- How to calculate the heating system on gas cylinders

- Basic rules for heating a house with gas cylinders.

- What can be gas heating

- Water heating

- Air (convector) heating

- We reconfigure the floor heat generator

- Types of propane boilers

- Features of single-circuit devices

- Nuances of double-circuit products

- How condensing units work

- The principle of operation and arrangement of gas boilers

- Calculation of costs for an autonomous gas heating device

- Initial equipment and set-up costs

- Gas costs for heating a private house

- How to turn on the gas convector

- The principle of operation of a storage gas boiler

- Theoretical part

- Advantages of gas-balloon heating at home

How to calculate the heating system on gas cylinders

To understand the practicality and efficiency of this heating system, it is necessary to carry out preliminary calculations and answer an important question: how long does one cylinder last?

The sequence of the calculation, based on the average readings:

- The power of the boiler must correspond to 1 kW of energy per 10 m2 of the room. For a private house with a total area of up to 100 m2, it is necessary to purchase a gas boiler with a capacity of at least 10 kW.Installing heating radiators, instead of ordinary multi-section batteries, will contribute to faster heat transfer throughout the entire area of \u200b\u200bthe house.

- For the gas boiler described above, at least 0.86 kg / h of liquefied gas will be required, given the fact that the efficiency of the boiler must be at least 90%.

- The heating season usually takes no more than 6 months, sometimes 7 (if April is too cold). 7 months - 5040 hours. Of course, the boiler will not work with the same power all this time; for greater efficiency, the operating modes should be alternated.

- 1 cylinder with a capacity of 50 liters holds 21.2 kg of liquefied gas. A calculation is made: 5040 is multiplied by 0.86 kg / h and the resulting value is divided by 21.2 kg of gas. The final value (rounded down) is 204 cylinders for the entire heating season. This figure will be even higher if, instead of cylinders with a capacity of 50 liters, products of 27 liters are used.

Such calculations are very superficial, because no user will constantly keep the gas boiler in full power mode. But, based on these values, which should also be multiplied by the price of gas (add more transportation and refueling of cylinders), you can decide whether to install a gas-balloon heating system.

Basic rules for heating a house with gas cylinders.

In order to correctly calculate how much a gas boiler will consume gas from cylinders, it is necessary to know the area of \u200b\u200bthe heated room and the heat loss of the room. Windows should be insulated to reduce heat loss. insulate the walls. roofs and foundations. Without these data, any calculations are not relevant.For example, for heating a standard brick house with an area of about 50 square meters, about 2-4 cylinders of 5 liters per month are needed.

Basic rules for the use of gas cylinders when heating a house with gas cylinders:

- For replacement and inspection of cylinders, free access must be provided to them.

- Gas cylinders must not be installed lying down, and they must not be allowed to fall.

- The distance from the electrical appliance (electric switch) or gas stove to the cylinders must be at least one meter.

- It is forbidden to conduct gas (including placing gas cylinders) in the basement or basement.

Important! For safety reasons, gas cylinders are filled to a maximum of 85%. This is due to the fact that in the case of heating, the gas expands and the pressure in the interior of the cylinders increases, which can lead to an explosion. It is strictly forbidden that direct sunlight falls on gas cylinders, and cylinders must not be stored in hot rooms (for example, a bathhouse)

It is strictly forbidden that direct sunlight falls on gas cylinders, and cylinders should not be stored in hot rooms (for example, a bathhouse).

Gas cylinders can be filled with three types of gases:

- Technical butane is marked - B;

- A mixture of propane and technical summer butane is marked - SPBTL;

- A mixture of propane and winter technical butane - SPBTZ.

Heating the house with gas cylinders, it is desirable to use a mixture of propane and winter technical butane.

The advantages of a gas boiler on bottled gas include the following factors:

- Environmental friendliness - environmentally friendly fuel is used,

- Autonomy (compared to solid fuel boilers),

- Convenience and ease of use.

At the same time, this type of heating has a significant drawback - the cost of bottled gas.

It must be remembered that a gas boiler will not only be able to heat your house, but will provide you with hot water, in this case it is necessary to install a double-circuit gas boiler.

Important! Installation of all gas equipment must be carried out by highly qualified specialists with appropriate permits and licenses. The use of gas cylinders is an effective way of heating. Using gas cylinders is an effective way to heat

Using gas cylinders is an effective way to heat

Any method can be used to effectively heat a private house. Practice shows that natural gas is the most efficient fuel. If the highway does not pass to the villages, then it is always possible to heat the house with gas cylinders, reviews of which speak of their efficiency and availability.

Before direct installation of this type of heating, you should consult with professionals. They will help you choose the appropriate option based on the specific case. A consultation of this kind will provide not only theoretical knowledge, but will also allow you to organize efficient heating of a private house.

What can be gas heating

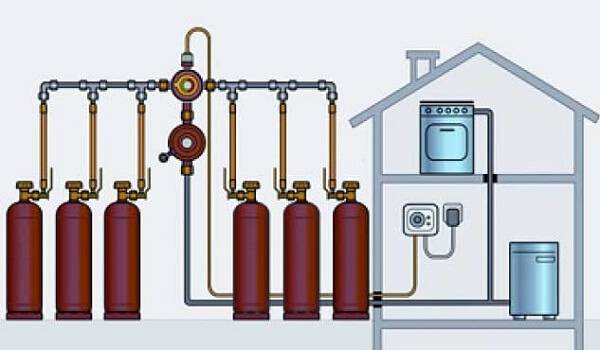

Two types of gas can be used for heating - main and liquefied. Main gas under a certain pressure is supplied through pipes to consumers. It is a single centralized system. Liquefied gas can be supplied in cylinders of different capacities, but usually in 50 liters. It is also poured into gas holders - special sealed containers for storing this type of fuel.

An approximate picture of the cost of heating by different types of fuel

Cheaper heating - using mains gas (not counting the connection), the use of liquefied gas is only slightly cheaper than the use of liquid fuels. These are general statistics, but specifically it is necessary to count for each region - prices differ significantly.

Water heating

Traditionally, in private houses they make a water heating system. It consists of:

- a heat source - in this case - a gas boiler;

- heating radiators;

- pipes - connecting the boiler and radiators;

- coolant - water or non-freezing liquid that moves through the system, transferring heat from the boiler. Water gas heating scheme for a private house.

This is the most general description of the water gas heating system of a private house, because there are still many additional elements that ensure operability and safety. But schematically, these are the main components. In these systems, heating boilers can be on natural or liquefied gas. Some models of floor boilers can work with these two types of fuel, and there are those that do not even require a burner replacement.

Air (convector) heating

In addition, liquefied gas can also be used as fuel for special convectors. In this case, the premises are heated with heated air, respectively, heating - air. Not so long ago, convectors appeared on the market that can operate on liquefied gas. They require reconfiguration, but can work on this type of fuel.

Gas convectors are good if you need to quickly raise the temperature in the room.They start heating the room immediately after turning on, but they also quickly stop heating - as soon as they turn off. Another disadvantage is that they dry the air and burn out oxygen. Therefore, good ventilation is required in the room, but there is no need to install radiators and build a pipeline. So this option has its advantages.

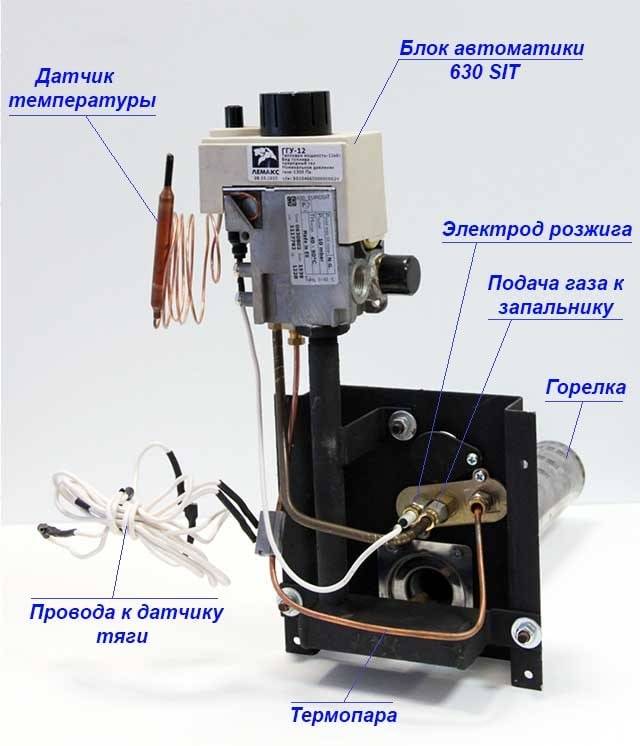

We reconfigure the floor heat generator

Non-volatile boilers of the AOGV type, equipped with automatic equipment of the 630 SIT and 710 MiniSIT series, are converted to liquefied gas in a similar way to wall-mounted "brothers". The transition is done in 2 stages - the installation of new jets and the subsequent pressure adjustment.

The burner on most units is removed together with the mounting plate and safety automatics

We will not consider disassembly and dismantling of the burner - this topic is discussed in detail in the publication on cleaning gas heaters. Install the nozzles from the LPG kit and proceed to the setting:

- Remove the top plastic cap from the 630 SIT valve. On the right side, find the screw for adjusting the pressure of the fuel supplied to the main burner.

- There are 2 fittings on the left end of the automation unit. Connect the pressure gauge to the upper branch pipe, after unscrewing the plug.

- Ignite the boiler and bring the burner to the maximum mode by setting the power control washer to the number "7".

- By turning the screw clockwise, increase the pressure of the propane mixture to the desired value (usually 26-28 mbar).

The igniter flame is regulated by a small screw located on the upper plane of the automation (see photo). Reduce the intensity of burning, but do not overdo it, otherwise the wick will go out from the gusts of wind from the chimney.Similarly, the pressure is adjusted in gas convectors equipped with 710 MiniSIT and 630 SIT valves.

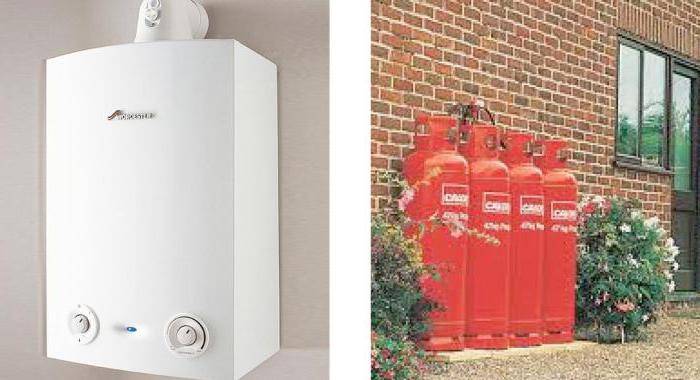

Types of propane boilers

There are three types of units on the home appliance market. These are single-circuit, double-circuit and condensing boilers. They perform similar tasks, but differ in the principle of device and functionality.

Features of single-circuit devices

A boiler with one circuit is intended only for space heating and is usually placed where water heating is solved in some alternative way.

The cost of single-circuit boilers is slightly lower than that of similar devices with two circuits. This is due to the fact that the equipment performs only a narrowly focused function - heating the home.

The module is equipped with a closed combustion chamber, and in the process of operation, the boiler flame is enriched with oxygen coming from the room where the equipment is located. The materials spent during the combustion process are discharged to the street through a vertical chimney, specially equipped for this purpose.

Nuances of double-circuit products

Devices equipped with two circuits effectively heat living quarters of any size and provide households with hot water. The coolant is heated by two burners, ignited with an igniter equipped with a built-in system of piezoelectric elements.

When the flame ignites, the temperature sensor is activated. Upon reaching certain indicators, it gives a signal to the automation, and access to the combustion chamber is covered.

If the unit has a closed combustion chamber, for correct operation and timely removal of combustion products, it is necessary to equip a coaxial chimney with forced draft.This design will ensure a uniform flow of oxygen to the wick and ensure stable combustion.

Waste materials and acid impurities leave the room through a chimney or through a ventilation outlet.

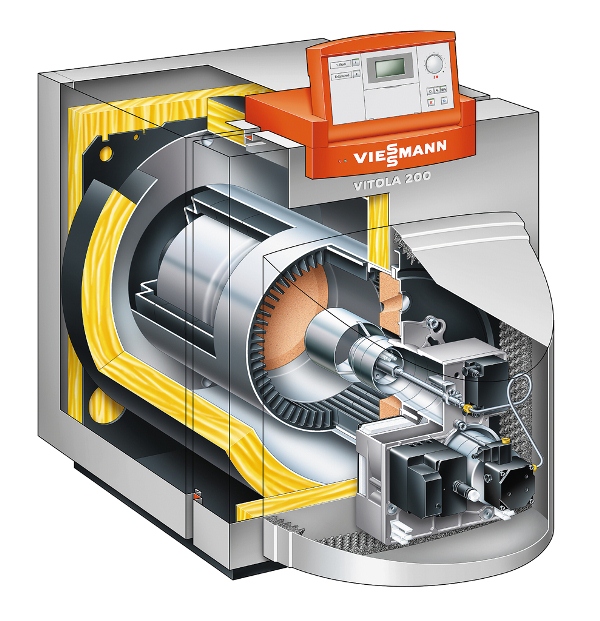

How condensing units work

A condensing-type boiler supplies both heating and hot water for domestic purposes to the living room, but it does this in a slightly different way than a double-circuit one. In the condensing device, cold water, once in the heat exchanger, is heated by the burner and hot air.

The condensing boiler belongs to high-tech types of equipment and consumes fuel very economically. The flue gas temperature at the burner is 40°C and the efficiency level reaches 97%. At the same time, heat losses do not exceed 0.5%

Then half of the liquid goes into the communications of the heating system, and the second half enters the taps for washing, washing and other household needs. After going through a full cycle, the water from the radiator returns to the heat exchanger and the whole procedure is repeated again.

The principle of operation and arrangement of gas boilers

A gas boiler is a wall-mounted or floor-standing unit, predominantly of a rectangular-parallelepiped shape, which generates energy during the combustion of fuel and thereby ensures the functioning of heating and hot water supply systems.

In general, the boiler consists of the following elements:

1. Housing;

2. Burner;

3. Heat exchanger;

4. Circulation pump;

5. Branch for products of combustion;

6. Block of control and management.

Depending on the design, the boiler operates in one of several modes - according to a simplified scheme: gas is supplied to the burner, which is turned on by a piezoelectric element or electricity; the fuel ignites and heats the coolant through the heat exchanger; the latter, with the help of a pump, is forcibly circulated in the heating system.

During operation, an important role is played by safety systems that prevent overheating, freezing, gas leakage, pump blocking and other troubles.

In the operation of the units there are individual features. In the variant with a 2-circuit model, hot water supply is additionally arranged. In the case of an open firebox, combustion products are removed through the chimney, with a closed chamber - through a coaxial pipe. In condensation models, steam energy is also used.

Calculation of costs for an autonomous gas heating device

Comparing which of the types of heating systems will be the least expensive, you must first pay attention to the consumption of liquefied gas for heating. It is advisable to compare the upcoming costs with similar costs for other types of fuel and decide which option will be more profitable.

Initial equipment and set-up costs

The cost of purchasing equipment and installing an autonomous liquefied gas heating system in your home may vary slightly in different regions of residence. But in general, when compared with connecting to the main gas pipeline, the difference in cost will be insignificant. It will be more expensive only if you use not cylinders, but a gas tank with a volume of several cubic meters.Its cost will be more than 300,000 rubles.

It is also almost equivalent in cost to equip premises for boilers using LPG, in comparison with those that run on diesel fuel. According to reviews, heating with liquefied gas only requires higher initial costs when it serves as an alternative to solid fuel or electric heating. But in the course of further operation, invested in heating private house with liquefied gas the funds will gradually pay off due to the profitability of this type of fuel.

Gas costs for heating a private house

A few years ago, a propane-butane mixture cost much more than main gas (methane), but over time, the price difference between them decreases. Therefore, the relative indicators of the cost and consumption of liquefied gas for heating demonstrate the feasibility of using this energy carrier.

Specific heat of combustion, mJ

The easiest way to determine the real consumption of liquefied gas for heating a house is to correlate the mass of gas in one cylinder with the technological characteristics of heating equipment. In this case, it is more convenient to calculate the flow rate precisely by mass, since the volume (in liters) depends on the density and percentage composition of the propane-butane mixture pumped into the cylinder.

A standard 50-liter cylinder is filled with 35-40 liters of LPG, which, in terms of mass, gives an average of 22 kg of gas.

Let's analyze a specific example to determine the required amount of liquefied gas in cylinders for heating a house with an area of 100 m²:

- For heating the indicated area, it will be necessary (according to the maximum standards) 10 kW of heat energy;

- However, the boiler does not operate constantly in the maximum mode, and its average load factor can be taken as 0.5. So we need 5 kW;

- With a calorific value of liquefied gas of 46 mJ / kg, about 0.1 kg of LPG per hour will be consumed to produce 1 kW of heat energy, and 0.5 kg of LPG will be required for 5 kW;

- 12 kg, or almost half of the cylinder, will be consumed per day;

- The monthly consumption of liquefied gas for continuous heating of the house will be approximately 13-15 cylinders.

The volume of the gas tank may be enough to operate the heating system throughout the season

What will be the consumption if you do not use cylinders, but pump fuel into a gas tank? How often will you have to call a tanker to replenish the gas supply in the “five-cc” tank most common among consumers? Let's figure it out:

- Any of the containers for liquefied gas is not filled “under the neck”, but only by 80-85%. Accordingly, in a tank with a volume of 5 m³ there will be about 4250 liters or (in terms of mass) 2300 kg of gas;

- We have already determined that in our case the liquefied gas heating system consumes 0.5 kg of fuel per hour;

- We divide the total mass of 2300 kg of gas contained in the gas tank by 0.5 kg / hour, and we get 4600 hours - for such a time we have enough fuel;

- Dividing 4600 hours by 24 gives us a total of 190 days. That is, one filling of a gas tank with a volume of 5 m³ is enough to heat a house of 100 m² for almost the entire heating season (in a temperate climate).

These are theoretical calculations, but in reality, fuel consumption can be significantly reduced.With the correct setting of the combustion modes, a gas heating boiler for liquefied gas is able to consume 1.5–2 times less fuel, and the temperature in the house will be maintained at an acceptable level.

To reduce the amount of combustible gas, use automation, which switches the boiler to a moderate mode at night, reducing the temperature in the system by 7–9 degrees, thereby achieving a 30% reduction in costs.

How to turn on the gas convector

For normal and correct operation of the device, you need to know how to turn on the gas convector. It is better to entrust the first start-up of the unit to a specialist who did the installation. After the master carries out commissioning, you can use the device yourself.

The algorithm for turning on a gas convector implies:

- check for traction;

- opening the gas valve at the heater inlet;

- igniter ignition.

When igniting the igniter, hold the adjusting holder-handle on the valve for several seconds. If the wick does not go out during this time, you need to slowly turn the knob and set the desired temperature. The main burner will ignite automatically.

If the convector is additionally equipped with a blower, electric ignition, and a supercharger, the start-up occurs in automatic mode. To do this, you only need to turn on the unit in the network, open the gas supply valve and start the corresponding button on the panel. Complete with devices comes instructions for turning on the device, thanks to which you can also adjust the temperature. Many people wonder why the gas convector began to heat badly.This may be due to its clogging, which is why it is necessary to periodically call the wizard to clean the nozzle and regulate the temperature.

The principle of operation of a storage gas boiler

There are several different types of water heaters. Despite the difference in design, all capacitive-type gas boilers differ in the same principle of operation. Water heating is carried out as follows:

- Combustion chamber - at the bottom of the body is a burner with forced or natural draft. When gas is burned, heat is released. Unlike flow columns, the burner does not come into direct contact with the heat exchanger. The task of the combustion chamber is to generate heat and direct it to the flame tube.

- Heat exchanger - in the boiler there are no radiators familiar to instantaneous water heaters. The heat generated during combustion of the gas is directed to the flame tube. The walls of the heated pipe are in contact with hot water. Heat exchange takes place.

- Water supply to the consumer - the heated liquid remains in a heat-insulated container. The water heater automatically maintains the temperature. When the water supply tap is opened, hot water pressure is created, as in a conventional boiler, by displacing it with liquid from the cold water supply. Hot water is instantly supplied to the consumer.

The first heating is carried out within 20-30 minutes. After that, the boiler continues to maintain the required comfortable temperature, while gas consumption is minimized. The internal device contains: automation, a system for preventing calcium deposits (magnesium anode), as well as various sensors (gas pressure, water pressure, draft).The volume of the storage tank for domestic purposes varies from 80 to 200 liters.

Theoretical part

Heating is carried out using gas:

- butane;

- propane.

The gas is liquefied, bottled and supplied in this state to industries and the private sector.

Since in the gaseous state of aggregation, the gas occupies a large volume with a small amount, as a result of its treatment with high pressure, it passes into a liquid state. This allows you to pump gas into the cylinders of a larger volume.

The cylinder is connected to the heating boiler through a reducer (a device for reducing the pressure in the system).

Reducer to connect

The gas leaving the cylinder passes through the reducer and, as a result of a rapid decrease in pressure, returns to its original (gaseous) state of aggregation. In the boiler, it is burned, releasing a large amount of heat.

Advantages of gas-balloon heating at home

- Fuel: clean (environmentally) and meets all regulations and standards.

- Autonomy.

- Relative stability: the pressure in the pipes does not jump and does not change.

- Simple operation and ease of management.

- Fuel consumption is minimal.

During the construction of a new and reconstruction of an old building, it is necessary to carefully consider the heating of the dacha with gas cylinders, which has become even more popular in recent years.

In addition, from the heating system on gas cylinders, you can supply your suburban real estate with hot water.

Gas heating of a country house is used in cases where it is not possible to connect the cottage to the main gas pipeline.

Heating with gas cylinders has a high efficiency, since liquefied (natural) gas very quickly, almost instantly, passes from one state of aggregation to another (from liquid to gas).

LPG boiler

Such heating of a country house with gas cylinders is truly autonomous, since natural gas cylinders you can even bring it to the forester's hut and organize heating from a gas cylinder there.

Individual heating of a country house with bottled gas makes it possible:

- warm up interior spaces and rooms;

- use the water heated by the system for your immediate needs (through a heat exchanger).

Today, many people prefer to use propane-butane in cylinders. It is the most sought after, as it has more advantages.

Such as:

- availability;

- high calorific value;

- safety;

- ease of operation;

- equipment durability;

- the possibility of replacing the burner with a variant for natural gas;

- work in automatic mode.

Thanks to these advantages, suburban property owners have:

- reliable;

- cost-effective;

- continuous heating of the house from a gas cylinder.

A big plus makes it possible to turn on autonomous heating of the house on gas cylinders with liquefied gas at any time. And then, when the house is still under construction and when the house has been built for a long time and you have already completely settled down in it.

Heating with gas cylinders is also possible when it has become unacceptable economically or aesthetically to use other types of heating. For example: diesel fuel (more expensive every day); firewood (soot, smoke).

Connecting multiple cylinders

When you use gas cylinder heating, you should listen to all the recommendations and advice of craftsmen and people who have been using bottled gas heating for more than a year (see Gas heating in a wooden house: implementation options and safety precautions)

In many stores you can buy a burner designed to work from liquefied gas cylinders.

There are many options to choose from, but it is best to choose a burner with a capacity of approximately 10-20 kW, depending on the total volume of heated rooms.

A liquefied gas cylinder is connected to the purchased burner through a special gearbox (purchased separately), which should consume from 1.8 cubic meters per hour to 2 cubic meters per hour (the usual one uses 0.8).

If you use a burner that is designed to work from main gas, it will be necessary to adjust the valve for proportional gas supply, since the pressure in the line is an order of magnitude lower and the hole in the valve is larger.

Each burner, which is designed for heating the house with bottled gas, is accompanied by an instruction in which you will find a description of this adjustment.

You can, of course, use an old, Soviet-style gas stove (to save money), but you will also have to replace the jet in it (see photo)

Gas stove jets

on the other (with a smaller hole).

You can find all methods, methods and instructions on how to do this in articles and forums on the Internet or watch a video about reinstalling jets.