- Types of heating boilers on pellets: fireplaces, devices with a water circuit

- How to tie solid fuel boilers

- Using buffer capacity

- TT boiler and storage water heater

- Advantages of the polypropylene option

- What is the piping scheme for double-circuit boilers?

- Polypropylene pipes in heating systems

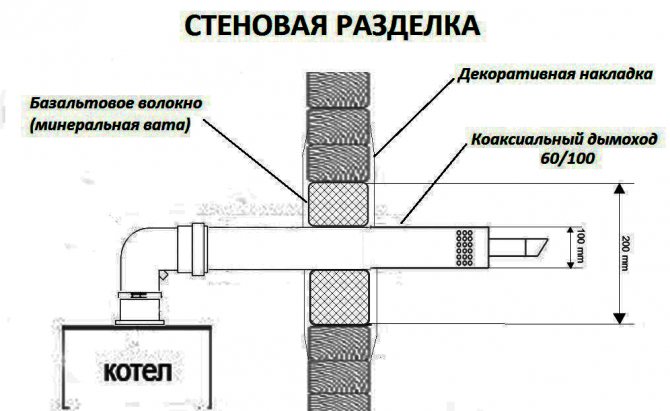

- Features of operation and installation of pellet boilers

- Radiators with bottom connection

- Bottom connection principle

- Selection and installation of radiators

- Choosing a polypropylene pipe for piping the boiler

- Advantages and disadvantages of one-pipe and two-pipe heating systems

- Single pipe heating system

- Two-pipe heating system

- What is a pellet boiler for heating a private country house

- The device of the unit and the principle of operation

- Advantages

- Flaws

- Errors when piping heating boilers.

- Heating system from polypropylene pipes

- Single pipe

- Two-pipe

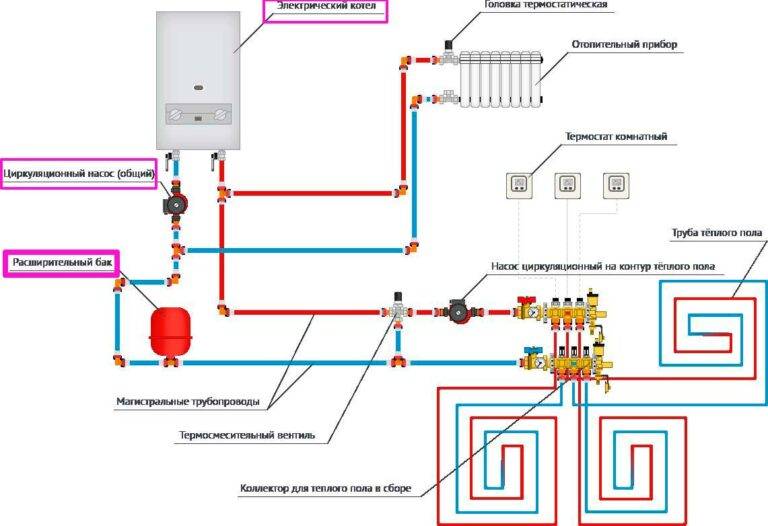

- Collector

Types of heating boilers on pellets: fireplaces, devices with a water circuit

Boilers according to the type of fuel used are:

- pellet;

- conditionally combined;

- combined.

Pellet boilers use wood pellets as fuel. The continuous operation of the pellet device is achieved due to the stable and timely supply of pellets.

Conditionally combined devices allow the use of briquettes, firewood and other raw materials. But burning alternative fuels is possible only in extreme cases. At the same time, additional details are attached to the boiler design. For example, a grate, which is installed in the firebox until the firewood is loaded.

Combined boilers use several types of fuel. This is possible due to the presence of two or more fireboxes. These devices are larger and more expensive.

According to the type of fuel supply, pellet boilers are:

- automatic;

- semi-automatic;

- with mechanical fuel supply.

Automatic pellet products work without human intervention. Simply turn on the device.

The operation of the semi-automatic device is controlled by the processor, but the power is set manually by the owner. Periodically (no more than 1 time per week) clean the ash pans. On average, this process takes 15 minutes.

The design of mechanized pellet boilers is the simplest, the devices are compact and cheaper than other models. The operation of the devices is completely dependent on the person.

Due to the small size of the hopper, you will have to load the device every 2-3 days.

According to their intended purpose, pellet boilers are divided into:

- for hot water heating models;

- for convection stoves;

- for hybrid plants.

Hot water heating boilers maintain a favorable temperature in the room and heat the water. Such equipment is suitable for small offices, private houses, cottages. But it is best to install devices in the basement or in a specially designated place.

Convection ovens-fireplaces are used to heat small rooms.They are installed in the living room, are practically silent, have a small size and attractive appearance.

Hybrid boilers look like fireplace stoves. The devices are equipped with a heating function using a water coolant. Some models have a hob and oven.

Solid fuel boilers have the following types of burners:

- torch;

- bulk combustion;

- fireplace.

Flare burners are unpretentious. They are suitable for cottages where uninterrupted operation of the device is not required. The downside is the unidirectionality of the torch fire, which locally heats the walls of the boiler.

Volumetric combustion burners are installed in industrial boilers of high power. Such devices are undemanding to the quality of the granules.

Fireplace burners are best suited for small boilers. They are not very efficient, but they are reliable.

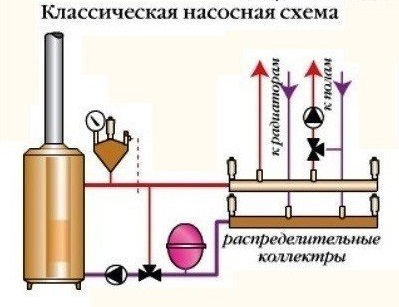

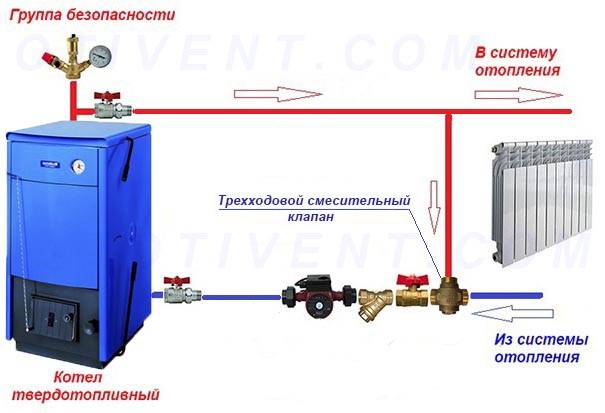

How to tie solid fuel boilers

The connection scheme for a wood-burning heat generator is designed to solve 3 tasks (in addition to supplying batteries with coolant):

- Prevention of overheating and boiling of the TT boiler.

- Protection against cold "return", abundant condensate inside the firebox.

- Work with maximum efficiency, that is, in the mode of full combustion and high heat transfer.

The presented piping scheme for a solid fuel boiler with a three-way mixing valve allows you to protect yourself from condensate in the furnace and bring the heat generator to maximum efficiency mode. How it works:

- While the system and the heater are not warmed up, the pump drives water through the small boiler circuit, since the three-way valve is closed on the side of the radiators.

- When the coolant is heated to 55-60 degrees, the valve set to the specified temperature begins to mix water from the cold "return".The heating network of a country house is gradually warming up.

- When the maximum temperature is reached, the valve closes the bypass completely, all the water from the TT boiler goes into the system.

- The pump installed on the return line pumps water through the jacket of the unit, preventing the latter from overheating and boiling. If you put the pump on the feed, the chamber with the impeller can fill with steam, the pumping will stop and the boiler is guaranteed to boil.

The principle of heating with a three-way valve is used for piping any solid fuel heat generators - pyrolysis, pellet, direct and long-term combustion. The exception is gravity wiring, where the water moves too slowly and does not provoke condensation. The valve will create a high hydraulic resistance that prevents gravity flow.

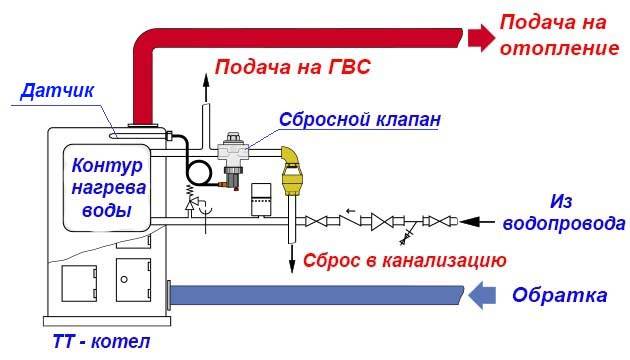

If the manufacturer has equipped the solid fuel unit with a water circuit, the coil can be used for emergency cooling in case of overheating. Note: the fuse on the safety group operates on pressure, not temperature, therefore it is not always able to protect the boiler.

A proven solution - we connect the DHW coil to the water supply through a special thermal reset valve, as shown in the diagram. The element will work from the temperature sensor and at the right time will pass a large volume of cold water through the heat exchanger.

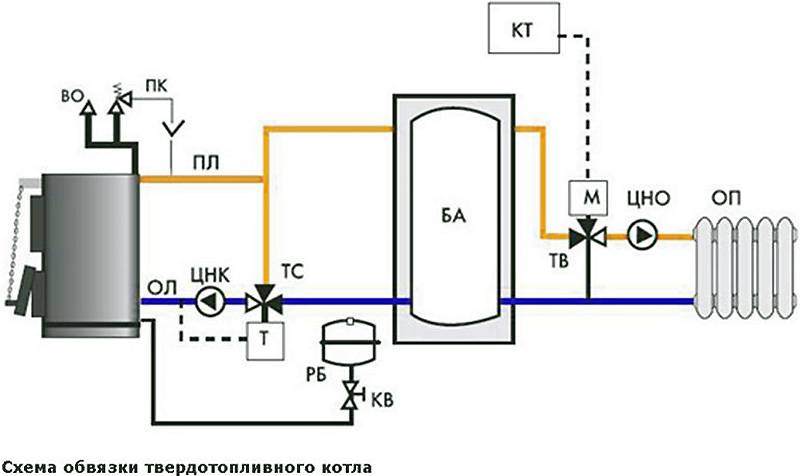

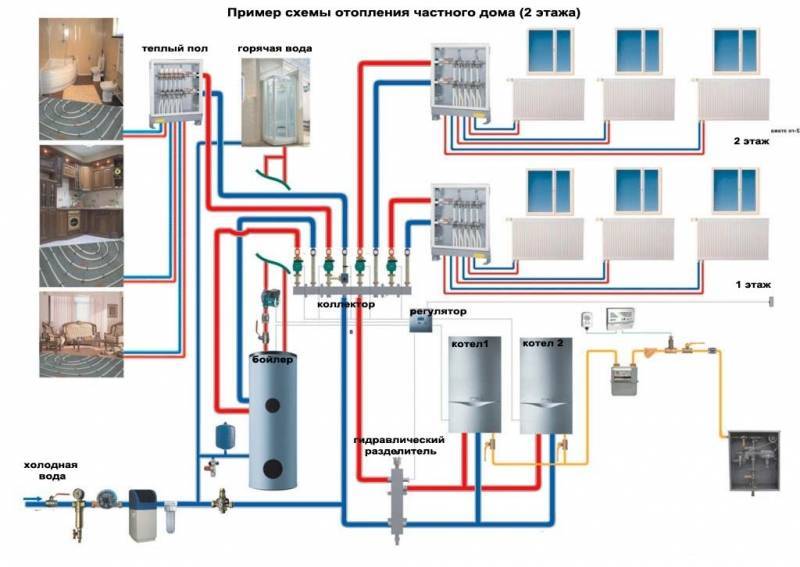

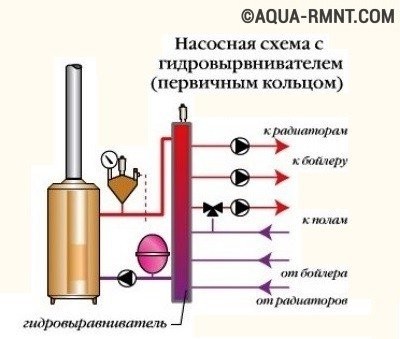

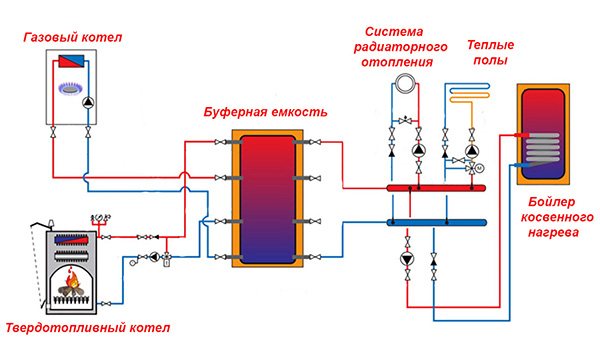

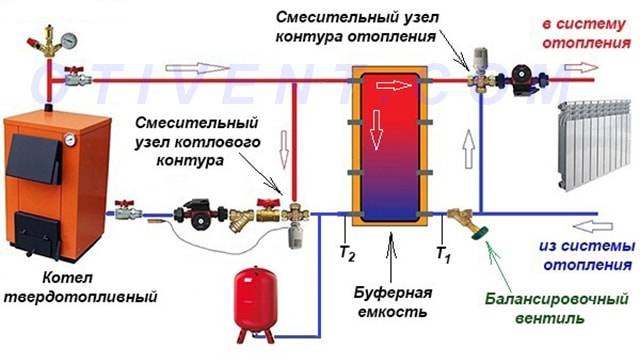

Using buffer capacity

The best way to increase the efficiency of a TT boiler is to connect it to the heating system through a buffer tank. At the inlet of the heat accumulator we assemble a proven circuit with a three-way mixer, at the outlet we put a second valve that maintains the required temperature in the batteries. The circulation in the heating network is provided by the second pump.

A balancing valve on the return line is needed to adjust the performance of the pumps

What do we gain with a heat accumulator:

- the boiler burns at maximum and reaches the declared efficiency, the fuel is used efficiently;

- the probability of overheating is sharply reduced, since the unit dumps excess heat into the buffer tank;

- the heat accumulator plays the role of a hydraulic arrow, several heating branches can be connected to the tank, for example, radiators of the 1st and 2nd floors, floor heating circuits;

- a fully heated tank keeps the system running for a long time when the firewood in the boiler burns out.

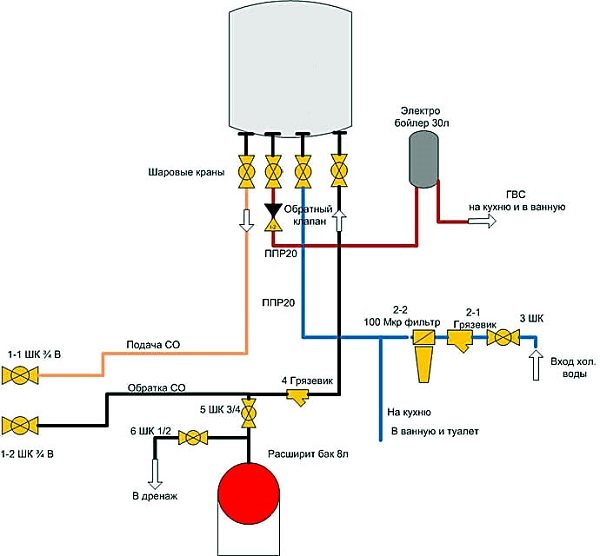

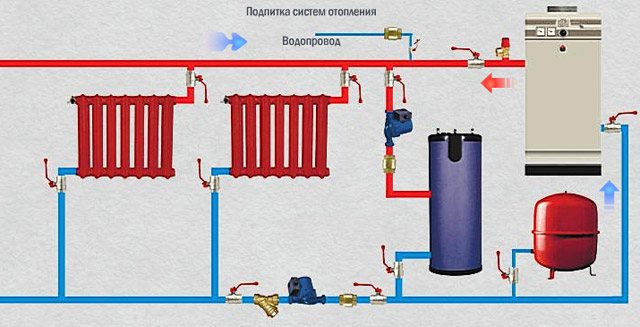

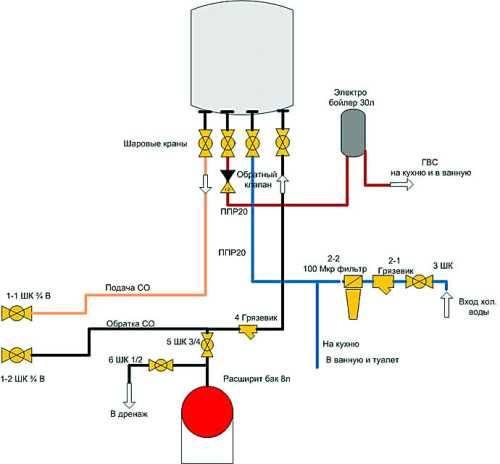

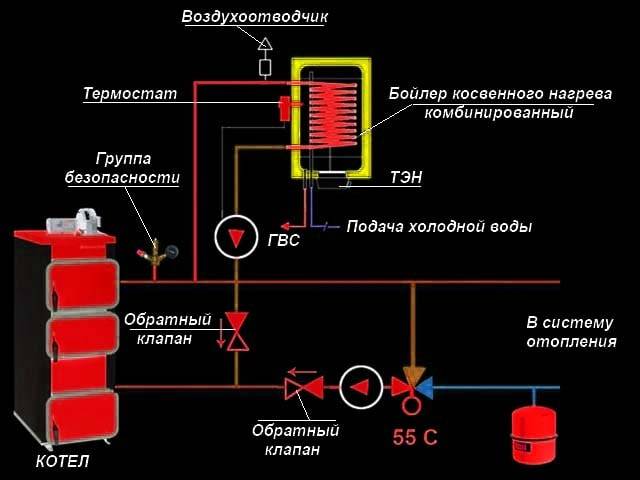

TT boiler and storage water heater

In order to load the boiler with the help of a wood-fired heat generator - “indirect”, you need to embed the latter into the boiler circuit, as shown in the picture. Let's explain the functions individual circuit elements:

- check valves prevent the coolant from flowing in the other direction along the circuits;

- the second pump (it is enough to take a low-power model 25/40) circulates through the spiral heat exchanger of the water heater;

- the thermostat turns off this pump when the boiler reaches the set temperature;

- an additional air vent prevents the supply line from being aired, which will be higher than the regular safety group.

In a similar way, you can dock the boiler with any boiler that is not equipped with an electronic control unit.

Advantages of the polypropylene option

Polypropylene is widely used for the manufacture of strapping, which is explained by its significant advantages, such as:

- Ease of installation - for its implementation you need a special soldering iron and a supply of keys.

- The speed of work - the wiring of the heating system of the whole house is made in 1-7 days.

- Heat resistance - is provided by a layer of thermal fiber, which creates a kind of frame and protects the pipe from expansion when the coolant passes through.

- Minimum thermal conductivity, as a result of which the heat supplied from the boiler to the radiator is not lost.

- Resistance to deposits - due to the smoothness of the inner surface of the pipes, which is also responsible for the rapid circulation of the coolant.

- Long service life, which is 40 years. The material can withstand pressure up to 25 atmospheres.

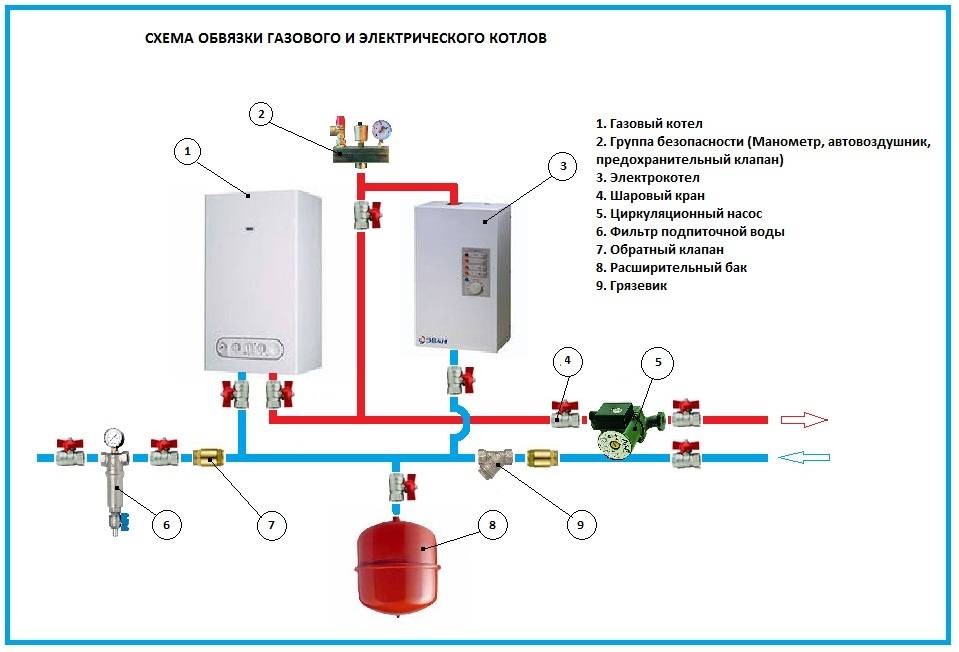

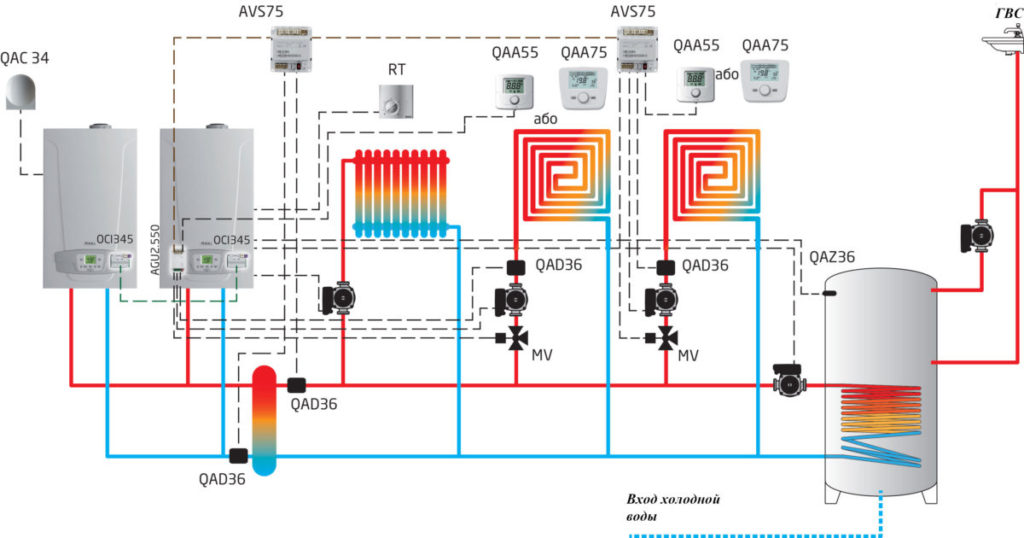

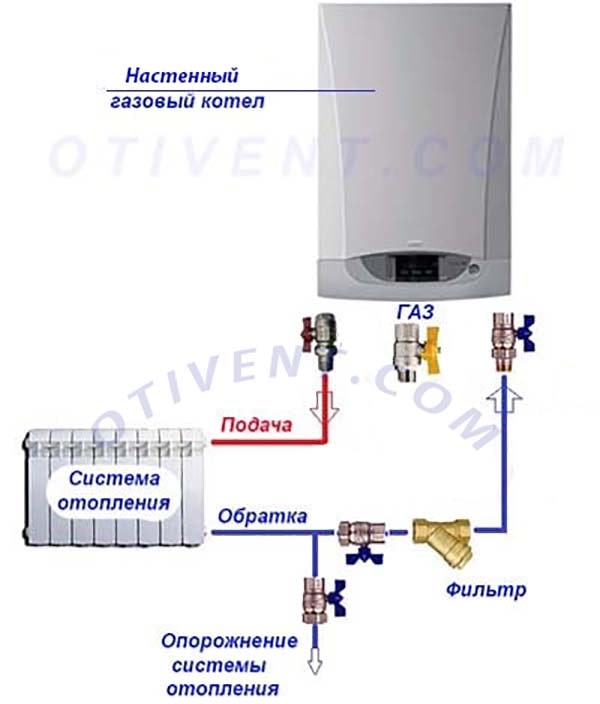

What is the piping scheme for double-circuit boilers?

We plan to install a double-circuit gas boiler in the house. What are the schemes, how to choose? Does it affect the schema? turbocharged gas boiler or chimney? What influences the choice of scheme?

The connection scheme for all types of double-circuit boilers is the same, since both the turbocharged and the chimney boiler have the same location of the nozzles for connecting the boiler to heating, water supply and gas systems.

Before starting the connection, it is imperative to mount a coarse filter. This will prevent debris from entering the boiler. A shut-off valve should be installed on the boiler return, which is necessary in order to eliminate the need for airing the coolant in the heating system. The valve must be mounted on a detachable connection so that it can be removed if necessary.

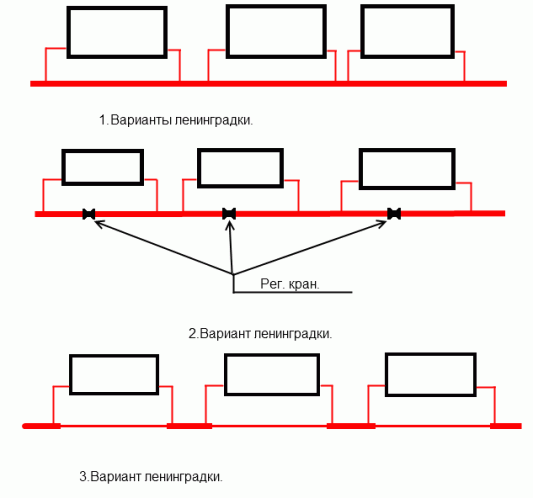

The choice of scheme is influenced by the number of storeys of the house and the amount of area that needs to be heated. The simplest scheme is a single-pipe or Leningradka used for a one-story house.

Here's what such a scheme looks like:

The numbers from 1 to 9 indicate the ball valves installed in the cold (1) and hot (2) water supply systems, on the supply (3) and return (4) heating pipes, to drain the coolant (5 and 6), on the heat supply return ( 8 and 9). The rest of the numbers indicate the drive (10), the magnetic filter (11) and the gas filter (12).

A more complex scheme is a two-pipe one, when the boiler will heat either the coolant or hot water, but in no case not at the same time. It is used for two-story houses with a large number of rooms. From the boiler, heated water or coolant is sent to the supply pipeline, which should be located in the attic or in the risers supplying heat, and on each radiator jumper and control choke are installed. Through the lower pipeline, which serves to remove the coolant, it returns to the boiler.

The connection diagram also includes the installation of boiler piping, which may vary depending on the type of boiler and heating system. The binding is arranged with automatic circulation or natural.

Polypropylene pipes in heating systems

Fittings and pipes made of polypropylene (PPR) are popular due to their low cost and ease of installation. They are not subject to corrosion, have smooth inner walls and serve at least 50 years declared by the manufacturer.

There are several types of these tubular products, which differ in technical characteristics and purpose.

In the construction of heating systems, as well as in the device of DHW circuits close to them in terms of operational parameters, they use:

- Pipes marked PN 25. Products with reinforcement made with aluminum foil. They are used in systems with nominal pressure up to 2.5 MPa. Operating temperature limit +95º С.

- Pipes marked PN 20. A reinforced version used in the DHW branches of double-circuit heating boilers. They will work out the period declared by the manufacturer, if the temperature of the coolant is not higher than + 80º C, and the pressure is up to 2 MPa.

- Pipes marked PN 10. Thin-walled polymer products. They are used if the boiler supplies the coolant to the water floor heating system. Working temperature is not higher than +45º С, nominal pressure is up to 1 MPa.

Polymer pipes are suitable for all known laying methods: open and hidden. But this material has a high coefficient of thermal expansion. When heated, such products begin to slightly increase in length. This effect is called thermal linear expansion, it must be taken into account when constructing pipelines.

tie the cauldron followed by polypropylene pipes, which in the marking have an operating class of 5, an operating pressure of 4–6 atmospheres and a nominal pressure PN of 25 and higher

To prevent the destruction of polypropylene heating pipelines, compensation loops can be installed. But it is easier to take multilayer pipes, the reinforcement in which is specifically designed to compensate for this stretch. A layer of foil inside polypropylene pipes PN 25 reduces their thermal elongation by half, and fiberglass by all five times.

Image gallery

Photo from

Large Diameter PP Pipe Welding Machine

Features of welding wide plastic pipes

Connection of narrow polypropylene pipes

Apparatus for connecting small diameter PP pipes

Features of operation and installation of pellet boilers

Although pellet boilers are classified as solid fuel equipment, they are an order of magnitude better than traditional units that burn wood or coal, because:

- dry pellets burn, giving off much more heat, which significantly increases the efficiency of the unit;

- in the process of work, a minimum amount of fuel combustion products is produced;

- loading pellets into the bunker is carried out much less frequently than when using firewood or coal.

This effect is achieved due to the special design of the equipment, as well as through the use of highly efficient pyrolysis combustion processes. An important point in operation of the pellet boiler is the moisture content of the fuel, which must be less than 20%. If this requirement is not met, the capacity of the equipment will subsequently decrease and condensed moisture will enter the system. And this can very soon lead to serious damage to the equipment.

There are combined pellet boilers in which there are two fireboxes: one for burning pellets, the other for conventional solid fuels. The efficiency of such units is somewhat lower than that of boilers that operate only on pellets, and the requirements for installation and piping remain quite high.

During the installation of a pellet boiler, it is necessary to install a bunker, a burner and a screw mechanism for feeding pellets. Often, experts also recommend using a special buffer tank, the volume of which can be 50 liters per kW of pellet boiler power. All this significantly increases the size of the boiler room, in which the installation and piping of the equipment will be carried out.

Radiators with bottom connection

You can hide bulky pipes if you make heating with a bottom connection. Of course, standard systems are more familiar to understanding when the coolant enters from above or from the side and exits down.But such a system is rather unaesthetic, and it is difficult to cover it with a screen or somehow ennoble it.

Bottom connection principle

With a lower connection, the main part of the pipes is hidden under the floor covering, sometimes there are difficulties in seasonal inspection or preventive maintenance. But there are also pluses - this is a minimum of complex bends or joints, which reduces the risk of leaks or accidents.

The connection diagram for heating radiators with a lower type is simple - the return and coolant supply pipes are located nearby, in the lower corner of the radiator. It is also allowed to connect pipes from different sides of the radiator. The upper holes (if any) are screwed with a plug.

The radiator installation kit is identical to the standard one:

For bottom connection, it is best to use bimetallic radiators. they are strong, durable, have excellent heat dissipation due to heating, radiation and convection. Even when using the bottom connection, heat loss will not exceed 15 percent. Due to the supply of hot coolant from below, the bottom of the battery heats up and heats up the top by convection.

Selection and installation of radiators

For the bottom connections recommend bimetal radiators heating, they are easy to assemble, install and repair. Radiator sections can be removed, added or replaced if damaged.

When buying, it is better to give preference to domestic manufacturers, it is important to check the integrity of the battery and packaging. Documentation should be understandable and written in Russian. Before installation, you need to make a markup

it is done with a pencil on the wall.In this case, the points where the brackets will be installed are marked. The bottom of the radiator must be at least 7 cm from the floor and 10 cm from the window (if located under the window). Distances are maintained so that the air in the room circulates freely. The distance to the wall should be about 5cm

Before installation, you need to make a markup. it is done with a pencil on the wall. In this case, the points where the brackets will be installed are marked. The bottom of the radiator must be at least 7 cm from the floor and 10 cm from the window (if located under the window). Distances are maintained so that the air in the room circulates freely. The distance to the wall should be about 5 cm.

For more efficient circulation of the coolant, heating radiators are installed with a slight slope. this excludes the accumulation air in the heating system.

When connecting, it is important to follow the markings and not confuse the return and supply. If connected incorrectly, the heating radiator can be damaged, and its efficiency will decrease by more than 60 percent. There are the following types of bottom connection:

There are the following types of bottom connection:

- one-way connection - the pipes come out from the corner below and are located side by side, heat loss can be about 20 percent;

- versatile piping - pipes are connected from different sides. such a system has more advantages, since the length of the supply and return lines is less, and circulation can occur from different sides, heat losses are up to 12 percent;

A top-down connection is also used. but in this case it will not be possible to hide all the heating pipes, since the coolant will be supplied in the upper corner, and the output will be from the opposite lower corner.If the heating radiator is closing, then the return line will be brought out from the same side, but from the lower corner. In this case, heat losses are reduced to 2 percent.

If you plan to connect heating radiators with your own hands, it is important to follow the installation and safety techniques. The coolant during installation or repair must be drained, the batteries are cold. If in doubt, it is better to call the master or use the training video tutorial, since with a lower connection it will be difficult to repair the sections

It is better to plan a heating system with bottom heating together with the layout of the house

If in doubt, it is better to call the wizard or use the training video tutorial, since with a lower connection it will be difficult to repair the sections. It is better to plan a heating system with bottom heating together with the layout of the house.

Choosing a polypropylene pipe for piping the boiler

The choice of pipe type depends on its purpose, namely, on the pressure of the coolant and its temperature:

- PN10 pipes - used in cold water supply systems with water temperatures up to +20 degrees, as well as in the installation of underfloor heating with a working environment temperature not higher than 45 degrees; this is a thin-walled version of pipes that can withstand pressure within 1 MPa;

- PN16 pipes - used in the distribution of cold water pipelines with increased pressure in the system, as well as in central heating pipelines with reduced pressure in the system;

- pipes PN20 - universal products used for both cold and hot water supply (with a temperature in the system up to +80 degrees); withstand a nominal pressure of 2 MPa;

- pipes PN25 - products reinforced with aluminum foil reinforcement and used in the installation of hot and cold water supply pipelines with a nominal pressure of up to 2.5 MPa.

If you have an oil-fired boiler, the article on universal oil-fired burners will come in handy.

Propylene pipes have a different structure:

Reinforcement with solid aluminum sheet and perforated aluminum sheet. It is applied to the outer surface of the pipe.

- Aluminum reinforcement is located between the inner and outer layer of polypropylene.

- Fiberglass reinforcement is also produced between the layers of polypropylene.

- Composite reinforcement is a mixture of polypropylene and fiberglass.

The most suitable type of polypropylene for heating are pipes with composite reinforcement.

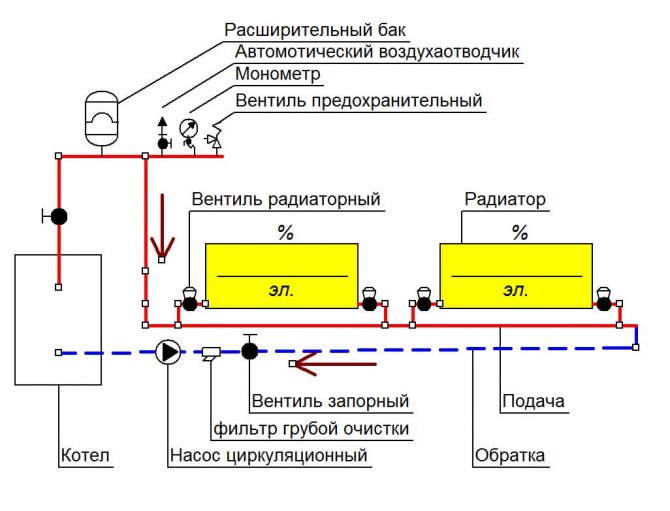

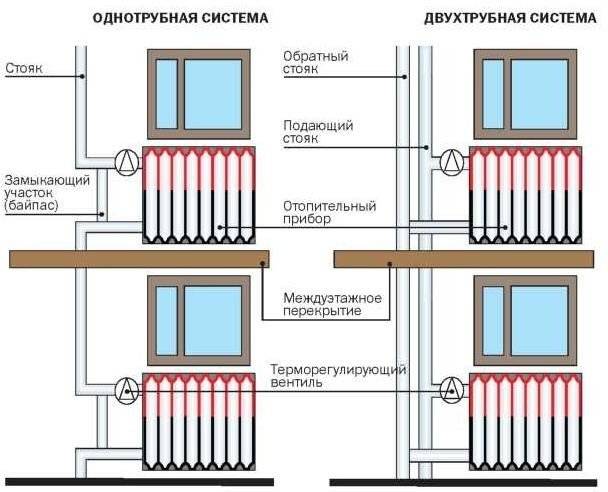

Advantages and disadvantages of one-pipe and two-pipe heating systems

The main difference between the two heating schemes is that the two-pipe connection system is more efficient in operation due to the parallel arrangement of two pipes, one of which supplies the heated coolant to the radiator, and the other drains the cooled liquid.

The scheme of a single-pipe system is a series-type wiring, in connection with which the first connected radiator receives the maximum amount of thermal energy, and each subsequent one heats up less and less.

However, efficiency is an important, but not the only criterion that you need to rely on when deciding to choose one or another scheme. Consider all the pros and cons of both options.

Single pipe heating system

- ease of design and installation;

- savings in materials due to the installation of only one line;

- natural circulation of the coolant, possible due to high pressure.

- complex calculation of thermal and hydraulic parameters of the network;

- the difficulty of eliminating errors made in the design;

- all elements of the network are interdependent; if one section of the network fails, the entire circuit stops working;

- the number of radiators on one riser is limited;

- regulation of the flow of coolant into a separate battery is not possible;

- high coefficient of heat loss.

Two-pipe heating system

- the ability to install a thermostat on each radiator;

- independence of the network elements;

- the possibility of inserting additional batteries into an already assembled line;

- ease of elimination of errors made at the design stage;

- to increase the volume of coolant in heating devices, it is not necessary to add additional sections;

- no restrictions on the length of the contour along the length;

- the coolant with the desired temperature is supplied throughout the entire ring of the pipeline, regardless of the heating parameters.

- complex connection scheme compared to single-pipe;

- higher consumption of materials;

- installation requires a lot of time and labor.

Thus, a two-pipe heating system is more preferable in all respects. Why do the owners of apartments and houses refuse it in favor of a one-pipe scheme? Most likely, this is due to the high cost of the installation and the high consumption of materials necessary for laying two highways at once. However, one should take into account the fact that a two-pipe system involves the use of pipes of a smaller diameter, which are cheaper, so the total cost of arranging a two-pipe option will not be much more than a single-pipe one.

The owners of apartments in new buildings are lucky: in new houses, in contrast to residential buildings of Soviet development, a more efficient two-pipe heating system is increasingly being used.

What is a pellet boiler for heating a private country house

A pellet boiler is a type of solid fuel boiler that works by using special combustible granules - pellets. Pellet fuel has a number of advantages:

- Low cost.

- Convenient storage. Combustible pellets do not take up much space. Their length is 7 cm, and their diameter is 5-10 mm.

- A few bags of fuel will last all winter.

Photo 1. Pellet boiler installed indoors. A supply of pellets for burning in the device is stored nearby.

The device of the unit and the principle of operation

The pellet boiler consists of 3 elements:

- from a container equipped with a burner for burning fuel;

- from the convective system in which the heat exchanger is located;

- from a bunker containing a tank for combustion waste.

For the operation of the device, an attachment is required that provides timely fuel supply. The pellet boiler is equipped with a control unit, with the help of which the parameters of the device are set.

The heat exchanger is made of steel or cast iron. Foreign manufacturers prefer to use cast iron. Rust does not appear on it, but this material does not respond well to temperature changes and weighs a lot. In Russia, models are equipped with steel heat exchangers. They quickly react to temperature changes, weigh little, but are prone to corrosion. Therefore, most manufacturers cover the boilers with an anti-corrosion compound.

Pellets are fed into the boiler furnace, where they are completely burned. Due to this, the coolant is heated, which distributes heat throughout the room.

The pellet feed time depends on the size of the hopper. Periodically, it is required to clean the channels from accumulated emissions.

Advantages

- The operation of the device is safe for the environment. Combustion materials do not contain impurities.

- The unit is economical. Pellets in the boiler burn out completely and are consumed in a minimal amount.

- The range of solid fuel boilers is diverse.

- The operation of the device is automated.

- With proper maintenance, the boiler will last for many years.

Flaws

- High price. Although the pricing policy of many manufacturers is democratic, not everyone can afford to buy a pellet boiler.

- Some models of pellet boilers are powered by electricity, so you should take care of the power source or generator in advance.

Errors when piping heating boilers.

Attention: Incorrectly calculated boiler power will not be able to provide the proper level of heating. The power must exceed the heat transfer parameters according to the formula 1kV x 10m2, since in cold weather heat is quickly vented through windows and doors. A large boiler will be able to heat the system faster and, of course, will consume more resources, but it will turn on less often

You should also not forget about the inflow of fresh air into the room in which the boiler operates, this is necessary for the combustion process and especially for a small area

A large boiler will be able to heat the system faster and, of course, will consume more resources, but turn on less often.You should also not forget about the influx of fresh air into the room in which the boiler operates, this is necessary for the combustion process and especially for a small area.

Conclusion: Competent installation and accuracy of calculations heating boiler power will help to create maximum comfort for living in a country house at any time of the year.

Heating system from polypropylene pipes

The technical characteristics of the object and the amount of allocated funds affect the heating installation scheme. In apartments of multi-storey buildings, it is connected to the central heating system, and in private houses - to an individual boiler. Regardless of the type of object, the system can have one of three versions.

Single pipe

The system is characterized by simple installation and quantity of materials. It mounts one pipe for supply and return, which reduces the number of fittings and fasteners.

It is one closed circuit with alternate vertical or horizontal placement of radiators. The second type is used specifically in private homes.

When passing through each the radiator at the coolant temperature decreases. Therefore, a single-pipe circuit is not able to evenly heat the entire object. There is also the difficulty of temperature control, since the heat loss factor is not taken into account.

If the radiators are not connected through valves, then when one battery is repaired, the heat supply is stopped throughout the facility. When arranging such a network in a private house, an expansion tank is connected. It allows you to compensate for changes in pressure in the system.

The single-pipe circuit allows the installation of radiators with temperature controllers and thermostatic valves to correct heat loss.Ball valves, valves and bypasses are also installed for the repair of individual sections of the thermal circuit.

Two-pipe

The system consists of two circuits. One is for submission and the other is for return. Therefore, more pipes, valves, fittings, consumables are installed. This increases installation time and budget.

The advantages of a 2-pipe network include:

- Uniform distribution of heat throughout the facility.

- Minimum pressure loss.

- Possibility of installing a low power pump. Therefore, the circulation of the coolant can occur by gravity.

- Repair of a single radiator is possible without shutting down the entire system.

The 2-pipe system uses a passing or dead-end scheme for the movement of the coolant. In the first case, it is allowed to install batteries with the same heat output or radiators with different capacities, but with thermostatic valves.

A passing scheme is used if the thermal circuit is long. The dead-end option is used for short highways. When installing a 2-pipe network, it is necessary to install radiators with Mayevsky taps. The elements allow air to be expelled.

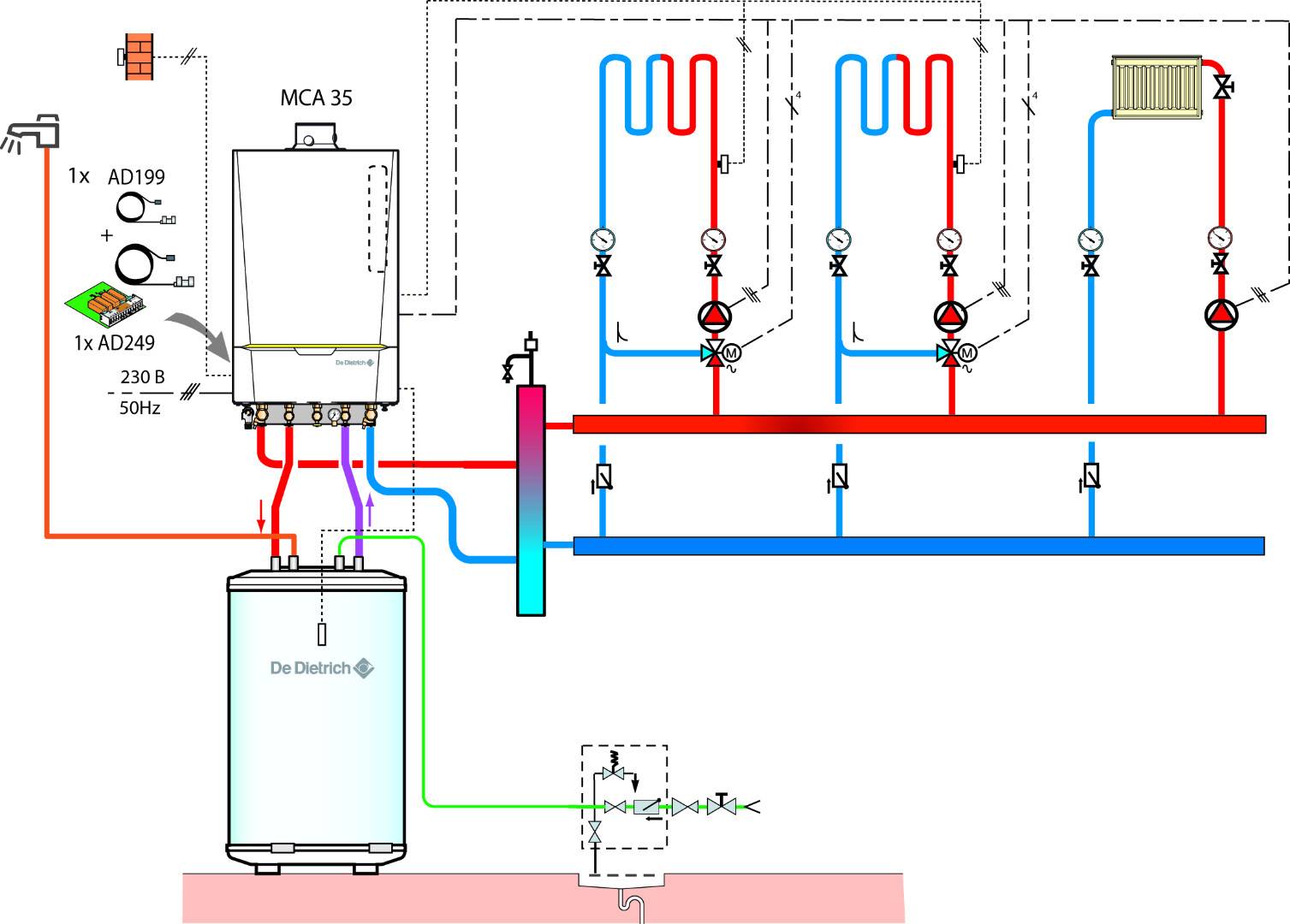

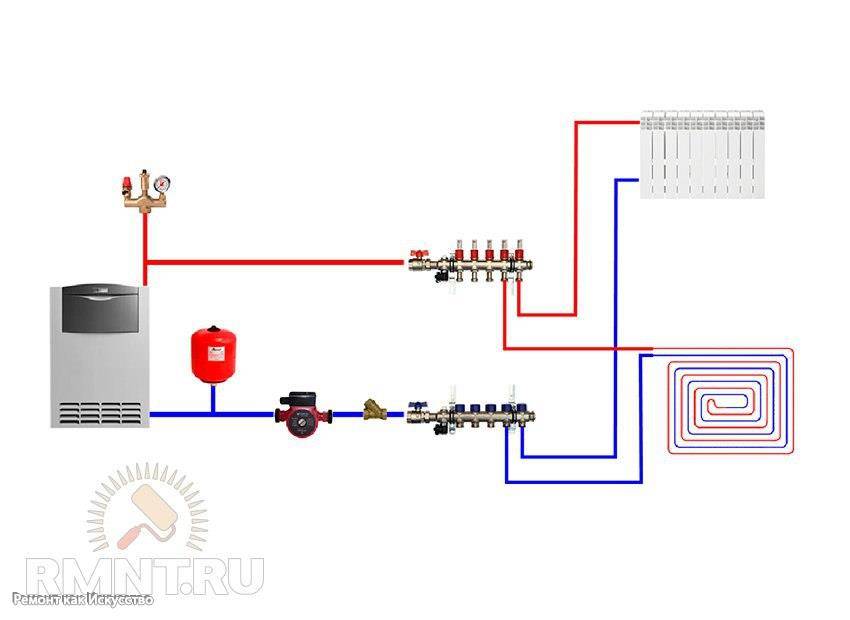

Collector

This system uses a comb. It is a collector and is installed on the supply and return. This is a two-pipe heating circuit. A separate pipe is mounted, both for supplying coolant to each radiator, and for returning cooled water.

The system may consist of many circuits, the number of which depends on the number of batteries.

When constructing a collector thermal circuit, expansion tank installation. It contains at least 10% of the total volume of coolant used.

During installation, a manifold cabinet is also used.They try to place it at an equal distance from all batteries.

Each circuit in the manifold system is a separate hydraulic system. It has its own shut-off valve. This allows you to turn off any of the circuits without stopping the operation of the entire system.

Collector

Collector

Advantages of the collector network:

- It is possible to regulate the heating temperature of any of the heaters without prejudice to the rest of the batteries.

- High efficiency of the system due to the direct supply of coolant to each radiator.

- It is possible to use pipes with a smaller cross section and a less powerful boiler due to the high efficiency of the system. Therefore, the costs for the purchase of equipment, materials and network operation are reduced.

- Simple design process, no complicated calculations.

- Possibility of underfloor heating. This allows you to create a more aesthetic interior, as there is no need to install traditional batteries.

For the device of the collector system, a large number of pipes, fittings and valves will be required. You will also need to purchase combs, a circulation pump, an expansion tank and a cabinet for collectors.

A large number of elements increases the complexity of the installation process. Installation of batteries is carried out together with Mayevsky cranes to prevent airing of each of the circuits.