- Components of the boiler piping

- Where to put the circulation pump

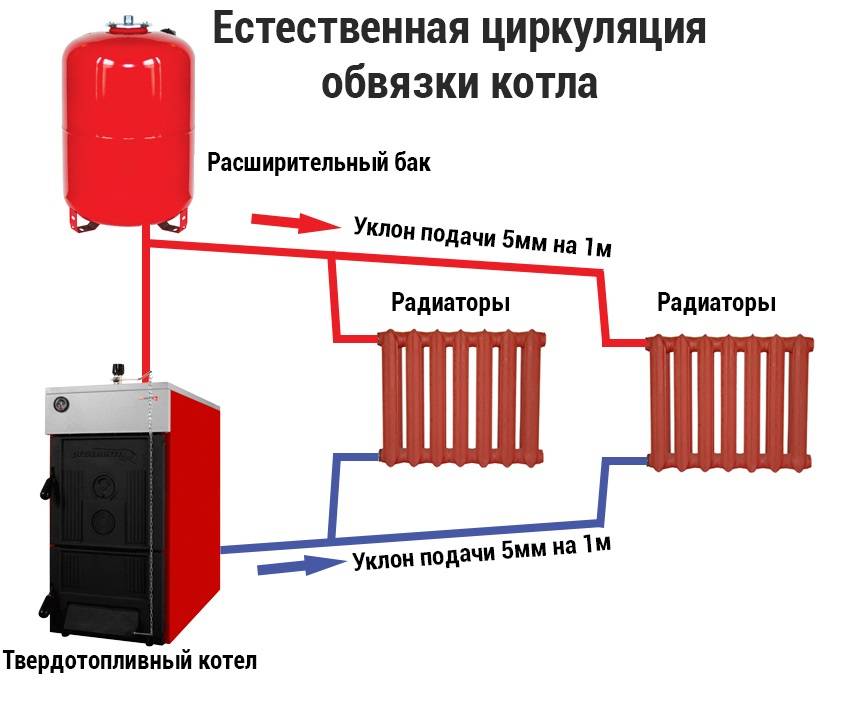

- Open Network Package

- Boiler

- Circulation pump

- Expansion tank

- Heating radiators

- Pipes

- Device

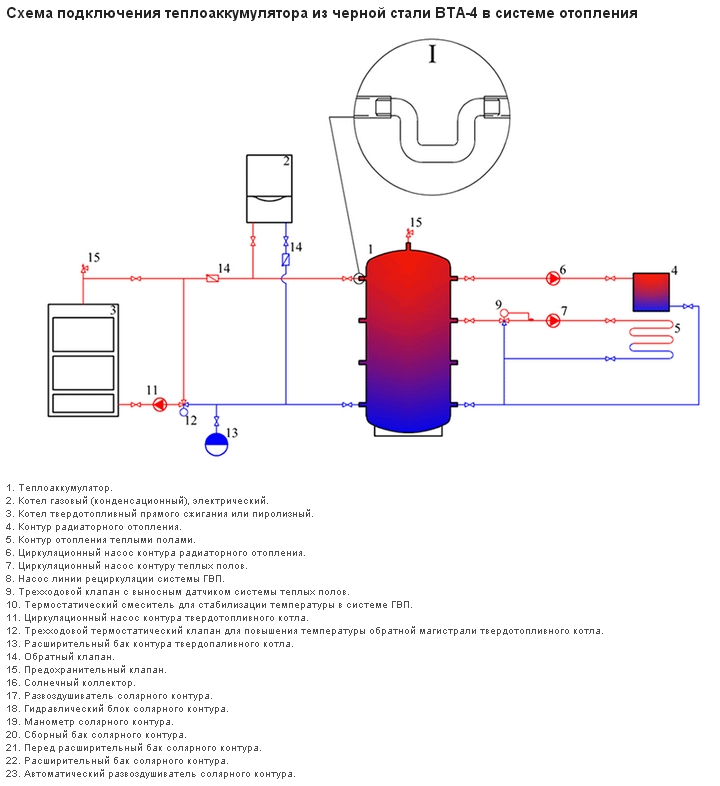

- What is a heat accumulator buffer capacity and its purpose.

- Parallel operation of boilers on wood and gas

- 1 scheme (open and closed systems)

- Advantages and disadvantages

- 2 scheme, two closed systems

- Heat supply through 3-way valve

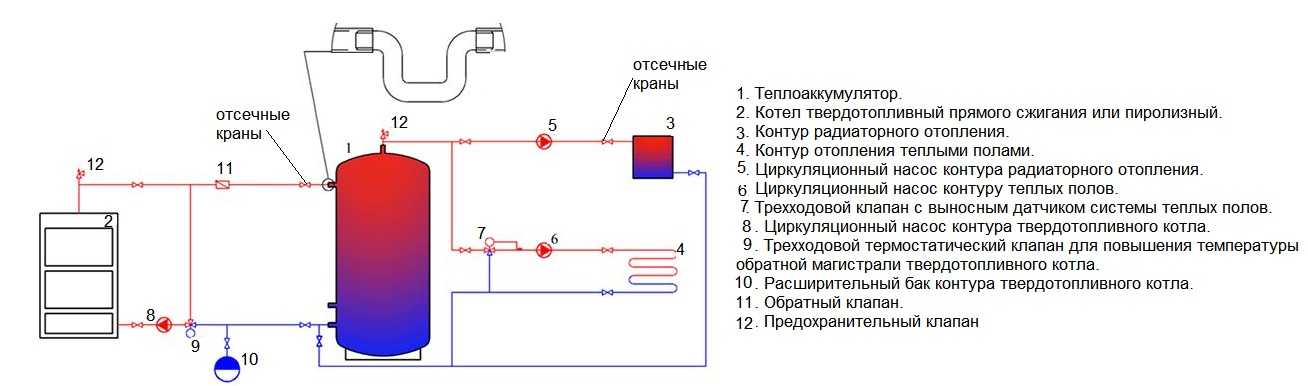

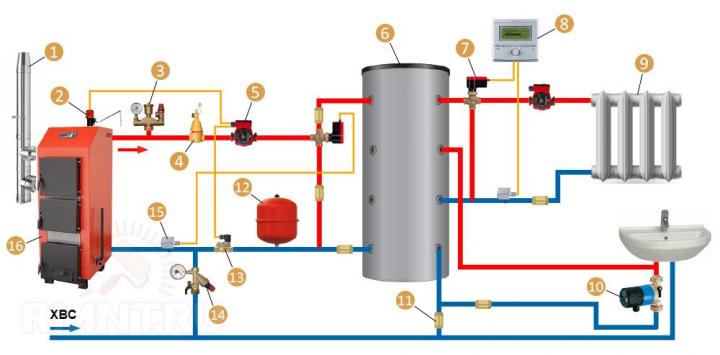

- System with a heat accumulator, why is it

- Schematic diagram of strapping

- Piping scheme with a floor single-circuit gas boiler

- Basic principles for connecting a solid fuel unit

- How to make strapping cheaper

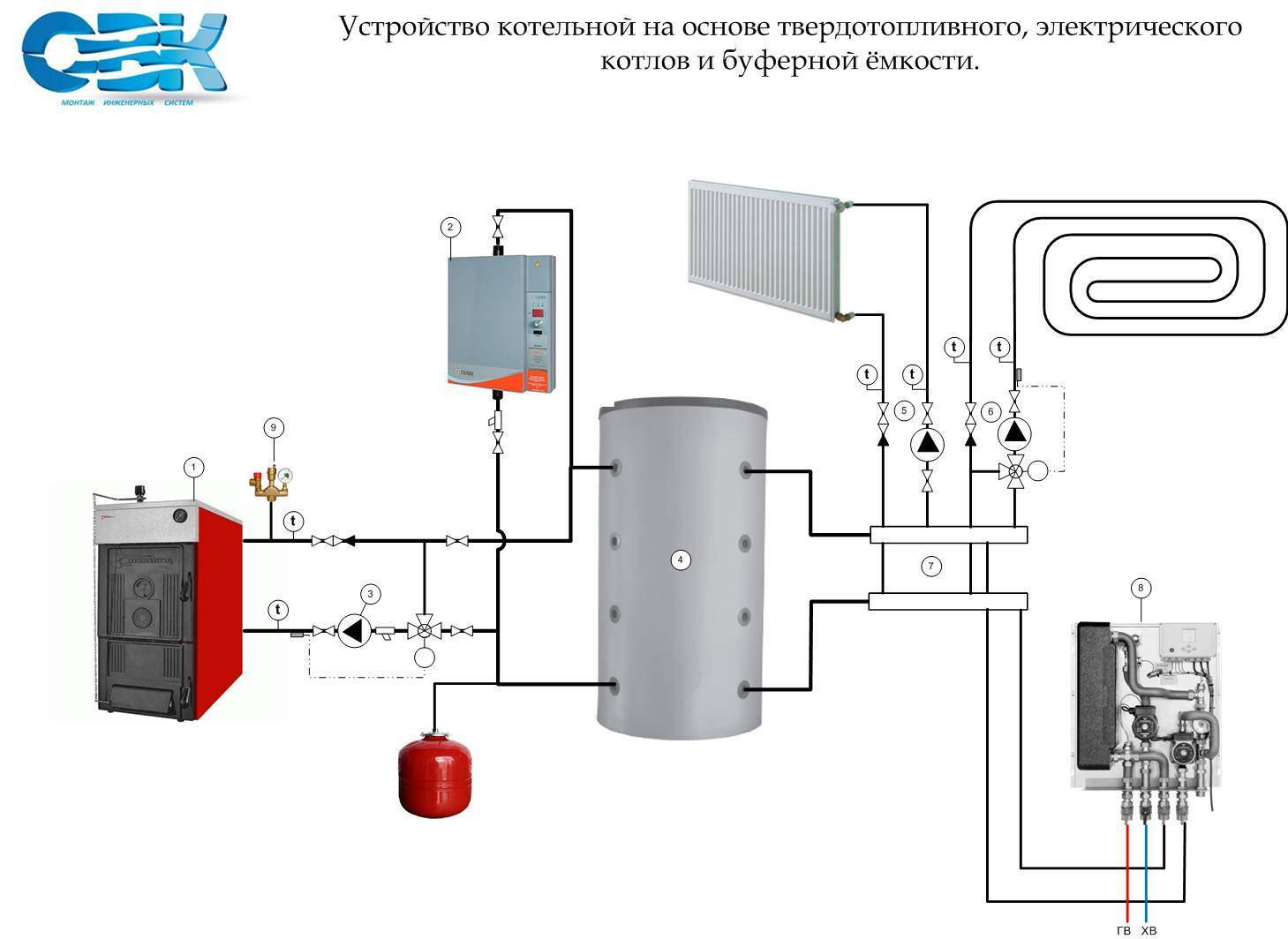

- Installation with electric or gas unit

- Method of primary and secondary rings

- Finally, an important conclusion

- Boiler options with different fuels

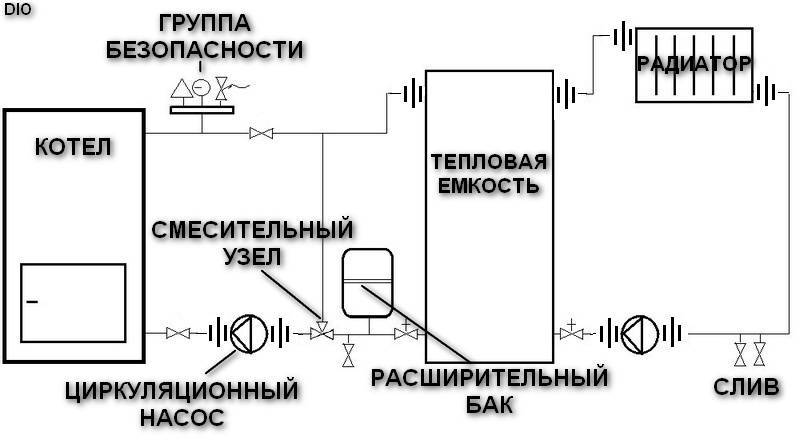

- Serial installation

Components of the boiler piping

the prohibition of its placement in the upper part of the pipeline layout a clear vertical position

The branch pipes located at the bottom of the unit will “tell” about the presence of an automatic air vent, which is necessary for connecting to the heating network. They are provided in wall-mounted electric and gas models.This feature should be taken into account when piping the boiler, since wall-mounted monoblock models can cope on their own with the release of air masses.

Boilers are sold both fully equipped and without additional elements. The necessary parts are purchased separately and included in the circuit. Those who have settled on the choice of heating with natural circulation will not need them.

Where to put the circulation pump

In most piping schemes for a heat accumulator with a circulation pump, it stands in the return pipeline in front of the boiler. In the return line - because the temperature is lower here, but you can also put it on the supply. Modern pumps are designed to pump coolant up to 110 ° C, so they feel good there. The second point: when installed on the supply, the pump will not create additional pressure on the heat exchanger, which will extend its service life.

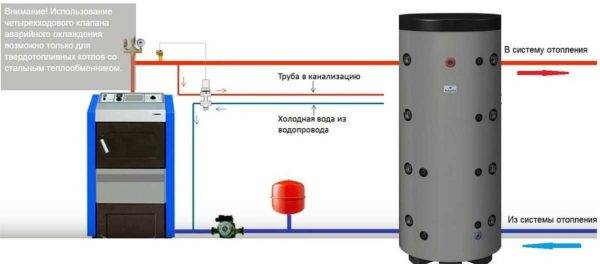

In any case, when installing a circulation pump in the supply or return, there is no possibility of natural circulation. That is, in the event of a power outage, the circulation will stop, the boiler will inevitably boil. To avoid this, they put a four-way valve through which they organize the discharge of superheated water into the sewer and make-up with cold water from cold water. This is how the emergency cooling of the heat exchanger is organized and the boiling of the coolant is prevented.

One of the ways to avoid overheating of the coolant in the heating boiler

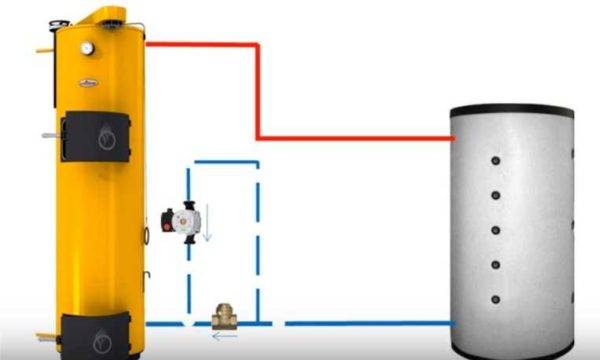

There is another way. It is more gentle on the heat exchanger (also suitable for cast iron) and requires fewer materials. It is possible to make a piping between the boiler and the heat accumulator for heating so as to maintain natural circulation.In this case, when the power is turned off, the boiler will not boil - it will continue to heat the water in the tank.

To preserve the natural circulation of the coolant, the pump is placed in a separate, specially created circuit. In order for the circuit to work, a large-section flap check valve is placed in the circuit.

This maintains natural circulation even in the absence of power supply.

When the circulation pump does not work, it passes the coolant flow from the TA. When the circulation pump is operating, it supports the valve with its pressure and the coolant flows through the pump. The pump has a pipe at least an inch in diameter. Only in this case can natural circulation be preserved.

Open Network Package

To assemble an open type circuit, you will need the following elements:

- heating equipment;

- pipelines;

- atmospheric expansion tank;

- heating devices;

- pumping equipment is needed only for open-type water heating with a pump;

- drain valve;

- valve for filling the network with coolant.

Boiler

Open circuits can work with boilers of the following types:

- Heating equipment on gas is advisable to use in regions where there are gas pipelines. Gas boilers are the most economical, but they are installed after obtaining permission from the gas service.

- Solid fuel units run on wood, coal, pellets or briquettes. There are long-burning boilers on sale, which are economical, efficient, and do not require frequent fuel loading.

- Electric heaters are not used as often because energy resources are quite expensive.

- Combined type units can operate on two different types of fuel, which makes it possible to make the operation of the equipment non-volatile.

Circulation pump

If we compare natural and forced circulation, then the latter is much better, because it increases the efficiency of the heating system. Despite the consumption of electricity by the pump, there is a saving in the energy carrier that the boiler uses.

Pumping equipment is selected according to the diameter of the pipes at the tie-in point, fluid pressure and performance

When choosing a pump, pay attention to its technical characteristics

Expansion tank

The expansion tank can be made independently or bought. The tank from stainless steel is completed with the opening cover for control of level of the heat carrier. A pipe is installed in the upper part of the tank to drain excess liquid.

The expansion tank can be installed at the following network points:

- at a remote stand;

- at the highest point of the system;

- on the return pipeline;

- together with pumping equipment that is installed on the supply pipes.

Heating radiators

Open heating can work with the following types of heating devices:

- Cast iron batteries are ideal for open systems because they have high inertia, which saves energy.

- Steel radiators with anti-corrosion coating are light and inexpensive, but it is better to refuse their use. The device cools down quickly, which will lead to frequent operation of the heater, excessive consumption of energy.

- When choosing aluminum appliances, give preference to units with an anti-corrosion coating. They are valued for their durability, good heat dissipation, light weight and attractiveness.

- The most expensive bimetallic devices. They combine the advantages of steel and aluminum appliances, but are completely devoid of their shortcomings. But they are better used in centralized networks with high pressure.

Pipes

For the natural flow of the coolant, pipes of large diameter will be needed.

You can use pipelines from the following materials:

- steel pipes are almost never used due to the complexity of installation and high weight;

- copper pipelines are the highest quality and durable, but they are very expensive;

- metal-plastic pipes are not bad in themselves, but they are connected on fittings, which often leak;

- it is better to choose elements made of cross-linked polyethylene with oxidation protection and reinforcement;

- there is another inexpensive and practical option - polypropylene pipelines with fiberglass reinforcement.

Device

Recall that a double-circuit wall-mounted boiler is a small boiler room, which includes:

- two heat exchangers. The main one is designed to heat the coolant in the heating system. Secondary allows you to organize the supply of hot water for the DHW system. Many models of double-circuit boilers work according to the following principle - if hot water is consumed from the DHW system, the gas supply to the first heat exchanger is immediately turned off. This is a big minus of this type of heating devices. But boilers have already appeared on the market that have a dual heat exchanger, which allows solving a similar problem.

- Circulation pump. This unit is pre-installed in the boiler. And this eliminates the difficulty in acquiring a pump of the required power.Plus, it is not necessary to carry out the installation of this additional equipment and its strapping.

- Expansion tank. It is selected for certain sizes of the heating system, which depends on the power of the heating unit.

Since we are interested in the boiler piping, we will consider only heat exchangers.

What is a heat accumulator buffer capacity and its purpose.

The purpose of the heat accumulator (TA) will be easier to describe with several examples-tasks.

Task one. The heating system is based on a solid fuel boiler. It is not possible to constantly monitor the temperature of the coolant at the supply and throw firewood in time, as a result of which the supply temperature either exceeds what we need, or drops below the norm. How to ensure that the required coolant temperature is maintained?

Task two. The house is heated by an electric boiler. Electricity supply is two-tariff. How to reduce energy costs by reducing energy consumption during the day and increasing at night?

Task three. There is a heating system in which heat is generated by heat generators operating on various types of fuel and energy - for example. gas, electricity, solar energy (solar collectors), earth energy (heat pump). How to ensure their efficient operation without loss of generated heat when there is no need for it, while providing the house with heat during peak energy consumption?

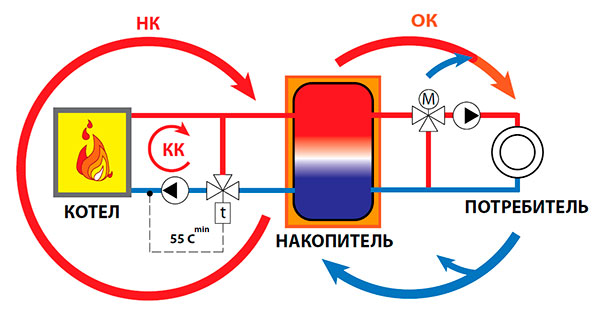

Without really going into the theory of heat engineering, for all problems, a solution suggests itself in the form of installing a buffer tank in the system, which would serve as a reservoir for the coolant and in which its temperature would be maintained at a given level. It is this buffer capacity that is the heat accumulator.To solve these problems, the heat accumulator is usually included in the "break" of the system with the formation of the boiler and heating circuits. The conditional scheme for including a heat accumulator in the heating system is shown in the figure below.

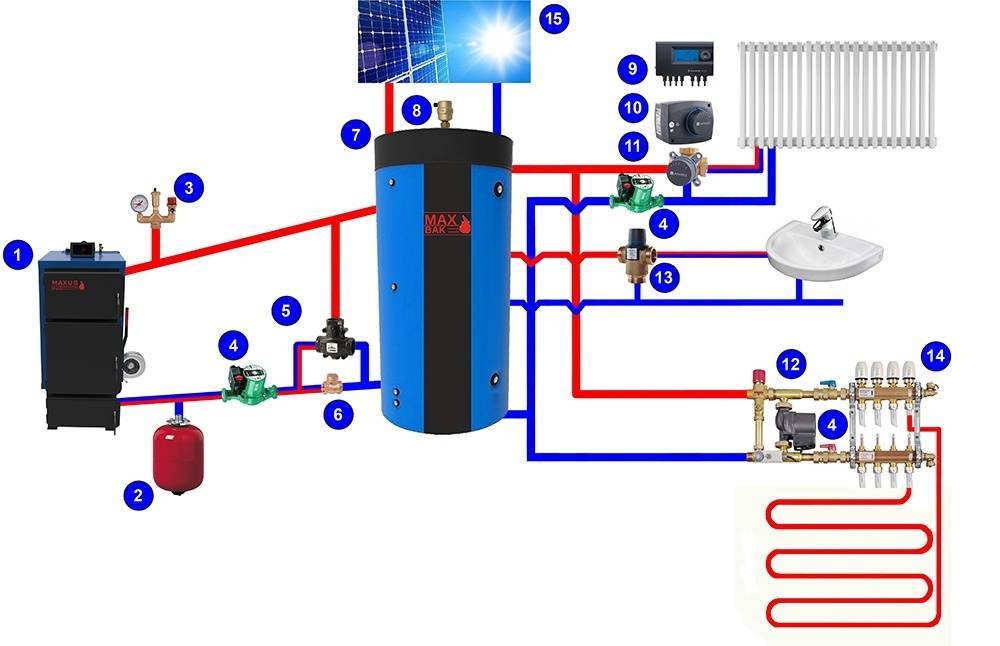

Rice. Schematic diagram of the inclusion of a buffer tank (heat accumulator)

For various ways to include a buffer tank in the heating system, see the article “Heat accumulator connection diagrams”.

Currently, heat accumulators are most often used in heating systems with solid fuel boilers. In these systems, the use of a heat accumulator makes it possible to load fuel less often, to ensure comfortable heat supply, regardless of fluctuations in the temperature of the coolant at the outlet of the boiler. Buffer tanks are often installed with electric boilers to save money due to a reduced night tariff and in combined systems with the simultaneous use of solid fuel and electric boilers. A heat accumulator (TA) can be useful in systems with gas boilers, especially when the minimum heat output of the boiler exceeds the heat load of the object. Due to the longer periods of "loading" of the TA (heating of the coolant), it is possible to avoid the "clocking" of the boiler.

In addition to being used as a buffer tank, TA performs the function of a hydraulic separator. Especially this property of a heat accumulator is in demand in systems with heat generators operating on different types of energy (including alternative).As a rule, these heat sources operate on special heat carriers that do not allow mixing with other types, require a unique temperature and hydraulic regime, often incompatible with the regimes of the heating circuit (radiator, underfloor heating). For example, the temperature range of a heat pump is usually

5°C, and in the heat distribution circuit the temperature range can be much larger (10-20°C). To separate the circuits, the heat accumulator can be equipped with additional built-in heat exchangers.

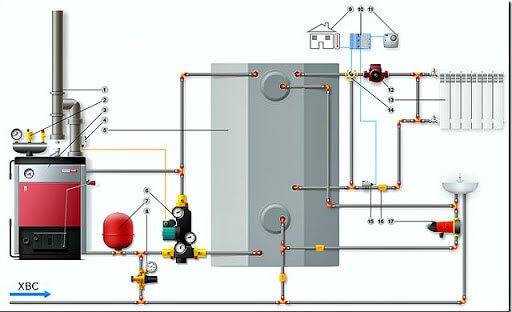

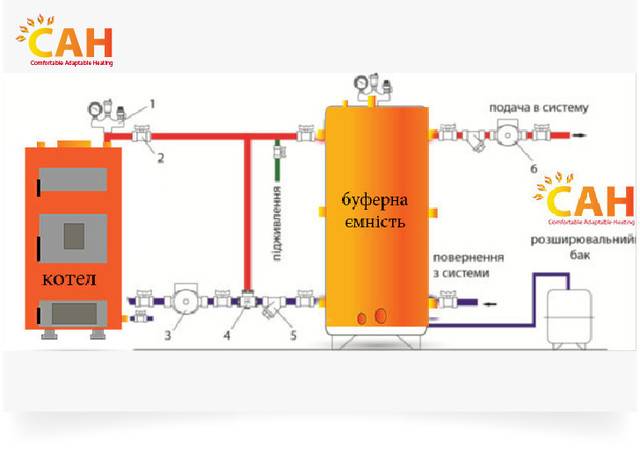

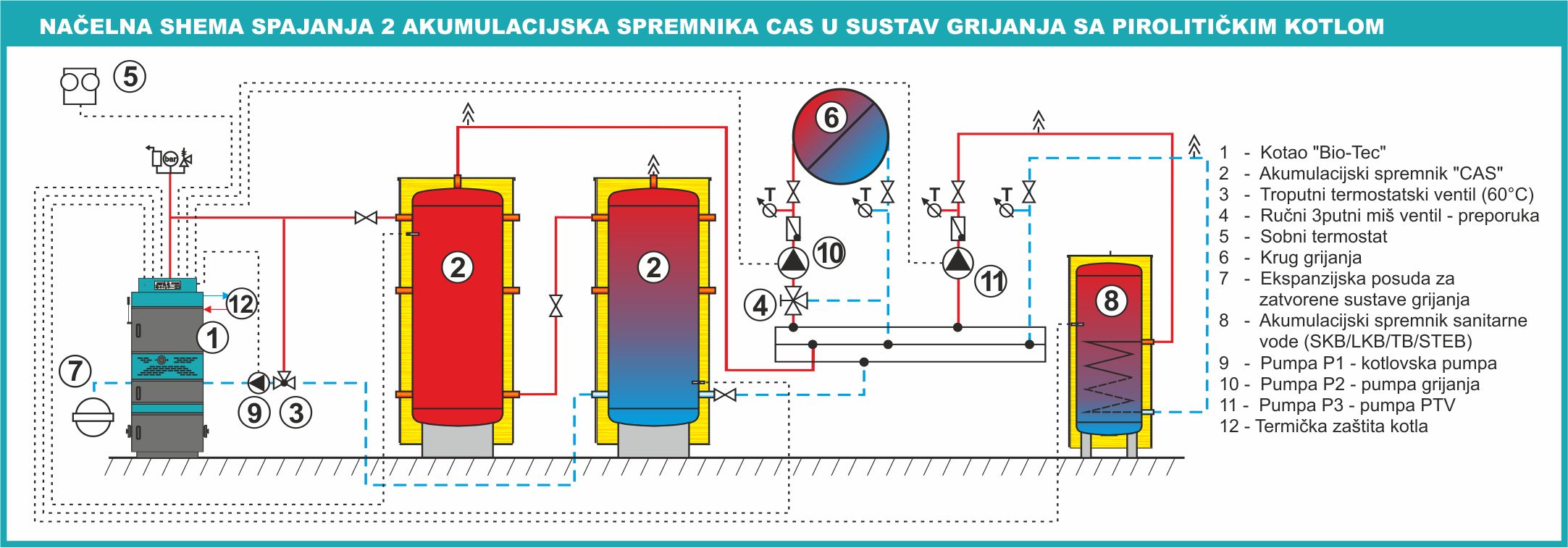

Parallel operation of boilers on wood and gas

This option of heating the house from two boilers provides for their separate connection to the circulation system. Each heat source must have its own circulation pump at the return inlet. For a wall-mounted gas boiler, this is not necessary, the pump is already installed in it by the manufacturer. In the event of a burnout of solid fuel, the temperature of the coolant will decrease and the gas boiler will automatically turn on.

An important design point is the binding of a solid fuel boiler with metal pipes and the presence of an emergency discharge device with the simultaneous supply of cold water to the return line.

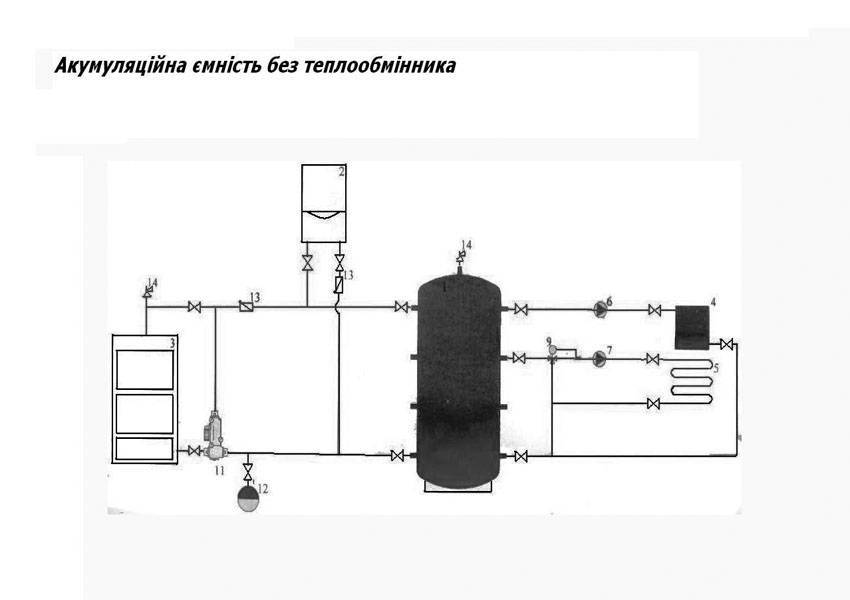

1 scheme (open and closed systems)

This method convenient because the fluids of the two systems do not mix. This allows you to use different coolants.

Advantages and disadvantages

| pros | Minuses |

| Possibility to use different coolants | A large number of additional equipment |

| Safe operation, the reserve tank will dump excess water in case of boiling | Efficiency is lower due to excess water in the system |

| Can be used without additional automation |

2 scheme, two closed systems

It uses a closed system, which eliminates the need for a heat accumulator. The control is carried out by thermostats and three-way sensors. Operational safety is ensured by automation.

Here we use the battery for excess heat. Thus, we increase the efficiency of the system and eliminate the need for temperature sensors and automation.

Heat supply through 3-way valve

Each boiler must be equipped with its own circulation pump, and another pump will be required to circulate through the heating system appliances. An automatic air vent must be installed at the top of the hydraulic separator, and an emergency drain valve at the bottom.

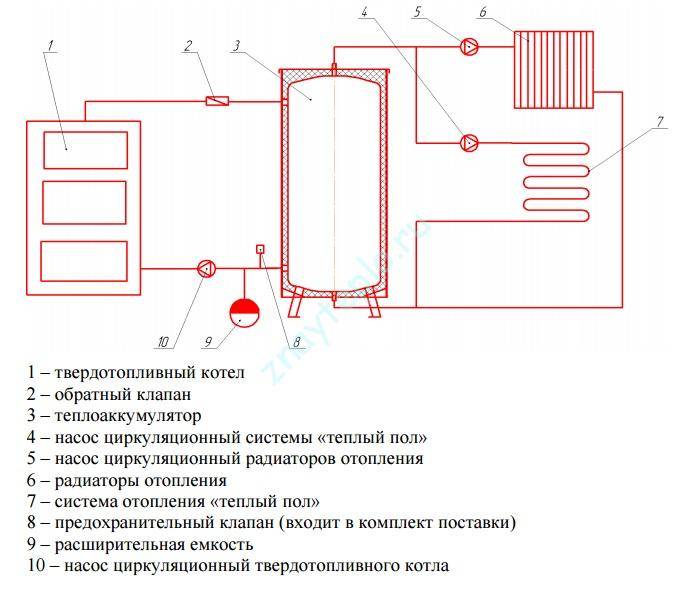

System with a heat accumulator, why is it

The heat generated by the wood-fired boiler enters this tank. From not, through a coil, a heat exchanger or without them, into a gas boiler. The automation of the second understands that the water has the required temperature and turns off the gas. This will be so long as there is enough temperature in the heat accumulator.

A heat accumulator or a heat-insulated container with a built-in coil, designed to accumulate heated coolant and supply it to the heating system. In this scheme, the gas boiler, heaters and battery are connected by pipelines into one closed-type system. The solid fuel boiler is connected to the built-in battery coil and thus heats the coolant in a closed system. The organization of the heating work in this scheme occurs in the following order:

- firewood burns in a solid fuel boiler, and the coolant is heated from the coil in the tank;

- solid fuel burned out, the coolant cooled down;

- the gas boiler turns on automatically;

- firewood is laid again, and a solid fuel boiler is ignited;

- the temperature of the water in the accumulator rises to that which is set on the gas boiler, which stops automatically.

This scheme requires the highest costs for the purchase of materials and equipment, but it has a number of advantages:

- a solid fuel boiler can operate in an open circuit;

- the highest level of security;

- no need for constant replenishment of the firebox with wood or coal;

- coolant circulation through a closed-type system;

- the possibility of simultaneous operation of two boilers simultaneously and each separately.

Among the additional costs, it is necessary to take into account the purchase of an accumulator tank with a coil, two expansion tanks and an additional circulation pump.

calculate the required capacity

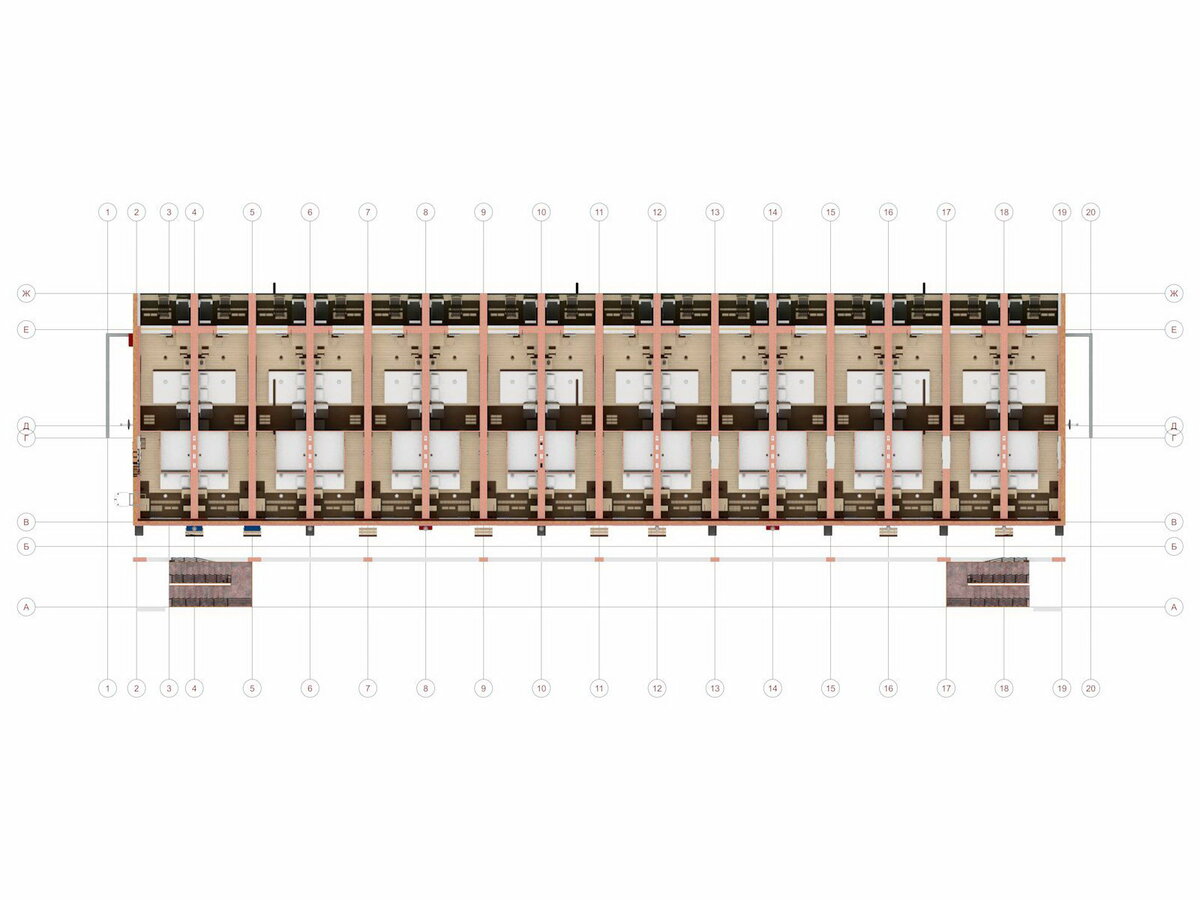

h2 id="printsipialnaya-shema-obvyazki">Principal diagram of strapping

The heating efficiency depends on the accuracy of the connection. The general piping scheme for boilers of all types, including solid fuel and condensing types, is simple, and looks like this:

- Boiler.

- Radiator.

- Nuts "American" - for attaching the boiler to the heating system.

- Ball valves - for disconnecting the boiler from the system.

- Filters for cleaning - protect against non-standard fractions of water.

- Thermal heads, tees, Mayevsky taps

- Corners and tees.

- Valves: through passage, dividing, air and safety.

- Expansion tanks.

- Heat meters.

- Manometers, thermometers, hydraulic separators, circulation pump.

- Clamps and other fasteners.

Piping scheme with a floor single-circuit gas boiler

What will be the piping scheme for a single-circuit floor-standing gas boiler? In fact, it will be identical to the one we considered above. Only the boiler body will be "gutted" - all components will be outside and will stand separately.

It turns out that in the case of a single-circuit gas boiler there will be only two components from the list above:

- Gas-burner.

- Heat exchanger.

All other devices will be located in the boiler room itself - this is a security group, an expansion tank and a circulation pump.

And in the case of the production of hot water here, the role of the "second circuit" will be performed by the BKN - an indirect heating boiler.

All other attributes of heat generating equipment - a chimney, a water mixing system and a gas supply pipe with sensors and meters - are the same in any scheme. That is, they can of course be different, they no longer depend on the type of boiler.

Basic principles for connecting a solid fuel unit

When considering how to properly connect a solid fuel boiler, it is necessary to pay attention to the basic piping elements that ensure the safety of the heat generator. We are talking about the safety group and the mixing unit. The safety group, which includes a pressure gauge, as well as a safety valve and an air vent, mounted on one manifold, is installed directly on the outlet pipe of the boiler unit

A manometer helps to monitor the pressure in the system, an air vent serves to remove air plugs, and a safety valve vents excess steam-water mixture when the pressure exceeds the specified parameters.

The safety group, which includes a pressure gauge, as well as a safety valve and an air vent, mounted on one manifold, is installed directly on the outlet pipe of the boiler unit. The pressure gauge helps to monitor the pressure in the system, the air vent is used to remove air plugs, and the safety valve dumps excess steam-water mixture when the pressure exceeds the specified parameters.

A mixing unit based on a three-way valve with a thermal head is installed together with a bypass (jumper) connecting the supply and return pipes, thereby forming a small circulation circuit.

The system that protects the boiler from condensate and temperature shock operates according to the following scheme:

- While the fuel flares up, the valve blocks the flow of the cooled coolant from the large circuit of the heating system. As a result, the circulation pump drives a limited volume of coolant in a small circle.

- A sensor is installed on the return pipe, connected to the thermal head of the three-way valve. When the coolant in the return pipe heats up to 50-55 degrees, the thermal head works and presses on the valve stem.

- The valve opens smoothly and the cooled coolant begins to gradually enter the boiler jacket, mixing with the heated one from the bypass.

- When all radiators warm up and the return temperature rises to values that are safe for the boiler, the three-way valve closes the bypass, completely opening the passage for the coolant flow through the return pipeline.

The basic scheme for connecting a solid fuel boiler to the heating system is as simple and reliable as possible; you can install the piping yourself.

It is important to know how to connect a solid fuel boiler using polymer pipes in order to avoid common problems:

- Polymer pipes are not safe to use for piping the boiler - they may not withstand an emergency increase in temperature and pressure. Therefore, it is recommended that the piping be made with steel or copper, and the polymer pipes should be connected to a collector that distributes the coolant through the heating circuits. In extreme cases, a metal pipe is mounted only between the boiler supply pipe and the safety group.

- The use of a thick-walled polypropylene pipe for the return pipeline in the area between the three-way valve and the boiler nozzle leads to the fact that the temperature sensor overhead reacts to the heating of the coolant with a noticeable delay. It is better to install a metal pipe.

The pump for the heating system with forced coolant supply is installed on the return pipe between the three-way valve and the boiler. This arrangement allows it to circulate water or antifreeze in a small circle. It is impossible to put a circulation pump on the supply pipe, since the device is not designed to work with a steam-water mixture, which is formed when the coolant is overheated. Stopping the pump will accelerate or provoke an explosion of the heating boiler, since the cooled coolant will no longer flow into it.

How to make strapping cheaper

The basic scheme for connecting a solid fuel boiler provides for the use of a three-way mixing valve equipped with a thermal head and an attached sensor.This equipment is quite expensive, and it can be replaced with a cheaper option - a three-way valve with a built-in thermostatic element. Such a device is distinguished by a fixed setting - the valve is activated when the temperature of the medium reaches 55 or 60 degrees (depending on the model).

Installing a valve that maintains a fixed temperature reduces the financial costs of installing the protection of a solid fuel unit from condensate and thermal shock. The ability to flexibly control the temperature of the coolant is lost, deviations from the set value can reach 1-2 degrees, but this is not critical.

Installation with electric or gas unit

Two heat generators can be installed in one heating system, the main of which is a solid fuel unit, and the additional one is a boiler running on gas or electricity. This option is convenient because at night you can turn on the boiler, which operates in automatic mode. It is inconvenient to use bottled gas as the main energy carrier because of the need to take care of regular fuel supplies. Electricity is the most expensive energy carrier and it is most profitable to operate such a boiler unit only at night, if the region has a system of cheap night tariffs.

How to connect solid fuel and gas boilers in one system for heating a large house? The simplest option is to connect two heat generators in parallel through a heat accumulator, which will additionally perform the function of a hydraulic separator.

The gas boiler operates in standby mode while the water in the buffer tank is heated by a solid fuel unit.After the fuel burns out, the coolant begins to cool down, and as soon as the temperature sensor transmits the appropriate signal to the gas unit controller, it automatically turns on. When a solid fuel heat generator is restarted, the reverse process occurs - heating the coolant above a certain temperature leads to the shutdown of the gas burner.

A system with an electric boiler in large-area houses is mounted according to a similar principle. But for small private houses, a simpler and cheaper option for connecting a TT and an electric boiler is relevant (see diagram).

Boiler units are connected in parallel with the installation of check valves at each outlet. The electric boiler is equipped with a built-in circulation pump, which cannot be turned off, therefore, for a solid fuel heat generator, it is necessary to select a more powerful pump so that the TT boiler has an advantage over an electric one when operating together.

The system is complemented:

- a thermostat that turns off the circulation pump TT of the boiler when the coolant cools down;

- a room temperature sensor that turns on the electric boiler when the room temperature drops after the fuel burns out in the TT unit.

Method of primary and secondary rings

How to connect two boilers in one system using a minimum amount of electronics? The use of the method of primary and secondary circulation rings allows you to perform a joint piping of the CT of the unit and the electric boiler. Hydraulic flow separation is carried out without the installation of a hydraulic switch.

Both boilers, the DHW boiler, as well as all heating circuits, are connected by both the supply and return pipelines to a single circulation ring - they are primary.The minimum pressure difference is ensured due to the small distance between each pair of connections (no more than 300 mm). The pressure of the pump installed on the main circuit ensures the movement of the coolant along the primary ring, while the flow rate is not affected by the pumps of the secondary circuits (to which heat consumers are connected).

In order for the system to function properly, it is necessary to perform complex hydraulic calculations and select the optimal pipeline diameter for all circuits.

It is also important to calculate the performance of the pumps. The actual performance of the pumping unit on the main circuit must exceed the flow rate of the coolant on the most "volumetric" secondary circuit. Both boilers are equipped with shut-off thermostats so that they can work replacing each other

Both boilers are equipped with shut-off thermostats so that they can work replacing each other.

Finally, an important conclusion

From the foregoing, it can be seen that the solution to the question of how to connect a gas boiler with solid fuel depends on financial capabilities, the total heated area and the required level of security. If finances allow and the house is large, then it is best to use a heat accumulator, and in a small house a sequential circuit will work fine.

However, as experience shows, the best option is a system with a hydraulic separator 93x way valve). With a wall-mounted gas boiler, you only need to buy 2 pumps - for a solid fuel boiler and for the system as a whole. And the separator itself, in its essence, is a heat accumulator in miniature, only without a coil.The only drawback is that the solid fuel boiler operates in a closed circulation system, which reduces the level of safety in the event of a power outage.

Boiler options with different fuels

solid fuel boilers

There are several schemes for tying two boilers to work together. The most common are:

- sequential installation;

- parallel connection of two heat sources to the heating system;

- heat supply from boilers through a hydraulic separator;

- using a heat accumulator.

Each of the methods has its own advantages and disadvantages. One scheme will cost less, but will lose in reliability. The other costs more, but benefits from more stable performance and increased fuel economy.

Serial installation

The coolant from the return first enters a less powerful heat source, and then to the next one. Closed type heating system with one common expansion tank. The strapping will require minimal financial costs, but can only be used in small residential buildings with a heated area of \u200b\u200bno more than 120 m2.