- Instructions for installing a pellet boiler

- Preparatory work

- Boiler installation and piping

- Chimney connection, start-up and adjustment

- Requirements for the room under the boiler

- What is a harness

- Production of a pellet burner

- Polypropylene contour for different boilers

- Option #1: Gas Water Heater

- Option #2: Solid fuel model

- Option #3: Oil and Electric Heaters

- The main elements of the strapping

- Expansion tanks and their varieties

- Circulation pumps

- How is the binding of such equipment made?

- Room preparation

- Making an economical device with your own hands

- Installation of additional equipment

Instructions for installing a pellet boiler

Of course, you can install the unit on your own if you have special knowledge, but still better seek qualified assistance from a specialized organization that has a building license.

Of course, you can install the unit on your own if you have special knowledge, but still better seek qualified assistance from a specialized organization that has a building license.

The main and important stage in the installation is a professionally executed design. It is followed by the following steps for installing heating equipment:

- Preparatory stage. Includes the preparation of the boiler room, the erection of a hill for the boiler, the installation of a chimney, ventilation;

- Installation of the heating unit on a hill;

- Connection to the boiler pipes of the heating system and hot water supply;

- Connection of the chimney channel;

- Adjustment and start-up of the heating device.

Preparatory work

It is necessary to prepare the boiler room - level and strengthen the base, which must withstand weight up to 200 kilograms. According to the requirements, the boiler is installed vertically, so there should not be any slope. The base must have a fireproof surface.

Laying electrical wiring is needed to automate the heater and to illuminate the boiler room, which will ensure convenience during operation. The construction of a chimney of the sandwich type, at least 5 meters high. A chimney and ventilation are also installed.

Boiler installation and piping

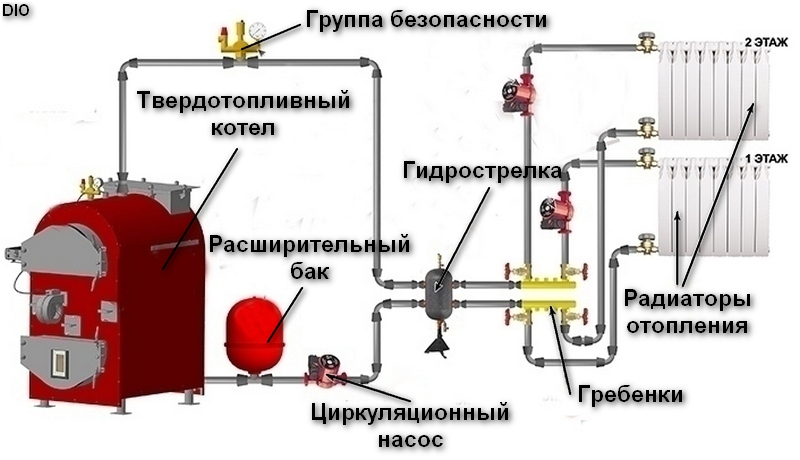

Installation and strapping occurs in the following sequence:

Installation and strapping occurs in the following sequence:

- The brought boiler is mounted on the podium;

- A fuel compartment and an auger supplying pellets are mounted;

- The distribution comb is connected;

- An expansion tank and shutoff valves are being installed;

- The boiler is connected to the circuit supplying the coolant and the return circuit.

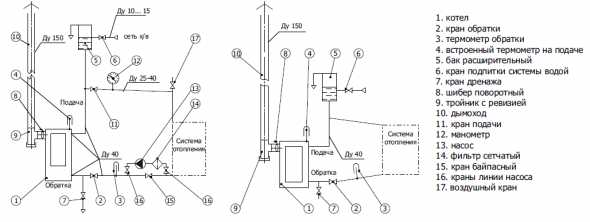

Chimney connection, start-up and adjustment

After the system has been filled with a coolant (water, ethylene glycol or propylene glycol), it should be connected to the chimney. Moreover, the diameter of the chimney must correspond to the diameter of the outlet pipe. And the height of the chimney - technical requirements.

After the system has been filled with a coolant (water, ethylene glycol or propylene glycol), it should be connected to the chimney. Moreover, the diameter of the chimney must correspond to the diameter of the outlet pipe. And the height of the chimney - technical requirements.

The appropriate diameter will provide good traction regardless of wind strength and air temperature. Good traction is the key to the efficient operation of pellet equipment. But this type of boiler is afraid of strong traction, but too small will not work either. Therefore, to solve this problem, a thrust stabilizer or a slide gate is used.

Most often, the chimney is made of a metal pipe, in which hatches are built for further cleaning. Also, the chimney should be equipped with a device for removing condensate and insulating it. An important step is pressure testing, if it is done poorly, pyrolysis gases will leak, which will lead to a decrease in efficiency.

After that, a test run and adjustment are carried out. An improperly tuned device will entail such problems: the boiler will smoke, smoke, go out and the pellets will not burn out to the end.

Requirements for the room under the boiler

The PC is mounted in an independent building or an extension to it. With a PC performance of more than 30 kW, it is placed in a separate building - a furnace.

To organize its work, the owners of the boilers draw up regulatory documents regarding operation and fire safety.

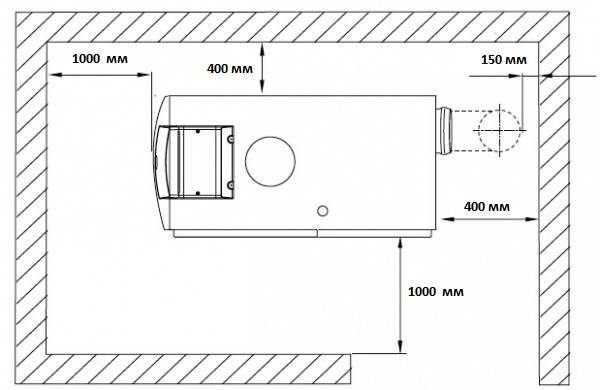

Dimensions to be held

Dimensions to be held

Basic requirements for placement:

- The floor for installation must be made of non-combustible materials: concrete or metal sheet.

- The base for the PC should be made of reinforced concrete with a height of 10-20 cm.

- Emergency and operational passages must be provided, between the boiler and the walls of the building - a distance of at least 1 m.

- The room must be dry and heated, with an internal air temperature above + 10 C.

- Supply and exhaust ventilation in the building should be calculated based on the power of the PC, the data can be clarified from the technical and design documentation of the boiler room.

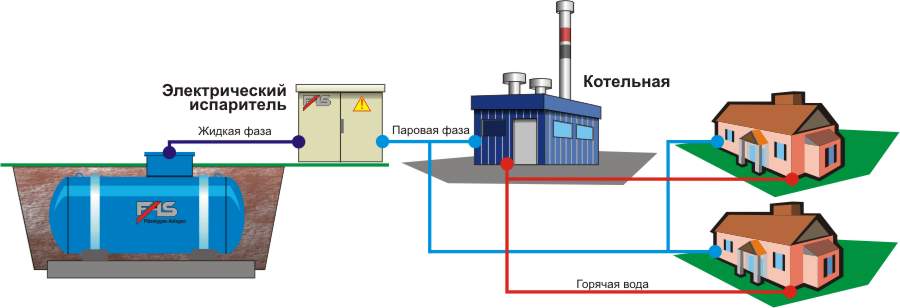

- If the boiler house is installed in a separate room, heat networks to the heating facility are laid either underground, with laying below the freezing level of the soil, or by air.In both cases, the heating main must be well insulated from heat loss to the environment.

- The height of the chimney must be at least 5 m and protrude above the roof level by at least 0.5 m; it is recommended to install a draft stabilizer or a conventional rotary damper.

- The calculation of the chimney diameter is carried out in accordance with the boiler power. For pellet boilers, it must be at least 150 mm.

- The installation of a condensate trap is mandatory.

- The roof is treated with a master flush, the gap is filled with non-combustible mineral wool.

What is a harness

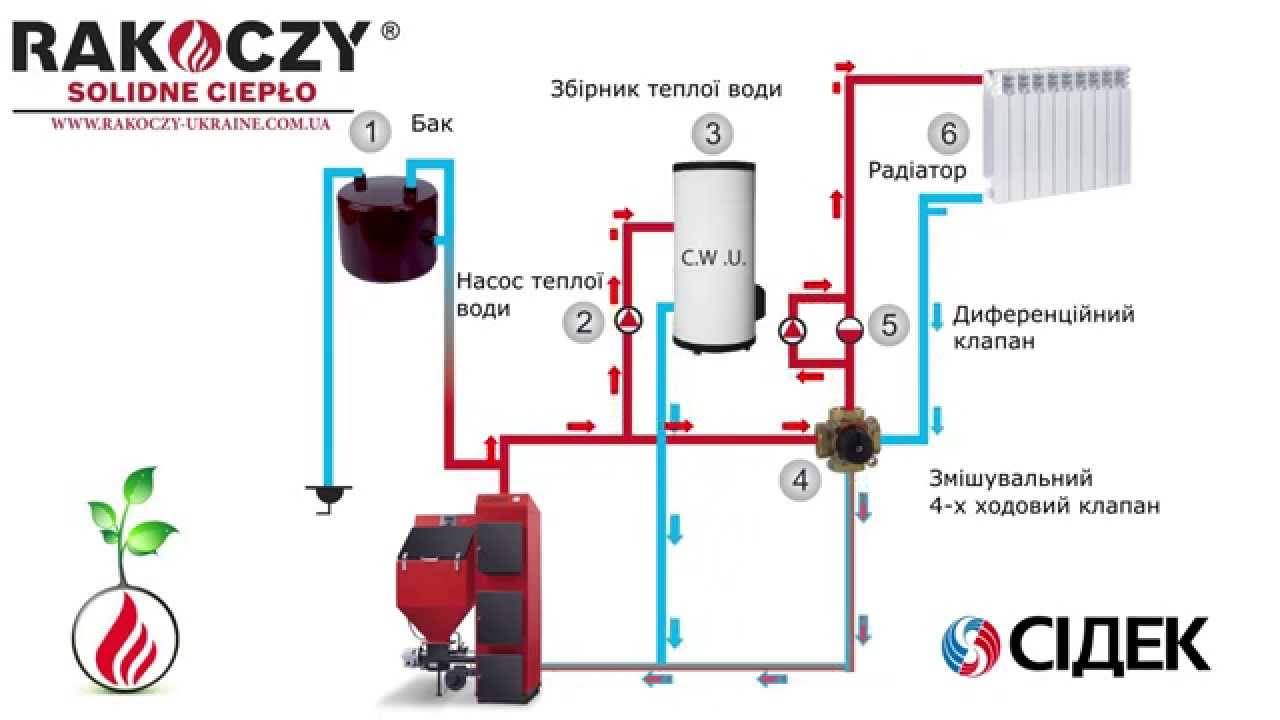

If you are completely new to heating matters, then it would be useful to first find out what is generally meant by the term "strapping". Actually, this is the entire heating system, except for the heating boiler. It depends on the piping how exactly the coolant will circulate to all destinations, how well it will turn out, etc.

For all this, several elements are used:

pipes. It is they that interest us today, and indeed this is one of the main components of the design. You can see their appearance in the photo:

In addition to them, fittings are also important - connecting elements that make it possible to lay a pipeline along the desired route and connect pipes to various heating equipment,

- expansion tank. Required to remove excess air and water from the heating system,

- heating radiators. They are stationary devices installed indoors and have a high level of heat transfer,

- bypasses. Strictly speaking, these are all the same pipes, but they are not intended for the main circulation, but for an additional one. The bypass is a bypass route.If for some reason you need, for example, to turn off one of the radiators, you can close it using the shut-off valve. If there is no bypass at the same time, then the coolant will run into this barrier and will not go further - thus, all batteries located further than the one being repaired will become cold. And if there is a bypass, such a problem will not arise - the coolant will simply bypass and successfully reach all the following goals.

The heart of any heating system is the heating boiler. It is he who is responsible for reaching the required temperature by the coolant. All of the listed elements are connected directly to the boiler, directly or using pipes.

In addition to the already mentioned, some other equipment may also participate in the strapping:

- Mayevsky crane. It is installed on each radiator and in some other places. It is necessary for quick and easy release of excess air from the system, which helps to prevent the formation of air pockets that impede the flow of the coolant. That is, in fact, this equipment is auxiliary, in addition to the expansion tank,

- circulation pump. All heating systems are divided into two broad categories. In the first of them, the circulation of the coolant is carried out in a natural way. This is due to the difference in the density of cold and hot water. The arrangement of such a system is not difficult, and economically quite profitable. But the efficiency is low. Natural circulation can only be used in small houses, since it simply cannot cope with a long circuit - the water will reach the distant radiators, having already cooled down. The second category includes systems with forced circulation.The movement of the coolant in this case occurs due to the operation of special equipment - a circulation pump. This allows you to give the liquid the necessary speed and, accordingly, prevents it from cooling in the middle of the route,

- gauges and thermostats. This equipment is necessary to monitor the correct operation of the heating system as a whole and its individual sections in particular. Thermostats monitor the temperature of the coolant, and pressure gauges monitor the pressure level. Accordingly, in the event of any malfunctions, you can detect them in a timely manner, focusing on the indicators of the devices.

Production of a pellet burner

Pellet plants are often ignored by buyers due to their high cost compared to gas and electrical equipment, while the problem is solved by making the device at home.

General scheme for self-production of a pellet burner

The combustion chamber can be equipped with a square or round pipe. It is better to give preference to heat-resistant steel that can withstand elevated temperatures, the wall thickness should be at least 4 mm.

The home-made installation is fastened to the boiler with a flange plate made from heat-resistant steel thickness from 3 mm.

A container for supplying fuel to the combustion chamber can be purchased or made by hand. The best option is to immediately make an installation in which fuel will be supplied automatically. To do this, we place an auger in the purchased pipe of the desired diameter. The rotation of the device will be carried out due to the bearing, gearbox and motor, working at low revolutions.

Additionally, a fan is purchased in the store, which will pump air. The fan is mounted on a plate, which is made depending on the size and design of the door of the boiler used in your home.

It is also important to take care of adjusting the amount of incoming fuel and the volume of air blown by the fan, otherwise the home-made device will work unstably. In home devices air force adjustment and the number of pellets is produced manually. This method is inconvenient due to the fact that it requires constant supervision of the burner.

This method is inconvenient due to the fact that it requires constant supervision of the burner.

For automation, an electric incandescent element and a photo sensor are purchased. The first device ignites the flame in case the pellets are extinguished and also regulates the activation of the device. The photo sensor monitors the appearance of the flame: if the flame is stable, the sensor transmits a signal to the incandescent element to stop ignition.

To automate the system, a filling sensor is also purchased. It will notify the electronic filling of the device about the degree of filling of the combustion chamber with pellets.

Pellet burners - modern equipment for boilers, which improves the environmental friendliness of the process and reduces fuel costs. At the same time, the equipment itself in the store has a high cost. For basic household needs, it is better to give preference to home-made devices, the operation of which, if necessary, can be automated.

Minimizing the cost of maintaining housing today is one of the most important tasks. The search for cost optimization tools is ongoing.Heating at home, with regularly rising tariffs, is a significant item in the family budget.

You can reduce it in several ways. With the help of energy-saving technologies in the construction of a house and the use of efficient heating systems. A pellet boiler is more economical than gas-fired counterparts, not to mention electricity and other energy sources. The reason lies in the low cost of consumables and the high energy efficiency of the device.

Polypropylene contour for different boilers

Most manufacturers of water heaters recommend that the first meter of the pipeline from it be made of metal. This is especially true for solid fuel devices with a higher outlet water temperature. When tying, polypropylene should be connected already to this outlet, otherwise, if there is a malfunction in the boiler, it will receive a thermal shock and may burst.

Option #1: Gas Water Heater

It is recommended to tie a gas boiler with polypropylene using a hydraulic gun and a manifold. Often gas models are already equipped with built-in pumps for pumping water. Almost all of them are originally designed for forced systems.

The most reliable in terms of safety will be a circuit with circulation equipment for each circuit behind the collector.

In this case, the built-in pump will pressurize a small section of the pipeline from the boiler to the distributor, and then additional pumps will be activated. It is on them that the main load on pumping the coolant will fall.

It is possible to tie a gas boiler with polypropylene without long metal pipes, the water in such a heater rarely heats up to 75–80 degrees

It is possible to tie a gas boiler with polypropylene without long metal pipes, the water in such a heater rarely heats up to 75–80 degrees

If a the gas boiler has a cast iron heat exchanger, then when tying it into the system, an additional heat accumulator should be installed. It will smooth out sudden changes in water temperature that have a negative effect on cast iron. With abrupt heating or cooling of the coolant, it can even burst.

When piping a double-circuit apparatus with parallel heating of water for hot water supply, additional filters will have to be installed on this outlet fine and coarse cleaning. They should also be mounted at the inlet to the water heater, where cold water is supplied.

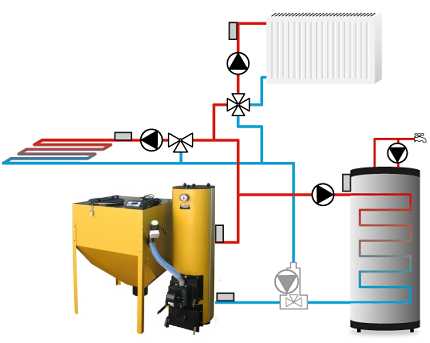

Option #2: Solid fuel model

The main feature of a solid fuel boiler is its inertia when the fuel supply is cut off. Until everything in the furnace burns out completely, it will continue to heat the coolant. And this can adversely affect polypropylene.

When tying a solid fuel boiler, only metal pipes should be connected to it immediately, and only after a meter and a half can polypropylene pipes be inserted. In addition to this, it is necessary to provide a backup supply of cold water for emergency cooling of the heat exchanger, as well as its removal to the sewer.

The section of the pipeline from the solid fuel boiler to the collector should be made of metal, and then you can tie it with polypropylene - this is the only way to protect plastic pipes from overheating

If the system is built on forced circulation, then it will definitely need to install a source uninterruptible power supply for pump. Water must constantly remove heat from the furnace where solid fuel burns, even during power outages.

In addition to it, you can make a small gravity circuit or equip all batteries with bypasses to turn off individual sections of the system. In case of accidents, this will allow repairing the damaged section while the heating is running.

solid fuel the boiler must be covered with a protective casing, which limits the spread of heat from the walls of the furnace into the boiler room. But even if it is present, the collector and plastic pipes should be removed away from the stove.

Option #3: Oil and Electric Heaters

A mining or diesel boiler is tied with polypropylene according to a scheme identical to that of a solid fuel counterpart. The polymer must be removed from it as far as possible.

At piping of an electric boiler PPR does not have to worry about pipe breaks, it has protective automation that prevents water from reaching a boil

Heating of the coolant in the water heater on electricity to critical temperatures for polypropylene is practically excluded. When the power goes out, it just stops working. In this case, the pipes are protected from hydraulic shocks by a hydraulic accumulator and valves for pressure relief.

The main elements of the strapping

In this section, we will look at the required and desirable strapping elements. Let's start with the most necessary - these are expansion tanks. Our recommendations apply to gas and electric heating units. The piping of the gas heating boiler and the piping of the electric heating boiler are the same in their equipment.

Expansion tanks and their varieties

Even at school, they explained to us that when water is heated, it expands, and in physics lessons we arranged laboratory work confirming this fact. The same thing happens in heating systems.Water is the most common coolant here, so its thermal expansion must be somehow compensated. Otherwise, pipe breaks, leaks and damage to heating devices are possible.

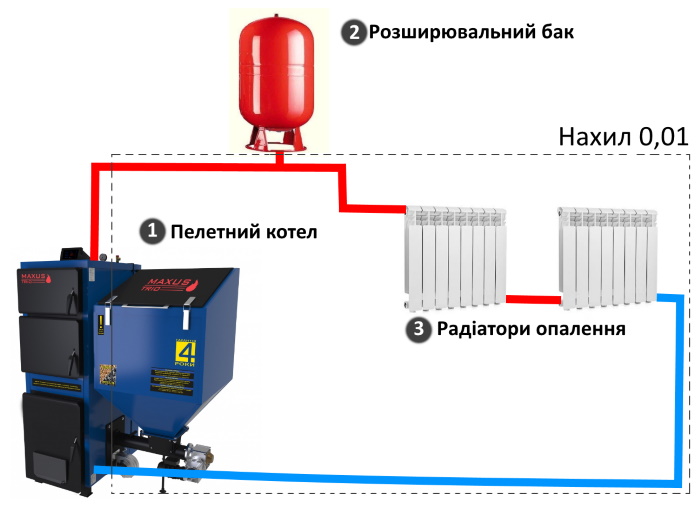

The piping of the heating boiler necessarily includes an expansion tank. It is placed next to the boiler or at the highest point of the circuit - it all depends on the type of system. In open systems, traditional expansion tanks are used that communicate with the atmosphere. For the operation of closed circuits, sealed membrane tanks are required.

In open heating systems expansion tanks play three roles at once - through them the coolant is added, they take in the excess of expanding water, through them the air formed in the pipes and radiators exits. Therefore, they are placed at the highest points. Sealed membrane tanks in the piping schemes are located in arbitrary places of closed circuits, for example, next to the boiler. Special vents are used to remove air.

The advantage of closed circuits is that any type of coolant can circulate in them.

Circulation pumps

The piping of a boiler room in a private house increasingly includes circulation pumps. Previously, heating was done on the basis of thick metal pipes. The result was low hydrodynamic resistance of the circuits. By mounting pipes at a certain angle, it was possible to achieve natural circulation of the coolant. Today, thick metal pipes have given way to thin plastic and metal-plastic samples.

Thin pipes are good because they are almost invisible.They can also be hidden in walls, floors or mounted behind ceilings, achieving complete disguise. But they are distinguished by high hydrodynamic resistance. Numerous connections and branchings also add barriers. Therefore, it is impossible to count on the independent movement of the coolant. In this case, circulation pumps are included in the heating boiler piping circuit.

Consider the main advantages of using circulation pumps:

- Possibility to increase the length of heating systems;

- Forced circulation allows you to deliver heat to the most remote points of the house;

- Ability to design heating of any level of complexity;

- Possibility of organizing several heating circuits.

There are also some disadvantages:

- The purchase of a circulation pump entails additional costs;

- Increasing electricity consumption - in operating mode up to 100 W / h, depending on the model;

- Possible noises spreading throughout the house.

For simultaneous operation of several circuits, it is necessary to purchase and install a collector that ensures uniform distribution of the coolant.

In the latter case, you just need to buy a good pump.

Circulation pumps in the piping circuits of heating boilers are mounted immediately after or in front of the heating equipment, and with a bypass. If you plan to lay several circuits in the house, you should put a separate device on each of them. This approach is used if there are underfloor heating in the house - one pump drives the coolant across the floors, and the second - along the main heating circuit.

How is the binding of such equipment made?

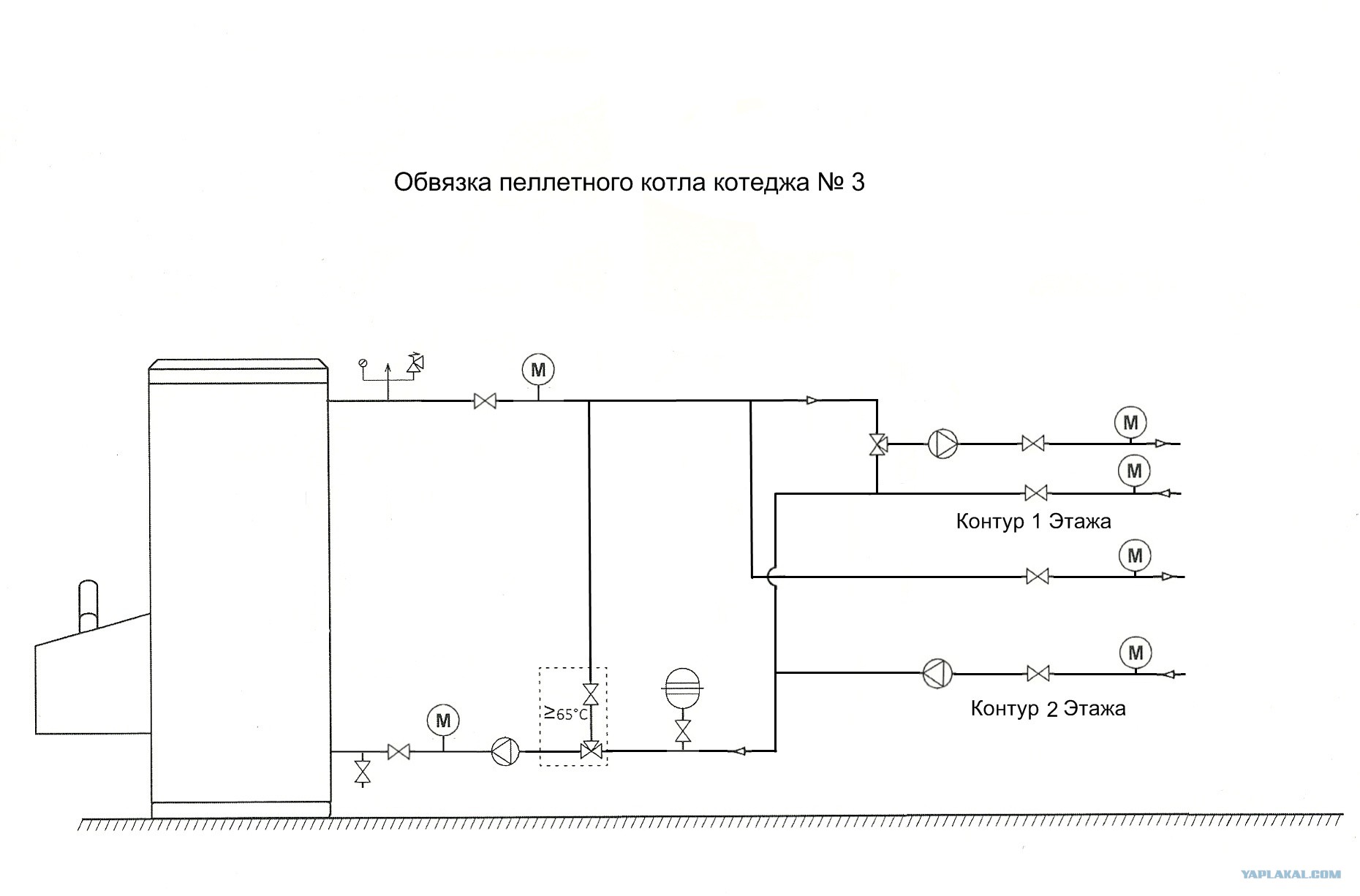

General scheme installation of heating boilers consists of the following series of steps:

- installation of distribution combs;

- installation of appropriate pumping circuits for each consumer;

- installation of safety equipment;

- installation of an expansion tank;

- installation of shutoff valves;

- connection of the boiler with the supply and return circuits;

- filling the circuits with coolant;

- pressure testing of equipment and checking its operation.

In practice, everything depends on the power of the equipment, the number of consumers, the design features of the boiler, etc. It should be noted that rather high requirements are imposed on the piping of pellet boilers. Firstly, because the moisture content of the fuel must remain acceptably low, and secondly, because both the fuel and the coolant are heated to very high temperatures. Poor-quality piping can lead to the fact that the operating conditions of the equipment will be violated, and the boiler will quickly fail.

In accordance with fire safety standards, it is recommended to use non-combustible metal pipelines for piping pellet boilers. The use of polypropylene structures in practice is not only dangerous, but also unprofitable, since the temperature of the coolant at the outlet of the boiler often exceeds the performance of polymeric materials. As a result, pipelines will have to be replaced in a couple of years.

Pellet boiler is a rather complicated device. Experts strongly do not recommend inexperienced beginners to engage in the installation and strapping of such devices. However, knowledge of the main stages of strapping and some of the nuances of this process will allow you to effectively control the work of the invited team of installers.

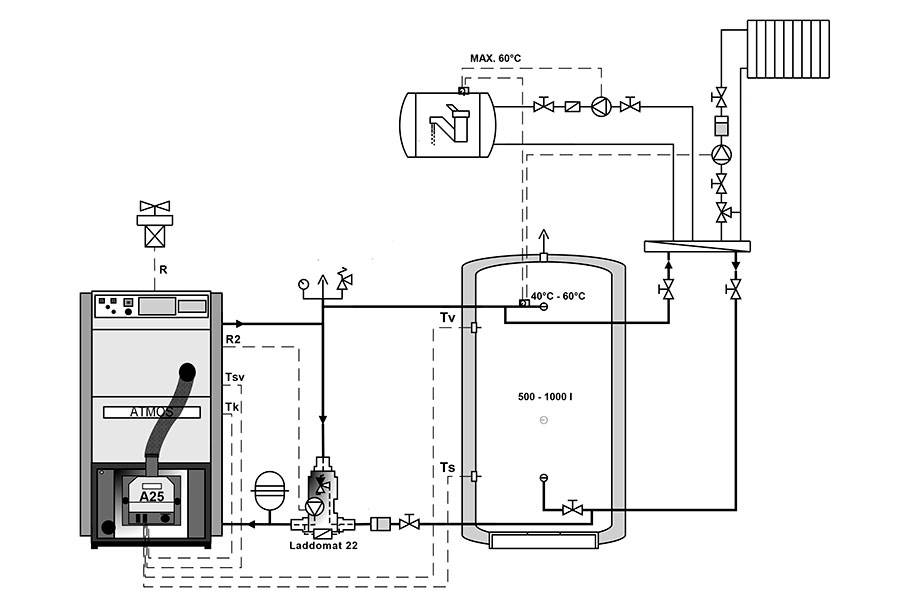

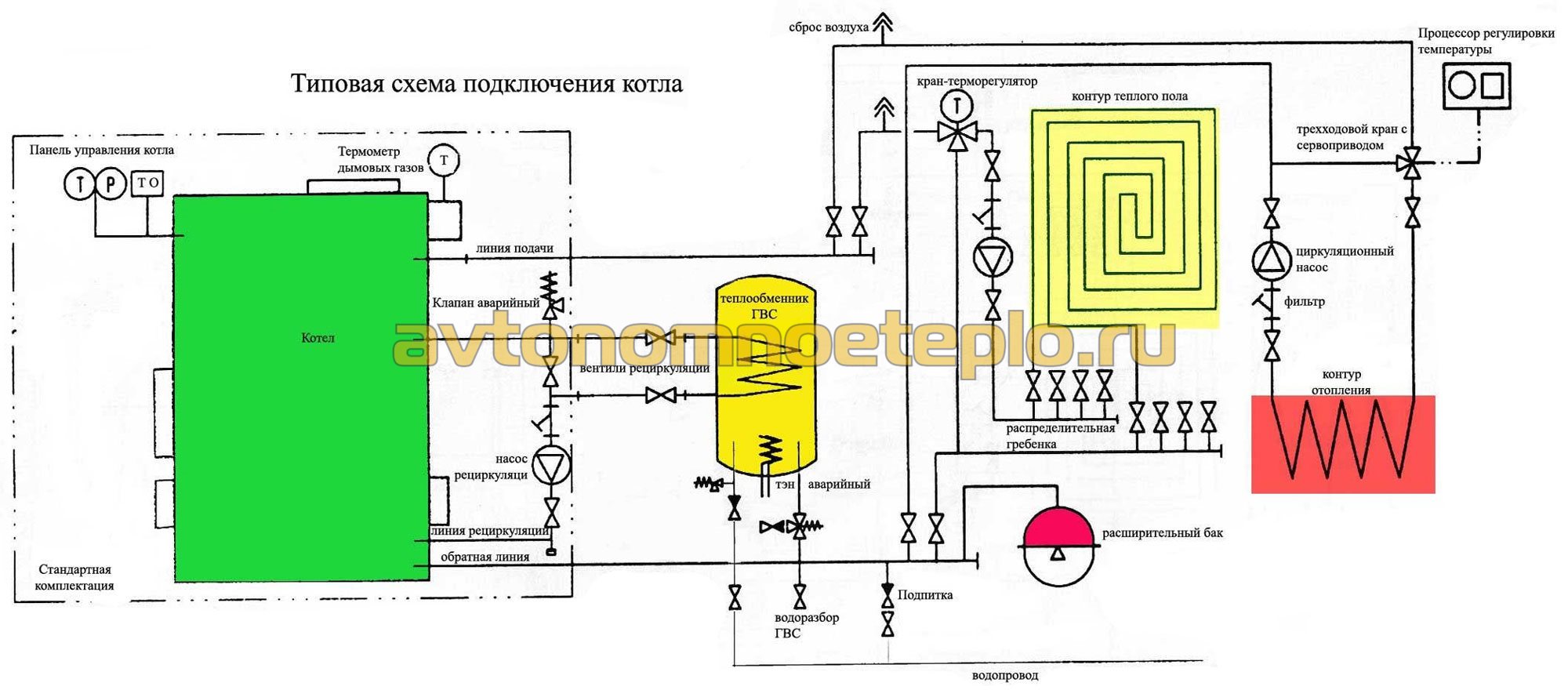

The diagram shows one of the options for piping a pellet heating boiler: 1 - MK pump; 2 - mixing valve MK; 3 - pump TK1; 4 - mixing tap TK1; 5 - water recirculation in TC1; 6 - pump TK2; 7 - mixing tap TK2; 8 - water recirculation in TC2; 9 - DHW pump; 10 - hot water heat exchanger; 11 - supply of running water to the hot water supply

To piping a pellet boiler, you must:

- perform boiler installation;

- connect the appropriate burner (if a combined boiler model is used);

- install a pellet hopper;

- connect the auger for fuel supply;

- connect the automatic boiler control panel.

After that, you should run:

- Installation for the boiler supply of a safety group, which includes a pressure gauge, an automatic air vent and a relief valve.

- Installation of a thermal valve sensor, if it is provided for by the design of the model;

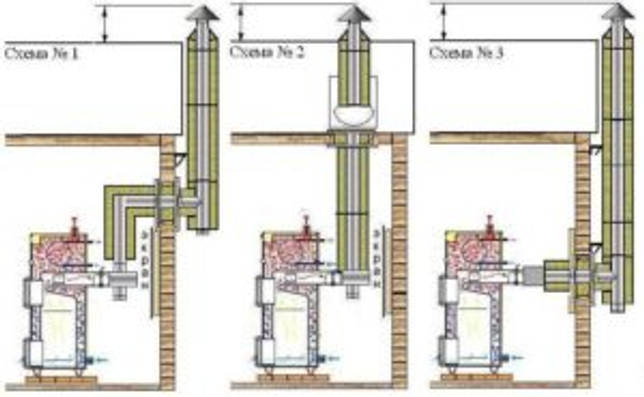

- Installation of a chimney, the diameter and height of which meet the technical requirements.

- Installation of a system of devices for maintaining a reverse flow: two pressure gauge valves for supply and return, a circulation pump and a thermal head.

- When there is a high probability of sudden power outages, it is recommended to supplement the system with a suitable UPS model.

Backflow support allows you to control the level of heating of the coolant before it enters the system. While the temperature no return reaches the required level (usually 60 degrees and above), the coolant will remain within the small circulation circle.Only when the coolant is heated to the required level, the thermal head opens and cold coolant begins to flow through it, and hot coolant begins to circulate in the main circle.

Under no circumstances should a pellet boiler with a low heat carrier temperature be used. A temperature of 55 degrees is the so-called "dew point", upon reaching which a significant amount of condensate is formed. As a result, the amount of soot in the chimney and also on the heat exchanger can increase significantly. The equipment will require additional maintenance efforts, and its power will noticeably decrease.

This is what the combustion chamber of a pellet heating boiler looks like after exposure to an excess amount of condensate that appears due to errors during the installation of the recirculation system

The process of tying a combined pellet boiler is presented in detail in the video:

Many manufacturers of pellet boilers recommend supplementing the design with a special storage tank that allows you to accumulate heat. Fuel savings in this case can reach 20-30%. In addition, the use of a storage tank allows you to avoid overheating of the boiler and achieve the highest possible efficiency.

Room preparation

When installing a pellet boiler, first of all, it is necessary to properly prepare the room where the heating generator will be located. It is better to use a zone remote from housing (cellars, outbuildings, garages are well suited, sometimes boilers are placed in attics).

If the room with the boiler is located close to the living rooms, then it is better to take care of a tight sealed door and covering the floors and doors with washable materials (wood dust and ash will constantly settle on them).The best option for cladding is a standard tile.

The area of the room for a boiler with a power of 15-18 kW should not be less than 2.5-3 square meters. m., otherwise it violates the rules of fire safety. The temperature in the room was not lower than +10 degrees, in order to achieve this, the walls and ceiling can be insulated with foam (a layer of 10 centimeters is enough). There is no need for radiators.

Humidity above 40% is not welcome, as it will reduce the operational life of the system - if water enters the room from the roof or through the walls, then it will be necessary to make the perimeter sheathing with waterproofing membrane material.

A few more important conditions in the preparation of the premises:

- Supply ventilation. A hole with a diameter of 12-15 centimeters is enough. No particularly complex air conditioning systems are required. You can make a hood to make it comfortable to be in the room.

- Availability of access to the chimney or the organization of a new one. For pellet boilers, only a “sandwich” type chimney (with a layer of insulation) is suitable. The height of the pipe must be at least 5 meters. A condensate collector is recommended so that the accumulation of moisture does not interfere with the operation of the furnace.

- Presence of power supply in the room. Pellet boilers require electricity to automate their work. It is also recommended to bring light into the room, which will greatly facilitate the maintenance of the furnace.

General scheme, but read more below

Making an economical device with your own hands

The pellet boiler has a fairly simple device, so it is easy to assemble it with your own hands. For this you will need steel pipes or sheets of thickness 3-5 millimeters, grinder and welding machine.If you have never had to deal with welding before, contact a professional.

The main element of the boiler is the heat exchanger. It is better to make a rectangular shape from pipes with a square section. For this:

- Pipes of the same size are taken.

- A round window is made in a vertical rack.

- Drainage holes are cut in the front pipes (one for cold water, the other for hot).

- Structural parts are connected using a welding machine.

To make the seams even, the racks are best placed on a flat surface.

Before carrying out installation work, the device is checked for strength:

- the apparatus is placed vertically;

- close the bottom hole;

- pour water into the container.

Attention! The design should not let liquid through even in small quantities. Otherwise, it is necessary to carry out welding work again.

After the boiler is assembled and tested, proceed to its installation. There are simple rules for installing this device:

The boiler should be installed in a non-residential area, for example, in a basement. Take care of the flooring in advance

It is important that the floor is concrete or made of ceramic tiles. The room must be well ventilated

In the room with the boiler monitor the humidity and temperature. The boiler room should not be small size, as it will be inconvenient to carry out maintenance work in it.

Installation of additional equipment

In the following cases, it is necessary to improve the existing heating system:

- The pumping of the coolant occurs naturally.

- Expansion of the heating surface.

- The existing pump in the boiler does not provide a uniform distribution of the heat carrier.

In each of these situations, installing an additional device can guarantee high-quality heating for every room in the house.

One way to solve this problem is to install an additional circulation pump. This solution will be much more profitable than a complete replacement of the main equipment with a suitable one.

Most private houses are equipped with slotless pumps.

The design feature of the system is the absence of special lubricants.

The heating fluid acts as a coolant and lubricates the rotating elements.

In this sense, the following rules must be observed:

- the pump shaft is strictly horizontal relative to the ground;

- The direction of the coolant flow must correspond to the special marking on the device;

- Installation in the section of the system with the minimum liquid temperature.

The implementation of the above recommendations will provide the necessary conditions for the operation of the pump. Overheating and activation of the protection system are excluded.

Additional equipment for the heating system is connected through a central control panel, which can be controlled.

New models of circulation pumps have built-in protection and blocking current resistance, which allows you to establish a normal ground.

Care must also be taken to ensure that liquids do not come into direct contact with the terminal box. Therefore, when installing, the terminal box must be positioned side or top.