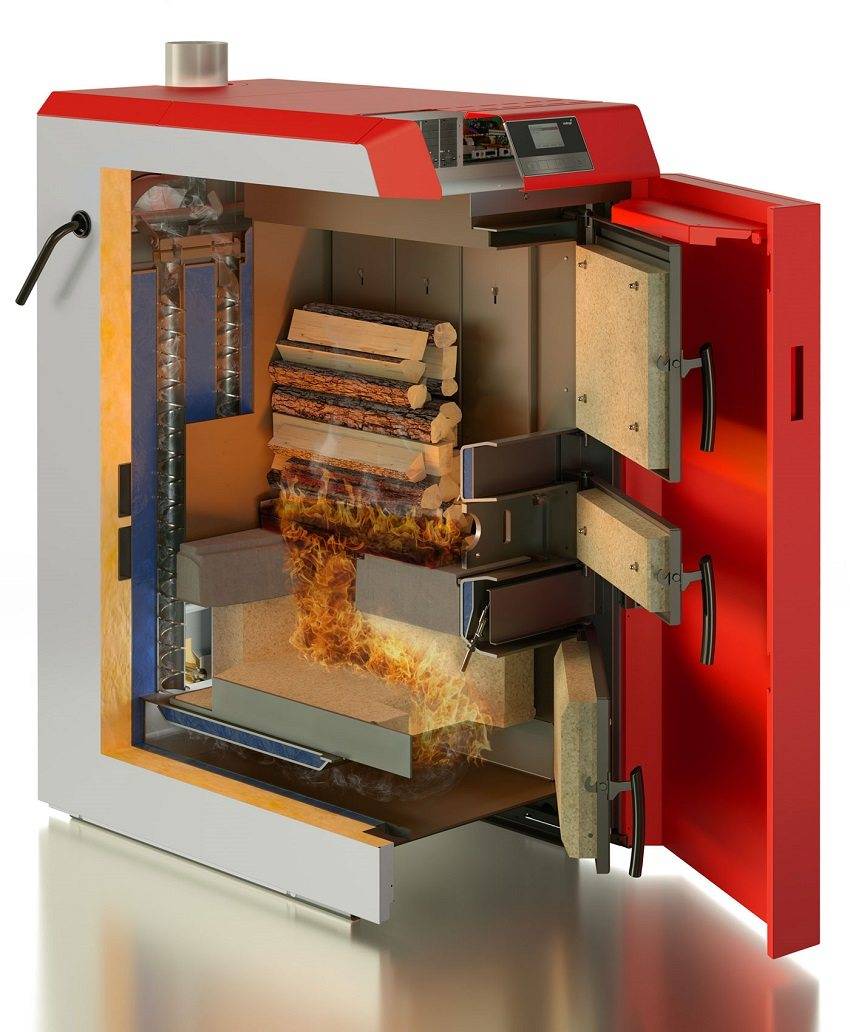

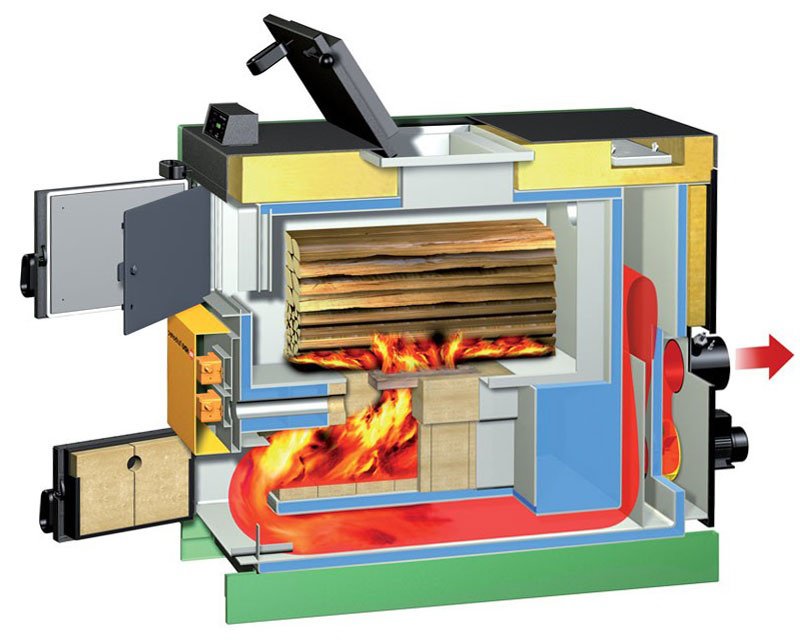

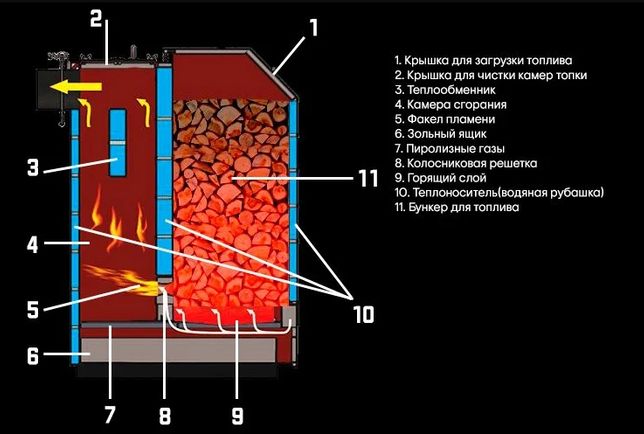

Pyrolysis (gas generating) boilers - this type of boiler works on the principle of pyrolysis, that is, decomposition and gasification of solid fuel. This process takes place with a closed chimney and a closed combustion chamber. After the release of the wood gas formed during the pyrolysis process, it is sent to the burner nozzle, where it mixes with secondary air, which is pumped by a fan. After that, the gas mixture enters the combustion chamber, where it ignites. Combustion occurs at a temperature that sometimes reaches 1200°, and the process will continue until the solid fuel is completely burned.

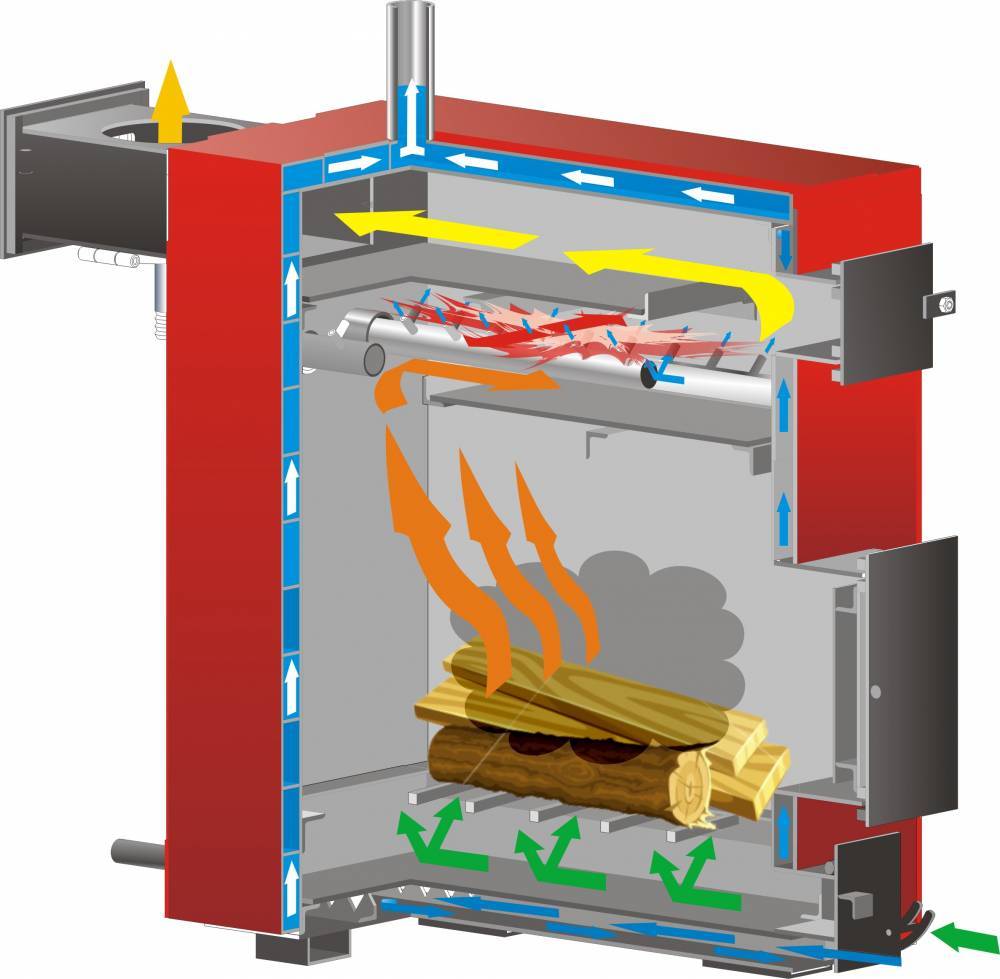

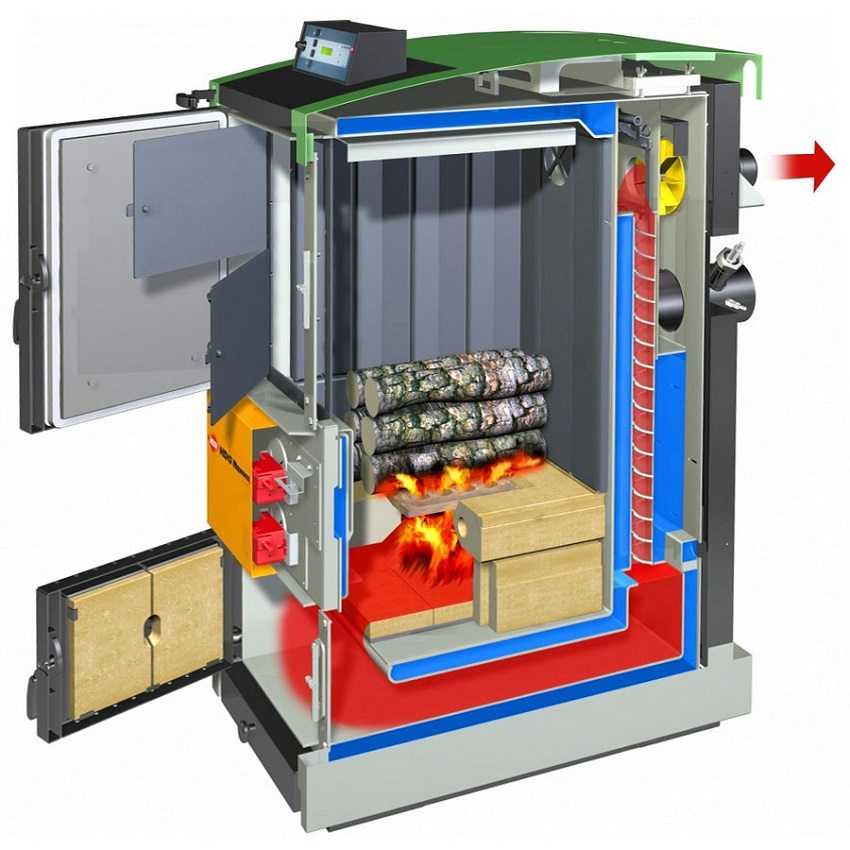

Long-burning boilers - in this type of boiler, a long burning process is ensured by special techniques. Currently, there are two long-burning systems (the Canadian system Buleryan, and the Baltic Stropuva), but the second one has not found wide application due to the high cost, complexity of operation and many other technical parameters.

Long-burning boilers can be attributed to pyrolysis boilers, but the principle of operation will be slightly different.The first system (Burelyan) is a furnace consisting of two chambers, where smoldering and gas formation occurs in the lower chamber. After the gas enters the second chamber, it mixes with air and then completely burns it (fuel afterburning). The design of such a solid fuel boiler is a cylinder, with pipes welded into it for half a circle. The arrangement of pipes from the bottom up provides good air circulation, thereby increasing heat transfer. Installed mainly in non-residential premises, perfect for heating a garage or cottage. The price for such a boiler is adequate, it is possible to choose size suitable for a particular area.

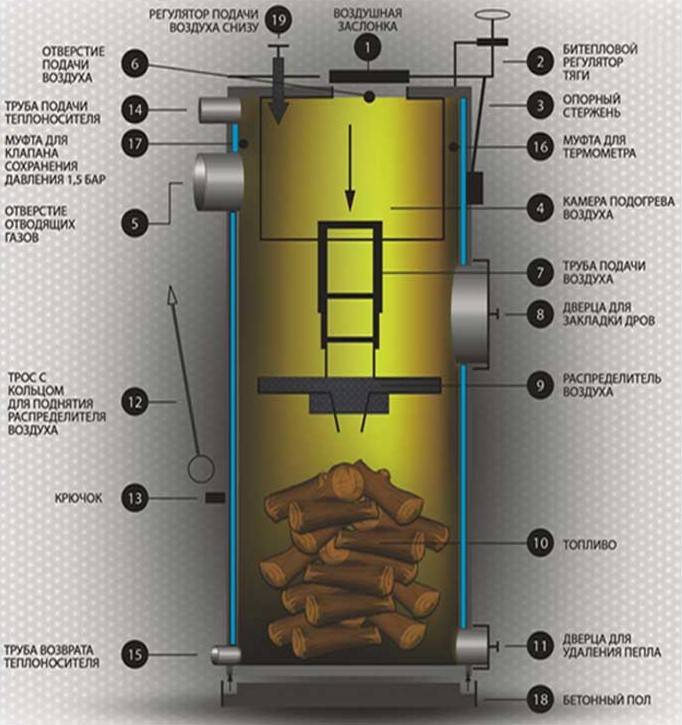

The boiler according to the Stropuva system has two cylinders, one of which is located inside the second, according to the principle of a nesting doll. All the space between them is filled with water, which gradually heats up. The internal cylinder of the system plays the role of a firebox, where air is supplied with the help of a distributor. After loading the fuel, it begins to burn from top to bottom, thereby heating the coolant. The price declared by the manufacturer, a long burning time, from 2 to 4 days, depending on the fuel, the required cooling of the boiler and further cleaning before a new ignition, double the task and bring inconvenience. Therefore, this type of boiler did not bring wide distribution.

Automatic boilers - in this type of boiler, the process of loading fuel and removing ash is fully automated. The boiler is equipped with a screw or conveyor hopper for fuel supply and automatic ash removal. The option of a coal-fired automatic boiler implies the movement of the fuel combustion layer, which is necessary for complete combustion.For this, the automatic boiler is equipped with movable grates, or chopping and moving mechanisms. The parameters of heating of the coolant and combustion of fuel are provided by forced pressurization.

The advantages and features of automatic boilers can include;

- Do not require time-consuming maintenance and close attention to the combustion process;

- Are supplied with the included temperature regulator;

- Many are equipped with a sensor that monitors the temperature in the boiler itself;

- The efficiency of an automatic boiler is up to 85% of the total;

- Long-term operation, limited only by the capacity of the bunker for automatic fuel supply.

It is worth considering that fuel consumption, in particular coal, is much less than in traditional solid fuel boilers.

Types of boilers, their advantages and disadvantages

Modern technologies have allowed the development and production of several types of solid fuel boilers with a higher under-ice coefficient, let's look at them in more detail.

Classic boilers

The advantages of a two-circuit system are the compactness of the unit and ease of operation, but it is more expensive than a single-circuit analogue and requires a minimum content of mineral impurities in the water that cause deposits on the pipe walls.

When using a single-circuit boiler, providing hot water is possible only with the purchase of additional equipment - an indirect heating boiler. The advantages of this unit are - low cost, high efficiency, the ability to install a cast-iron heat exchanger. Of the disadvantages, the need for additional space when installing a hot water supply system and the cost of a boiler should be mentioned.

Gas generating (pyrolysis) boilers

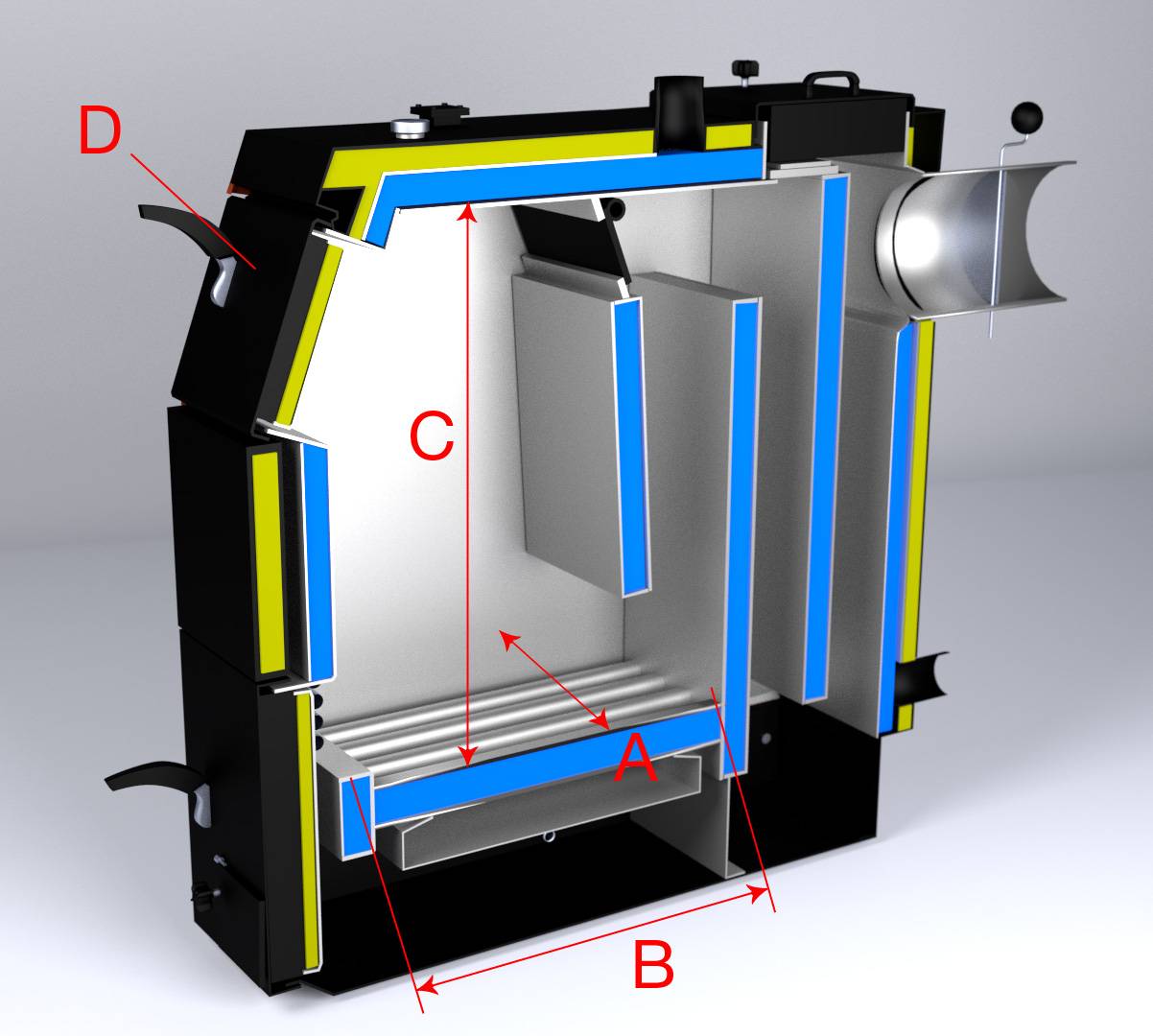

Among all solid fuel units, models using the pyrolysis process are the most efficient devices, their efficiency reaches 90%. The process is based on the principle of high-temperature decomposition of organic fuel. Combustion occurs in several stages, first the fuel is heated with limited access to oxygen, heating causes the release of pyrolysis gases, which are burned in a separate chamber, and gaseous wastes, having passed through an additional heat exchanger, are removed through the chimney.

Advantages:

- Efficiency 90%;

- minimum amount of ash and soot formation;

- laying firewood for 8-12 hours;

- minimum waste in the form of ash;

- reduced emission of harmful smoke into the atmosphere.

Due to the high temperature in the combustion chamber, maximum heat transfer is achieved

As fuel for this type of boilers, coal, wood chips, briquettes, pellets and firewood are used, it is very important for the efficient operation of the equipment to use fuel with minimal moisture content. Strict requirements for humidity characteristics of not more than 20%, the high price of units and energy dependence are the main negative qualities of these devices, but nevertheless, the purchase of a pyrolysis boiler is justified, so how to save on fuel volume, which requires much less than for classic models

You can read more about this type of boiler here.

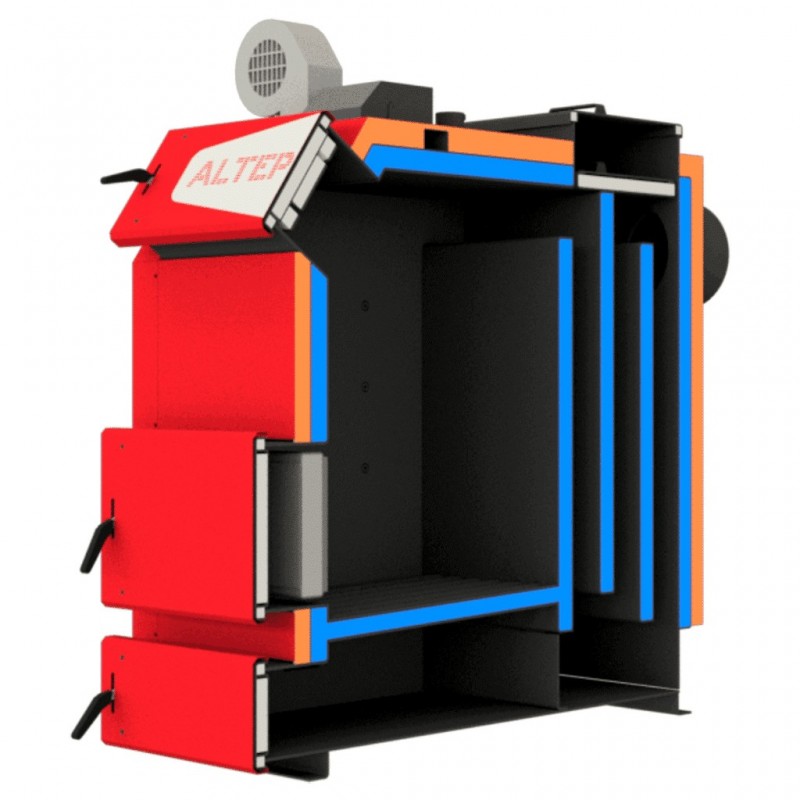

Features of long-burning boilers

boilers Energy TT allows you to load the furnace for a period of 12 hours to 5 days

Most often, in structures of this type, upper combustion is used, air is supplied through a telescopic duct, the air is preheated in a special chamber, as the fuel burns, the duct descends, providing combustion of the next layer of fuel mass, in some models of this type, direct (lower) combustion is used. The heat carrier temperature is controlled by supplying air to the combustion chamber, which makes it possible, if necessary, to transfer the combustion process to a smoldering mode. Another feature of long-burning boilers is the large combustion chamber volume, which starts from 100 liters.

Advantages:

- non-volatile;

- loading the furnace every 2-3 days;

- deep power adjustment;

- low ash residue;

- average price range.

Video review of what you need to know and how to choose the right one, the expert explains

Solid fuel and electric heater

The main task of electric heaters

Combined devices provide more comfortable use of boilers, there is no need to get up at night for the next load of firewood, it is possible to leave home without the risk of an emergency situation in the heating system. But, you have to pay for comfort, combined units are much more expensive than analogues without electric heating.

The best solid fuel boilers for direct combustion

Viadrus Hercules U22

The lineup

The model range of this series of Vidarus boilers is represented by seven solid fuel boilers with power from 20 to 49 kW. The most productive of them is able to heat a building up to 370 sq.m.All equipment is designed for a maximum pressure in the heating circuit of 4 atm. The operating temperature range in the coolant circulation system is from 60 to 90 ° C. The manufacturer claims the efficiency of each product at the level of 78%.

Watch product video

Design features

All models of the presented line are designed for floor installation. They have an open combustion chamber with air supply due to natural draft. The large square-shaped doors easily open wide, which is convenient when loading fuel, removing ash and inspecting the condition of internal elements.

The built-in heat exchanger made of high-quality cast iron is adapted to work in a single-circuit heating system. The boilers do not have devices powered by an external electrical network and are operated in a completely autonomous mode. All settings are mechanical.

Fuel used. The design of a spacious firebox is designed to use firewood as the main fuel, but coal, peat and briquettes can be used.

Zota Topol-M

The lineup

The line of six Zota Topol-M solid fuel boilers starts with a compact 14 kW model designed to heat a house for an average family, and ends with an 80 kW unit capable of heating a large cottage or production workshop. The boilers are designed for operation in systems with pressure up to 3 bar. Efficiency of thermal energy use is 75%.

Watch product video

Design features

Their distinctive feature is a slightly raised design, which makes it more convenient to open the ash pan door and empty it. Open type combustion chamber with chimney connection from the rear wall. There is a built-in temperature sensor.All adjustments are made manually.

A heat exchanger for a single-circuit heating system is mounted inside, connected to 1.5 or 2” pipelines. Boilers work offline. Products of this brand are easy to install and reliable in operation.

Fuel used. Firewood or coal is used as fuel, for which a special grate is provided.

Bosch Solid 2000 B-2 SFU

The lineup

Solid fuel boilers Bosch Solid 2000 B-2 SFU are represented by a number of models with a capacity of 13.5 to 32 kW. They are able to heat buildings with a usable area of up to 240 sq.m. Parameters of the circuit operation: pressure up to 2 bar, heating temperature from 65 to 95 ° C. Efficiency according to the passport is 76%.

Watch product video

Design features

The units have a built-in single-section heat exchanger made of cast iron. It is connected to a single-circuit heating system through standard 1 ½” fittings. The boilers are equipped with an open type combustion chamber with a 145 mm chimney. For normal operation, a connection to the electrical network with a voltage of 220 volts is required.

The temperature regulator and protection against an overheat of water is provided. The ash pan has a small volume, so it requires regular cleaning. Manufacturer's warranty 2 years. The design is simple, safe and highly reliable.

Fuel used. The boiler is designed to use hard coal. On this type of fuel, it demonstrates high efficiency. When working on wood or briquettes, the efficiency is noticeably reduced.

Protherm Beaver

The lineup

A series of solid fuel boilers Protherm Bober is represented by five models with power from 18 to 45 kW. This range completely covers any private house. Unit designed for work as part of a single-circuit heating scheme with maximum pressure 3 bar and coolant temperature up to 90 ° C. For the correct operation of the control system and actuation of the circulation pump, connection to household electrical network.

Watch product video

Design features

Boilers of this series are equipped with reliable cast-iron heat exchangers. The original design of the combustion chamber increases the efficiency of heat transfer. Exhaust gases are discharged through a chimney with a diameter of 150 mm. For connection to the heating circuit, there are branch pipes for 2”. Such boilers are designed for long-term operation.

Fuel used. The declared power is designed for burning firewood with a moisture content of up to 20%. The manufacturer has provided for the possibility of using coal. In this case, the efficiency of work increases by several percent.

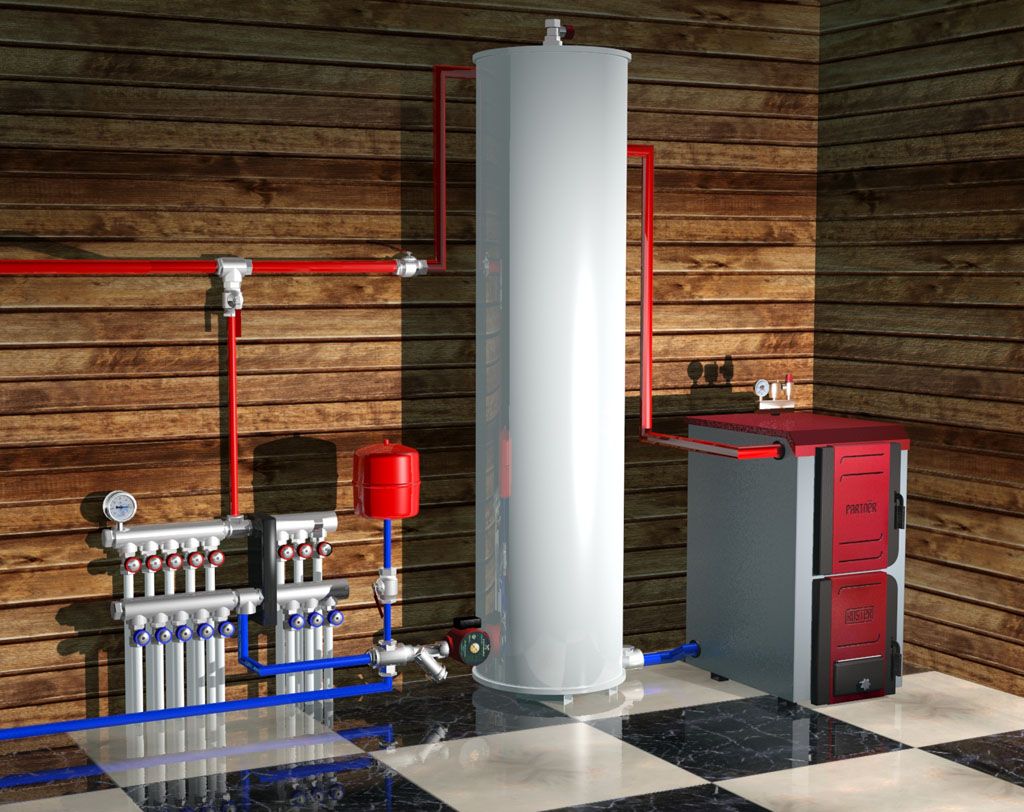

Mounting order

The boiler belongs to objects of increased danger, it must be installed according to the project of a specialized organization that has licenses for the corresponding types of work.

The algorithm for carrying out work during the installation of a coal-fired boiler:

- Preparatory measures are being carried out: Selection of a room for the furnace and concreting of the base for the placement of the unit and auxiliary equipment.

- The boiler is connected to the in-house heating circuit.

- The boiler is connected to the smoke ventilation system.

- Auxiliary equipment is installed: a blower fan, a centrifugal pump, air vents, a safety valve, temperature sensors, a water purification filter and an expansion tank.

- A test run and pressure testing of the system with a water pressure of 1.5 working hours is carried out to check the tightness of the connection of pipe and structural elements.

What to look for when choosing a boiler?

Due to the simply huge demand for boilers that work on one tab of firewood for more than 12 hours, manufacturers are actively replenishing the market with new models. As a result, almost every buyer has a number of questions related to the choice of manufacturer, design, type of fuel.

In addition, not everyone will be able to correctly calculate the power. In order not to encounter these problems in the store, we will deal with all the nuances in more detail.

Types of equipment by design

There are three types of solid fuel boilers on the market. These include classic models, pyrolysis, as well as pellet units. The first type will be an excellent choice for both home and industrial or commercial use.

The advantages of such models include:

- Versatility. The equipment can work on heating granules (pellets), firewood, peat and coal.

- Multifunctionality. Classic boilers are great not only for space heating, but also for heating water.

- Efficiency. The efficiency of the presented devices in most cases varies between 80-85%. This allows you to use them both as the main source of heat and as an additional one.

Pyrolysis models are most often used for heating water. This kind of device runs on organic fuel.

The performance coefficient of pyrolysis boilers mainly depends on the quality of the fuel used. The most optimal choice are briquettes, pellets, as well as brown coal

It should be noted that pyrolysis boilers are quite demanding on the moisture content of the fuel feedstock. If this indicator is higher than 25-35%, then the heating efficiency will decrease significantly.

The third variation of long-burning boilers was patented in Europe relatively recently. But in a fairly short period of time, such devices have won recognition among hundreds of thousands of customers.

Pellet boilers in operation on wood pellets. Fuel is made from compressed chips, sawdust, as well as a number of other types of waste from the woodworking industry.

The advantages of this type include:

- durability - the average life of the device is more than 20 years;

- autonomy - the device independently and quite well maintains the temperature indicated by the owner;

- efficiency - the efficiency of models on pellets reaches 90%.

As for the shortcomings, only one stands out - a high and inaccessible price for many. But this minus is fully paid off by the ease of maintenance and performance of the equipment.

An article devoted to this interesting issue will acquaint you with the features of the operation and operation of solid fuel boilers.

How to calculate power correctly?

If you need to determine the performance of the boiler, it is important to take into account the area, the quality of wall insulation, the type of fuel used, as well as the length of the heating circuit. Calculations can be greatly simplified

To do this, you just need to use the following formula:

1 kW per 1 m2 of the room.

In this case, the height of the ceilings should not exceed 3 meters. A more convenient option would be to use a special table when calculating. Below is one of them.

| Boiler power | Heating area, sq. m. |

| 15 kW | up to 150 |

| 20 kW | up to 200 |

| 30 kW | up to 300 |

| 50 kW | up to 500 |

| 70 kW | up to 700 |

With its help, you can find out the right power in a matter of minutes. In this case, the only parameter that you need is the area of \u200b\u200bthe room in cubic meters.

Regulator type and price tag

If you have constant interruptions in the electrical network in your house, then it would be advisable to choose a boiler with a mechanical regulator. It does not need to be supplied with current, since its principle of operation is based on air circulation in a natural way.

Automation is suitable for those who do not want to bother once again and waste their time going to the boiler room. This kind of regulator pumps air with a fan.

A reasonable choice would be to purchase a heater from an authorized dealer or directly from the manufacturer. This will allow not only to purchase goods at a reasonable price, but also to receive a long-term warranty and rely on after-sales service in the event of a unit breakdown.

The cost of heating equipment largely depends on the material from which the device is made, brand, as well as power.

It is important to understand that this kind of equipment is bought for decades. Therefore, do not even look towards cheap models.

Remember - an efficient boiler cannot be cheap.

The best solid fuel boilers for long burning

Stropuva Mini S8 8 kW

Bright solid fuel boiler with a safety valve, 8 kW. Suitable for heating a room of 80 m2. The fuel burns up to twenty hours, the temperature is enough for the whole night.

Characteristics:

- device type - solid fuel boiler;

- type of burning - long;

- contours - single-circuit;

- power - 8 kW;

- area - 80 m2;

- placement - outdoor;

- energy independence - yes;

- management - mechanics;

- combustion chamber - open;

- fuel - firewood, wood briquettes;

- safety valve - yes;

- thermometer - yes;

- weight - 145 kg;

- price - 53,000 rubles.

Advantages:

- compactness;

- long burning;

- ease of use;

- reliable handles;

- does not require power supply;

- durable construction.

Flaws:

- high price;

- heavy weight;

- it is difficult to wash the lining from soot;

- not very convenient loading of firewood.

ZOTA Topol-22VK 22 kW

A high-quality solid fuel device with a power of 22 kW, which is enough to heat an area of 220 m2. Convenient loading consists of two sections for laying firewood.

Characteristics:

- device - solid fuel boiler;

- contours - single-circuit;

- power - 22 kW;

- placement - outdoor;

- control - without control panel;

- fuel - coal, coal briquettes, firewood, wood briquettes;

- thermometer - yes;

- weight - 128 kg;

- price - 36860 rubles.

Advantages:

- various types of fuel;

- long burning;

- economical consumption;

- convenient operation;

- reliable construction.

Flaws:

- heavy weight;

- no control panel.

ZOTA Topol-16VK 16 kW

A worthy model of a solid fuel boiler with two sections for loading fuel. Designed for heating a small private house or workshop of 160 m2.

Provides long burning of firewood or coal.

Options:

- unit - heating boiler;

- fuel - coal, firewood, coal and wood briquettes;

- power - 16 kW;

- placement - outdoor;

- control - without control panel;

- Efficiency - 75%;

- thermometer - yes;

- weight - 108 kg;

- cost - 30100 rubles.

Advantages:

- heats up quickly;

- gives uniform heat;

- quality materials;

- long burning;

- the possibility of laying briquettes;

- easy control.

Flaws:

- high price;

- big weight;

- no control panel.

ZOTA Topol-32VK 32 kW

Reliable unit for solid fuel, power up to 32 kW. Capable of heating an area of 320 square meters. It is possible to install an additional heating element and connect an external control.

Great for a country house, provides long-term fuel burning.

Characteristics:

- device type - solid fuel boiler;

- the number of circuits is one;

- power - 32 kW;

- area - 320 m2;

- installation - floor;

- energy independence - yes;

- management - mechanics;

- Efficiency - 75%;

- fuel - coal, coal briquettes, wood briquettes, firewood;

- thermometer - yes;

- connection of external control - yes;

- weight - 143 kg;

- price - 40370 rubles.

Advantages:

- fast heating;

- reliable assembly;

- simple control;

- the ability to purchase a burner;

- economical fuel consumption;

- stylish design.

Flaws:

- heavy weight;

- high price.

Stropuva S30 30 kW

A full-fledged solid fuel boiler with a power of 30 kW for heating a room of 300 m2. Equipped with thermometer and safety valve.

Made of high quality steel, the material does not become red-hot when the boiler is heated.

The only boiler that continues burning up to 31 hours.

Characteristics:

- device - solid fuel boiler;

- power - 30 kW;

- area - 300 sq.m.;

- placement - outdoor;

- control - mechanical;

- contours - one;

- non-volatile - yes;

- combustion chamber - open;

- Efficiency - 85%;

- material - steel;

- fuel - firewood, wood briquettes;

- thermometer - yes;

- safety valve - yes;

- weight - 257;

- price - 89800 rubles.

Advantages:

- long burning;

- uniform heat;

- fast heating;

- quality materials;

- the presence of a thermometer;

- economical fuel consumption.

Flaws:

- high price;

- heavy weight;

- bulky.

Features of the operation of gas-generating boilers

The efficiency of the pyrolysis boiler largely depends on the type and quality of the fuel. Technically, not only wood, but also coal, and even peat can be loaded into the furnace; most modern boiler models are designed to use several types of fuel.

Wood burns in about 5-6 hours, depending on the type. The harder the wood, the longer it burns.

Modern models of pyrolysis combustion boilers can operate on various types of wood fuel: firewood, briquettes, pellets, coal, peat, etc.

Modern models of pyrolysis combustion boilers can operate on various types of wood fuel: firewood, briquettes, pellets, coal, peat, etc.

It will take about ten hours to burn black coal, and the same amount of brown coal will smolder for eight hours. In practice, pyrolysis technology demonstrates the highest heat transfer when loaded with dry wood. Firewood is considered optimal with a moisture content of no more than 20%, and a length of about 45-65 cm.

If access to such a fuel is not available, coal or other organic fuels can be used: special sawdust briquettes and wood pellets, wood waste, peat, materials with cellulose, etc.

Before using the boiler, you should carefully study the recommendations of the manufacturer of the device regarding fuel.

In pyrolysis combustion boilers, the air flow is regulated by conventional mechanical valves. The absence of complex electronics provides high fault tolerance of the device

Too wet fuel in such devices is unacceptable. When it is burned in the furnace, additional water vapor is formed, which contributes to the formation of by-products such as tar and soot.

The walls of the boiler become dirty, the heat transfer decreases, over time the boiler may even stop working, die out.

If you use wood with too high humidity for the pyrolysis combustion boiler, conditions will arise inside the device for the formation of tar, which will impair the heat transfer of the device and may lead to breakdowns.

If dry fuel is placed in the furnace and the boiler is set up correctly, the pyrolysis gas obtained as a result of the operation of the device will produce a yellow-white flame. Such combustion is accompanied by a negligible release of by-products of fuel combustion.

If the color of the flame is colored differently, it makes sense to check the quality of the fuel, as well as the settings of the device.

Pyrolysis gases mixed with air burn with an even yellow-white flame. If the color of the flame has changed, it may be necessary to check the boiler settings or the quality of the fuel.

Unlike conventional solid fuel devices, before loading firewood into solid fuel pyrolysis boilers, the firebox should be heated.

To do this, perform the following steps:

- Fine dry kindling (paper, wood chips, etc.) is loaded onto the bottom of the furnace.

- It is set on fire with a torch made of similar materials.

- Close the combustion chamber door.

- The loading chamber door is left slightly ajar.

- Add portions of kindling as it burns.

- The process is repeated until a layer of glowing coals is formed at the bottom.

By this moment, the furnace is already warming up to about 500-800 ° C, creating conditions to load the main fuel. Do not use gasoline, kerosene or any other similar liquid substances to light the kindling. Before warming up the furnace of a long-burning boiler, you should make sure that the device is ready for operation.

A characteristic feature of pyrolysis combustion boilers is a small amount of ash and ash, which facilitates the process of cleaning the device and its maintenance.

To do this, check the presence of traction, the tightness of the doors, the serviceability of the locking mechanisms and control equipment, the presence of a coolant in the heating system, etc.

Then you should turn on the thermostat to make sure that the device is receiving voltage. After that, the direct draft gate is opened and the boiler is ventilated for 5-10 minutes.

Device types

Each instrument has its own unique specifications.

But all models can be divided into several types, depending on the type of combustion process:

- Traditional. A distinctive feature is that the combustion process occurs from the bottom up. Fuel is loaded manually, combustion products are removed through a flue. The boiler does not require electricity to function.

- Long burning. Features - the combustion process goes from top to bottom, fuel is laid from above. The unit is designed for uninterrupted operation during the day without "refilling". Due to the complex design, long-burning boilers have a high cost.

- Pyrolysis. Features - the presence of two fuel chambers: the first is designed for the combustion of solid fuel, the second - consumes the gas that was formed in the first. Advantages - high efficiency, minimum waste, environmental friendliness. But such boilers require special attention - they are allowed to be installed only in rooms with a humidity of 17-20%.

- Universal. Features — functioning on all types of solid fuel. If you change the burner, you can use liquid fuel. Models are equipped with a security system that eliminates spontaneous combustion or cessation of work.

3 ZOTA Pellet 100A

One such boiler is more than enough to heat the whole building, where there is a water heating system with a pre-installed pump for forced circulation. Manipulation of all aspects the system is reduced to an electronic control panel. This system is truly indestructible - unless, of course, the user has a reverse goal. The rated power of the boiler reaches 100 kilowatts, but it can be reduced by regulating the air supply. The supply of pellets to the furnace is regulated in the same way. The only and most significant drawback of the system is the excess weight of the structure. 829 kilograms - this is how much this unit weighs, which is not so easy to move even within the delivery task, not to mention the final installation.

Advantages:

- the price corresponds to the declared parameters;

- fuel is supplied to the combustion chamber by a screw mechanism;

- the electronic control system controls all aspects of the unit's functionality;

- high power rating.

Flaws:

very heavy structure.

Scope of pyrolysis boilers

heating cottagesindustrial premises,

When compared with an electric or gas boiler, of course, in terms of environmental friendliness, electric and gas boilers come first, which do not have smoke emissions. But the cost of electricity is quite high, so not every resident can afford to be heated by an electric boiler. It can be replaced by gas, if your house is located in an area where a gas main is laid.If you are economically spending your financial budget and do not have the opportunity to use main gas, then the best heating option for you would be to use solid fuel pyrolysis boiler.

What is a pyrolysis boiler

When meeting such equipment in stores, visitors often wonder what is a pyrolysis boiler? At the same time, many are confused by its price, as well as a device that differs from classical heating equipment.

It is distinguished from conventional classical systems not only by the structure itself, but also by the principle of operation.

Such a boiler is called gas generating, as it heats the room by burning gas. It is released by tree species and coal when they reach certain temperatures.

Thanks to this, the system works many times longer on one load of firewood, thereby consuming solid fuel more economically.