- But how is the installation of ventilation equipment at industrial facilities?

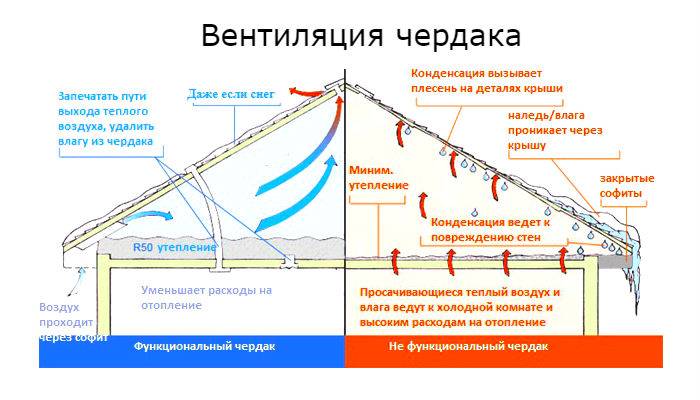

- Condensation accumulation

- Warming up and warming the dressing room

- Features of supply and exhaust ventilation

- Features of work

- Channelless forced ventilation

- Advanced wall valve

- Breezer - compact ventilation unit with climate control

- Fresh air conditioners

- Conclusions and useful video on the topic

But how is the installation of ventilation equipment at industrial facilities?

It is almost impossible to install the entire system as correctly and reliably as possible if this procedure is carried out by a person who does not know all the nuances and subtleties, and also does not have in his arsenal all the parts and devices necessary for these purposes. That is why the ventilation in the basement must be created by professional, experienced and equipped with all the necessary specialists.

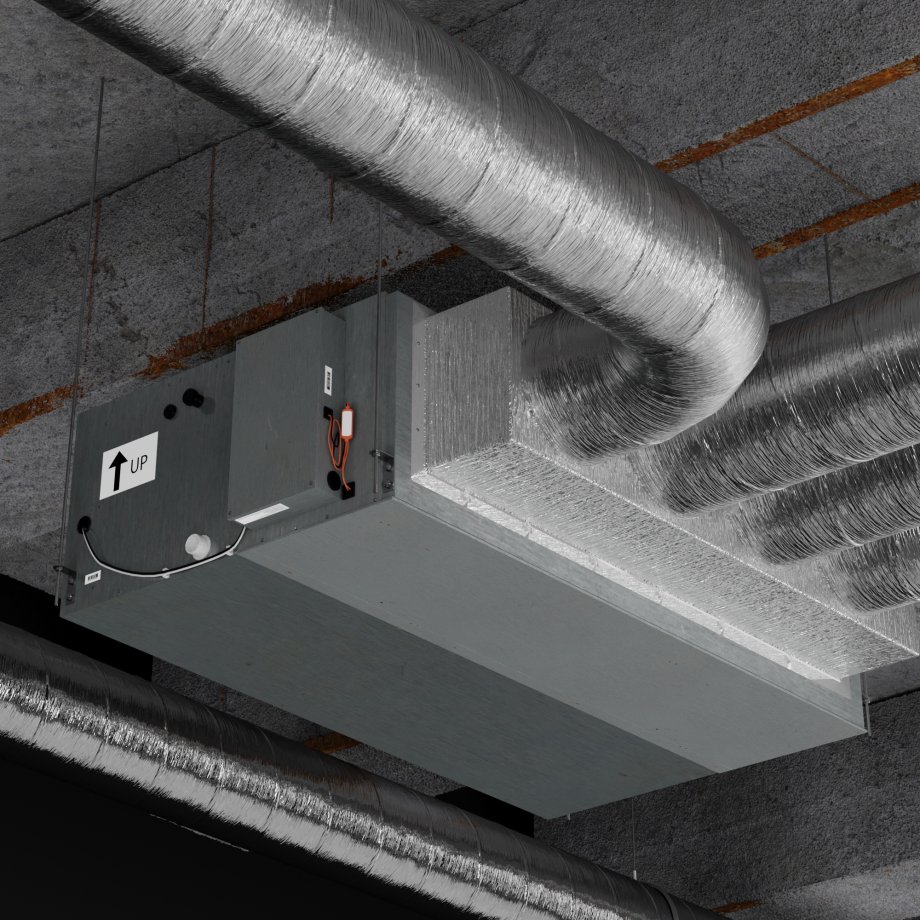

Installation of ventilation

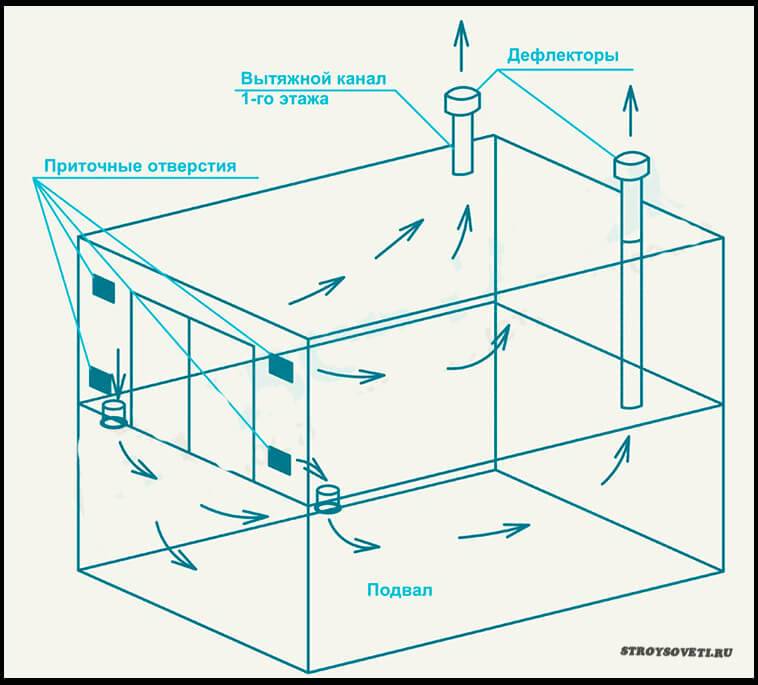

The design and construction process first of all involves determining the location of the main components of the ventilation system: the mechanical parts of the air outlet, the air intake fan, the filtration system, the distribution network responsible for air circulation (this element is the most difficult to install) and the heater.

Condensation accumulation

Warm and humid air tends to settle and accumulate on the ceiling. As a result, it has an adverse effect on the ceiling itself, and when the temperature drops, it begins to "move" to the floor and walls. To avoid such problems, special exhaust systems or systems for natural ventilation should be installed. The last point should be equipped with insulation and trays for draining accumulated condensate.

It is not forbidden to recirculate oxygen. For example, heating incoming oxygen with used. The main thing is to observe the norms of oxygen for each person. Otherwise, the hall will become warmer and warmer, up to the heat.

As mentioned above, one of the main problems of any gym is the accumulation of condensate due to non-compliance with temperature standards and recommendations for humidity levels. A similar problem can arise not only due to a large crowd of people in a small space, but also due to the use of "wrong" air circulation systems in relation to the interior material of a sports facility. So, if the gym is equipped with wooden structures, the relative humidity should be at least 40-45%. If metal, leather or other materials are used, the humidity must be maintained in the region of 35-60%.

The lower limit of these values refers to the cold seasons, the upper - to warm. Of course, in autumn or winter, such values \u200b\u200bare impossible to achieve, therefore additional moisture is required. Separate humidifiers or air conditioners will help to cope with this. The main thing is that the devices can not only increase humidity, but also reduce it if necessary.

Warming up and warming the dressing room

Between the locker room / lounge on the one hand, and the steam room on the other, ideally, a smooth transition between temperature conditions is left.

There are four options to achieve this:

- The stove goes into both rooms.

- An additional partition between the steam room and the dressing room, combined with a rest room.

- Part of the heated air is supplied from the steam room.

- On the direct path from the dressing room to the steam room there is a washing room.

You also need to take care of the insulation of the room. From the cold isolate the floor, walls and ceiling. Often they take foil insulation, but foil should be laid manually on a thick layer.

Mineral wool, polystyrene foam and other foamed materials, as well as expanded clay, are suitable for warming the dressing room, but mineral wool will be the best in terms of structure, especially if it is foil

Mineral wool, polystyrene foam and other foamed materials, as well as expanded clay, are suitable for warming the dressing room, but mineral wool will be the best in terms of structure, especially if it is foil

Warming of the floor begins with the fact that smaller cranial bars are nailed to the lower parts of the log, located in increments of 45-55 cm - longitudinally to the base. A rough coating is placed on top - oblong or wide boards. The draft floor is formed solid.

The resulting structure is covered with a waterproofing membrane. Lay so as to completely press the layer against the protruding lags. Then, in the gap between these strips, a proportionate piece of insulation is laid: a little larger in width, length and height. Mineral wool is also suitable as thermal insulation. It is taken more, as the material is highly compressed.

A vapor barrier is laid above with a slight approach to the walls. In the process, pipes are insulated, which will be in the thickness of the floor or below.

It remains only to make the floor itself. The surface can be paved with tiles or boards. Usually wood is chosen, this is how a warm floor is obtained and the unity of the interiors is preserved. The coating must be made continuous, moving the boards as close as possible to each other.

Under the ceiling, the finish deteriorates the most, so use a thick layer of insulation. Thermal insulation can be assembled on the floor, between the planks. Put a vapor barrier at the bottom, a heater above, then waterproof it. From above you can cover with a cement screed and wooden boards.

You can read more about ceiling insulation in this material.

Option for thermal insulation of the ceiling above the dressing room: densely laid expanded clay, hidden in two layers of vapor barrier, and a wooden plank floor without screed

Option for thermal insulation of the ceiling above the dressing room: densely laid expanded clay, hidden in two layers of vapor barrier, and a wooden plank floor without screed

Log houses can be insulated in a finished building, but thermal insulation should be planned in advance. It is also worth taking care of the insulation of the front door.

Due to thermal barriers, they effectively fight excess moisture, but condensation can be completely avoided if certain things are constantly done. Keep doors closed, open only for a short time. Adjust the shutters in the ventilation grilles.

Use plugs and first of all during warming up. After the procedures, cool the dressing room through open doors and windows. Make short drafts at the same time. Ventilate each room in turn - through their windows.

Features of supply and exhaust ventilation

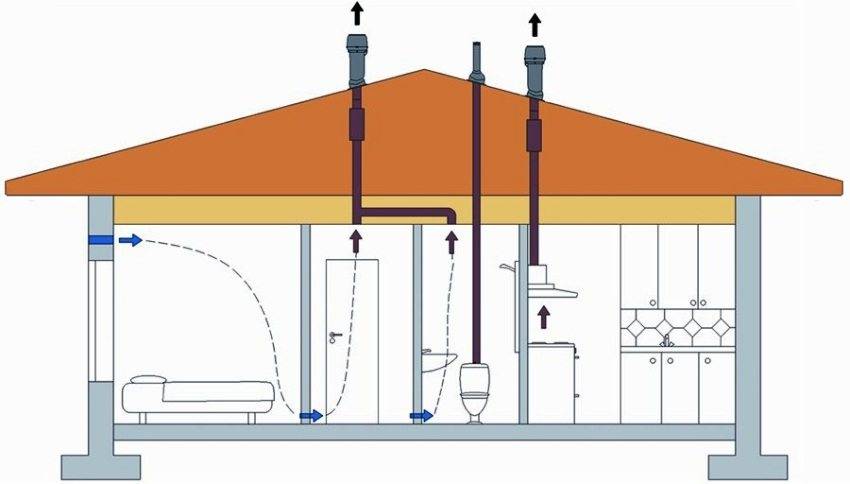

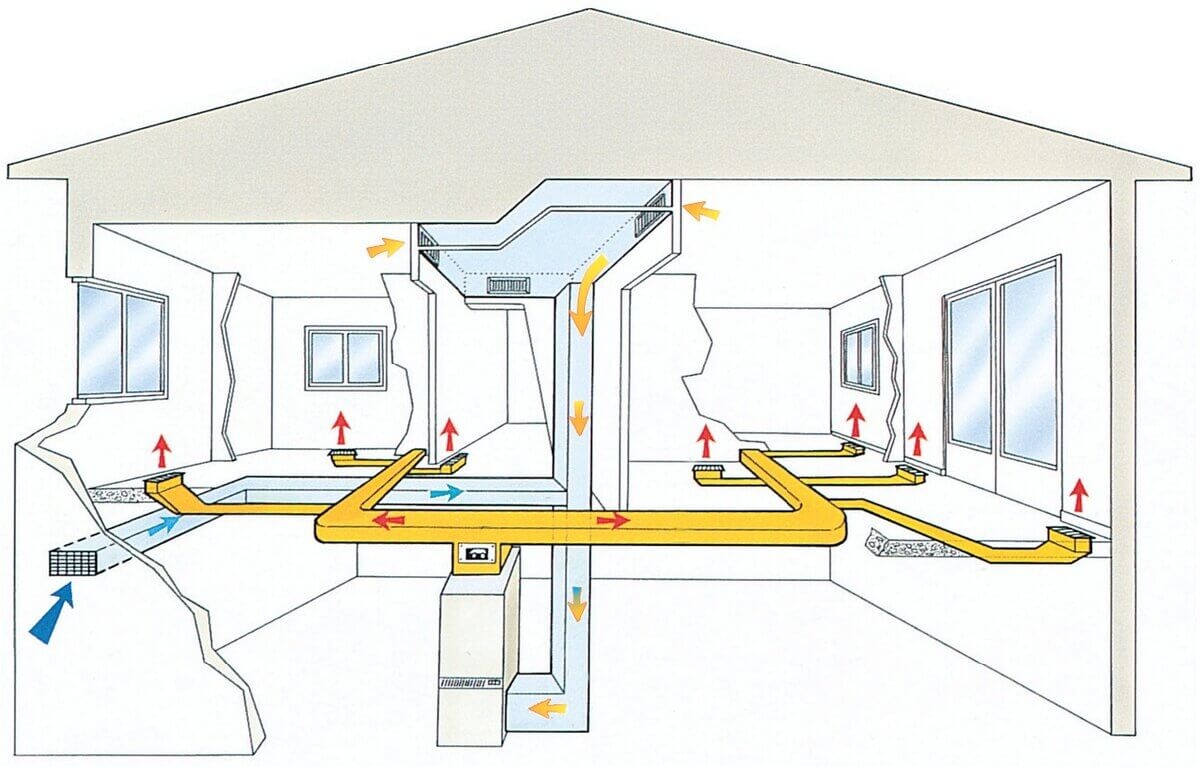

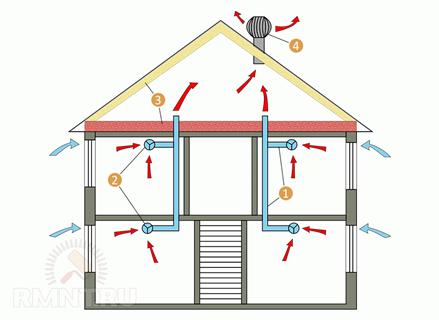

Supply and exhaust ventilation interacts with two air flows of different composition and purpose, which are subsequently processed.

In the PVV, all the necessary equipment and additional systems are placed in a single frame, which can be installed inside the loggia, in the attic, on the wall outside the house, etc.

The special design of the unit provides ample opportunities for ventilation of almost any number of rooms in the building.

In addition to the main function of moving air, supply and exhaust ventilation includes the following arsenal of auxiliary subsystems and additional functions.

Among which are the following:

- air cooling and heating;

- ionization and humidification of particles;

- disinfection and air filtration.

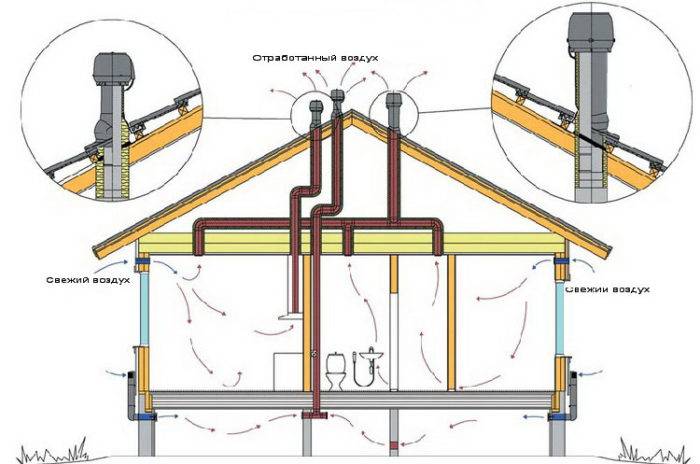

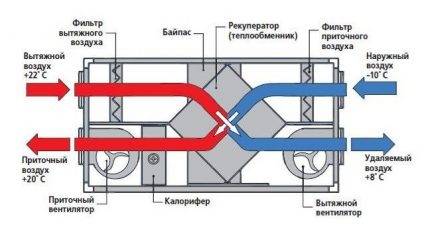

Consider a typical operating cycle of a supply and exhaust ventilation system, which is based on a two-circuit transportation model.

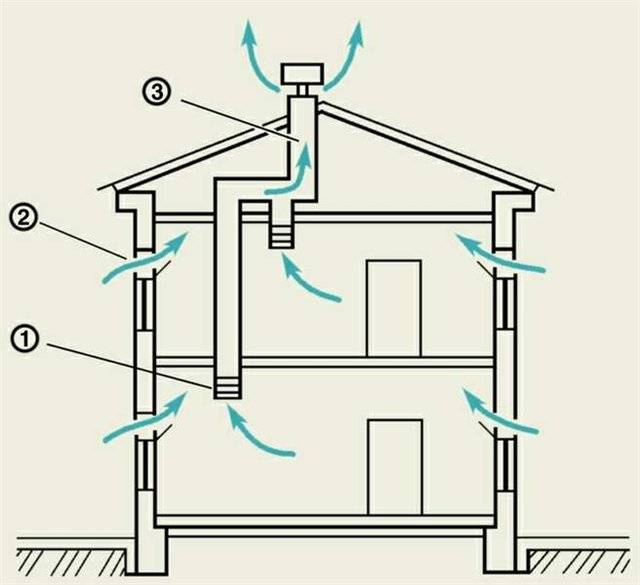

At the first stage, cold air is taken from the environment and warm air is extracted from the room. On both sides, the air passes through the purification system.

After that, cold air is transferred to the heater (heater) - typical for PVV with heat recovery. In addition, heat is transferred to the cold gas from the exhaust warm air, which is typical for conventional systems.

After heating and heat exchange, exhaust air is discharged through an external duct, and heated fresh air is supplied to the room.

A popular layout of the ventilation module includes a heat exchange chamber (recuperator), in which heat energy is exchanged between oncoming air flows. In any case, each stream passes through a double filtration system

A popular layout of the ventilation module includes a heat exchange chamber (recuperator), in which heat energy is exchanged between oncoming air flows. In any case, each stream passes through a double filtration system

The main principles of supply and exhaust ventilation are efficiency and economy.

The classic supply and exhaust ventilation scheme has the following advantages:

- high degree of purification of the input stream

- accessible operation and maintenance of removable elements

- integrity and modularity of the design.

To expand the functionality, air handling units are equipped with auxiliary control and monitoring units, filter systems, sensors, auto timers, noise suppressors, electric motor overload alarms, recuperative units, condensate trays, etc.

Features of work

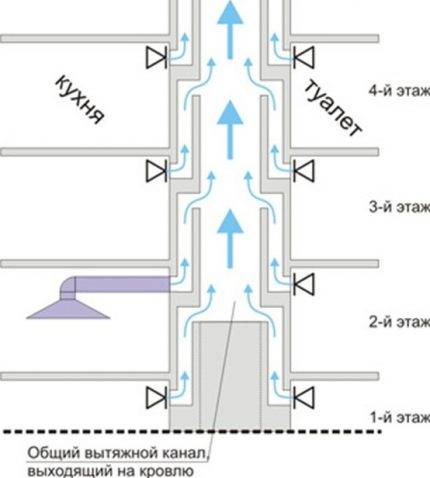

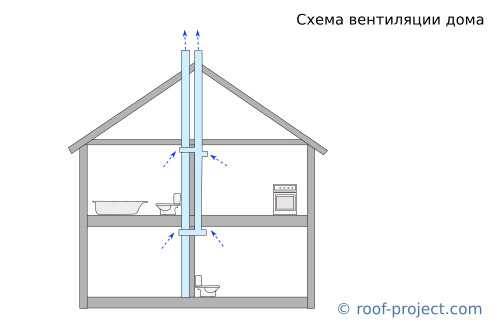

To understand the need for an air circulation device, consider how ventilation works in a closed room in apartment buildings:

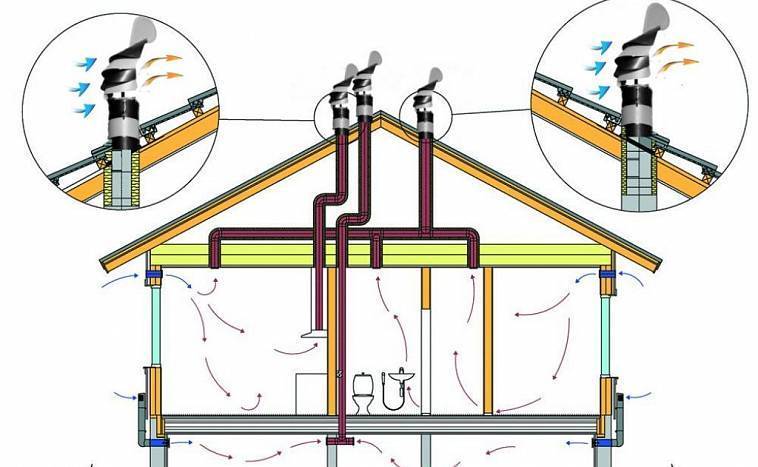

- It consists of interconnected pipes located inside the building and ending on its roof.

- The physical laws of nature contribute to the movement of air masses. So, due to the temperature difference between indoors and outdoors, a certain pressure is created in the pipes, which causes air masses to move. This is how the natural traction device works.

-

Windy weather affects the speed of air flow inside the ventilation pipes.

- To protect the pipeline from dust and dirt, it is recommended to install protective grilles at the ends of the pipes.

Channelless forced ventilation

Sources of this category are considered the best solution to problems with the supply of fresh air to a high-rise apartment and a private house. They are quite powerful, independent of weather changes, and their installation does not cause any particular difficulties.

Advanced wall valve

The wall-mounted ventilator with air jet induction is a modernized analogue of a wall supply damper.The fundamental difference in the design is the presence of a fan that pumps an air jet.

The performance of the mechanical inflow is determined fan speed. The amount of energy consumed and noise characteristics depend on the selected mode.

How the ventilator works:

- The rotating blades of the fan force the supply of outdoor air.

- Passing through the duct, the air masses are cleaned and enter the apartment.

- The exhaust air moves towards the exhaust ducts and is discharged through the vent.

The degree of purification of the supplied air flow depends on the built-in filtering system. It is optimal if the ventilator is equipped with different types of filters.

The ventilator with a fan works even with a weakly efficient exhaust system. Forced supply increases air pressure, which has a positive effect on the performance of the hood.

Breezer - compact ventilation unit with climate control

The breather is designed to maintain air circulation inside rooms with an area of 10-50 sq.m. The device solves several problems simultaneously: supply of clean air and its heating to the specified temperature values.

The main scope of breathers is residential premises, that is, cottages, private houses and apartments. The device is also in demand in small offices

Breather is a technically sophisticated device with the option climate control and system management. Components of the air handling unit:

- Air intake with grille - protects the device from insects and rainwater inside.

- Insulated duct - a sealed channel that provides air flow. The heat-insulating insert prevents freezing of the wall and reduces the noise level.

- Automatic damper - opens the street air inflow channel after turning on the device and closes it after turning it off. The element prevents the infiltration of cold air into the apartment.

- The fan is responsible for the amount of air taken in from the street.

- The communication unit and the control system are the “brains” of the breather, responsible for all the working processes of the device.

The compact unit is equipped with a complete filtration system. The filter cascade implements three levels of purification.

Coarse filter - removal of medium and large particles (wool, dust, plant pollen). HEPA filter - retention of particles with a size of 0.01-0.1 microns, including mold spores and bacteria. AK-filter - carbon filtration of smoke, odors and industrial emissions

Breezer is the optimal solution for creating ventilation in an apartment with filtration, providing up to 80-90% of air mass cleaning from atmospheric dust. The process of installing the device is quite simple:

Fresh air conditioners

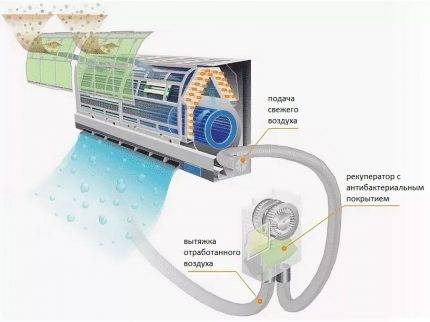

Manufacturers of split systems have proposed their own solution to the issue of lack of fresh air and have developed air conditioners with air from the outside.

Design features of a split system with an inflow:

- air is supplied through ducts going from the outdoor unit to the indoor unit;

- a turbine with a filtration system is provided on the street building, which is responsible for supplying and cleaning air.

Some models of ventilation units are equipped with an oxygen concentrator, and the oxygen level in the room is controlled by special sensors.

An oxygen concentrator passes outdoor air through a membrane partition that separates oxygen molecules from other gaseous substances. As a result, the oxygen concentration increases

An oxygen concentrator passes outdoor air through a membrane partition that separates oxygen molecules from other gaseous substances. As a result, the oxygen concentration increases

The principle of operation of the "split system with a mixture":

- Fresh air through the suction fan enters through the air duct to the evaporative (indoor) unit.

- Outdoor air currents are mixed with indoor air.

- After filtering and additional processing (cooling, heating), air flows enter the apartment.

Despite the good idea of technologists, such models of climate systems are in little demand. Air conditioners with an inflow work loudly and are not able to provide full ventilation of the apartment. In addition, the cost of advanced equipment is 20% higher than the price of a conventional air conditioner.

Conclusions and useful video on the topic

This video clearly shows the device and principle of operation of supply ventilation, as well as its difference from the natural ventilation of premises:

Here you can see an overview of the “Eco-freshness” air handling unit:

Fresh air ventilation is a great way to provide your home with fresh air and create a favorable microclimate in it. All the efforts and costs of creating such a system will fully pay off, since the health of all residents of the house depends on proper ventilation.

Share with readers your experience in improving the efficiency of supply ventilation. Please leave comments on the article and ask your questions. The feedback form is located below.