- Nuances and strapping options for different types of boilers

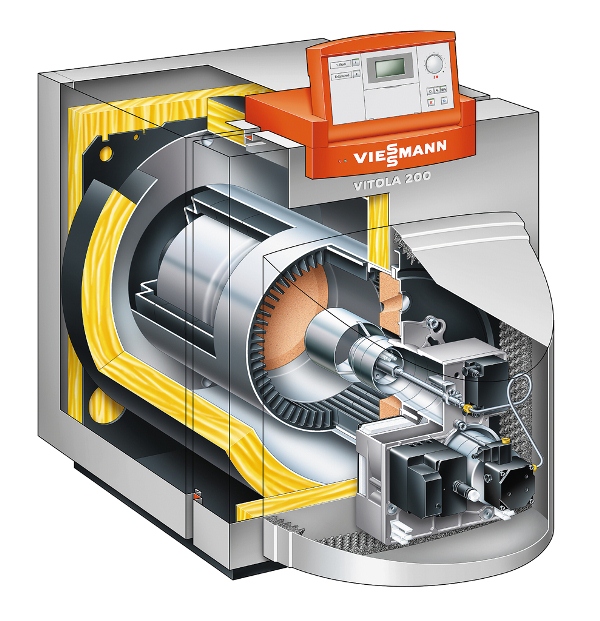

- Gas equipment

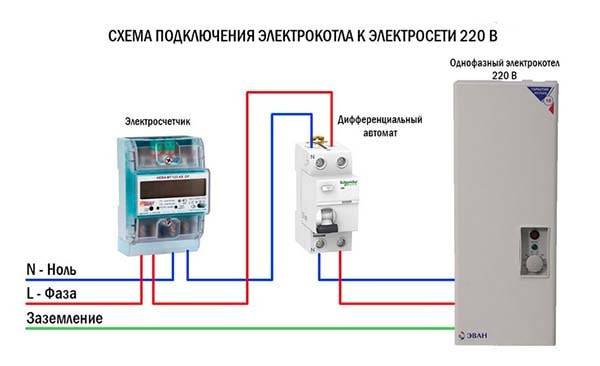

- Electric heater

- Solid fuel models

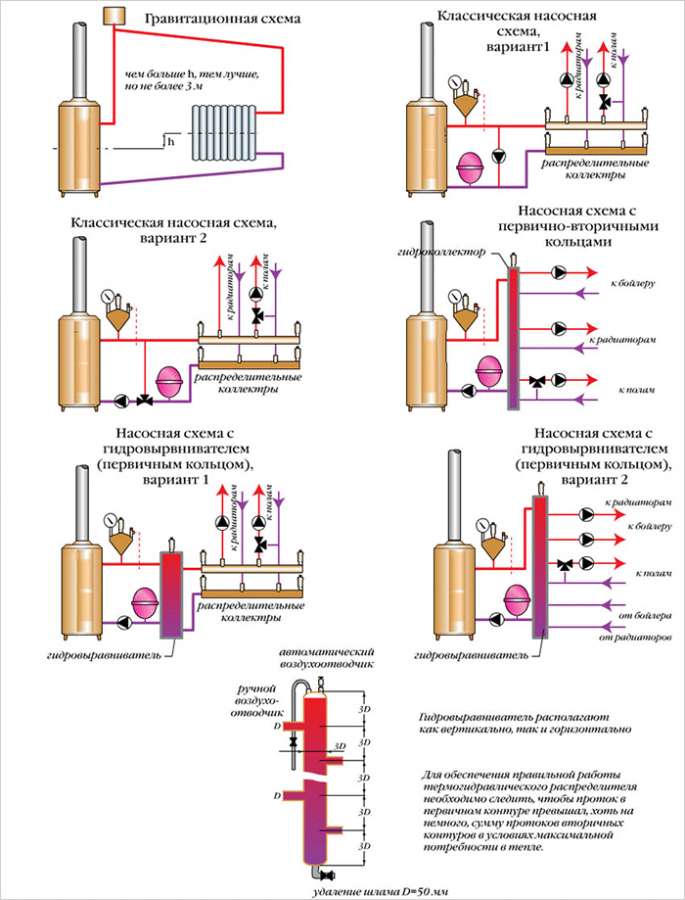

- primary-secondary rings

- The principle of strapping by type of placement

- Floor

- Wall

- Varieties of strapping

- Operating principle

- Optimal piping of boilers of various types

- Natural

- Forced

- Electric and diesel heat generators

- Radiators

- Strapping options

- Collector wiring diagram of the heating system

- What is a harness

- Heating system from polypropylene pipes

- Single pipe

- Two-pipe

- Collector

- Recommended Materials

- Polypropylene

- Metal eyeliner

- The location of the boiler in the heating system

- Polypropylene piping for different boilers

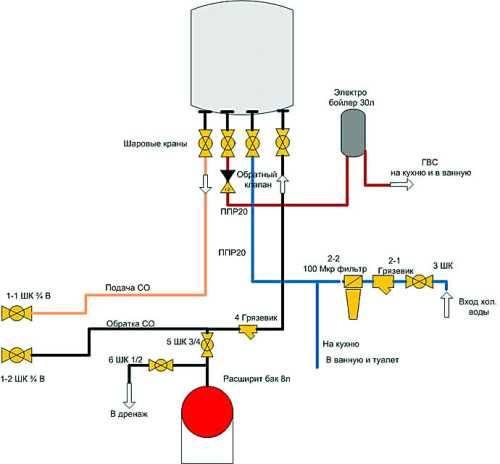

- Gas water heater

- Solid fuel model

- Heaters for liquid fuel and electricity

- Connecting the boiler to the system

- Detail made of polypropylene

- Features of polypropylene strapping

Nuances and strapping options for different types of boilers

General recommendations of experienced craftsmen:

The installation scheme is selected individually.

The boiler is installed in accordance with the rules of SNiP below the level of heating appliances.

The floor boiler is installed on a metal or concrete base before piping with polypropylene.

Forced ventilation and emergency lighting systems are recommended for all unit variants.

A coaxial chimney is included in the piping of a gas-fuelled device, which is sealed at all joints during installation.

After completing the piping of the boiler unit and the chimney, proceed to the device of the security system in the following order: pressure devices (pressure gauges), protective devices and then an automatic air vent.

The collector circuit is carried out by a 1.25-inch PPR pipeline, protective devices, a circulation pump, a hydraulic arrow and an air vent are installed according to the movement of the medium.

To supply the heating coolant to the heating devices, 3 branches of the PPR 1.0 inch pipe are removed from the comb, and the rest are closed with plugs.

Connect heating and return devices.

In a combined heating system, the underfloor heating circuit is equipped with an independent pump, while the expansion tank is installed between the hydraulic arrow and the boiler unit.

The piping of the boiler unit is completed by installing a drain valve, it is also used to fill the circuit, but it is better if these are two independent valves

The installation point depends on the chosen system, but there are general conditions - the drain valve is installed at the lowest point, which is especially important if you plan to mothball the system in winter so that there is no water left in it.

Gas equipment

Tying such equipment with polypropylene pipes is carried out with an independent circuit and a loop pump that creates working pressure in a small section of the network from the source to the distributor.

It is allowed to tie a gas unit with such pipes without steel pipes, since the heating temperature at the supply does not exceed 80 C.

In a gas-fired unit with a cast-iron boiler, a heat accumulator is mounted, which helps to balance the hydraulic regime and prevents sudden temperature fluctuations that affect the fragile cast-iron heating surfaces. When piping 2-circuit boilers, it is additionally necessary to place filters for fine and coarse water purification.

Electric heater

Tying an electric boiler with polypropylene is quite acceptable. The boiler has the highest rating of the protective system, which does not allow water to boil in the unit, with the subsequent formation of steam and rupture of the pipe. The heating process stops when the power supply to the electric heating elements is turned off.

In addition, the system has built-in hydraulic accumulators and devices to relieve excessive pressure of the medium, which can form during a sudden power outage and stop the pump for pumping hot water to heating devices and water points.

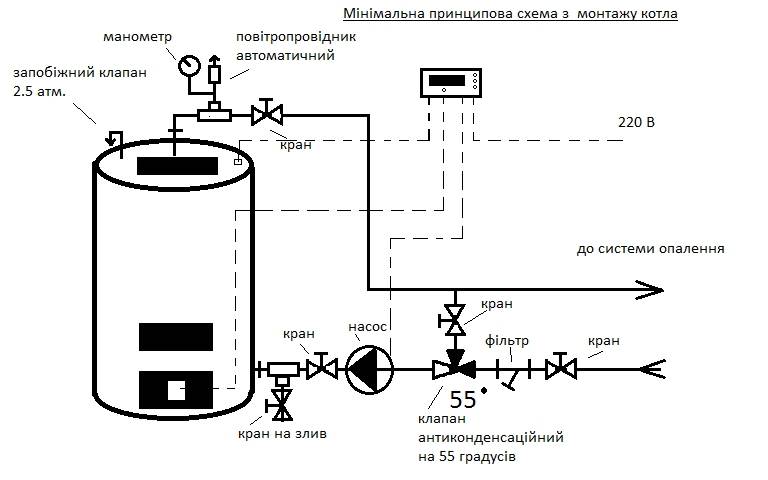

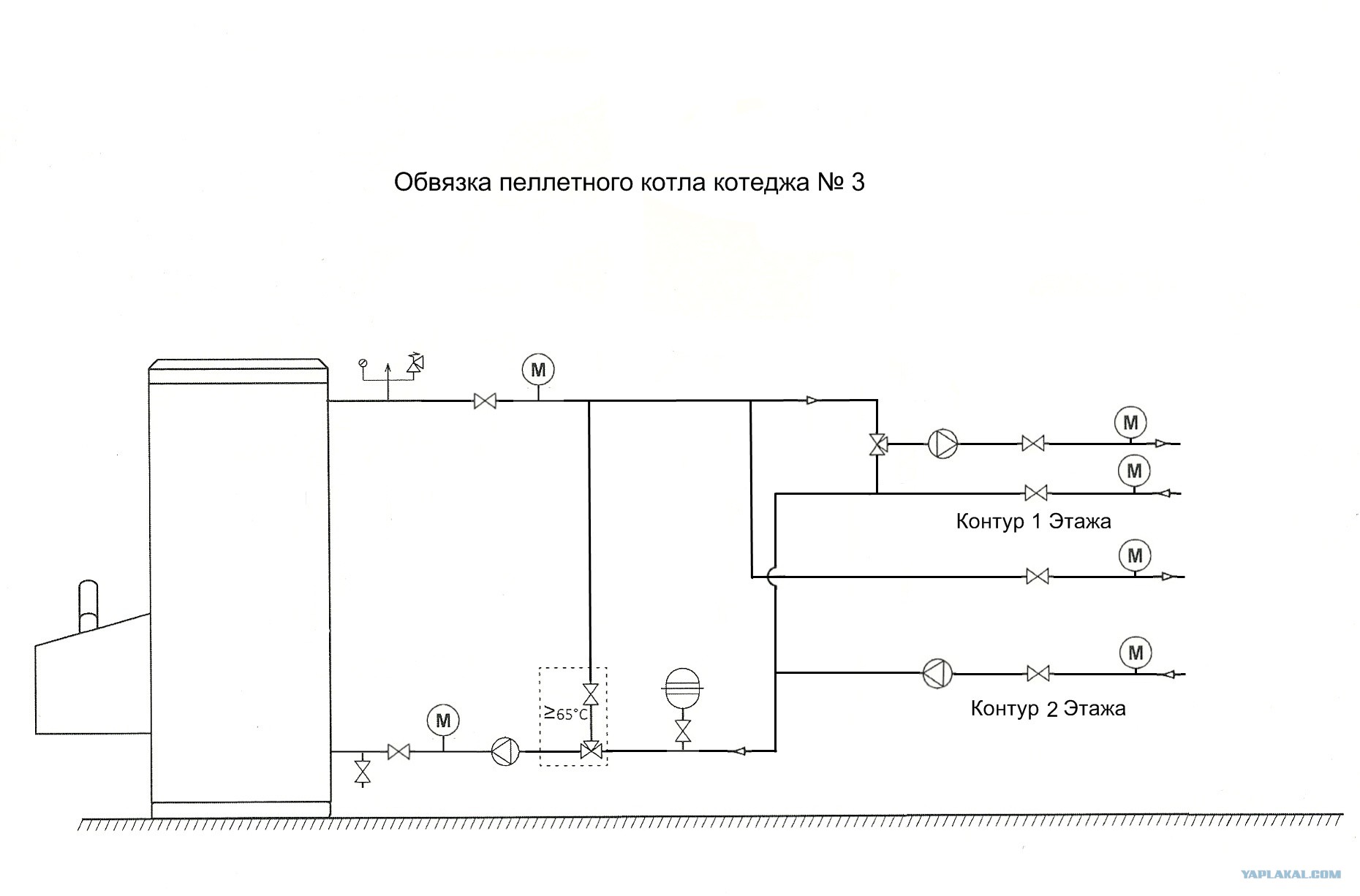

Solid fuel boiler piping

Solid fuel models

This is the most problematic unit for tying plastic pipes. For him, the installation of a protective meter pipe at the inlet / outlet of the medium is mandatory in order to protect them from overheating. For systems with pump circulation, an additional backup power supply device will be required to continue cooling the boiler during an emergency shutdown of the main source of electricity. In addition, a small gravity circuit is performed with a small number of batteries connected to cool the boiler heating surfaces until all the fuel has burned out.

The solid fuel boiler, according to the requirements of fire safety rules, is covered with a protective casing, which significantly reduces heat loss from the walls of the combustion chamber to the boiler room and, consequently, the negative impact on PPR pipes

A small reminder for the installation of plastic pipes - the quality will be determined not only by the installation work, but also by the selected range of pipes. You should purchase all the main and auxiliary equipment of the boiler room, only certified from reputable suppliers. Polymer pipes do not require insulation work and painting, they do not form scale and corrosion, they are distinguished by high sound insulation. The cost of the material is lower, and the pipes are lighter than those made of metal, so you can do the installation yourself.

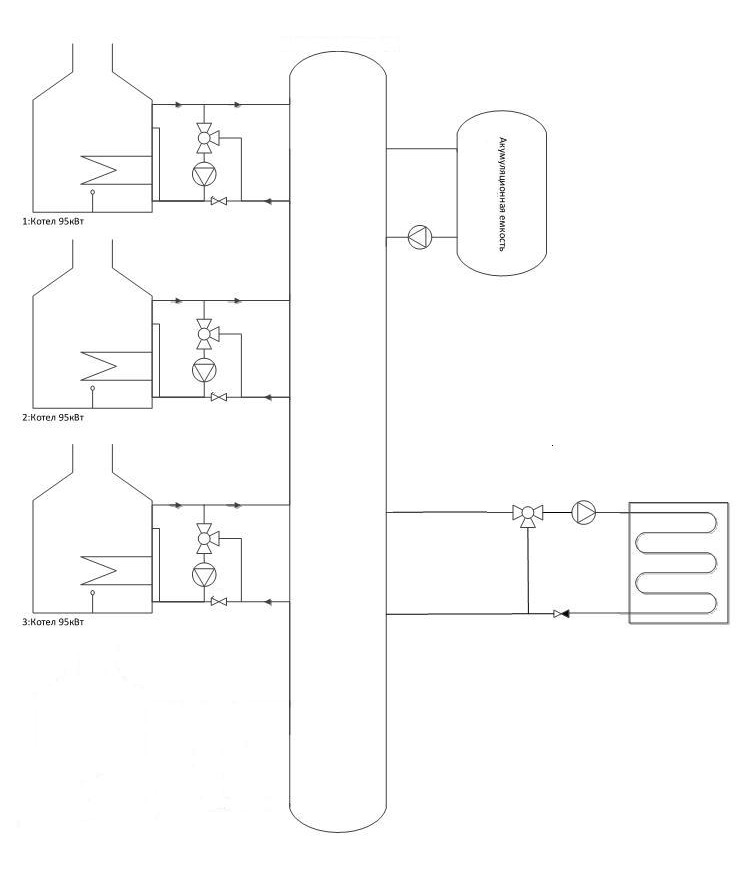

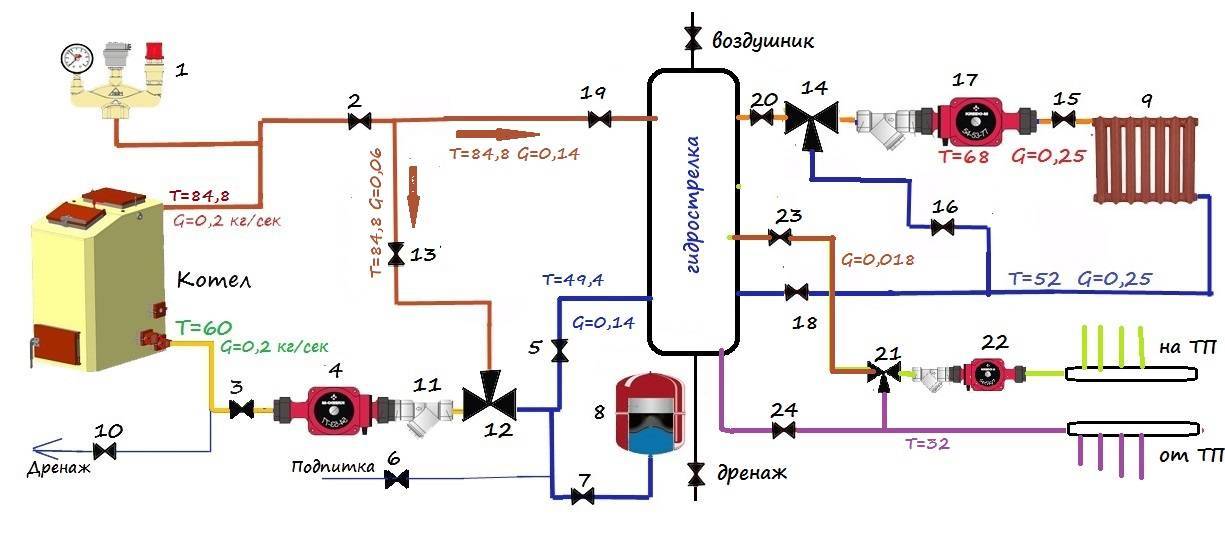

primary-secondary rings

For boilers with a capacity of 50 kW or more or a group of boilers that are designed for heating and hot water supply of large houses, a scheme of primary-secondary rings is used. The primary ring consists of boilers - heat generators, secondary rings - heat consumers. Moreover, consumers can be installed on the direct branch and be high-temperature, or on the reverse - and be called low-temperature.

In order to avoid hydraulic distortions in the system and to separate the circuits, a hydraulic separator (arrow) is installed between the primary and secondary circulation rings. It also protects the boiler heat exchanger from water hammer.

If the house is large, then after the separator they arrange a collector (comb). For the system to work, you need to calculate the diameter of the arrow.The choice of diameter is based on the maximum productivity (flow) of water and flow rate (not higher than 0.2 m / s) or as a derivative of the boiler power, taking into account the temperature gradient (recommended value Δt - 10 ° C).

Formulas for calculations:

- G - maximum flow, m 3 / h;

- w is the water velocity through the arrow cross section, m/s.

- P - boiler power, kW;

- w is the water velocity through the arrow cross section, m/s;

- Δt is the temperature gradient, °C.

The principle of strapping by type of placement

The heat generator occupies a key place in the heating circuit. Does the connection diagram of the elements of the heating system depend on the type of location of the boiler?

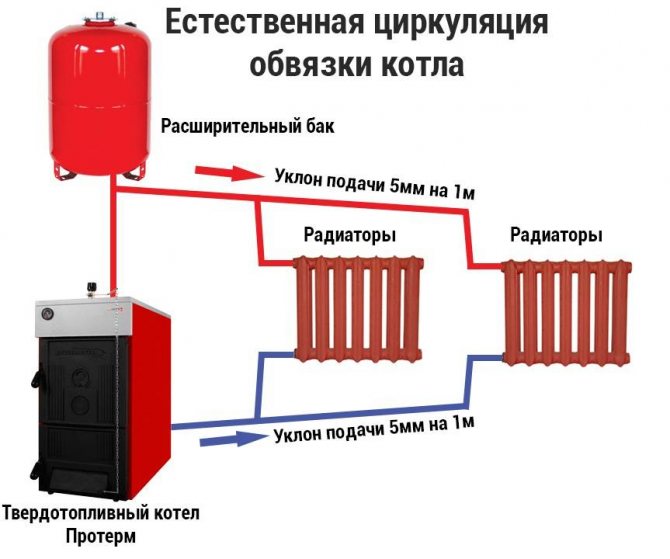

Floor

If it is planned to tie a floor-type heating boiler, the line should be designed so that the heat generator is not the highest point of the pipeline.

In no case should this rule be neglected, especially if the device is not equipped with an air exhaust system, because then air jams will constantly form in the heating network. The supply riser must be located strictly vertically.

Wall

Another thing is the binding of a wall-mounted boiler. As a rule, any gas or electric boiler with a wall mounting method has an automatic air vent.

The presence of this element is evidenced by the branch pipes in the lower part of the boiler body. The piping of the wall-mounted boiler must necessarily take into account this feature of the equipment configuration.

Varieties of strapping

- natural (gravitational). It is used for small buildings and cottages.

- Collector. For its effective operation, it is necessary to have a collector that will collect water from the heating system and the circulation pump.You also need a separate supply for each radiator. This scheme is used for high-rise buildings, and if it is necessary to heat several large rooms.

- Forced. It requires the installation of a special pump. The strapping is used for rooms in which continuous heating is carried out.

- On primary-secondary rings. The scheme provides for the presence of a ring, made immediately behind the boiler, from which there are branches for heating numerous rooms. This wiring is very convenient to use in high-rise buildings, where consumers use not only radiators for heating, but also “warm floors”.

An ideal option for any premises is a scheme in which 3 main circuits can be connected: radiators, underfloor heating and a boiler.

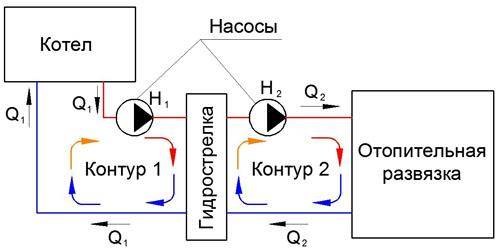

Operating principle

Hydro arrow for heating in the section is a piece of a hollow pipe with a square section. This device works very simply. The air is separated and removed by an automatic air vent. The heating system is divided into 2 different circuits - large and small. The small circuit is a boiler/hydraulic switch, and the large one is a boiler/hydraulic switch/consumer.

When the heating boiler provides an amount of heat carrier that is equal to its consumption, then in the hydraulic gun the liquid flows only horizontally. If this equilibrium is disturbed, then the heat carrier goes to a small circuit, after which the temperature in front of the boiler increases. The boiler reacts to such changes by shutting down, and the heat carrier continues to move until the temperature drops to a certain value. Then the boiler turns on again.In this way, hydraulic separator in the heating system ensures the balance of the boiler and boiler room circuits, while guaranteeing the independent operation of each individual circuit.

Optimal piping of boilers of various types

The piping of a gas boiler is a system of additional devices mounted between the boiler and radiators, it regulates the direction and intensity of movement of the coolant. Regardless of the type of heating - gas, electric, solid fuel, it is divided into two types:

- natural - gravitational;

- forced - using a circulation pump (more economical).

Natural

natural circulation

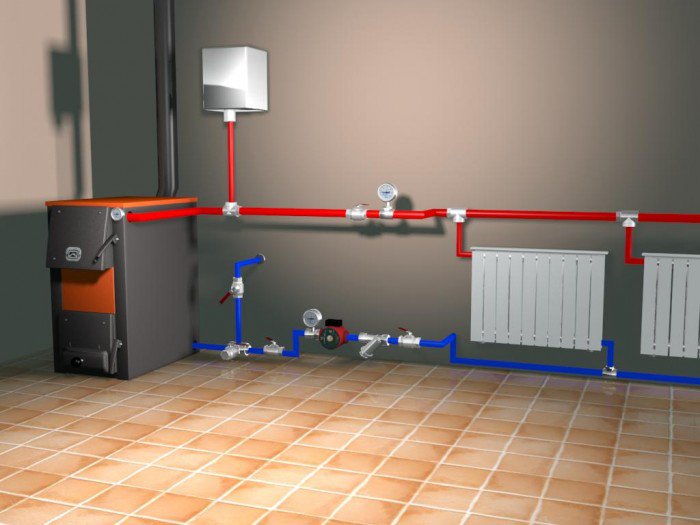

This piping is easy to install and does not require installation of a circulation pump in the system. It is enough to place the pipeline at a slight slope so that the heated coolant can flow into the heating radiators, and the cooled one can drain back to the boiler. This scheme is suitable for small one-story private buildings.

Forced

The best option for a two-story house is a forced circulation system.

As already mentioned, in systems with forced movement of the coolant, an electric pump is required. This means that in addition to the energy resources necessary for the operation of the gas or solid fuel heat generator itself, electricity will be constantly required. If power outages are not uncommon in your area, there will be interruptions in space heating as well.

At the same time, such heat supply systems allow you to fully control the temperature regime in the building, changing the heating of individual rooms at your discretion. Using this method, the boiler room located in a separate room can be tied.

Electric and diesel heat generators

Connecting a diesel fuel boiler to a radiator system is identical to piping gas-using installations. Reason: the diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set temperature of the coolant.

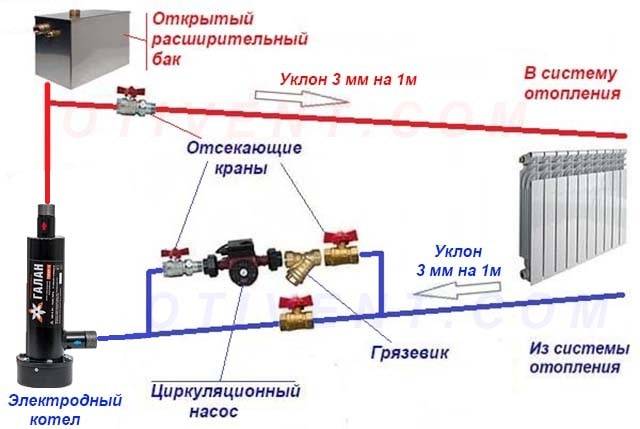

Electric boilers, in which water is heated by heating elements, an induction core, or due to the electrolysis of salts, are also connected directly to heating. For maintaining the temperature and safety, the automation is located in the electrical cabinet, connected to the network according to the above wiring diagram. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boilers equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

Radiators

Tying radiators, as well as boilers, is made of polypropylene. With its use, the piping system is tight and reliable.

Strapping options

There are two schemes for piping radiators. With a single-pipe type, all radiators are connected in series, temperature control is possible only when tapped into the bypass system. With the two-pipe method, a more efficient supply of coolant occurs, it cools down less and the load on the boiler decreases.

Connecting pipes directly to the radiator must be done in such a way that the coolant flow passes through the entire inner surface without the formation of stagnation zones.

IMPORTANT! Pipes to the batteries should be connected through taps, so that in case of damage to the radiator, exclude the defective area from the overall system

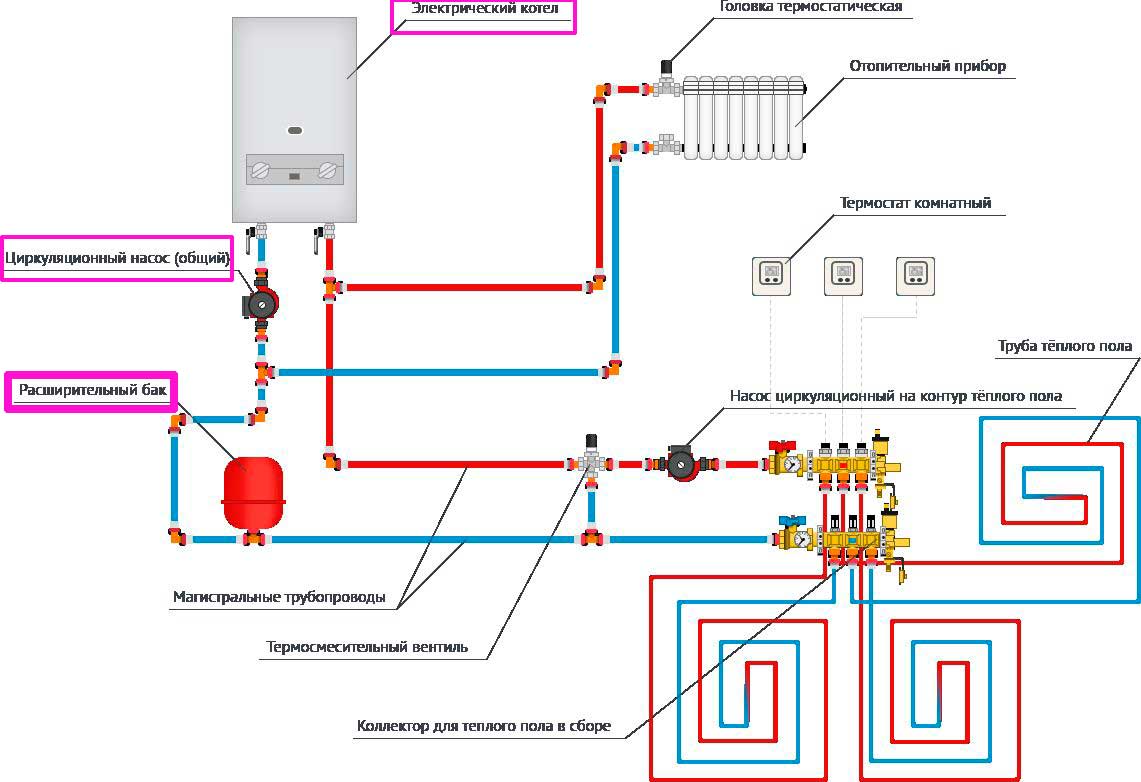

Collector wiring diagram of the heating system

With a large number of heating radiators located on different floors, or when connecting a "warm floor", the best wiring diagram is a collector one. At least two collectors are installed in the boiler circuit: on the water supply - distributing, and on the "return" - collecting. The collector is a piece of pipe into which bends with valves cut in order to be able to regulate individual groups.

Collector group

Collector group

An example of connecting a heating circuit and a "warm floor" system using a collector group

An example of connecting a heating circuit and a "warm floor" system using a collector group

Collector wiring is also called beam, since pipes can diverge in beams in different directions throughout the house. Such a scheme in modern homes is one of the most common and is considered practical.

What is a harness

If you are completely new to heating matters, then it would be useful to first find out what is generally meant by the term "strapping". Actually, this is the entire heating system, except for the heating boiler. It depends on the piping how exactly the coolant will circulate to all destinations, how well it will turn out, etc.

For all this, several elements are used:

pipes. It is they that interest us today, and indeed this is one of the main components of the design. You can see their appearance in the photo:

In addition to them, fittings are also important - connecting elements that make it possible to lay a pipeline along the desired route and connect pipes to various heating equipment,

- expansion tank. Required to remove excess air and water from the heating system,

- heating radiators. They are stationary devices installed indoors and have a high level of heat transfer,

- bypasses. Strictly speaking, these are all the same pipes, but they are not intended for the main circulation, but for an additional one. The bypass is a bypass route. If for some reason you need, for example, to turn off one of the radiators, you can close it using the shut-off valve. If there is no bypass at the same time, then the coolant will run into this barrier and will not go further - thus, all batteries located further than the one being repaired will become cold. And if there is a bypass, such a problem will not arise - the coolant will simply bypass and successfully reach all the following goals.

The heart of any heating system is the heating boiler. It is he who is responsible for reaching the required temperature by the coolant. All of the listed elements are connected directly to the boiler, directly or using pipes.

In addition to the already mentioned, some other equipment may also participate in the strapping:

- Mayevsky crane. It is installed on each radiator and in some other places. It is necessary for quick and easy release of excess air from the system, which helps to prevent the formation of air pockets that impede the flow of the coolant. That is, in fact, this equipment is auxiliary, in addition to the expansion tank,

- circulation pump. All heating systems are divided into two broad categories. In the first of them, the circulation of the coolant is carried out in a natural way.This is due to the difference in the density of cold and hot water. The arrangement of such a system is not difficult, and economically quite profitable. But the efficiency is low. Natural circulation can only be used in small houses, since it simply cannot cope with a long circuit - the water will reach the distant radiators, having already cooled down. The second category includes systems with forced circulation. The movement of the coolant in this case occurs due to the operation of special equipment - a circulation pump. This allows you to give the liquid the necessary speed and, accordingly, prevents it from cooling in the middle of the route,

- gauges and thermostats. This equipment is necessary to monitor the correct operation of the heating system as a whole and its individual sections in particular. Thermostats monitor the temperature of the coolant, and pressure gauges monitor the pressure level. Accordingly, in the event of any malfunctions, you can detect them in a timely manner, focusing on the indicators of the devices.

Heating system from polypropylene pipes

The technical characteristics of the object and the amount of allocated funds affect the heating installation scheme. In apartments of multi-storey buildings, it is connected to the central heating system, and in private houses - to an individual boiler. Regardless of the type of object, the system can have one of three versions.

Single pipe

The system is characterized by simple installation and quantity of materials. It mounts one pipe for supply and return, which reduces the number of fittings and fasteners.

It is one closed circuit with alternate vertical or horizontal placement of radiators. The second type is used specifically in private homes.

When passing through each radiator, the temperature of the coolant decreases. Therefore, a single-pipe circuit is not able to evenly heat the entire object. There is also the difficulty of temperature control, since the heat loss factor is not taken into account.

If the radiators are not connected through valves, then when one battery is repaired, the heat supply is stopped throughout the facility. When arranging such a network in a private house, an expansion tank is connected. It allows you to compensate for changes in pressure in the system.

The single-pipe circuit allows the installation of radiators with temperature controllers and thermostatic valves to correct heat loss. Ball valves, valves and bypasses are also installed for the repair of individual sections of the thermal circuit.

Two-pipe

The system consists of two circuits. One is for submission and the other is for return. Therefore, more pipes, valves, fittings, consumables are installed. This increases installation time and budget.

The advantages of a 2-pipe network include:

- Uniform distribution of heat throughout the facility.

- Minimum pressure loss.

- Possibility of installing a low power pump. Therefore, the circulation of the coolant can occur by gravity.

- Repair of a single radiator is possible without shutting down the entire system.

The 2-pipe system uses a passing or dead-end scheme for the movement of the coolant. In the first case, it is allowed to install batteries with the same heat output or radiators with different capacities, but with thermostatic valves.

A passing scheme is used if the thermal circuit is long. The dead-end option is used for short highways. When installing a 2-pipe network, it is necessary to install radiators with Mayevsky taps. The elements allow air to be expelled.

Collector

This system uses a comb. It is a collector and is installed on the supply and return. This is a two-pipe heating circuit. A separate pipe is mounted, both for supplying coolant to each radiator, and for returning cooled water.

The system may consist of many circuits, the number of which depends on the number of batteries.

When installing a collector thermal circuit, an expansion tank is installed. It contains at least 10% of the total volume of coolant used.

During installation, a manifold cabinet is also used. They try to place it at an equal distance from all batteries.

Each circuit in the manifold system is a separate hydraulic system. It has its own shut-off valve. This allows you to turn off any of the circuits without stopping the operation of the entire system.

Collector

Advantages of the collector network:

- It is possible to regulate the heating temperature of any of the heaters without prejudice to the rest of the batteries.

- High efficiency of the system due to the direct supply of coolant to each radiator.

- It is possible to use pipes with a smaller cross section and a less powerful boiler due to the high efficiency of the system. Therefore, the costs for the purchase of equipment, materials and network operation are reduced.

- Simple design process, no complicated calculations.

- Possibility of underfloor heating.This allows you to create a more aesthetic interior, as there is no need to install traditional batteries.

For the device of the collector system, a large number of pipes, fittings and valves will be required. You will also need to purchase combs, a circulation pump, an expansion tank and a cabinet for collectors.

A large number of elements increases the complexity of the installation process. Installation of batteries is carried out together with Mayevsky cranes to prevent airing of each of the circuits.

Recommended Materials

The choice of material is of the utmost importance. The pipeline must be reliable, practical and inexpensive, as well as easy to install and not be subject to corrosion.

Polypropylene

The most commonly used pipelines are made of polypropylene. This material is resistant to aggressive environmental influences and plaque formation.

Polypropylene pipes are connected to each other by soldering, and not by fittings like metal ones. Due to this, a strong monolithic connection is obtained, excluding the possibility of leaks.

In addition, most manufacturers give a guarantee of up to 40 years on their products. In this case, the pressure in the system can rise up to 25 bar, and the temperature up to 95°C. And this means that the piping of the heating boiler will not only be as reliable as possible, but durable.

Metal eyeliner

However, it should be borne in mind that the gas supply to the water heater must be rigid!

The best option is a metal pipe and a metal drive or "American". As a sealant, only a paronite gasket can be used.It is paronite that is most often used in the installation of boilers, because this material is not combustible, keeps its shape perfectly and keeps the connection tight for a long time. Paronite is a mixture of asbestos fibers, rubber and mineral additives.

The location of the boiler in the heating system

The main element in the heating circuit is the heating unit. The scheme according to which the piping of the heating boiler will be carried out largely depends on the type of this device.

The main rule for mounting the floor models shown in the photo is that they cannot be placed at the highest point of the pipe layout. If this condition is not met, then air pockets will form in the boiler without a device for removing trapped air. The supply pipe that exits the unit, in this case, should be placed strictly vertically.

Currently on sale are boilers equipped with a circulation pump, an expansion tank and a safety group, as well as appliances without these additional elements. In the event that the unit does not have them, these devices can be easily purchased and installed in the circuit. When a consumer installs a system with natural circulation, these elements are usually not required. But if the heating circuit will work on the forced movement of the coolant, then one cannot do without a pump, a tank and a safety group.

Polypropylene piping for different boilers

Most manufacturers of water heaters recommend that the first meter of the pipeline from it be made of metal. This is especially true for solid fuel devices with a higher outlet water temperature.When tying, polypropylene should be connected already to this outlet, otherwise, if there is a malfunction in the boiler, it will receive a thermal shock and may burst.

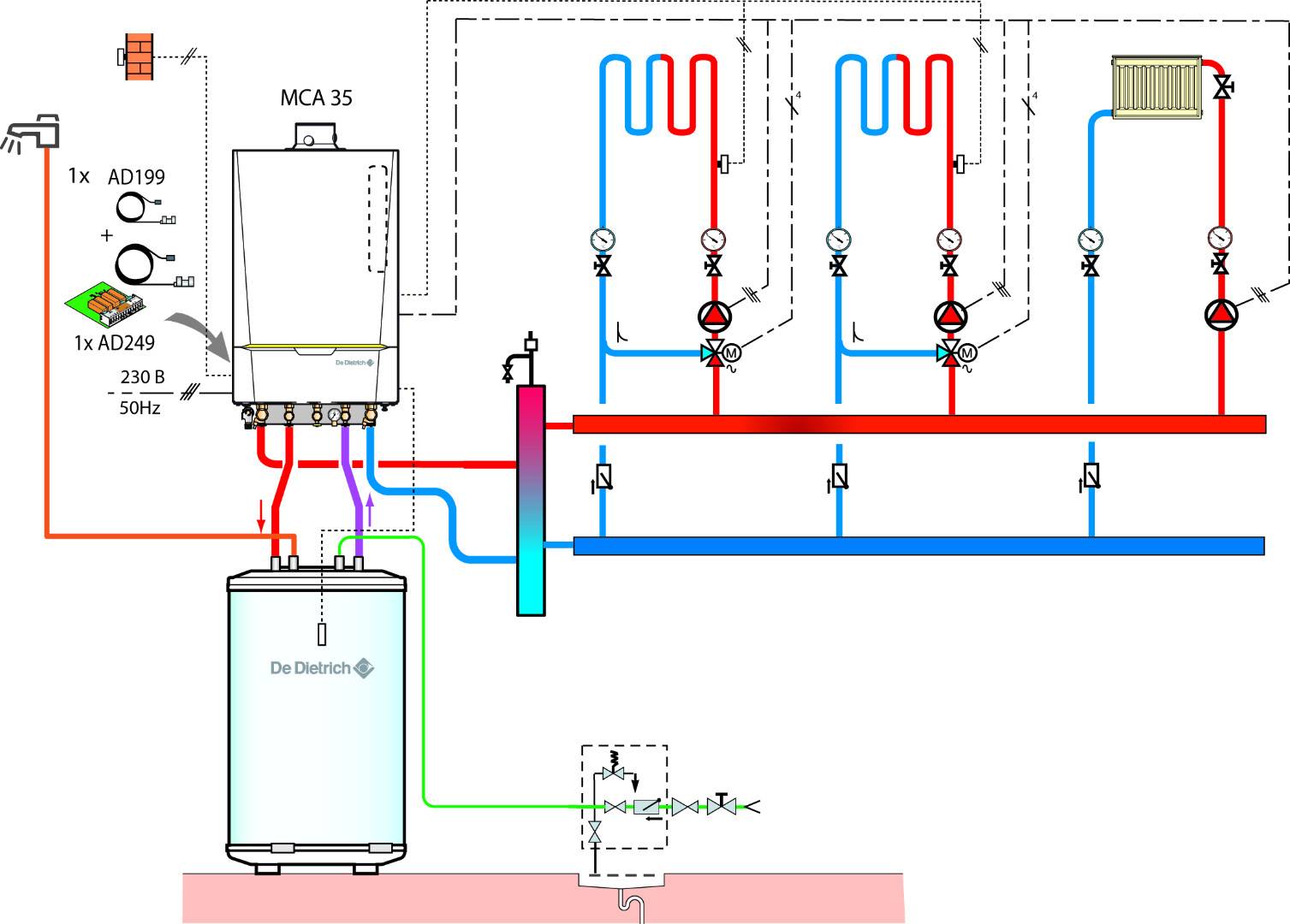

Gas water heater

It is recommended to tie a gas boiler with polypropylene using a hydraulic gun and a manifold. Often, gas models are already equipped with built-in pumps for pumping water. Almost all of them are originally designed for forced systems.

The most reliable in terms of safety will be a circuit with circulation equipment for each circuit behind the collector.

In this case, the built-in pump will pressurize a small section of the pipeline from the boiler to the distributor, and then additional pumps will be activated. It is on them that the main load on pumping the coolant will fall.

It is possible to tie a gas boiler with polypropylene without long metal pipes, the water in such a heater rarely heats up to 75–80 degrees

If the gas boiler has a cast-iron heat exchanger, then when piping it into the system, an additional heat accumulator should be installed. It will smooth out sudden changes in water temperature that have a negative effect on cast iron. With abrupt heating or cooling of the coolant, it can even burst.

Solid fuel model

The main feature of a solid fuel boiler is its inertia when the fuel supply is cut off. Until everything in the furnace burns out completely, it will continue to heat the coolant. And this can adversely affect polypropylene.

When tying a solid fuel boiler, only metal pipes should be connected to it immediately, and only after a meter and a half can polypropylene pipes be inserted. In addition to this, it is necessary to provide a backup supply of cold water for emergency cooling of the heat exchanger, as well as its removal to the sewer.

The section of the pipeline from the solid fuel boiler to the collector should be made of metal, and then you can tie it with polypropylene - this is the only way to protect plastic pipes from overheating

If the system is built on forced circulation, then it will definitely be necessary to install an uninterruptible power supply for the pump. Water must constantly remove heat from the furnace where solid fuel burns, even during power outages.

In addition to it, you can make a small gravity circuit or equip all batteries with bypasses to turn off individual sections of the system. In case of accidents, this will allow repairing the damaged section while the heating is running.

A solid fuel boiler must be covered with a protective casing that limits the spread of heat from the walls of the furnace into the boiler room. But even if it is present, the collector and plastic pipes should be removed away from the stove.

Heaters for liquid fuel and electricity

A mining or diesel boiler is tied with polypropylene according to a scheme identical to that of a solid fuel counterpart. The polymer must be removed from it as far as possible.

When piping an electric PPR boiler, you don’t have to worry about pipe breaks, it has protective automation that prevents the water from reaching a boil

Heating of the coolant in the water heater on electricity to critical temperatures for polypropylene is practically excluded.When the power goes out, it just stops working. In this case, the pipes are protected from hydraulic shocks by a hydraulic accumulator and valves for relieving excess pressure.

Connecting the boiler to the system

It is worth talking separately about how the polypropylene pipeline is connected to the boiler. The fact is that it depends on the type of heating equipment:

- gas boiler. It is possible to bring polypropylene pipes to it directly, since the temperature of the coolant leaving it usually does not exceed 80 degrees. Regardless of whether the gas boiler belongs to wall, floor or parapet, when installing a forced system, a circulation pump is built into each circuit located behind the manifold. It is also desirable to install filters for cleaning both incoming and heated coolant,

- solid fuel boiler. An important nuance must be taken into account in its strapping: heating of a pipe located close to the equipment may be excessive. This will adversely affect the state of polypropylene, quickly rendering it unusable. Therefore, the first one and a half meters of the pipe extending from the boiler must be made of metal, and only then can the polypropylene line be connected. The connection is carried out using all the same fittings made specifically for such a transition,

- liquid fuel and electric boilers. The strapping is carried out according to the same principle as in the case of solid fuel equipment - we remove polypropylene from the device by at least one and a half meters.

If you take into account all the above nuances, then the polypropylene pipeline will serve you for a long time and reliably.Do not be afraid to deal with it, since, as you can see, the assembly of the system is available even to a beginner. To consolidate the knowledge gained today, watch the video below. Good luck to you and warmth to your home!

Detail made of polypropylene

Now it is quite possible to carry out the installation of a hydraulic arrow made of polypropylene. It allows you to provide additional benefits in the system:

- Due to the low roughness of the material, the resistance to the coolant decreases during its movement. And when there is a boiler with a low power in the system, then such a hydraulic separator allows you to reduce heat loss, in comparison with metal appliances.

- Can be painted on the outside in any color.

- It has a significantly lower cost in comparison with analogues.

- The polypropylene product does not rot and does not form corrosion on it.

- It can work with boilers up to 35 kW.

At the same time, such hydraulic arrows also have their drawbacks:

- Cannot be used in a solid fuel boiler system.

- The higher the power of the boiler, the shorter the service life of such a product. This is due to faster wear at high pressure and temperature.

- For installation, additional equipment will be required to work with polypropylene products.

It should be noted that the quality of connection of any type of hydraulic separator will directly depend on how well the entire system will work in the future.

Why you need a hydraulic gun and how to calculate its parameters, see the following video:

Features of polypropylene strapping

For strapping well-proven polypropylene pipes. They are highly resistant, and plaque does not form on their walls, so blockages of the heating system do not occur.Separate sections of the pipeline are interconnected by soldering, creating a monolithic structure that eliminates leakage.

Polypropylene in comparison with analogues has a number of advantages:

- Heat resistance. Pipes need to be wrapped with a layer of thermal insulation, it will create a frame that protects the walls of the pipeline from the expansion of the heated coolant.

- Accelerated installation. To connect it, you need to have a soldering iron and a supply of keys. With such a minimal set of tools, tying can be done in no more than a week.

- Minimum thermal conductivity. Thanks to the heat-insulating layer, the coolant does not cool down during transportation.

- Durability. The pipe material can withstand pressure in the system up to 25 atmospheres, and the coolant temperature can reach 95 degrees. It is not subject to deformation and expansion, therefore it can serve up to 40 years.

- Resistant to plaque on the walls. Inside, polypropylene pipes have a smooth surface, due to this, the coolant circulates quickly, and deposits do not stagnate.

- Versatility. From such pipes you can create a heating circuit of any complexity. But a simple assembly will still be better.

By choosing this material, there is no doubt about the reliability of the pipeline connection.