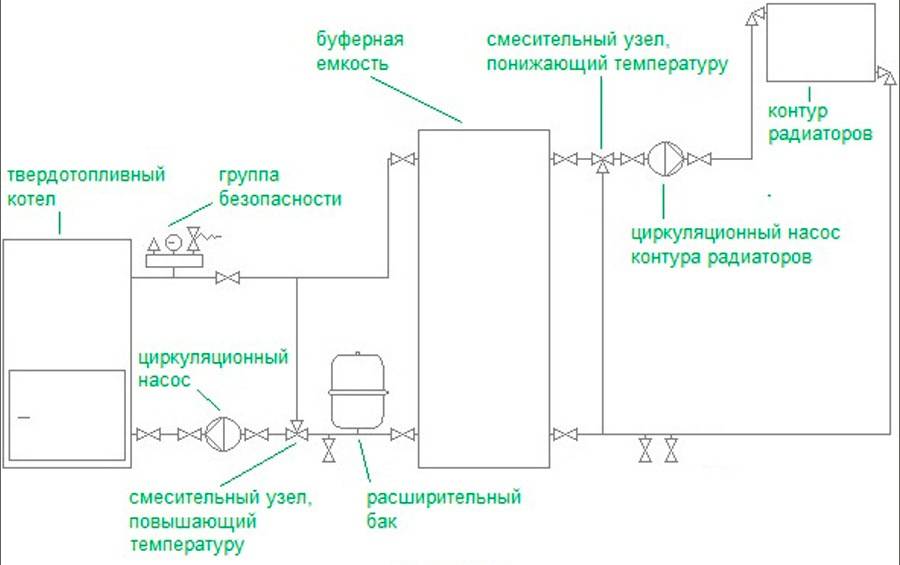

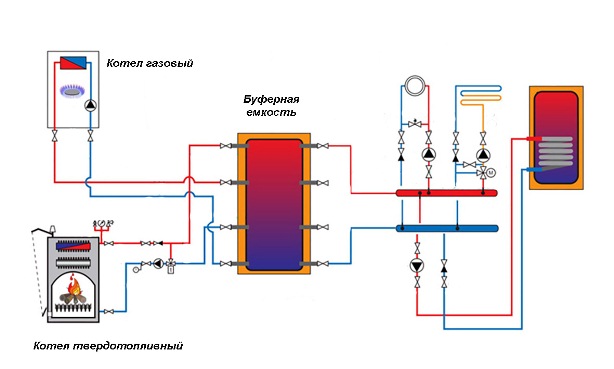

- What is a heat accumulator

- What is it needed for

- Principle of operation

- Flaws

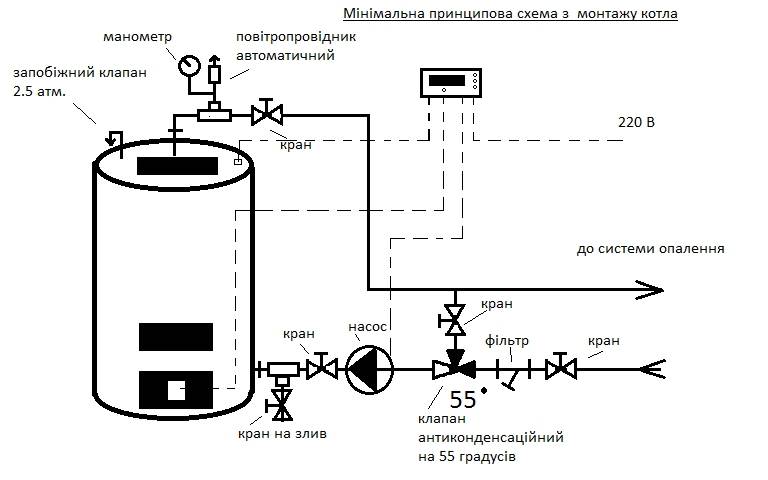

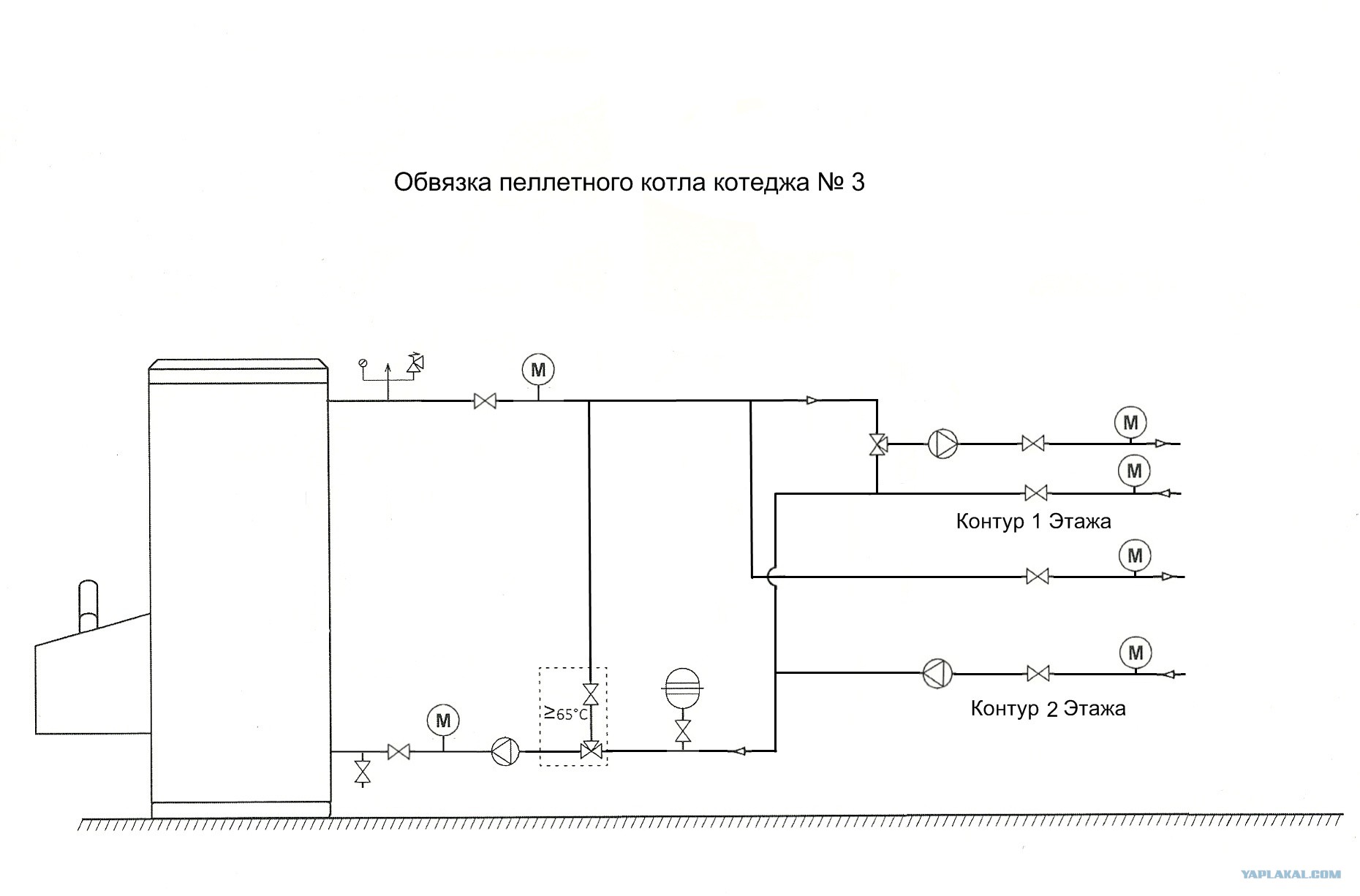

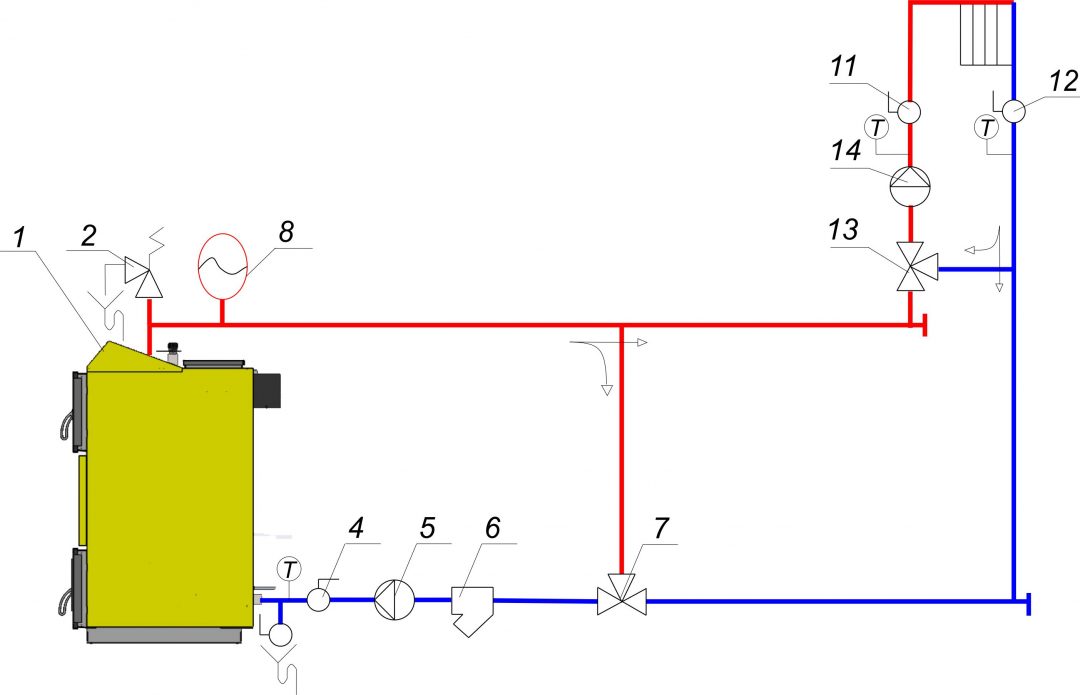

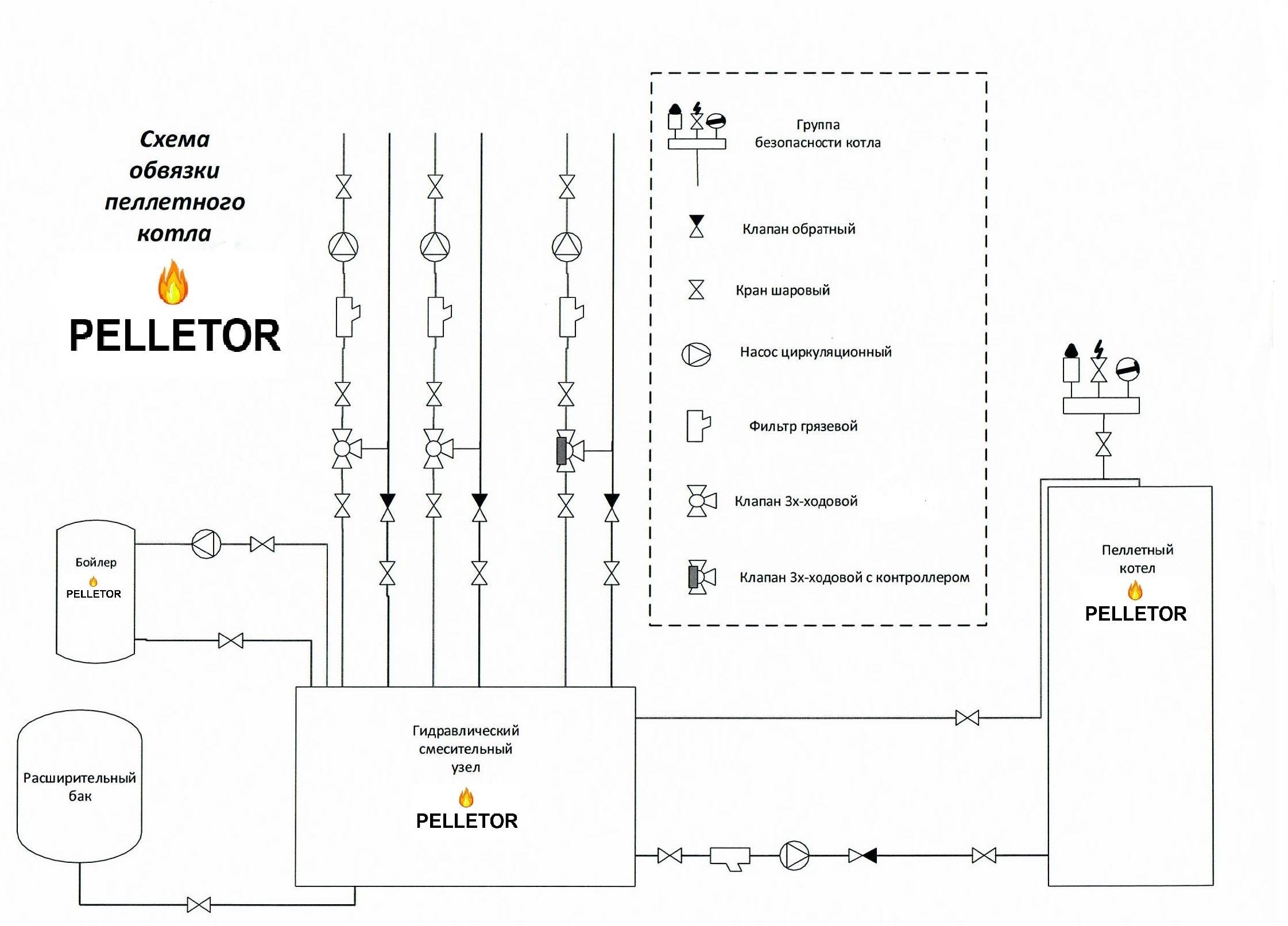

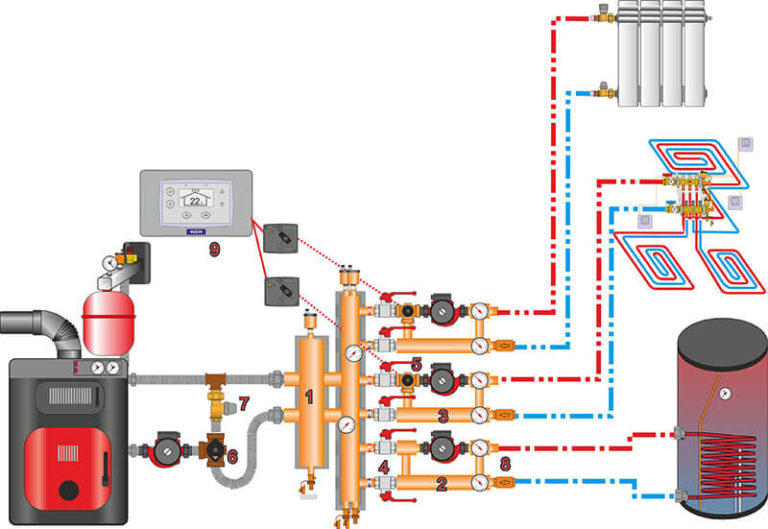

- Piping schemes for floor boilers

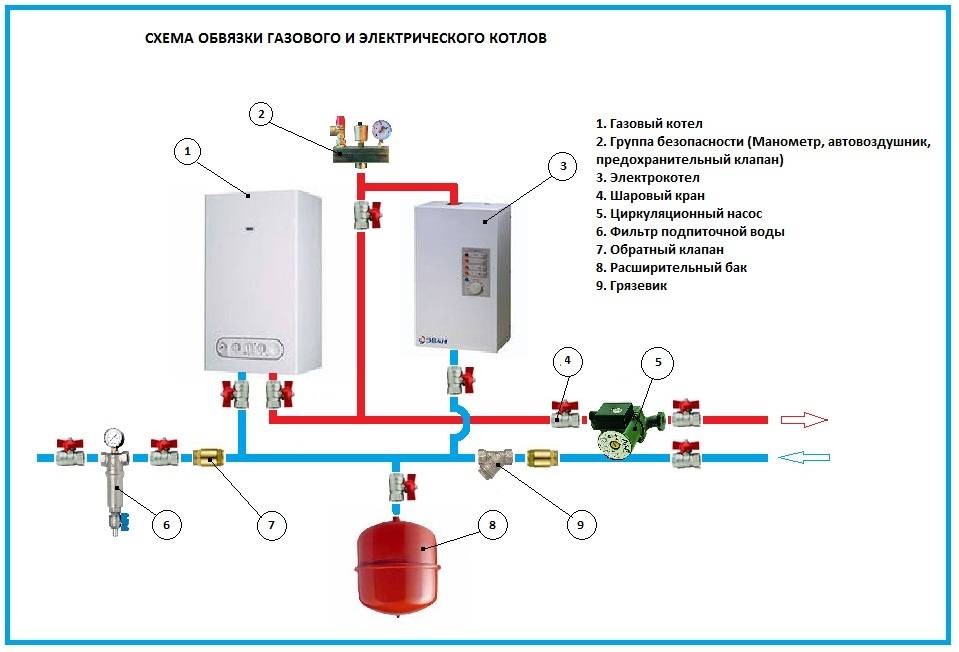

- Do-it-yourself piping of a double-circuit gas boiler

- Elements

- How to make a homemade register from shaped, smooth steel pipes

- DIY tools and materials

- The order of work: how to weld the structure?

- Double-circuit boiler

- Connection Features

- Typical connection errors

- Heating system piping

- Common mistakes when tying a gas boiler

- Membrane tank and radiators

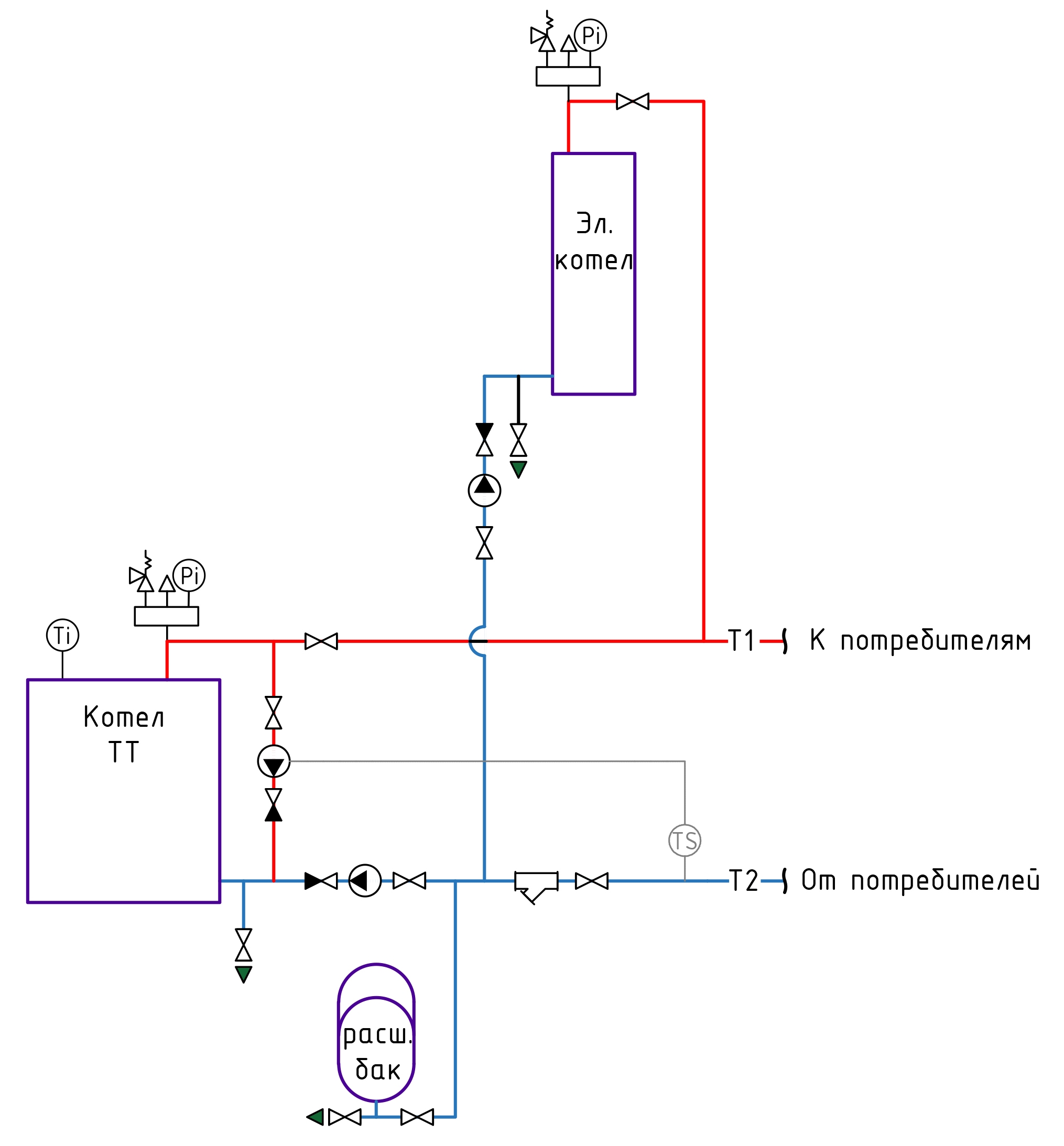

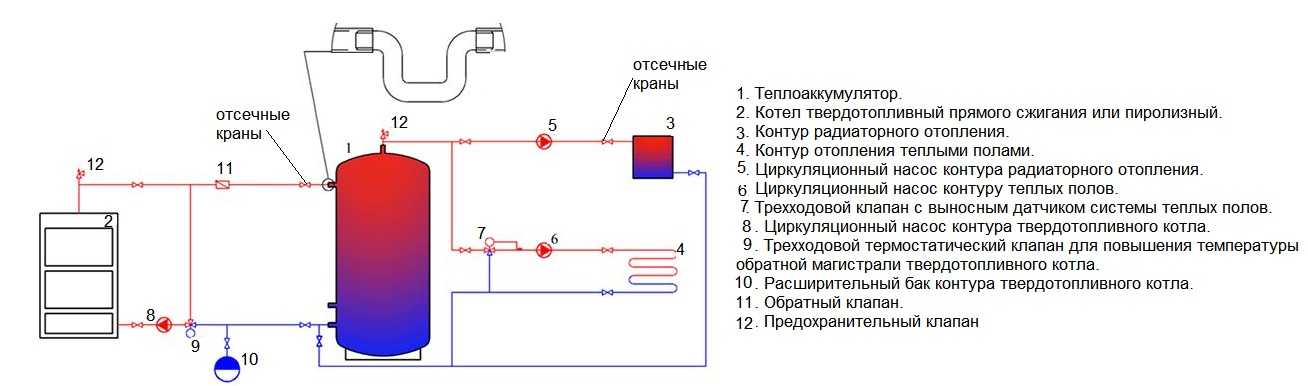

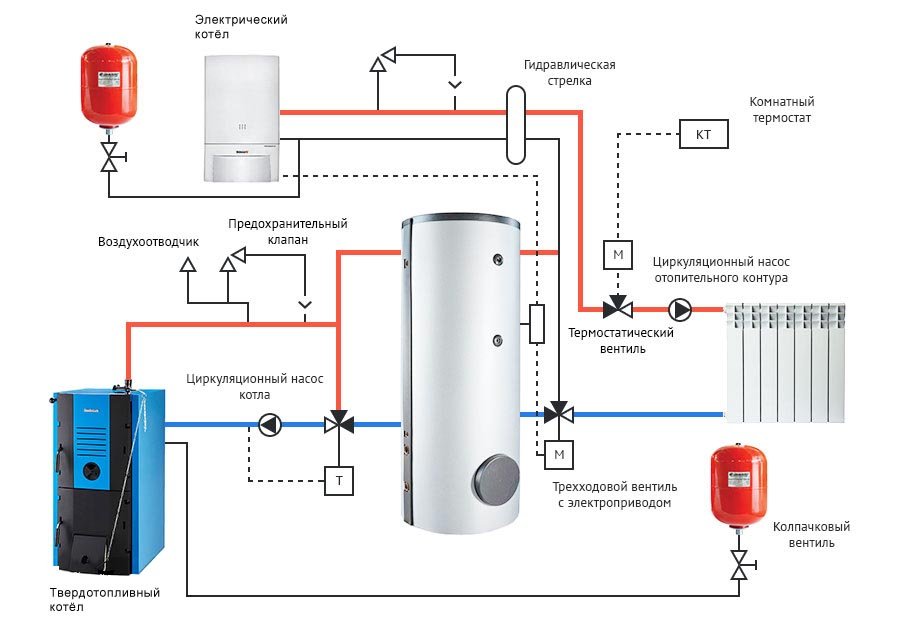

- Nuances for a solid fuel boiler

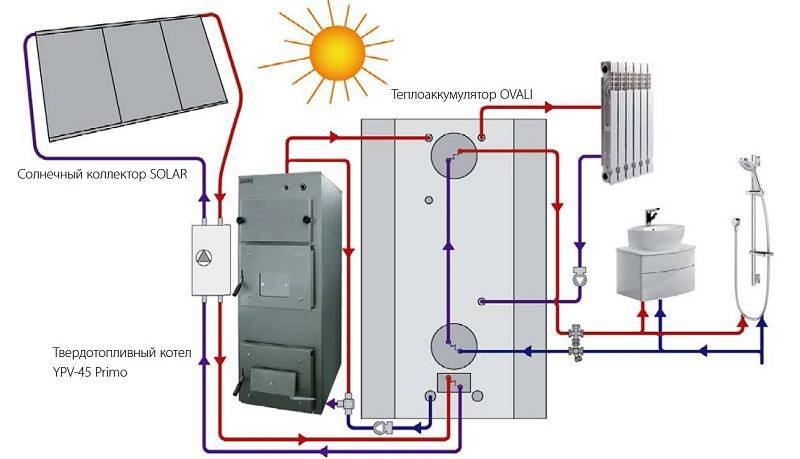

What is a heat accumulator

But when operating a solid fuel unit, one will have to face the problem of heterogeneity in obtaining thermal energy. While the boiler is running, the house is warm or even hot. Run out of fuel - the house becomes cold. Half of the heat received goes into the atmosphere, and firewood often has to be added. Therefore, we thought about how to store excess heat, and then slowly give it to the heating system.

This problem is solved when they begin to operate a solid fuel boiler with a heat accumulator.

In European countries, the use of thermal energy units without a buffer tank is prohibited, so that there are no carbon monoxide emissions into the atmosphere.

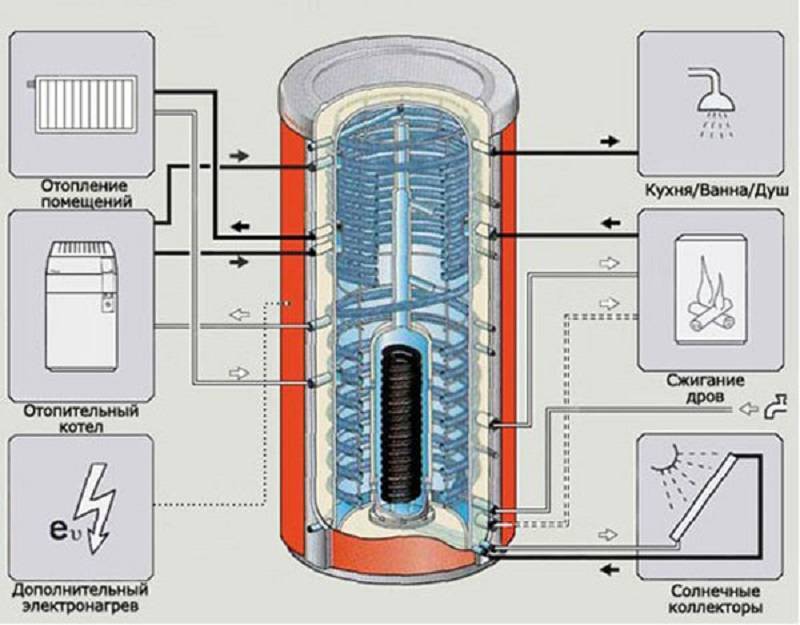

A heat accumulator is a container, most often round cylindrical, filled with water, depending on the purpose, there are different modifications.

The production version includes:

- the main body, which is made of various steel alloys or stainless steel;

- a layer of insulation made of basalt or mineral wool or polyurethane foam with a thickness of at least 50 mm;

- the outer skin is made either from painted thin sheet metal or from a cover made of polymer material;

- branch pipes for supplying and discharging coolant are cut into the main tank;

- in more expensive models, a coil is installed inside for heating water;

- thermometer and pressure gauge are used to monitor temperature and pressure.

Sometimes a block of electric heaters with sensors is built into the heat accumulator and solar panels are connected - this creates additional comfort when using it.

The prices for these options are high, so craftsmen most often make buffer tanks with their own hands.

What is it needed for

The range of application of the thermal energy accumulator is very wide and is determined according to the modification and the equipment used with it.

Its most important purpose:

- accumulate as much heat as possible, and then, when the fuel in the main heat generator runs out, give it to the heating system;

- prevent sudden changes in temperature in the system, thereby preventing the appearance of condensate in the boiler.

More modern and expensive allow you to create more comfort and more opportunities:

- hot water supply in the house;

- use it instead of an electric boiler if you install electric heaters in it.

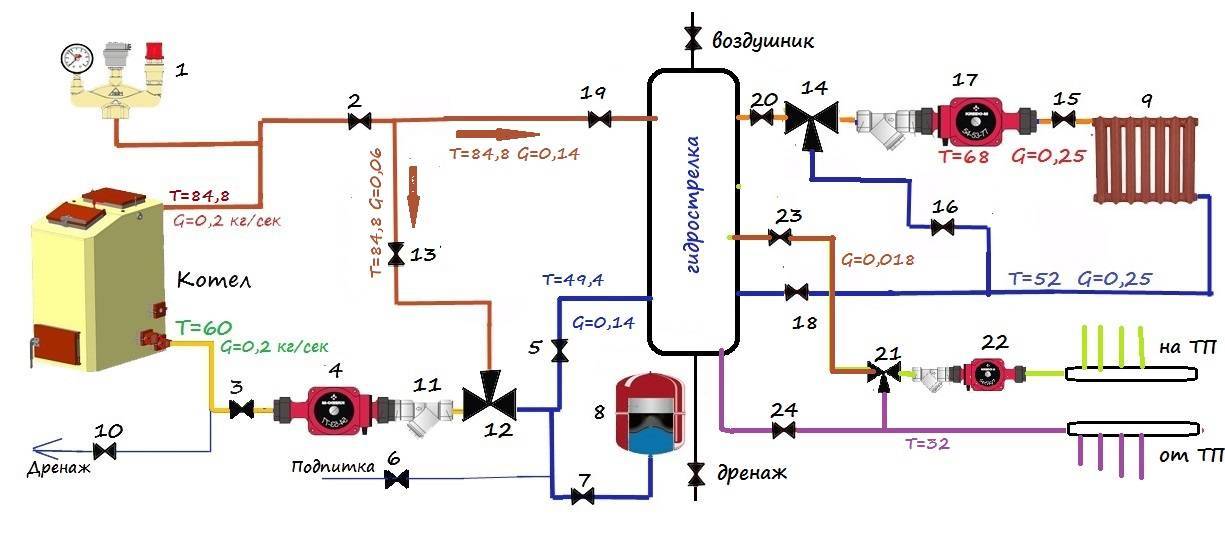

Principle of operation

Before the first use, it is recommended to study the scheme of operation of the boiler and tank.

The system works like this:

- Fired up the boiler.

- The heated water enters the heat generator, as if charging it.

- The circulation pump, installed behind the tank, through a pipeline mounted in its upper part, delivers the coolant to the heating pipes.

- Returning, the cooled water enters the lower part of the heat generator.

- Then she enters the boiler.

- The fuel ran out - the boiler went out.

- The heat generator comes into operation: with the help of a circulation pump from the upper hot zone, it gradually distributes the stored heat through pipes and radiators.

The second pump is provided with a room temperature sensor, which, if necessary, can turn it off if the temperature exceeds the temperature set for it. Then the boiler will only heat the heat accumulator. When the air temperature in the rooms drops, the pump turns on and the water will heat the batteries again.

The use of a thermal energy accumulator allows the owner of the household to satisfy all his requests.

Flaws

Of course, there are shortcomings in a bundle of a thermal heater with a thermal storage device, but over time, the buyer will realize that the investment was not spent in vain.

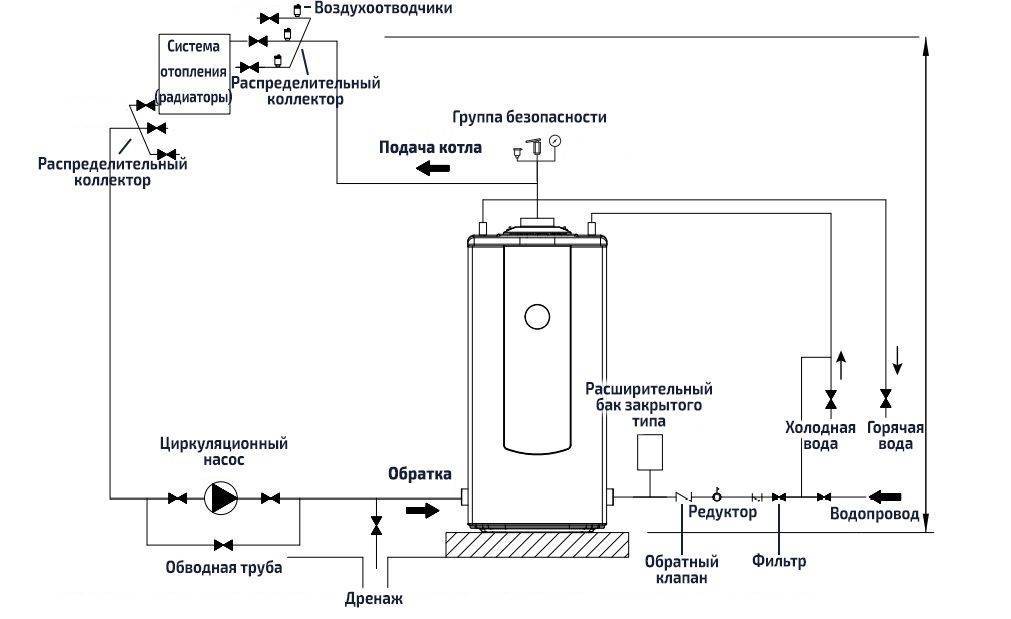

Piping schemes for floor boilers

As suggested by the piping diagram of a floor-standing gas boiler, when creating a heating system, the installation of a circular electric pump is required (read: “Connection diagram for a gas heating boiler with examples“).

Forced-type devices are easy to operate and are considered more comfortable to use.

The heating unit is controlled automatically.Among the advantages, it should be noted that for individual rooms it is possible to set a certain temperature, thanks to the presence of sensors that control the heating process.

At the same time, the piping scheme for a wall-mounted gas boiler has negative sides, including:

- high price for components;

- the complexity of the implementation of the strapping, which can only be performed by a professional;

- the need for constant balancing of parts;

- service cost.

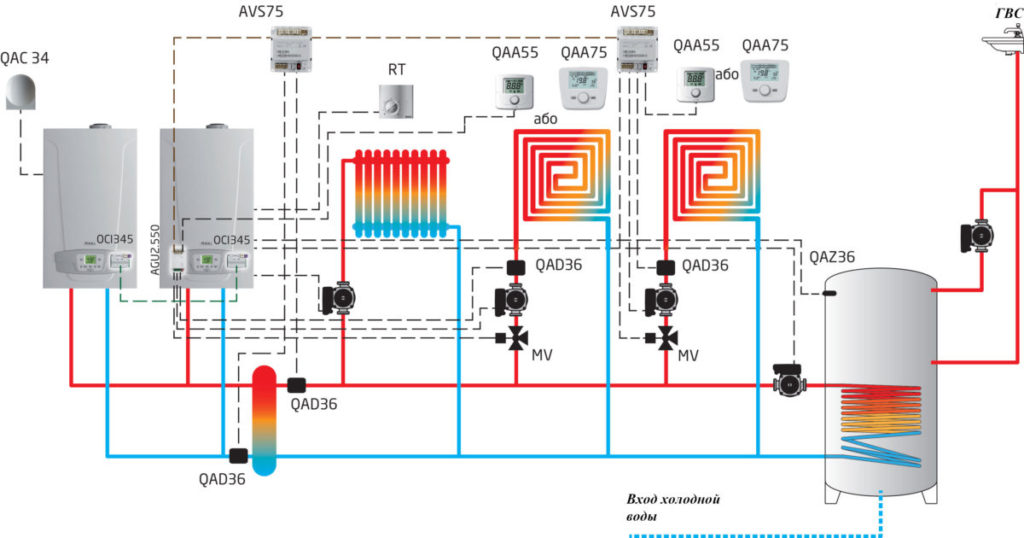

If the house has a complex heat supply system, for example, there is a “warm floor” and batteries, then some inconsistency can be noticed when the coolant moves. Therefore, to solve the problem, a hydraulic decoupling is included in the piping scheme, which forms several circuits for the movement of coolants - a common one and a boiler one.

For waterproofing each circuit, an additional heat exchanger is installed. This will be required to combine open and closed systems. Units belonging to the separate type must be equipped with circular pumps, a security system and taps (drain and make-up). How to connect a gas boiler, in detail on the video:

Do-it-yourself piping of a double-circuit gas boiler

Now let's look at how to tie a gas double-circuit heating boiler.

The main difference between such a heater and a single-circuit unit lies in the versatility of the first. It maintains the degree mode of the coolant in the heating circuit, and also heats water for domestic needs. Single-circuit units can also indirectly heat water. The process of heat transfer in them is carried out in the process of moving the coolant through the secondary heat exchanger.

Also, a distinctive feature of a double-circuit boiler is the direct return of thermal energy to water. At a consumption of hot water there is no heating of the heat carrier. Simultaneous operation of two circuits is impossible.

As practice shows, for houses with high-quality thermal insulation, the operating mode of the heating boiler is not of fundamental importance. The heating scheme will be the same for any type of heating.

Radiators and coolant provide long-term cooling. This result is due to the choice of radiators with a large capacity and a wide diameter of pipes. A large volume of hot water can be obtained by combining a single-circuit design and a heating column. On larger houses, the operation of the boiler is not affected in any particular way, so the heating schemes will be identical.

Elements

The specific filling to the strongest degree depends not only on the type of boiler and additional equipment, not only on the withdrawal of liquid into one or two circuits. For example, the strapping scheme for a two-story house has its own nuances.

The key element - the boiler itself - is calculated primarily taking into account such parameters as:

- total area and volume of heated rooms;

- weather stereotype and wind conditions of the area;

- the presence of windows, their size and tightness, the quality of thermal protection;

- type of roof, the degree of its insulation, the presence or absence of an attic;

- thermal insulation of walls, floors and ceilings;

- main building material.

If a non-freezing liquid is chosen as a coolant, it will be necessary to install the most powerful pumps and increase the cross section of pipelines. Otherwise, the flow of heat into the house and the heating rate will not satisfy the residents. Since antifreeze contains ethylene glycol, you will have to be more careful when using parts made of polypropylene and rubber. Moreover, this reagent is also harmful to cast iron and non-ferrous metals. Therefore, in most cases it is necessary to mount stainless steel pipes and radiators.

Batteries themselves can have a variety of heat dissipation levels. It depends on their size and the material used. To increase the length or shorten it, add or remove sections, respectively. A Mayevsky design faucet and a thermostatic expansion valve help to achieve a uniform heat supply to the entire surface of the radiator. Since maintenance may be required during the use of the appliance, it is useful to install a shut-off valve.

Heating batteries are installed strictly along the perimeter of the heated room - below the window sills and next to the front door. Optimum results are achieved with seamless steel pipes or polypropylene pipes. The lower the internal hydraulic resistance, the more efficient the system will work. Any two-story houses must be heated with the use of expansion tanks. Since the extended intricate contours inevitably have a lot of pressure inside, therefore, only the periodic discharge of the expanding liquid into the reservoir keeps the system stable. The situation is excluded when, due to a pressure surge, the water boils rapidly and damages the pipes themselves and their connections.

Closed heating systems involve mounting the tank on the return circuit pipe up to the suction pipe of the pump. The tank itself is raised to a minimum height of 1 m. The diameters of the components are always selected individually.

In addition to the products listed, the following can be installed:

- filters for water and gas;

- collectors;

- return valves;

- safety valves;

- air valves and a number of other components.

How to make a homemade register from shaped, smooth steel pipes

The welding work underlying the manufacture of registers for a heating system requires a certain number of different tools and materials.

DIY tools and materials

In addition to the welding machine, the following devices will be required:

- for cutting: grinder, plasma cutter or gas burner (cutter);

- tape measure and pencil;

- hammer and gas key;

- building level;

Materials for welding:

- electrodes, if electric welding is used;

- wire, if gas;

- oxygen and acetylene in cylinders.

The order of work: how to weld the structure?

Depending on the chosen type of construction (sectional or serpentine), the assembly of registers will be very different. The most difficult are sectional, because they have the most joints of elements of different sizes.

Before proceeding to the assembly of the register, it is necessary to make a drawing, deal with the dimensions and quantity. They depend on the heat transfer of the pipe. For example, 1 m of a pipe with a diameter of 60 mm or a section of 60x60 mm and a thickness of 3 mm is intended for heating 1 m² of the area of the heated room, taking into account that the ceiling height does not exceed 3 m.

The first thing to do is to cut segments from the selected pipe in accordance with the estimated length of the sections. The ends must be ground and cleaned of scale and burrs.

Before assembling sectional devices, you need to put markings on them, along which jumpers will be installed. Usually it is 10-20 cm from the edges of the sectional pipes. Immediately on the upper element, a mark is made where the air vent valve (Mayevsky crane) will be installed. It is located on the opposite side and along the edge of the section, and along the outer plane.

- With a gas burner or a plasma cutter, holes are made in the pipes according to the marks, taking into account that the jumper pipe can enter them.

- The lintels of 30-50 cm are cut out of pipes of a smaller diameter.

- Segments of the same length as the pipe jumpers are cut from the metal profile. They will be installed in the form of supports for section pipes on the opposite side from the installation of the adjoining element.

- Cut out of sheet metal with a thickness of 3-4 mm plugs in the shape of the main pipe (circle or rectangle). In two of them, holes are made for the spurs, to which the supply and return circuits of the heating system will be connected through shut-off valves.

- First of all, plugs are welded to the sections.

- Drives are welded to the latter.

- Welding of jumpers with pipe sections is carried out.

- Support elements made of cut steel profiles are immediately attached by welding.

- A branch pipe is welded for the installation of a Mayevsky crane.

- All seams are cleaned with a grinder and a grinding disc.

The assembly and welding process is best carried out on a flat plane, on which two or three wooden bars are laid (they can be replaced with steel profiles: a corner or a channel). It is on the bars that the pipe sections are laid out parallel to each other, taking into account the distance between the sections. As soon as the structure is assembled with tacks, you can begin to weld all the seams by rotating the device so that welding is carried out only in a horizontal plane.

As for the installation of registers. Depending on which plane they will be attached to, it is necessary to think over the fasteners. There are several commonly used options.

If the device will be based on a floor base, then legs are installed under it. If it will be attached to the wall, then use conventional brackets with curved hooks up.

After complete assembly of the register, it must be checked for tightness of the seams. To do this, one of the drives is closed with a threaded plug, and water is poured through the second. Welds are checked. If a smudge is found, then the defective place is boiled again and cleaned. After all the operations performed, the device is stained.

Making a serpentine register is much easier. Firstly, bends are ready-made factory parts that are selected according to the diameter of the pipe section. Secondly, they are boiled among themselves in the same way as with a pipe.

First, two outlets are connected to each other. The resulting C-shaped fitting is connected in series to the ends of two pipes, combining them into a single structure. Plugs are installed in the two free ends of the register, in which holes are pre-made, and the spurs are welded.

Double-circuit boiler

Now consider the difference between the heating scheme of a country house using a double-circuit boiler.

A unit of this type differs from a single-circuit analogue in its universal purpose: it maintains the degree mode of the coolant in the heating circuit, and heats water for domestic needs. Single-circuit generators can also indirectly heat water. The process of heat transfer in them occurs during the passage of the coolant through the secondary heat exchanger.

direct transfer of thermal energy to water with large capacity and wide pipe diameter

Connection Features

A double-circuit boiler should not be designed in combination with a natural circulation system - after the heating of the coolant stops, the movement will quickly stop. The reheating process takes a long time, and the heat in the radiator is distributed unevenly. However, most models are equipped with circulation pumps.

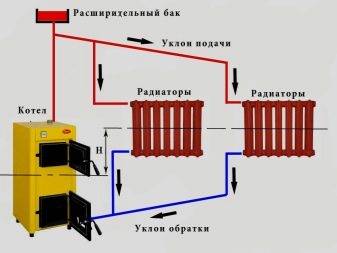

The classic version of piping boilers with a two-pipe scheme looks like this. The hot water rises into the supply pipe that surrounds the house above. Then the coolant passes through the connected risers with heating devices that do not completely open the riser. The radiators are equipped with a jumper and a choke required for heat regulation. A shut-off valve is needed on the second supply line. The air vent is attached to the top of the expansion tank circuit.

Through the lower connection of the system, the coolant is returned back. The advantage of the circuit is the ability to work in natural circulation mode. The accelerating collector will be a pipe through which the coolant moves to the top filling.

Typical connection errors

Incorrectly selected boiler power will not provide the proper level of heating.It should exceed the heat transfer parameters according to the formula 1kV x 10m2, since in cold weather heat is quickly dissipated through windows and doors. Boiler power does not affect fuel consumption. A large boiler heats the system faster and, of course, spends more resources, but it turns on less often.

Do not forget about the influx of fresh air into the room in which the boiler is located. This is necessary for the combustion process and especially for a small area.

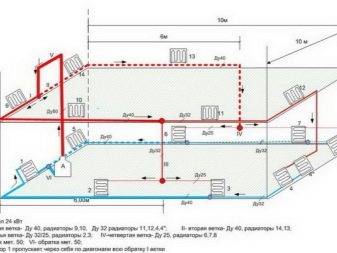

Heating system piping

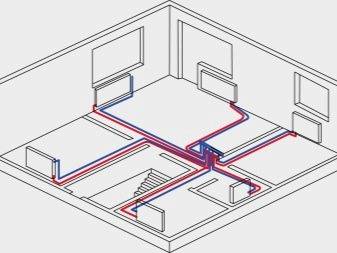

The most popular are 2 schemes: one-pipe and two-pipe. Let's take a look at what they are.

A single-pipe system is the most elementary option, however, not the most effective. It is a vicious circle of pipes, valves, automation, the center of which is the boiler. A pipe runs from it along the lower plinth to all rooms, connecting to all batteries and other heating devices.

Plus diagrams. ease of installation, a small amount of material for the construction of the circuit.

Minus. uneven distribution of coolant over radiators. Batteries in the outermost rooms will warm up worse, as the last ones in the way of water movement. However, this problem is solved by installing a pump or increasing the number of sections in the last radiators.

A two-pipe system is a more efficient way, since it solves the problem of uniform distribution of water across all heating devices. Pipes can be located at the top (this option is preferable, because then the water can circulate for natural reasons) or at the bottom (then a pump is required).

Common mistakes when tying a gas boiler

A large boiler heats water faster, which means it consumes more fuel. This is also worth keeping in mind when buying and connecting gas equipment.

Pay special attention to controlling the pressure level in the expansion tank. An incorrectly selected tank size can also adversely affect the operation of the entire system as a whole. The piping scheme for a double-circuit boiler is not an easy task

The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system

The piping scheme for a double-circuit boiler is not an easy task. The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system.

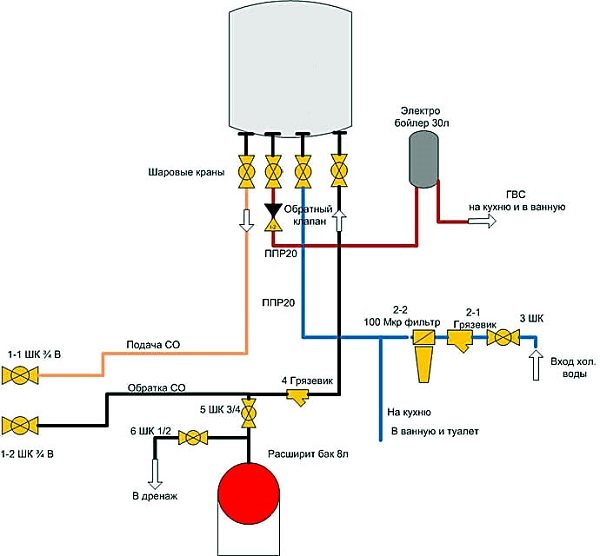

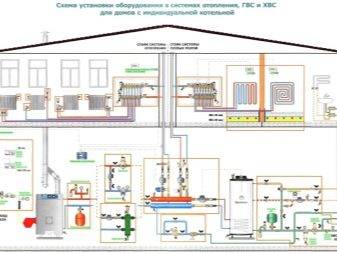

More and more owners of not only private houses, but also city apartments, not wanting to depend on communal structures, are installing autonomous heating systems in their homes, the “heart” of which is a boiler - a heat generator. But on its own, it cannot work. The heating boiler piping scheme is a set of all auxiliary devices and pipes that are connected according to a certain scheme and represent a single circuit.

Why is it necessary

- Ensuring the circulation of fluid through the system and the transfer of thermal energy to the premises in which heating devices - radiators are installed.

- Protection of the boiler from overheating, as well as protection of the home from the penetration of natural or carbon monoxide gases into it in case of emergency situations. For example, the loss of a burner flame, water leakage, and the like.

- Maintaining the pressure in the system at the required level (expansion tank).

- A properly installed gas boiler connection diagram (piping) allows it to operate stably in the optimal mode, which significantly reduces fuel consumption and saves on heating.

Main elements of the circuit

- Heat generator - boiler.

- Membrane (expansion) tank - expandomat.

- Pressure regulator.

- Pipeline.

- Stop valves (faucets, valves).

- Coarse filter - "mud".

- Connecting (fittings) and fasteners.

Depending on the type of the selected heating circuit (and boiler), there may be other components in it.

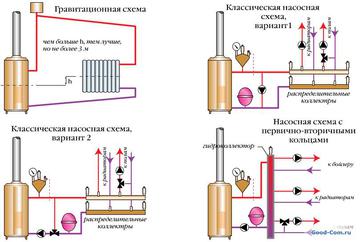

The piping scheme for a double-circuit heating boiler, like a single-circuit one, depends on many factors. These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design. But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

The piping scheme for a double-circuit heating boiler, like a single-circuit one, depends on many factors. These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design. But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

Heating circuit

The water, heated in the heat exchanger to the desired temperature, “leaves” from the boiler outlet through pipes to radiators, to which it transfers thermal energy. The cooled liquid is returned back to the inlet of the heat generator. Its movement is controlled by a circulation pump, which is equipped with almost every unit.

An expansion tank is installed between the last radiator in the chain and the boiler to compensate for possible pressure drops. There is also a “mud collector” here, which protects the heat exchanger from small fractions that can get into the coolant from batteries and pipes (rust particles and salt deposits).

A pipe insert for supplying cold water (feed) is made in the area between the boiler and the first radiator. If it is equipped on the "return", then this can cause deformation of the heat exchanger due to the temperature difference between it and the "feed" liquid.

DHW circuit

Works just like a gas stove. Cold water from the water supply system is supplied to the DHW inlet of the boiler, and from the outlet, the heated water goes through pipes to the points of water intake.

The piping scheme for wall-mounted boilers is similar.

There are a number of other types as well.

Gravity

It does not have a water pump, and the circulation of the liquid occurs due to the temperature difference at the inlet and outlet of the circuit. Such systems do not depend on the power supply. Open-type membrane tank (placed at the very top of the route).

With primary-secondary rings

In principle, this is an analogue of the already mentioned comb (collector). Such a scheme is used if it is necessary to heat a large number of rooms and connect the "warm floor" system.

There are others that do not apply to private houses. In addition, there may be some additions to the listed ones. For example, a mixer with a servo.

| Articles |

Membrane tank and radiators

An important piping element is a membrane expansion tank that allows you to protect the system from water hammer. Two cavities separated by a membrane control pressure drops: one moves the coolant, the other is filled with air.

Do not forget about the radiators, through which the heat exchange of air and hot water takes place. Pipes from polypropylene or metal. The option of working with polypropylene products has many advantages.

The advantage is ease of installation and low cost. Plaque does not form on the walls, and due to simple devices, the installation processes of the strapping are easy and simple, just like connecting pipes using polyvinyl chlorides.

Nuances for a solid fuel boiler

Choosing a place for a solid fuel boiler

Choosing a place for a solid fuel boiler

Such equipment cannot be simply turned off, like gas or electric. If a load has been made, then nothing will change until the fuel is completely burned out. Therefore, with such a strapping, it is necessary to provide protection systems. They can be of several types:

- Using tap water. To implement this option, a special device is purchased. In appearance, it resembles a heating element. It is built into the heat exchanger, some manufacturers specifically provide an additional input for such solutions. After that, running water is supplied, and the outlet pipe is lowered into the sewer. The essence of the method is that when the circulation pump stops working due to a lack of electrical energy or a breakdown, a valve opens that lets in cold water, it, passing through the coil, takes part of the temperature, and then is discharged into the sewer. The process continues until the fuel burns out completely. In some situations, this method will be ineffective, because when the light is turned off, the pressure in the water supply also disappears.

- Uninterrupted power supply unit. Various options are available today. Most of them support the connection of external batteries. The duration of operation will depend on the selected battery capacity. In this case, the pump is connected to the network through the UPS.As soon as the electrical energy disappears, a device comes into play that keeps the pump working until the power supply to the house is restored or until the batteries are discharged.

- Small gravity circuit. It implies the circulation of the carrier in a small circle, which does not need the use of a pump. It is made in compliance with all slopes and pipe diameter.

- Additional gravity circuit. This option implies the presence of two full circuits. At the same time, when an emergency situation arises and forced circulation disappears, hot water, under the influence of physical laws, continues to flow into the second circle, giving temperature to the heaters.