- Piping of gas boilers

- Scheme of piping a wall-mounted gas boiler

- Piping schemes for floor gas boilers

- Types and characteristics of pipe products for the heating system

- Installation of pellet boilers - some features

- Scheme of arrangement of the heating system

- Radiator connection in series

- Mounting

- The main elements of the strapping

- Expansion tanks and their varieties

- Circulation pumps

- Connection and setup

- Common problems and errors

- What is a heating boiler piping

- Necessary tools and materials

- Polypropylene contour for different boilers

- Option #1: Gas Water Heater

- Option #2: Solid fuel model

- Option #3: Oil and Electric Heaters

- How to connect a solid fuel boiler

- How the scheme works

- Way to reduce the cost of strapping

- The specifics of strapping with polypropylene

- Pellet boiler piping

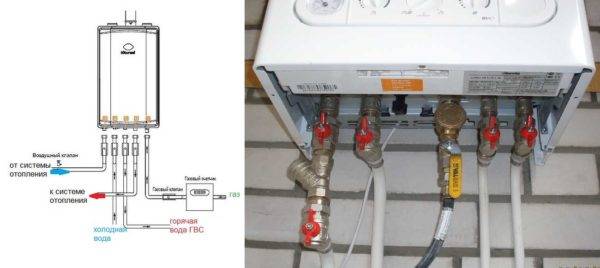

Piping of gas boilers

Modern gas boilers have good automation that controls all the parameters of the equipment: gas pressure, the presence of a flame on the burner, the pressure level and temperature of the coolant in the heating system. There is even automation that can adjust the work to the weather data. In addition, wall-mounted gas boilers in most cases contain such necessary devices as:

- safety group (pressure gauge, air bleed valve, emergency valve);

- expansion tank;

-

circulation pump.

The parameters of all these devices are indicated in the technical data of gas boilers

When choosing a model, you need to pay attention to them and choose a model not only in terms of power, but also in terms of the volume of the expansion tank and the maximum volume of coolant

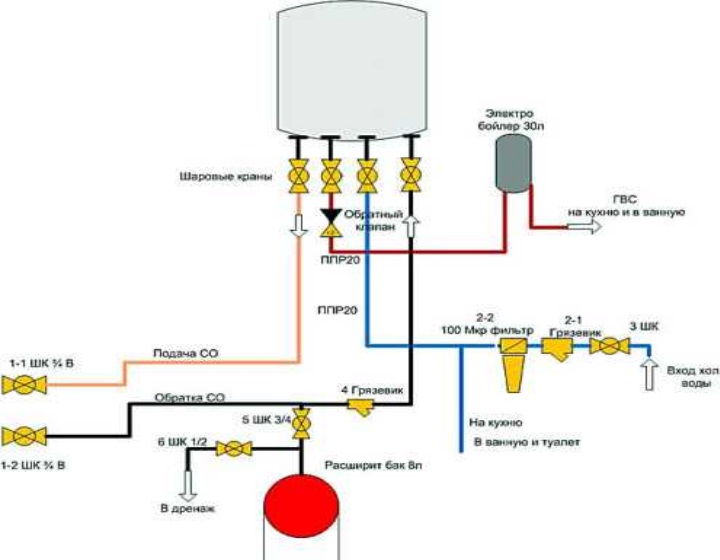

Scheme of piping a wall-mounted gas boiler

In the simplest case, the boiler piping contains only shut-off valves at the boiler inlet - so that repairs can be carried out if necessary. Even on the return pipeline coming from the heating system, they put a mud filter - to remove possible contaminants. That's the whole harness.

Example wall-mounted gas boiler piping (two-circuit)

In the photo above there are angled ball valves, but this, as you understand, is not necessary - it is quite possible to put ordinary models, and turn the pipes closer to the wall using corners

Also note that there are taps on both sides of the sump - this is in order to be able to remove it and clean it without draining the system

In the case of connecting a single-circuit wall-mounted gas boiler, it is still easier - only gas is supplied (gas workers are connected), hot water is supplied to radiators or a water-heated floor and the return from them.

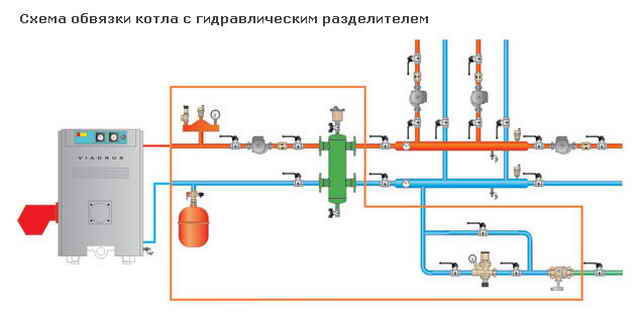

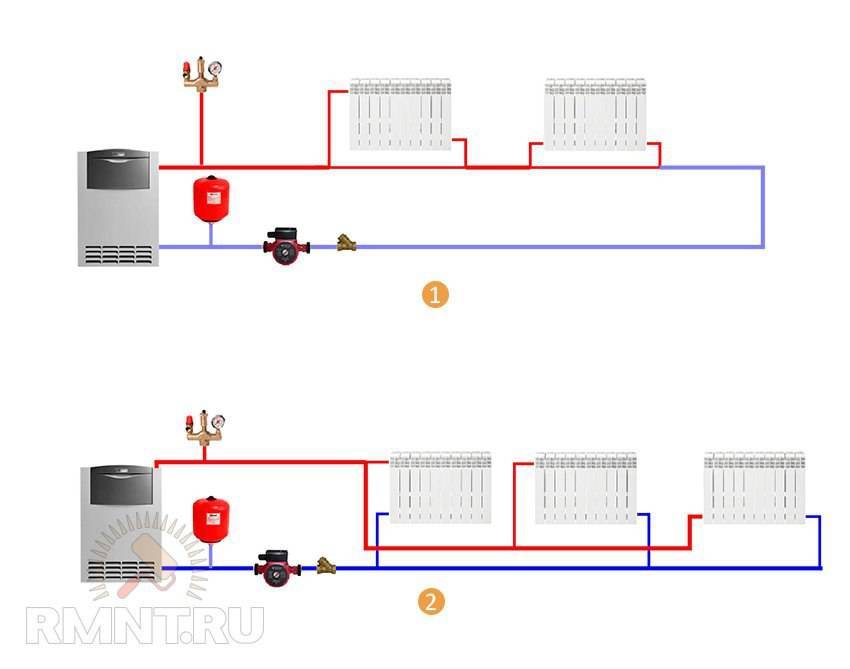

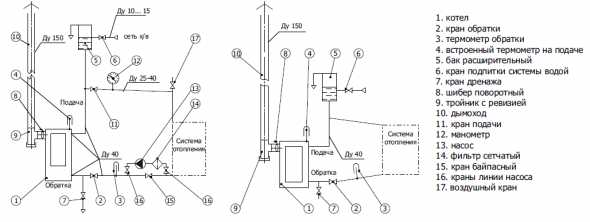

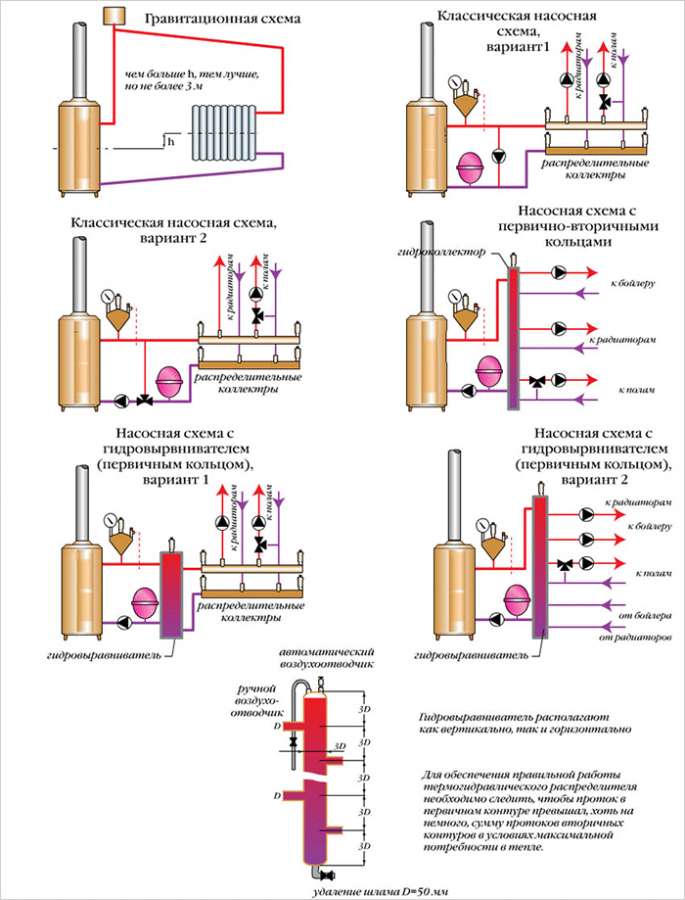

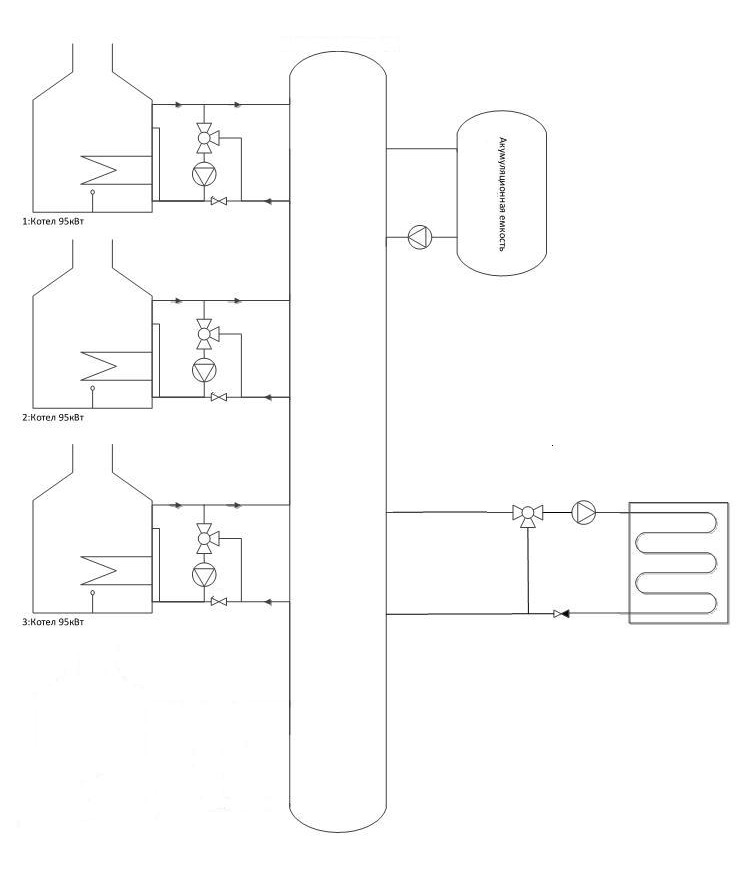

Piping schemes for floor gas boilers

Floor models of gas heating boilers are also equipped with automation, but have neither a safety group, nor an expansion tank, nor a circulation pump. All these devices have to be installed additionally. Because of this, the strapping scheme looks a little more complicated.

Piping schemes for a floor-standing gas boiler

An additional jumper is installed on two schemes of the classic boiler piping. This is the so-called "anti-condensation" loop. It is needed in large systems, if the water temperature in the return pipe is too low, it can cause condensation. To eliminate this phenomenon and arrange this jumper. With its help, hot water from the supply is mixed into the return pipe, raising the temperature above the dew point (usually 40 ° C). There are two main implementation methods:

- with the installation of a circulation pump with an external temperature sensor in the jumper (and the photo is at the top right);

- using a three-way valve (pictured below left).

In a circuit with a circulator on a jumper (a condensate pump), it is made a pipe with a step of a smaller diameter than the mains. The sensor is attached to the return pipe. When the temperature drops below the set temperature, the pump power circuit is turned on, hot water is added. When the temperature rises above the threshold, the pump turns off. The second pump is the heating system itself; it works all the time while the boiler is running.

In the second scheme with a three-way valve, it opens the hot water mixture when the temperature drops (set on the valve). The pump in this case is on the return pipeline.

Types and characteristics of pipe products for the heating system

Polypropylene pipelines are divided into 4 categories:

- PN 10 - pipes with a thin wall, for low pressure environments of not more than 1 atm and T up to 45 C, they are practically not used in the heating system of boilers, except in sewer low-temperature gravity lines or low-temperature "warm floor" construction.

- PN 16 - a slightly better quality, T up to 60C, and pressure -1.6 atm, but still for a boiler unit with a medium outlet up to 95 C - the material is not suitable.

- PN 20 - has technical characteristics T up to 80 C, and medium pressure up to 20 atm, can be used in hot water supply schemes or low-temperature heating of small one-story buildings.

- PN 25 - with an ambient temperature of up to 95 C and a pressure of up to 25 atm, they are acceptable for use in almost any heating system, except for those operating on steam and condensate.

In addition to marking, it is necessary to take into account the coefficient of thermal expansion of pipes, since pipes, when heated, elongate very much, without taking into account these properties, a new installed system at the first start will be deformed with the formation of numerous leaks. The problem is solved in two ways - compensating loops are mounted, which reduce the elongation and the use of pipes with a reinforcing layer. This option is implemented in PN 25 pipes.

Pipes PN 25 reinforced with glass fiber

Pipes PN 25 reinforced with glass fiber

The foil layer does not come into contact with water, and therefore they are not affected by corrosion processes, while reducing the thermal expansion coefficient by almost half.

There is an even more efficient version of PN 25, albeit a little more expensive, with a fiberglass reinforcing layer that virtually eliminates all thermal expansion.

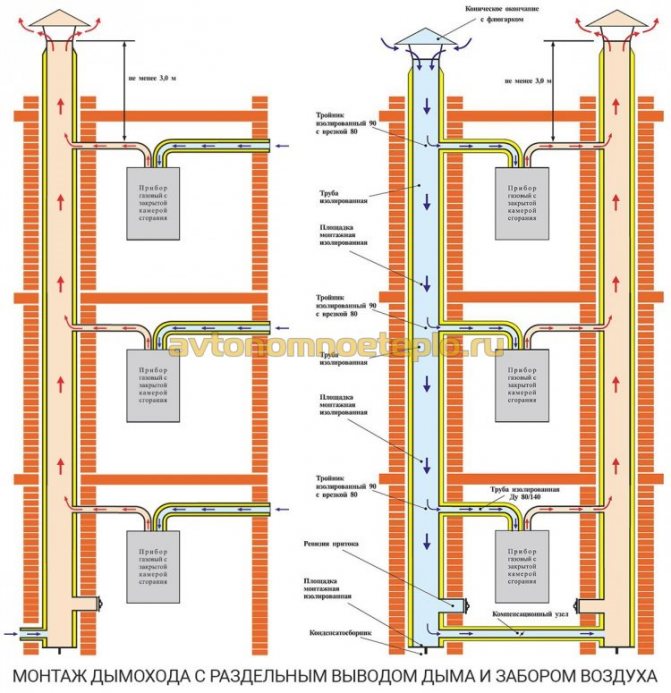

Installation of pellet boilers - some features

Most pellet boilers are made using boiler steel, the market share of cast iron pellet boilers is small. This is due to the fact that the high combustion temperature of the pellets is localized either in the flame of the blast burner or in the cup of the retort burner.Therefore, there is no need to make the entire boiler out of cast iron, as is the case with coal or wood boilers.

This means that a separate foundation or reinforced floors are not needed to install a pellet boiler. An ordinary boiler with a capacity of 20-40 kilowatts weighs from 150 to 300 kilograms, which allows it to be installed on the floor of the most ordinary boiler room, without any reinforcement.

Further, since the ash from the combustion of pellets is formed very, very little, there is no need to frequently clean the boiler and remove the ash. It is enough to buy a pellet boiler with a large ash pan and clean the boiler once a week. Some comrades come to their boiler once a month, but this, I think, is too much. The boiler must be monitored and serviced.

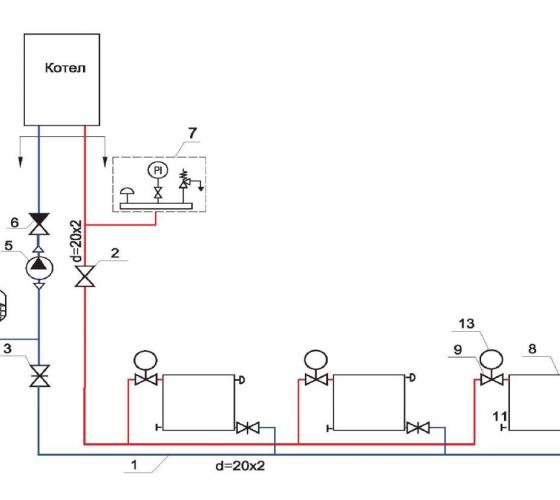

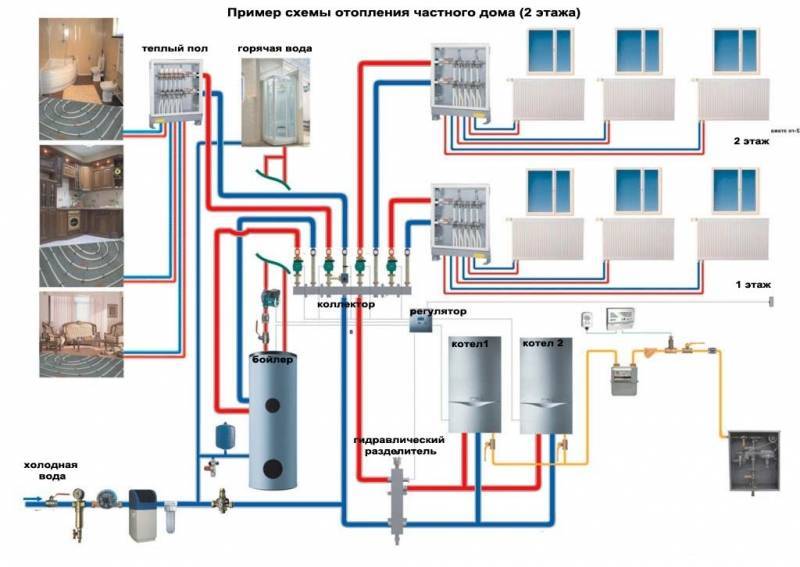

Scheme of arrangement of the heating system

The main element in every heating system is a heating boiler. In many ways, the wiring diagrams for heating radiators depend on it. If a floor-standing heater is selected, it should not be mounted on top of the heating structure, as such an arrangement reduces the efficiency of the system or can even lead to a malfunction in its operation.

Typically, such boilers do not have devices for venting air, and this often leads to air locks. It must be taken into account that in the absence of an air vent, the pipes of the supply section of the line should be mounted strictly vertically.

It is not difficult to find out if the boiler has an air vent - you need to look at whether or not there are nozzles in its lower part that are intended to connect the heater to the heating system.In this case, the supply line is connected to the return pipes using a special manifold. Usually, pipes are available for wall-mounted gas and electric heating boilers.

Some models of heating units do not have a circulation pump, expansion tank and pressure control device. All these components can be purchased and installed, if necessary, taking into account their location. So it is most reasonable to place a circular pump on the return pipes.

As for the safety group, it is allowed to mount it both on the supply section of the circuit and on the reverse (read: “Safety group for heating - we make the system reliable“).

When tying radiators with polypropylene is done, you need to consider the type of system on which additional components are to be installed. If the design provides for the natural circulation of the coolant, then they are unlikely to be required. In the case when the radiator is piping with polypropylene in a forced circulation design, it will be necessary to additionally use both a circulation pump and other elements. After that, to check the quality of the system, the heating radiators are pressure tested.

In apartments with central heating, it is now customary to install bimetallic radiators, and in private housing construction, piping of an aluminum radiator or a steel heating battery is more common.

Radiator connection in series

This option is possible if a condensing gas boiler is used, because. the operation of classical equipment is difficult at a return temperature below +55 degrees.The fact is that the cooled heat exchanger collects condensate on its surface. The products of gas combustion contain, along with water and carbon dioxide, aggressive acids. In this case, there is a real threat of destruction of steel or copper heat exchangers.

Condensing boilers have a different principle of operation. A special stainless steel heat exchanger (economizer) is used to collect combustion products. As a result, there is an additional heat transfer and an increase in the efficiency of the equipment. Because of this, the temperature level of the return pipe of + 30-40 degrees is optimal. The heating system consists of two series-connected circuits - radiator and underfloor. The return pipe of the first is the supply pipe of the second.

Mounting

Even the simplest do-it-yourself piping involves a competent choice of pipes. Products as simple and beloved by many people as polypropylene pipes also need to be used correctly. The ease of work should not be misleading, although you only need to use a soldering iron. It is allowed to use PN25 pipes, which are reinforced from the inside with aluminum foil.

To connect to a warm floor, you can tie the boiler with pipes of category PN10. Their walls are very thin and designed for pumping water heated to +45 degrees under a pressure of 1000 kPa. Polymer pipelines can be used in both open and hidden laying schemes, but thermal expansion must be taken into account. A bunch of fittings with pipes is made either by creating threads or using cold (hot) welding. Threading simplifies the matter, but the cost of such a solution immediately rises.

Before welding, the foil must be cleaned, otherwise you can forget about the strength of the connection. Glass fiber, when used for reinforcement, does not require such processing. Cold welding using specialized adhesives is almost out of circulation now, as it does not guarantee a reliable joint. If two or more small heating boilers are installed in the system, piping with parallel oriented passages is allowed. As practice shows, this can be more economical than the use of a single boiler of the same amount of power.

To prevent water from moving through temporarily disconnected circuits, it is very important to take care of blocking them with separating valves and other shut-off valves. In some cases, the equipment is mounted on a foundation pad (clay, 0.1 m high), on top of which sheet iron or asbestos is placed.

The main requirement is the installation of the boiler lower in level than the installation of batteries. It is necessary to resort to copper pipes only when it is planned to heat a house with very high temperatures and pressures. In all other cases, there is no point in these expensive components.

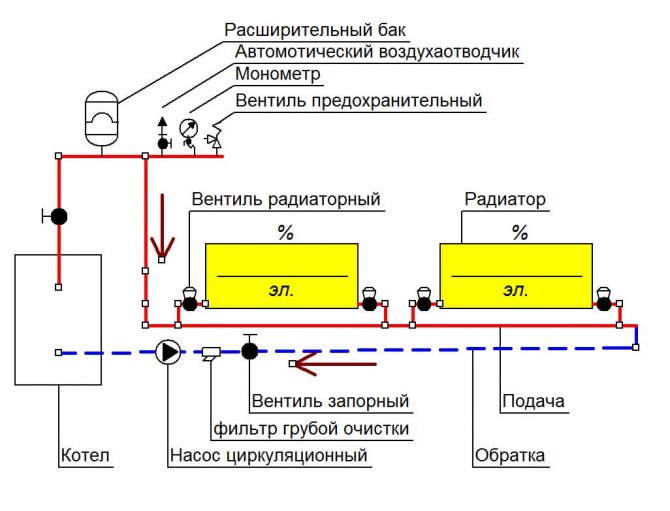

The main elements of the strapping

In this section, we will look at the required and desirable strapping elements. Let's start with the most necessary - these are expansion tanks. Our recommendations apply to gas and electric heating units. The piping of the gas heating boiler and the piping of the electric heating boiler are the same in their equipment.

Expansion tanks and their varieties

Even at school, they explained to us that when water is heated, it expands, and in physics lessons we arranged laboratory work confirming this fact.The same thing happens in heating systems. Water is the most common coolant here, so its thermal expansion must be somehow compensated. Otherwise, pipe breaks, leaks and damage to heating devices are possible.

The piping of the heating boiler necessarily includes an expansion tank. It is placed next to the boiler or at the highest point of the circuit - it all depends on the type of system. In open systems, traditional expansion tanks are used that communicate with the atmosphere. For the operation of closed circuits, sealed membrane tanks are required.

In open heating systems, expansion tanks play three roles at once - coolant is added through them, they take in excess expanding water, and the air formed in pipes and radiators exits through them. Therefore, they are placed at the highest points. Sealed membrane tanks in the piping schemes are located in arbitrary places of closed circuits, for example, next to the boiler. Special vents are used to remove air.

The advantage of closed circuits is that any type of coolant can circulate in them.

Circulation pumps

The piping of a boiler room in a private house increasingly includes circulation pumps. Previously, heating was done on the basis of thick metal pipes. The result was low hydrodynamic resistance of the circuits. By mounting the pipes at a certain angle, it was possible to achieve natural circulation of the coolant. Today, thick metal pipes have given way to thin plastic and metal-plastic samples.

Thin pipes are good because they are almost invisible.They can also be hidden in walls, floors or mounted behind ceilings, achieving complete disguise. But they are distinguished by high hydrodynamic resistance. Numerous connections and branchings also add barriers. Therefore, it is impossible to count on the independent movement of the coolant. In this case, circulation pumps are included in the heating boiler piping circuit.

Consider the main advantages of using circulation pumps:

- Possibility to increase the length of heating systems;

- Forced circulation allows you to deliver heat to the most remote points of the house;

- Ability to design heating of any level of complexity;

- Possibility of organizing several heating circuits.

There are also some disadvantages:

- The purchase of a circulation pump entails additional costs;

- Increasing electricity consumption - in operating mode up to 100 W / h, depending on the model;

- Possible noises spreading throughout the house.

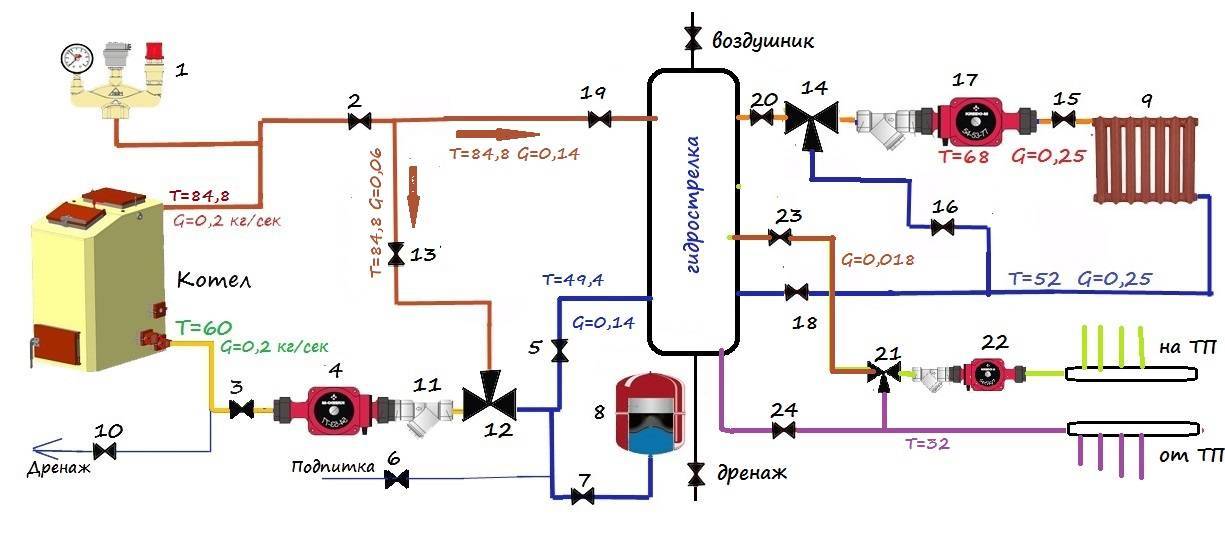

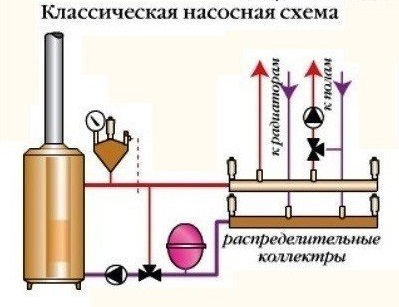

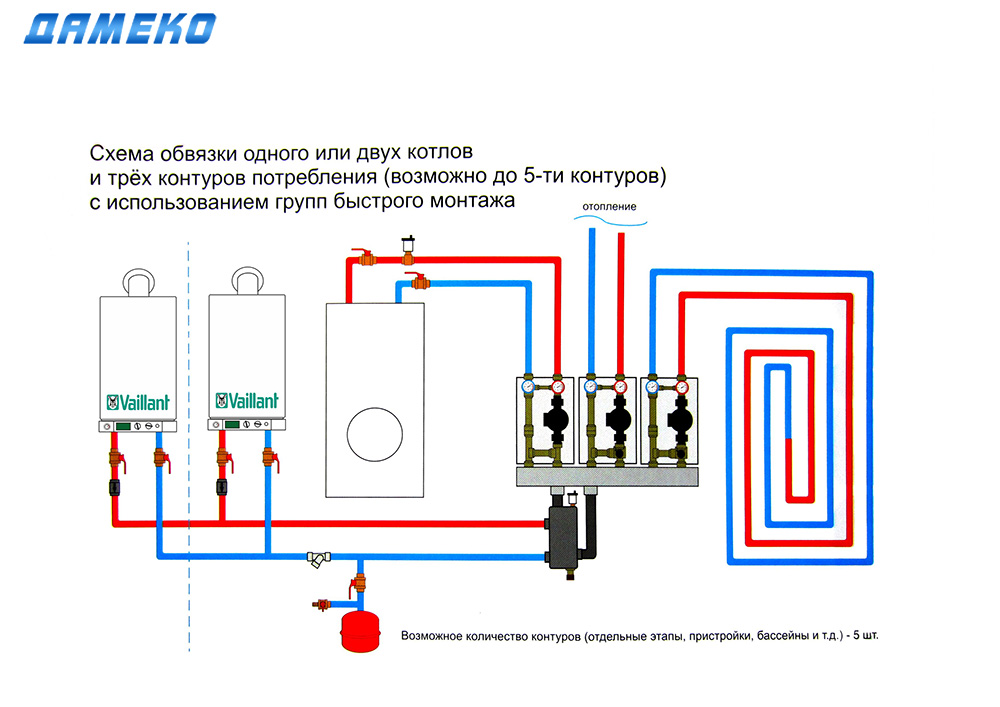

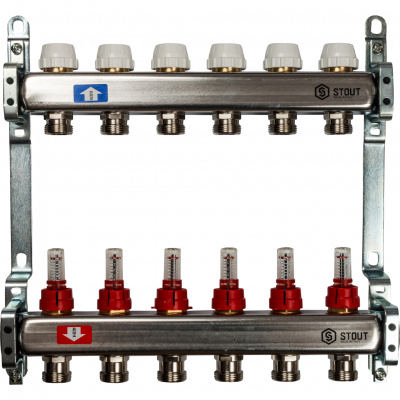

For simultaneous operation of several circuits, it is necessary to purchase and install a collector that ensures uniform distribution of the coolant.

In the latter case, you just need to buy a good pump.

Circulation pumps in the piping circuits of heating boilers are mounted immediately after or in front of the heating equipment, and with a bypass. If you plan to lay several circuits in the house, you should put a separate device on each of them. This approach is used if there are underfloor heating in the house - one pump drives the coolant across the floors, and the second - along the main heating circuit.

Connection and setup

After the installation of the boiler is completed, it is possible to carry out a test switch-on and check. To do this, you need to take the following steps:

- Connect the cable to the power supply.

- Place manually the pellets into the fuel compartment (bunker).

- Turn on the boiler, load the pellets from the bunker into the burner (this is done by pressing the corresponding keys on the dashboard).

- Check on the panel that all indicators light up: turning on the device, starting the burner, presence of a flame, setting the timer, auger operation, internal fan, pump.

- Make sure that there is normal draft and sealing of all docking elements of the boiler.

By default, the automatic factory setting of pellet boilers is enabled. Experts do not advise relying on them and check all parameters at the first connection. They are all shown on the display. You can also make adjustments and change modes.

If necessary, on the panel you can configure the pellet boiler to suit your requirements: change fuel consumption, operating time, equipment power

It is important to adjust the supply of pellets with the auger from the hopper (it must always be at the level of the upper edge or slightly lower)

Common problems and errors

Low efficiency and frequent breakdowns of heating equipment are a clear sign of mistakes made when tying it.

Mistake #1. Most often, problems arise due to insufficient heating of the thermal carrier. As a result, this leads to the appearance of a large amount of tar or soot.

Mistake #2. Incorrect adjustment or lack of protection against boiling water is one of the most common problems.Because of this, the coolant heats up excessively, which negatively affects heaters, pipes and other equipment.

Mistake #3

If the heating system is not highly efficient, then you should pay attention to the quality of sealing. To do this, you need to check whether the boiler and other structural parts of the system are reliably insulated.

What is a heating boiler piping

The piping of a heating boiler is the connection of a gas boiler to the heating system, water supply (if provided) and gas as fuel. The boiler piping includes the connection of all necessary devices to ensure reliable operation and control of the boiler.

According to building regulations and manufacturers' instructions, gas supply to the heating boiler must be carried out only through a rigid connection. A rigid connection means a metal pipe, and the connection is made using plumbing technologies for connecting metal pipes, through a metal “squeeze”. Polypropylene pipes with fiberglass for hot water supply are also suitable. If you live in Kazakhstan, you can view and download the pipe catalog at Allpipes.kz.

Important! As a seal of the gas supply pipe connections, EXCLUSIVELY, paronite gaskets are used. Other gaskets such as rubber, as well as sealing the threads of the joints with fum-tape and tow, are PROHIBITED. Paronite is a sealing material based on asbestos, mineral fibers and rubber, produced by vulcanization and is not flammable.

Paronite is a sealing material based on asbestos, mineral fibers and rubber, produced by vulcanization and is not flammable.

Necessary tools and materials

Before carrying out construction and installation work, the following materials and equipment are purchased:

- The pump for circulation of the heat carrier in a contour.

- Air valves for removing the air mixture from the expansion tank in schemes with natural circulation of the coolant.

- The collector for distribution of the heat carrier on contours of heating.

- Mud tank for removing debris from network water.

- Heating radiators

- Boiler of indirect heating.

- Polypropylene pipes for the internal heating system.

- Metal pipes for tying the boiler.

- Safety valve to protect the PC from a sudden pressure surge.

- Shutoff and control valves.

- Security automation on the PC is built-in and consists of the following elements: pressure gauge, sensors, signaling device, boiler control panel.

- Set of tools.

Polypropylene contour for different boilers

Most manufacturers of water heaters recommend that the first meter of the pipeline from it be made of metal. This is especially true for solid fuel devices with a higher outlet water temperature. When tying, polypropylene should be connected already to this outlet, otherwise, if there is a malfunction in the boiler, it will receive a thermal shock and may burst.

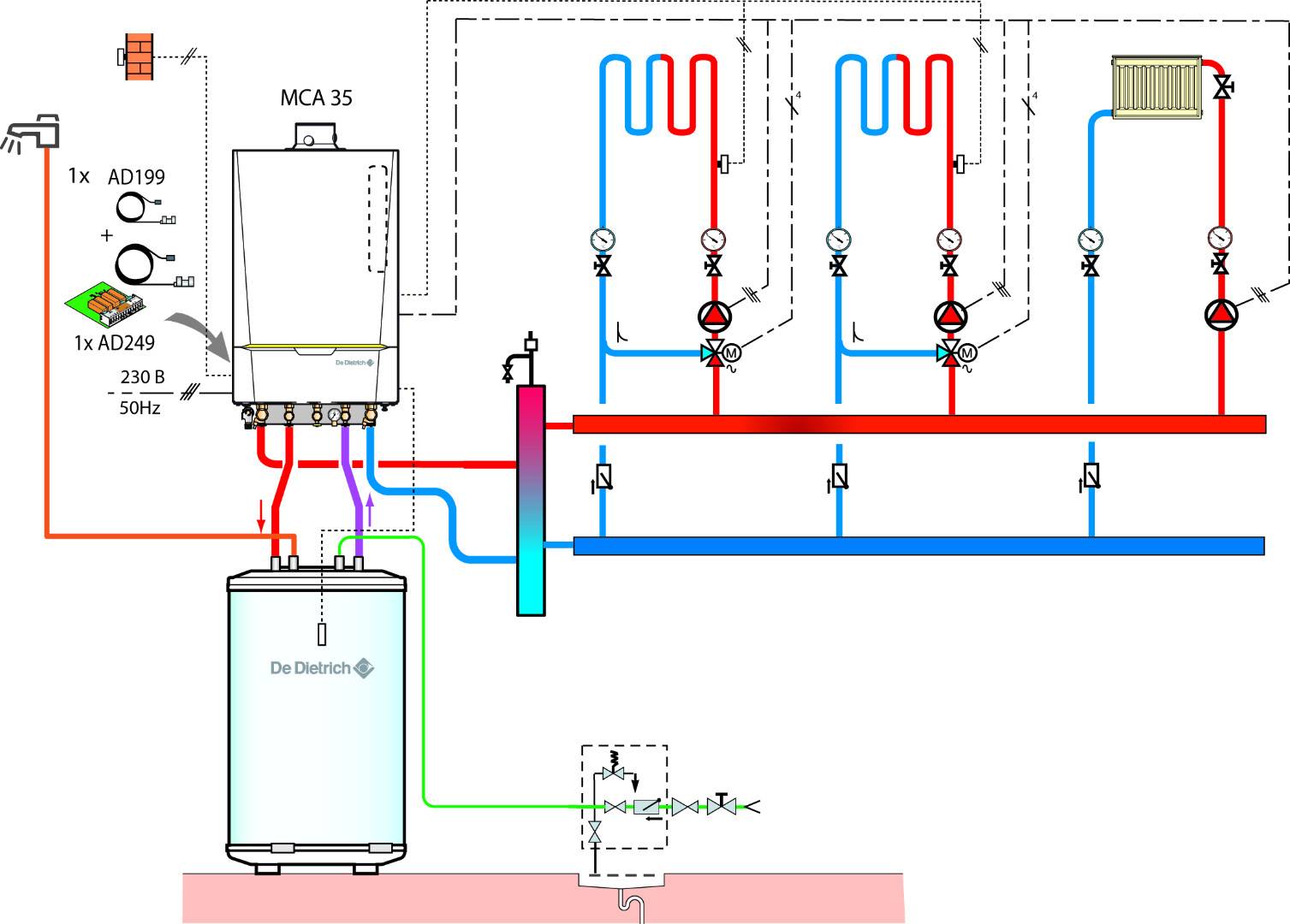

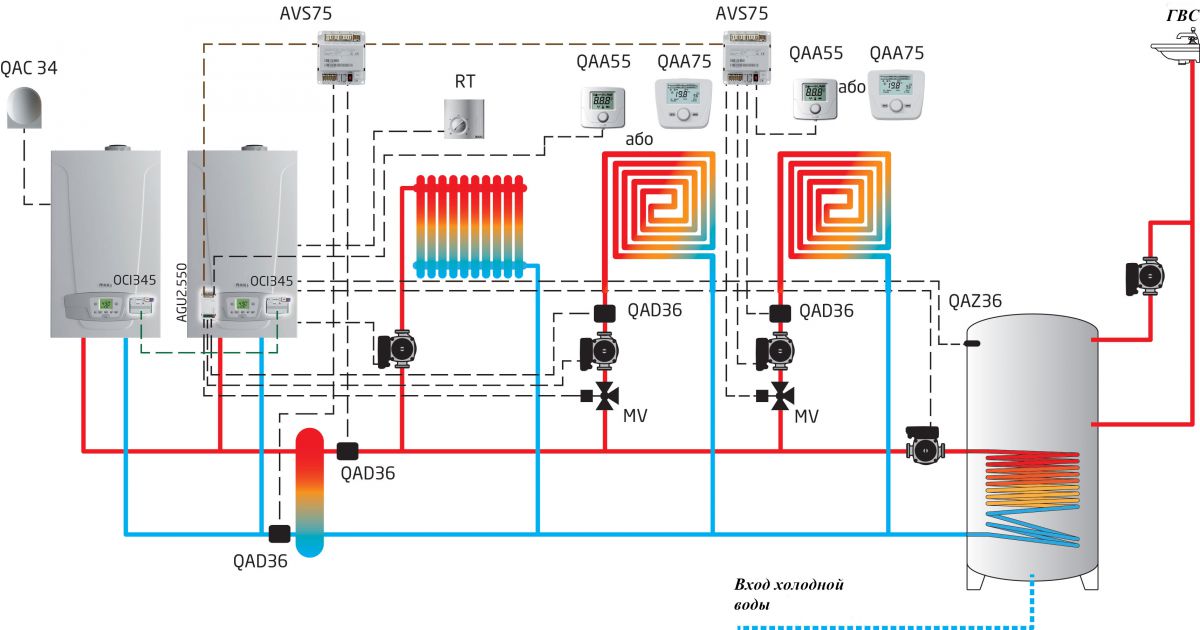

Option #1: Gas Water Heater

It is recommended to tie a gas boiler with polypropylene using a hydraulic gun and a manifold. Often, gas models are already equipped with built-in pumps for pumping water. Almost all of them are originally designed for forced systems.

The most reliable in terms of safety will be a circuit with circulation equipment for each circuit behind the collector.In this case, the built-in pump will pressurize a small section of the pipeline from the boiler to the distributor, and then additional pumps will be activated. It is on them that the main load on pumping the coolant will fall.

If the gas boiler has a cast-iron heat exchanger, then when piping it into the system, an additional heat accumulator should be installed. It will smooth out sudden changes in water temperature that have a negative effect on cast iron. With abrupt heating or cooling of the coolant, it can even burst.

When piping a double-circuit apparatus with parallel heating of water for hot water supply, in addition, fine and coarse filters will have to be installed on this outlet. They should also be mounted at the inlet to the water heater, where cold water is supplied.

Option #2: Solid fuel model

The main feature of a solid fuel boiler is its inertia when the fuel supply is cut off. Until everything in the furnace burns out completely, it will continue to heat the coolant. And this can adversely affect polypropylene.

When tying a solid fuel boiler, only metal pipes should be connected to it immediately, and only after a meter and a half can polypropylene pipes be inserted. In addition to this, it is necessary to provide a backup supply of cold water for emergency cooling of the heat exchanger, as well as its removal to the sewer.

If the system is built on forced circulation, then it will definitely be necessary to install an uninterruptible power supply for the pump. Water must constantly remove heat from the furnace where solid fuel burns, even during power outages.

In addition to it, you can make a small gravity circuit or equip all batteries with bypasses to turn off individual sections of the system. In case of accidents, this will allow repairing the damaged section while the heating is running.

A solid fuel boiler must be covered with a protective casing that limits the spread of heat from the walls of the furnace into the boiler room. But even if it is present, the collector and plastic pipes should be removed away from the stove.

Option #3: Oil and Electric Heaters

A mining or diesel boiler is tied with polypropylene according to a scheme identical to that of a solid fuel counterpart. The polymer must be removed from it as far as possible.

Heating of the coolant in the water heater on electricity to critical temperatures for polypropylene is practically excluded. When the power goes out, it just stops working. In this case, the pipes are protected from hydraulic shocks by a hydraulic accumulator and valves for relieving excess pressure.

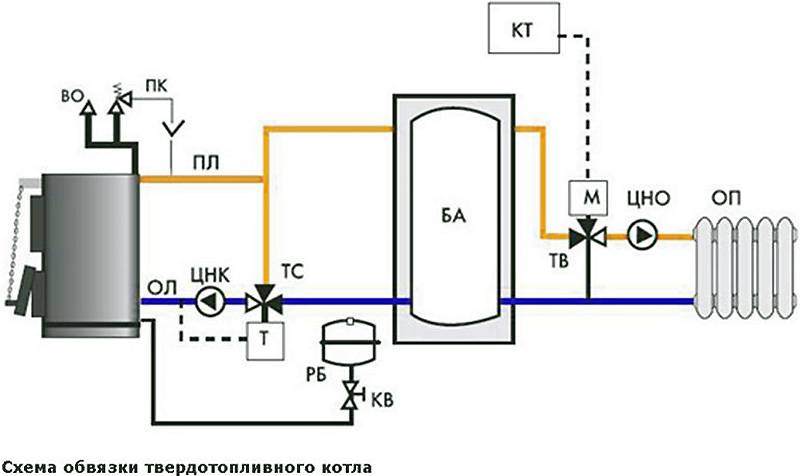

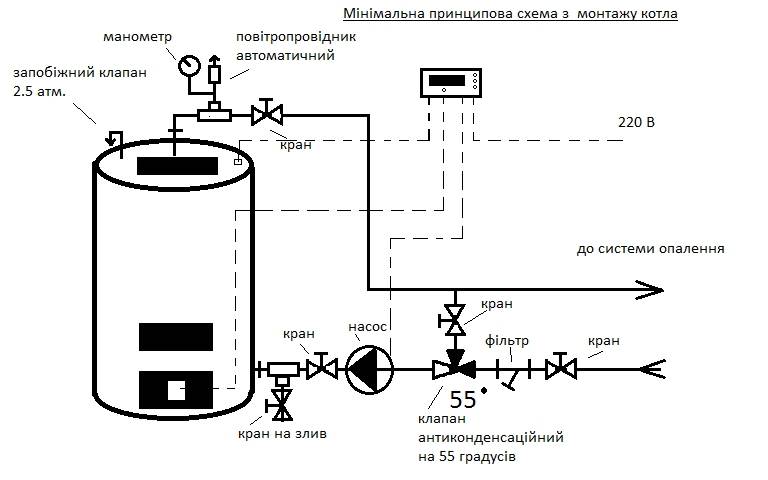

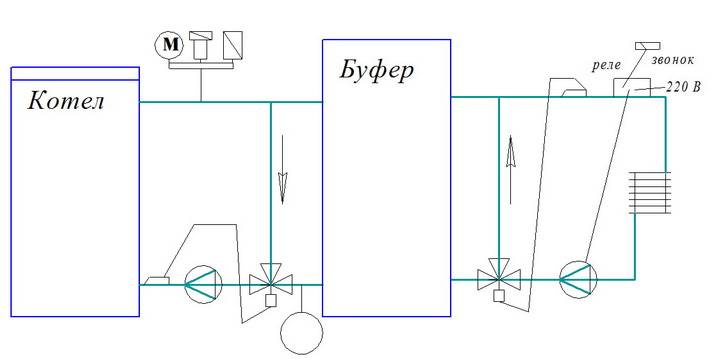

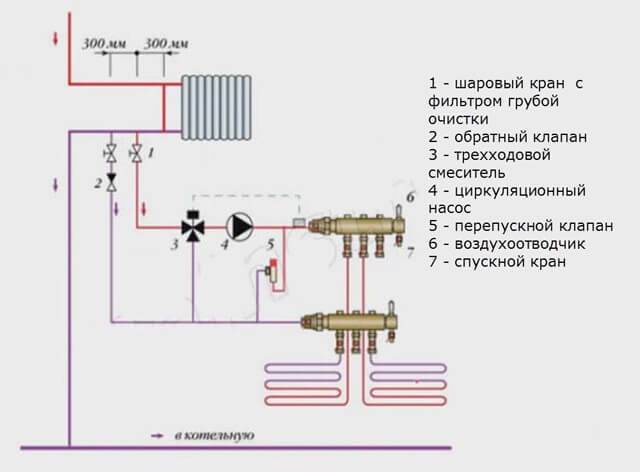

How to connect a solid fuel boiler

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. The expansion tank is conventionally not shown here, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one.You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar). This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the remote-type overhead sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late. For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head. A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note.Similar valves that maintain a fixed temperature of mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.

The specifics of strapping with polypropylene

A significant advantage of polypropylene pipelines is the ability to create a circuit of any complexity, which, in principle, is not very interesting for those who are tying a heating boiler with their own hands for the first time. The simpler the scheme of the future system, the easier it will be to realize the idea. And the heating performance is inversely proportional to the degree of complexity: the simpler, the more effective. To make connections, the home master can use both welding technology and fittings selected strictly according to the size of the pipes. True, at the slightest “movement” in the places where the fittings are installed, the system may begin to leak slightly.

Using polypropylene pipes, you can create heating circuits of any complexity, however, it should be remembered that complexity complicates installation and reduces the efficiency of the heating system

It is desirable that the heating system being created has the least number of connections. If there is an opportunity to make a smooth transition, it should be used.

The polypropylene pipeline will work without problems for 40 years, guaranteed by the manufacturer, it will perfectly withstand pressure, the values of which exceed 25 bar.Without harming the structure of the material, a coolant with a temperature of 95º can circulate through the pipes. However, there is a limitation that must be taken into account if the gas boiler is piping.

The gas connection to the boiler must be rigid, construction requirements dictate the use of metal elements for connection and the use of a paronite gasket

The gas supply to the boiler must have a rigid connection. Construction requirements recommend a metal pipe and docking with a heat generator through a metal spur or "American". You can only use a gasket made of paronite. Rubber materials, fum tapes, tow are prohibited. Paronite, obtained by vulcanization of a mixture of asbestos fibers, mineral fillers and rubber, perfectly keeps its shape, provides tightness and does not burn. Other gasket materials are prone to fire, and rubber sandwiched between elements can reduce the size of the gas passage. By reducing the diameter of the passage, the gas supply will be reduced and the boiler will not supply the required amount of heat.

Pellet boiler piping

Boiler piping methods

At the first stage, it is necessary to carry out the installation of distribution manifolds, which are selected individually for each brand of boiler. Next, install the pump circuits and ensure their connection to the boiler. At the end, make pressure testing of the equipment (testing the strength of its operation).

When making a strapping, you must adhere to the following rules:

- use of fuel with an extremely low degree of humidity;

- due to loose strapping, there is a high probability of premature failure of the mechanism.

In accordance with the requirements of safe operation, non-combustible metal pipelines are used for piping the boiler. All modern pellet boilers have independent heating systems. This type is the main competitor of the gas furnace. Only real professionals who know all these steps should take part in its direct installation and strapping:

- outdoor installation;

- connection of the burner;

- connection of a rigid auger as a fuel supply system to the combustion zone;

Pellet heating boiler must be with a control panel.

After that, the pressure gauge, air vent and relief valve are installed. For insurance against power outages, you can install an uninterruptible power supply model. The optimum combustion temperature starts at 60ºC. The use of a pellet boiler with a sufficiently low coolant temperature is undesirable, since the likelihood of clogging the chimney increases several times. A number of new modifications are equipped with an additional storage tank, where heat accumulation is possible.