- Where to drill?

- Arrangement options

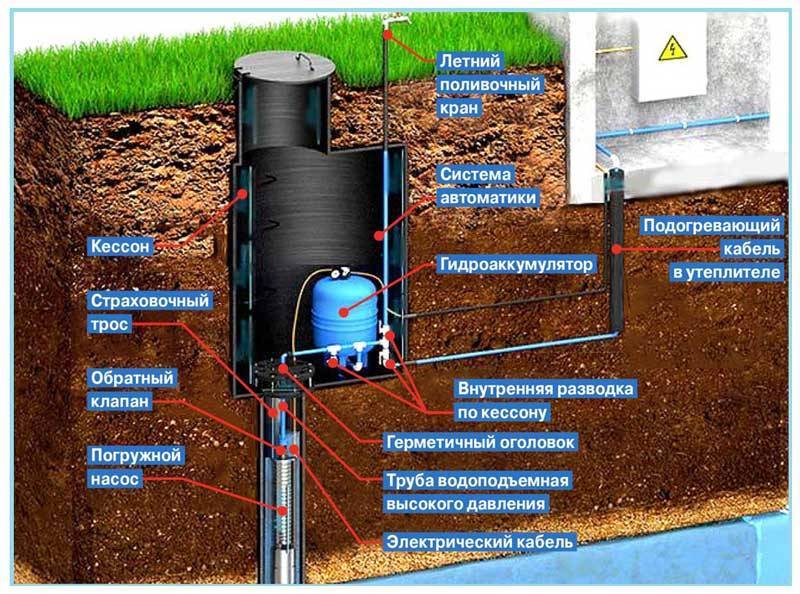

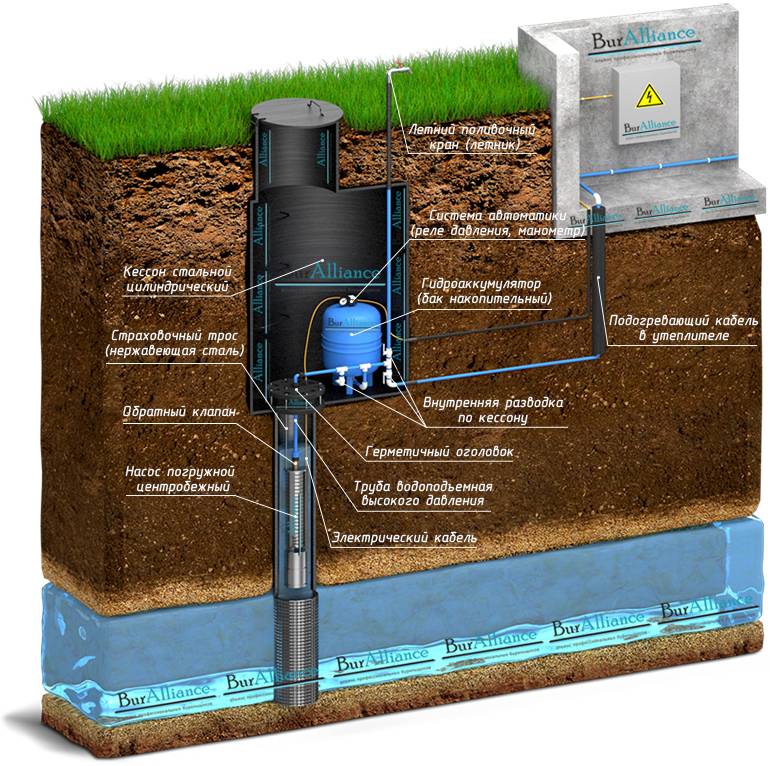

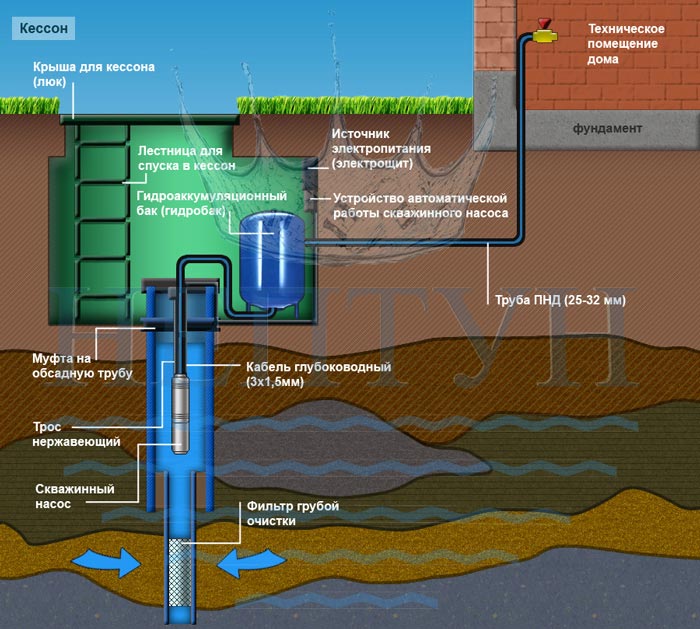

- The use of the caisson

- Adapter operation

- Head application

- Types and features of installation of caissons

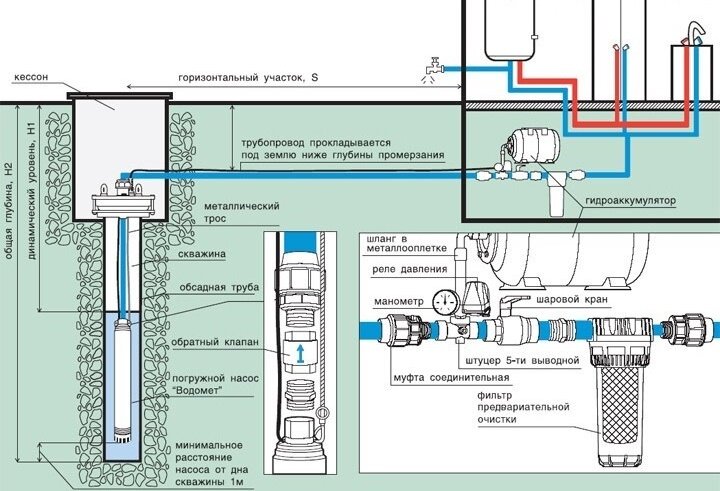

- How is a typical well arranged?

- Casing Functions

- Inner tube with filter

- Borehole device

- Caisson, adapter, packer

- Varieties of drilling workings

- How to install a hydraulic accumulator

- How to install and configure automation systems

- Yard highway conducting water supply from the well

- Well adapter

- The order of the device head

- Selection and installation of pumping equipment

- Surface pump for shallow well

- Deep well submersible pump

Where to drill?

How aquifers are formed in nature can be seen in the following diagram:

Riding waters, lying at a depth of up to 10 m, form mainly atmospheric precipitation. Such water can be used for drinking after purification (filtering through shungite, boiling), and for technical purposes, perch water is taken directly from the well. As for the debit of the well for it, it is too small, and even unstable.

For drinking water on your own, it is best to drill a well into interstratal waters (in the diagram they are indicated by red arrows).Of course, the highest quality water is artesian, but it is almost impossible to get to it on your own, even if you know for sure where to drill. And besides, the individual development and extraction of such a valuable natural resource is prohibited by law, up to criminal liability.

On their own, it turns out to drill a well only into a non-pressure reservoir - that is, into sand soaked with water and lying on a clay bed. Hence another common name for such wells is “sand” wells, although the aquifer in them may consist of pebbles, gravel, and some other substance. Their debit is small (if there are 2,000 "cubes" per day, then this is very good) and may fluctuate.

The depth of occurrence of non-pressure waters is 5-20 m from the surface of the earth. And such water can already be drunk, however, after the buildup of the well and a corresponding check of the quality of the produced fluid in the controlling authorities.

Note! The design of any well in a free-flow formation is quite complex, since it requires filtering sand during production. Adds complexity and lack of pressure - in this regard, there are a number of requirements for the pump and the water supply system as a whole

Pressure layers are lower than non-pressure ones. The depth range of their occurrence in the ground is from 7 to 50 m. Such layers are dense rocks: fractured, water-resistant (loam, limestone) or gravel-pebble deposits. The highest quality water can be extracted from limestone. And wells (they are also called “wells for limestone”) drilled into this rock serve for a long time. Their debit, as well as many other pressure wells, is up to 5 cubic meters of water per day. These structures are also distinguished by high stability indicators.Water almost to the surface of the earth is raised by its own pressure, so any pressure wells, as well as the corresponding water supply systems, are much easier to equip.

Pressure layers are lower than non-pressure ones. The depth range of their occurrence in the ground is from 7 to 50 m. Such layers are dense rocks: fractured, water-resistant (loam, limestone) or gravel-pebble deposits. The highest quality water can be extracted from limestone. And wells (they are also called “wells for limestone”) drilled into this rock serve for a long time. Their debit, as well as many other pressure wells, is up to 5 cubic meters of water per day. These structures are also distinguished by high stability indicators.Water almost to the surface of the earth is raised by its own pressure, so any pressure wells, as well as the corresponding water supply systems, are much easier to equip.

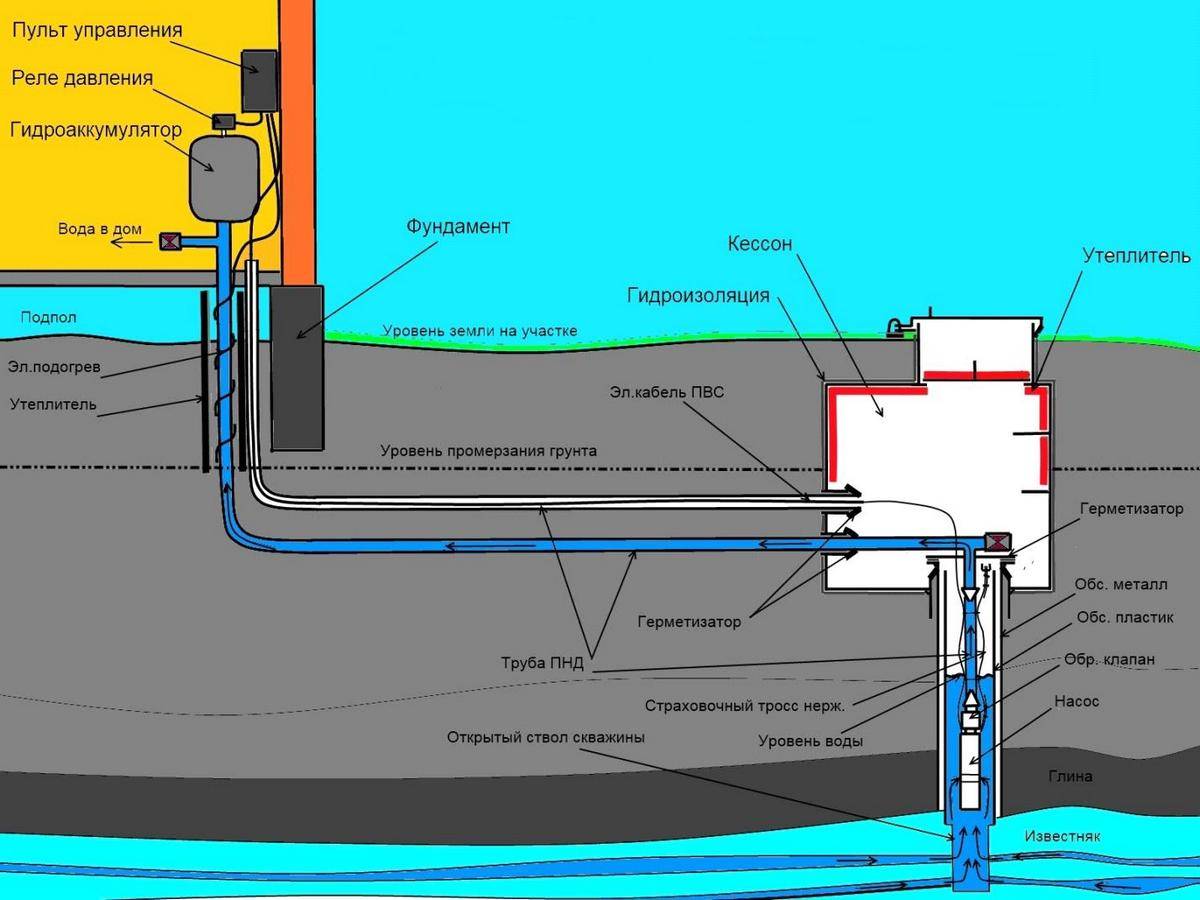

Arrangement options

At the moment, the following 3 methods of arranging wells are widespread - with a caisson, an adapter or a cap. The choice in favor of one or another option is carried out after drilling a well and studying the wishes of the customer.

The use of the caisson

The caisson is a moisture-proof chamber, which is made of metal or durable plastic. In appearance, the container resembles an ordinary barrel. The volume is usually equivalent to a standardized RC ring of 1 m. The product is buried in the ground and is used to solve the following tasks:

- protection against water and dirt;

- ensuring that the equipment is located all year round at a positive temperature;

- freezing prevention;

- ensuring tightness;

- year-round well operation.

First, a pit is pulled out. Depth - up to 2 m. Then a hole is cut at the bottom for the casing pipe. The container is lowered into the pit and placed in the center of the well. The casing is cut off and welded to the bottom. At the end, the product is covered with soil. Only a hatch is visible on the surface.

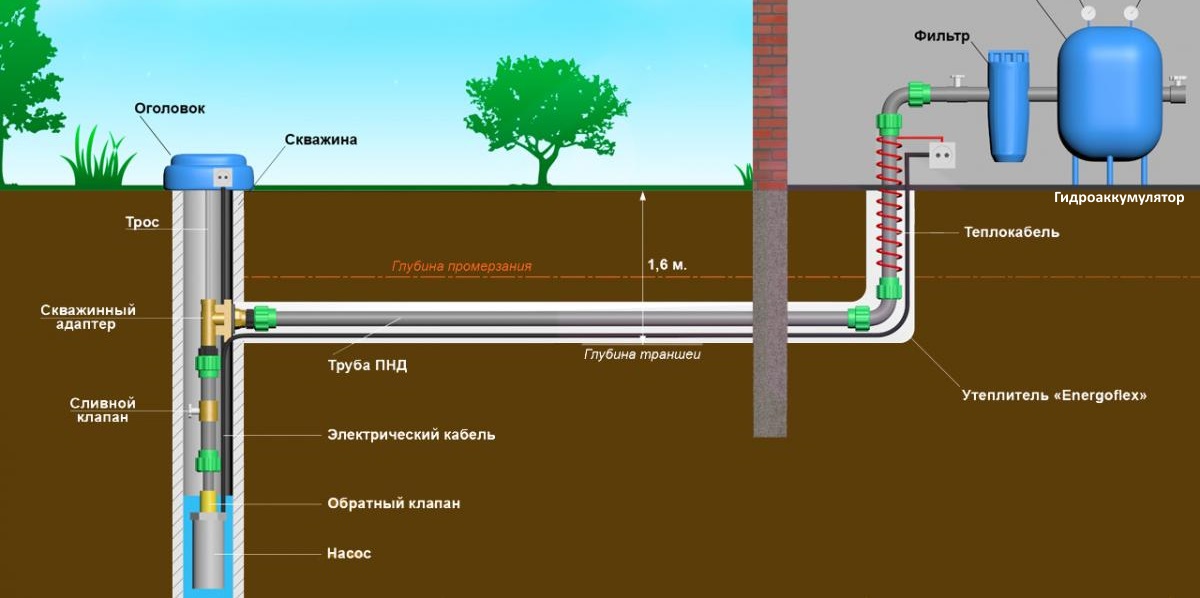

Adapter operation

The arrangement of a well for water involves the removal of a water supply directly through a cased column. The pipeline is laid below the freezing depth of the soil masses. The element itself is made in the form of a threadless type pipe connection. One end of the device is rigidly fastened to the casing, and the other is screwed into the pipe connected to the submersible pump.

Head application

Elements are either made of plastic or metal.The fixtures consist of covers, connecting flanges and rings made of rubber. Installation is not accompanied by welding.

Installation begins with trimming the casing. Then the pump is lowered and the cover is put on. The flange and rubber seal rise to its level. Fastening is carried out by tightening the bolts.

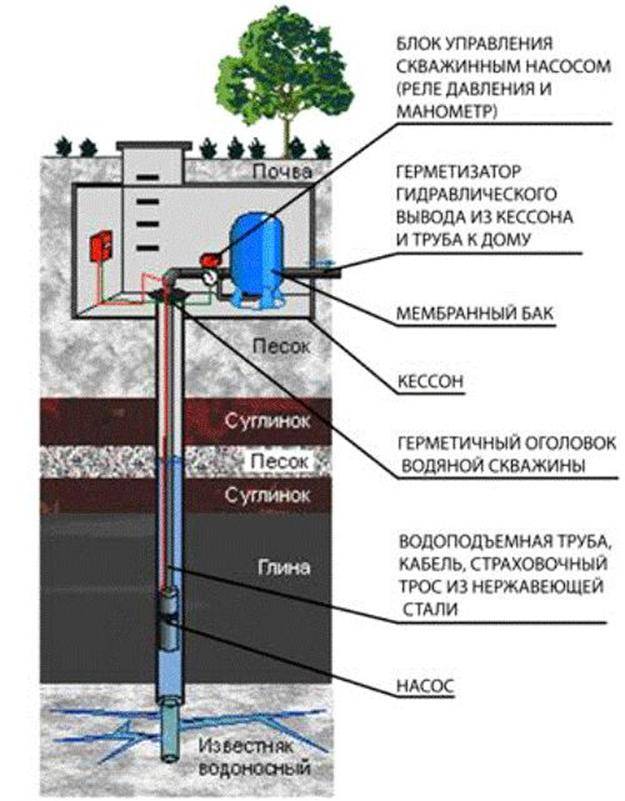

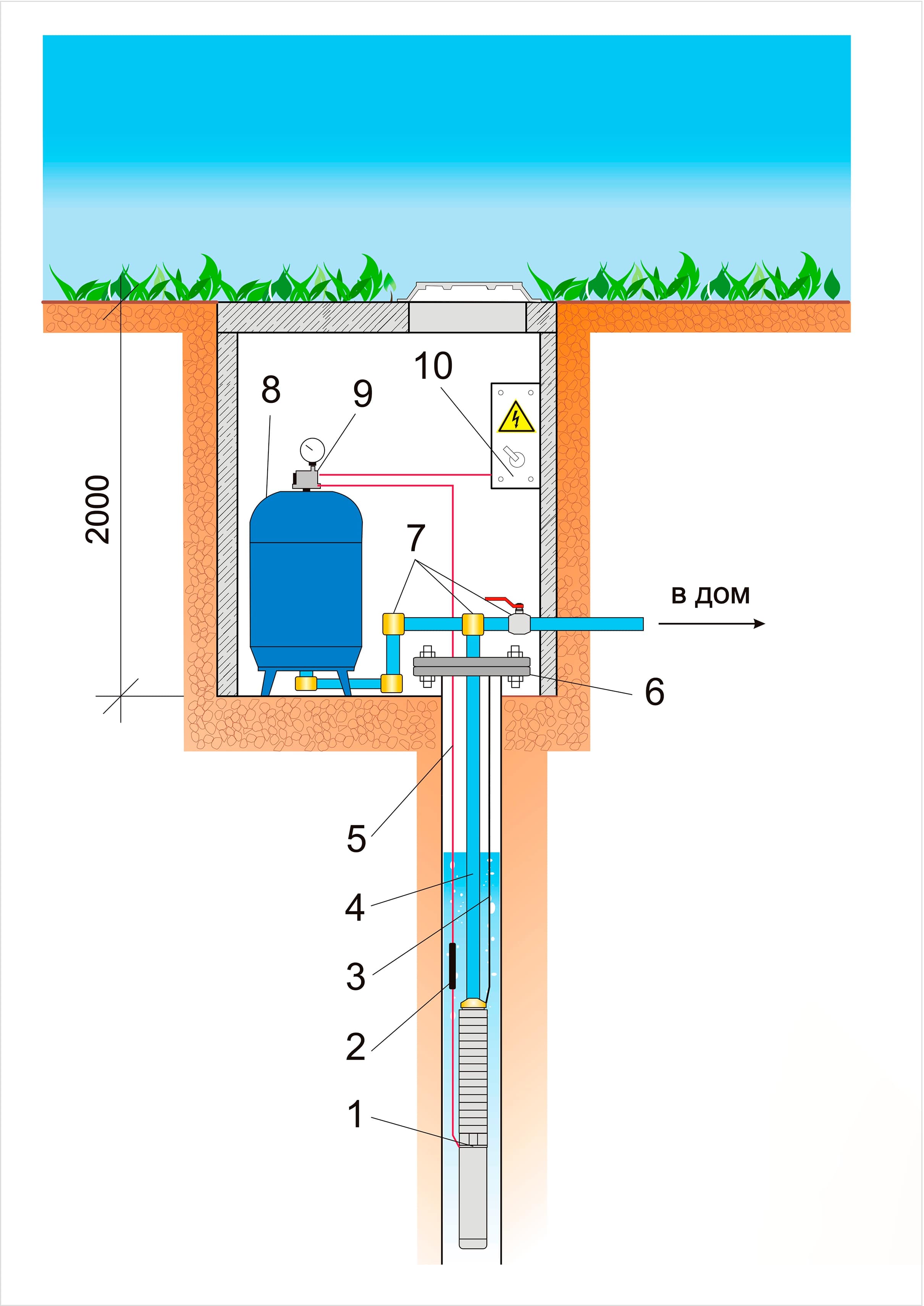

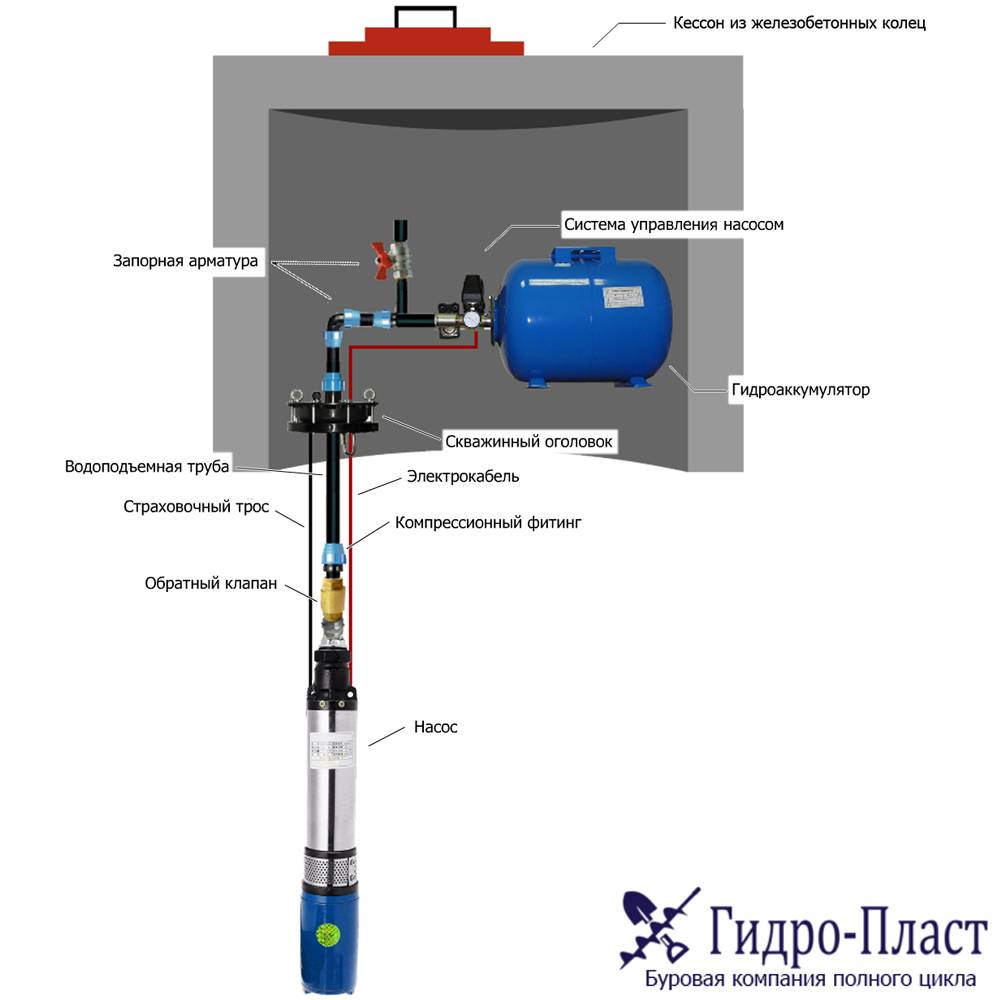

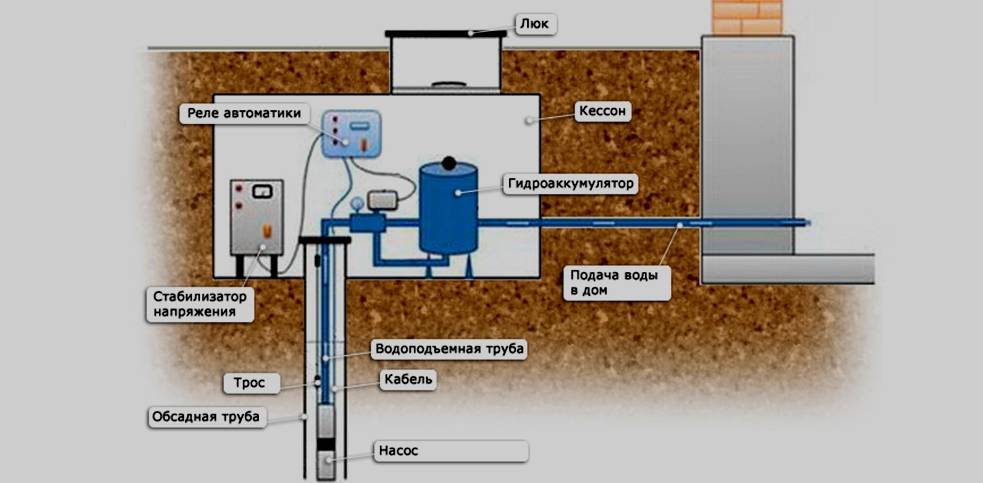

Types and features of installation of caissons

The uninterrupted operation of the well is designed to provide a caisson, an insulated waterproof container with the necessary equipment inside.

Usually a pump, shut-off valves, measuring instruments, automation, filters, etc. are mounted in it. Buildings are made from different materials. The most common:

Plastic. They are distinguished by excellent thermal insulation, which allows even without additional insulation to maintain the temperature inside the caisson at the level of 5C. Durability, excellent waterproofing characteristics, which makes it possible to avoid additional costs for insulation work, reasonable price, especially in comparison with other options. In addition, the system is quite easy to install due to its low weight. The main disadvantage is low rigidity, which can provoke deformation of the structure and damage to equipment. However, it is easy to deal with it by filling the container around the perimeter with cement mortar with a layer of 80-100 mm.

Plastic caissons have excellent thermal insulation, which allows them to be installed without additional insulation.

Steel. Most often, the arrangement of a water well is carried out with just such a design. The material allows you to make a caisson of any desired shape, while not requiring much effort.It will be enough just to weld the parts together and treat the structure from the inside and outside with a special anti-corrosion coating. For a high-quality container, metal 4 mm thick will be quite enough. You can also find ready-made structures on sale, but their purchase will cost much more than self-production.

There are various forms of steel caissons - for various needs

Reinforced concrete. Very strong and durable installations, previously extremely common. Due to their shortcomings, today they are used much less frequently. Their cost is very high, and special equipment is required for installation, which is due to the large weight of the equipment. For the same reason, over time, the concrete caisson sags, deforming the pipelines inside it.

Concrete has insufficient thermal insulation, which can cause water in the pump to freeze in severe frosts, and poor waterproofing, since concrete is hygroscopic

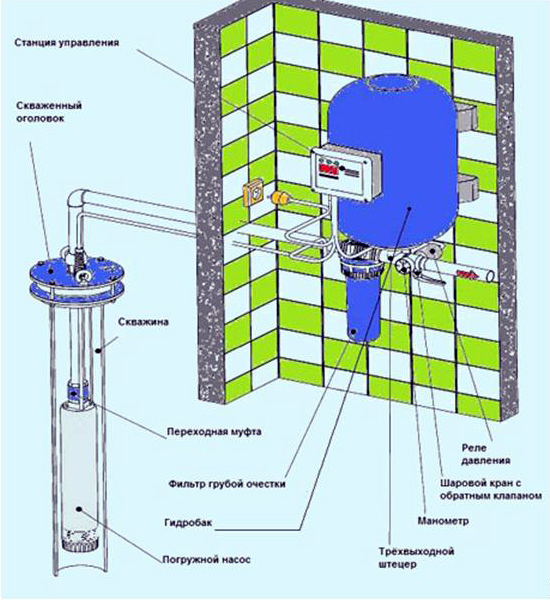

Here is an approximate scheme for installing equipment in a caisson and connecting communications:

Scheme of installation of equipment in the caisson

If you are going to complete the arrangement of the well with your own hands, it is worth getting acquainted with the stages of installing the caisson. They are almost the same for any type of structure, with slight nuances depending on the material of the equipment. Let's consider the stages of installing a steel tank:

Pit preparation. We dig a hole, the diameter of which is 20-30 cm greater than the diameter of the caisson. The depth must be calculated so that the neck of the structure rises about 15 cm above ground level. This way, it will be possible to avoid flooding the tank during the flood and heavy rainfall.

Casing sleeve installation. We make a hole in the bottom of the container. It can be positioned traditionally in the center or shifted as needed for equipment installation. A sleeve 10-15 cm long must be welded to the hole. Its diameter must be greater than the diameter of the casing pipe. Be sure to check that the sleeve can be easily put on the pipe.

Installation of nipples for the withdrawal of water pipes. We weld them into the wall of the container.

Caisson installation. We cut the casing pipe at ground level. We put the container on the bars above the pit so that the sleeve on the bottom of the container “dresses” on the pipe

We check that the axes of the caisson and the casing exactly match, then carefully remove the bars and carefully lower the structure down the casing. We install the container in the pit strictly vertically and fix it with bars. We weld the pipe to the bottom, while sealing the caisson

Through the nipples we start water pipes into the structure

We weld a pipe to the bottom, while sealing the caisson. Through the nipples we start water pipes into the structure.

Backfilling of the building.

The caisson is “put on” on the casing pipe and carefully lowered into the pit

It should be noted that, in principle, it is possible to equip a well without a caisson, but only if a heated building is located near it, in which the equipment is located.

The convenience of such a system is undeniable - all nodes are easily accessible. However, the disadvantages are also significant: it takes up a lot of space in the room and most often makes a lot of noise.

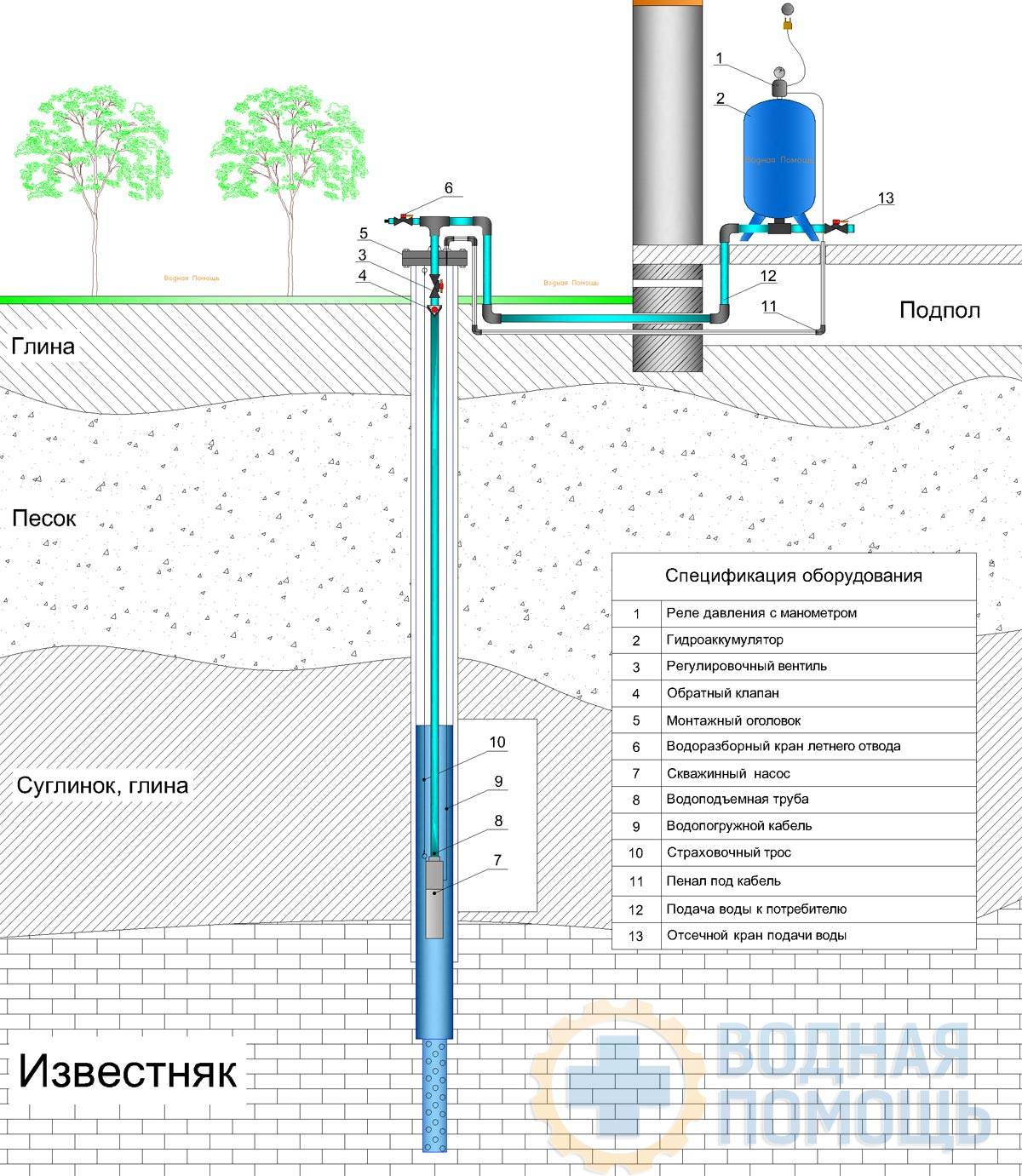

How is a typical well arranged?

If you do not focus on the nuances, the essence of arranging a water well for a country house is the same: it is a long narrow vertical shaft that reaches the depth of water.The walls of the excavation are reinforced with casing pipes

Wells differ from each other in width, depth and additional devices that increase their productivity and reliability.

In addition to the casing pipe, the wells are equipped with equipment for the forced lifting of fluid and its distribution. To choose the right pumping equipment and storage capacity, you need to know the characteristics of the well, the most important of which is its depth and flow rate.

The flow rate of a well is an indicator of its productivity: the maximum volume of fluid obtained per unit of time. It is calculated in cubic meters or liters per hour or day.

Casing Functions

Casing pipes are the main element of the well. Casing is carried out using separate segments, soldered, welded or screwed together

Particular attention should be paid to their equal diameter: the whole structure should create a straight, even column

If the casing pipes have an external thread, the links are connected by couplings, due to which the penetration diameter increases.

Casing pipes are needed to:

- while drilling the well, there was no shedding of the mine;

- the barrel is not clogged during its operation;

- the upper aquifers did not penetrate the structure.

Casing pipes made of steel alloys and polymers (PVC, PVC-U, HDPE) are widely used. Cast iron and obsolete asbestos-cement products are used less frequently. The space between the pipe and the ground around the mouth is poured with concrete if the working was drilled in loose soils or the aquifer lies at a considerable depth.

Only after this work is completed, all other equipment is installed. Sometimes during the operation of the well, a slight "squeezing" of the pipe to the surface may occur.This is a natural process that does not require any additional measures.

Threaded metal and plastic casing pipes are considered the most popular. The photo shows the installation of a blue plastic casing

Inner tube with filter

A pipe with a filter is lowered into the wellbore, made according to the double casing scheme. Through its perforated first link, the filtered water will flow into the backing, and then be pumped to the surface.

After the pipe is installed at the desired depth, it is desirable to fix its mouth. For this purpose, a clamp is used to prevent spontaneous subsidence of the pipe.

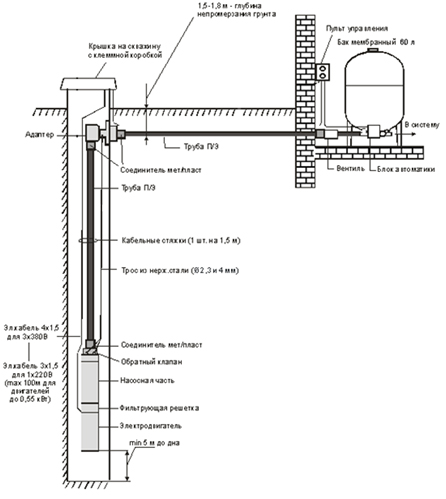

Borehole device

The upper part of the casing pipe is equipped with a head. The basic design of this device is the same for heads of any kind. It consists of a flange, a cover and a rubber ring.

Different types of heads differ from each other in the type of material from which they are made, and additional options.

Heads are made of cast iron and plastic. This is a sealed device. It is used to fasten the pump cable and the outlet of the water pipe.

Due to the low pressure created by the head in the pipes, the inflow of water and, as a result, the flow rate of the well increases.

Caisson, adapter, packer

So that high humidity does not affect the operation of devices associated with the well, a special reservoir is provided for them - a caisson. It is made either from metal or plastic.

Metal caissons, unlike plastic ones, can be repaired, they are better adapted to the climate with significant temperature differences.In addition, a metal product can be independently assembled from parts that are sold separately. But plastic models are cheaper and they don't rust.

Those who wish to arrange a caisson for a well with their own hands will find detailed instructions for its construction on our website.

To hermetically connect the ground water supply and the well, you will need a downhole adapter. This device is usually placed in the place where all the equipment that needs to be protected from water is assembled. Most often this is a technical room. One part of the adapter is attached to the casing, and the hose from the pump is screwed to the other part.

A metal caisson is an expensive thing: its price reaches 40 thousand rubles, so you can buy it in parts and assemble it yourself, which will make the purchase cheaper

Sometimes there is a need to allocate a local section of a deep artesian well, where, for example, repair work will be carried out. For this purpose, packers are used - compactors for wells.

The listed elements are part of the well device, exerting a great influence on its functionality.

Varieties of drilling workings

The Abyssinian well is a driven well, which is the simplest option. To equip it on the site, the water layer must have a depth of up to 12 meters. The quality of water in it depends mainly on the structure of the soil. Such a development, if necessary, can be arranged in the basement.

The sandy well, the scheme of which is in great demand, is suitable only for personal use.The water from it is characterized by its properties as technical, therefore it is used only for bathing or watering the garden. On average, the aquifers in this well lie at a depth of about 10-50 meters.

By the way, it is really possible to do drilling work with such layers with your own hands, the main thing is that shale does not pass through a few meters in the area. It is unlikely that it will be possible to pass it without the help of professionals.

Of course, sand wells have some disadvantages. The main disadvantage of such a development is an interruption in the water supply. The problem is related to seasonal fluctuations in the level of life-giving moisture. In addition, it needs to be serviced periodically, especially for summer residents who need water only in the summer. In this situation, the filter located in the well becomes silted over time. That is why the rise of water must be regular. In addition, the service life of such a well is no more than 15 years.

Artesian development, although considered the most expensive, is the most effective method of centralized water supply. For its drilling, large equipment is used, which allows you to go deeper by about 200-300 meters.

From an artesian well, water is better and better than from a sandy one. It also doesn't clog the filter. It is mounted at the bottom of the supply pipe with a diameter of 219 mm. This development guarantees a 99% constant supply of life-giving moisture, and its service life is 50 years.

True, such wells also have disadvantages. For example, sometimes the installation of additional filtration systems is required, since the water may contain various iron compounds. In addition, as mentioned earlier, its arrangement is expensive.You will also have to obtain permission to drill such a working and coordinate the project.

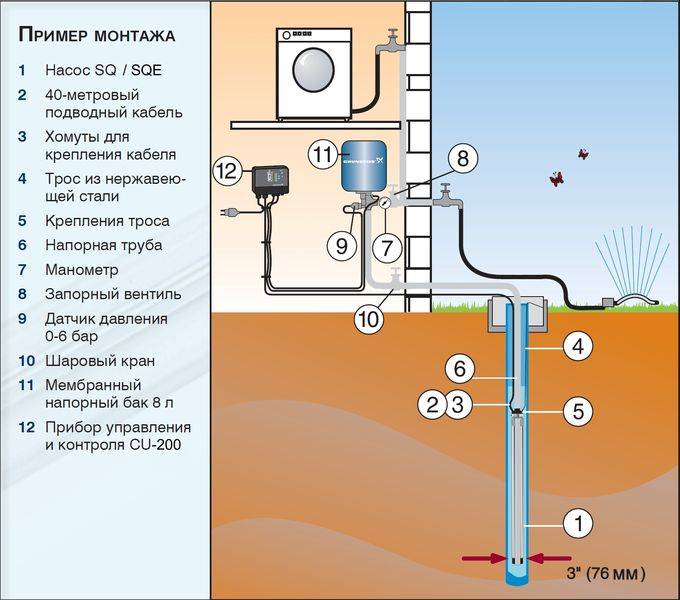

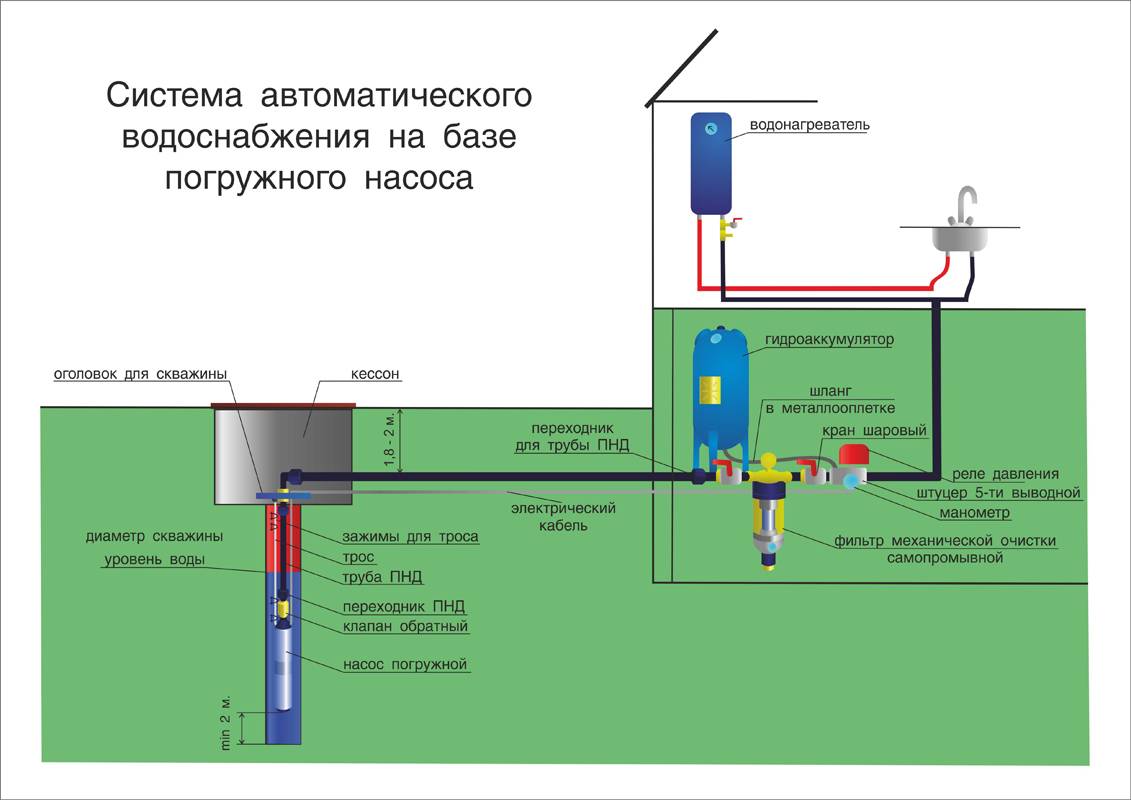

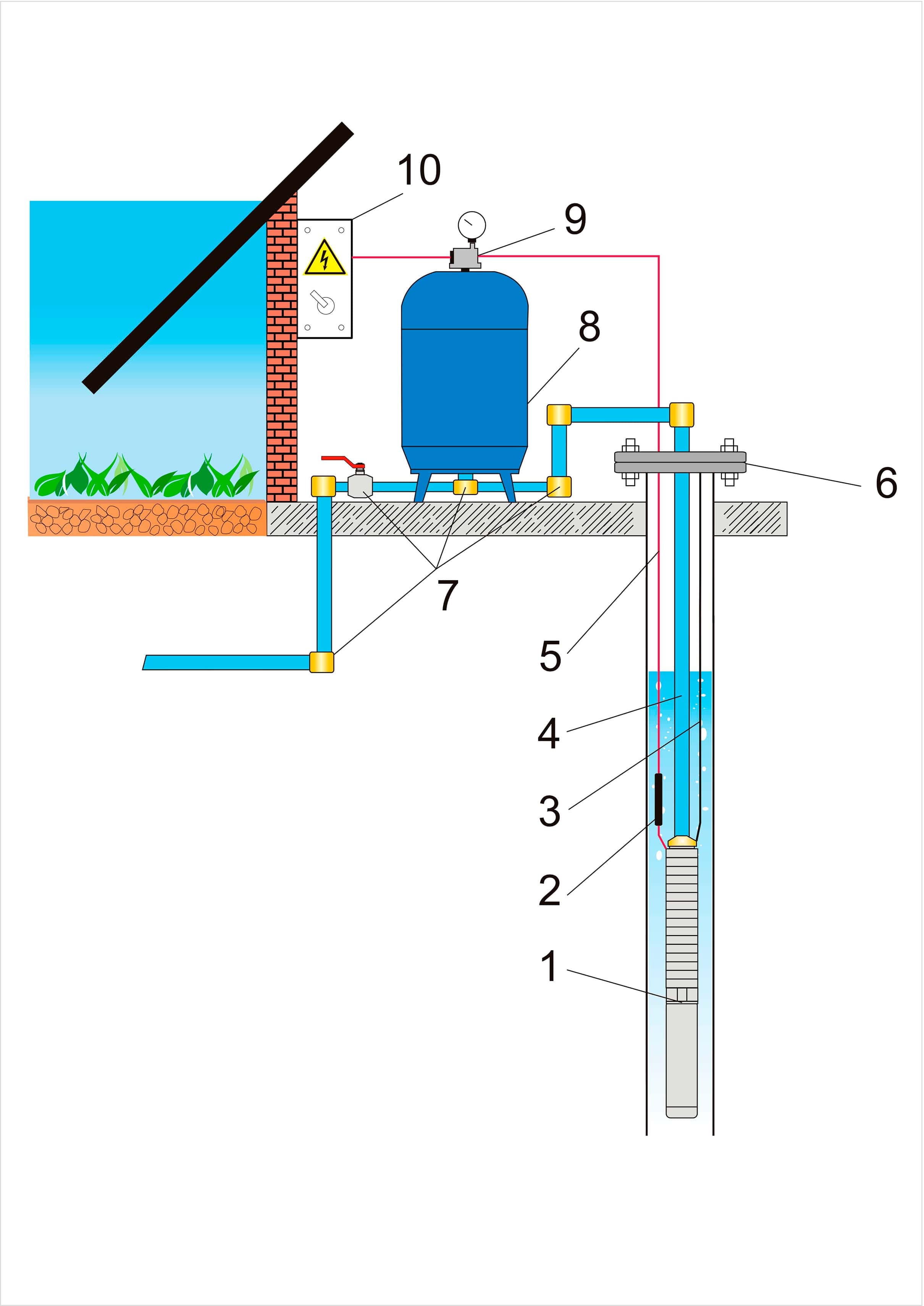

How to install a hydraulic accumulator

A hydraulic accumulator or pressure tank is installed in the basement of the house or in the caisson. Its volume can be from 10 to 1000 liters.

With the help of a hydraulic accumulator (see Hydraulic accumulator for a well: types of equipment and methods of its use), a constant pressure in the system is maintained and, if necessary, the load on the pump is reduced. The device accumulates a supply of water, to replenish the reserves, the pump turns on automatically.

Classic building scheme

How to install and configure automation systems

The last stage of work on the arrangement of the well is the installation and configuration of the automation system, which includes a control panel and a pressure switch. So:

- The relay allows you to set the desired pressure level in the system.

- The pump on/off control is carried out by the automation control panel. In addition, the remote control is needed to ensure the operation of the pressure switch, the dry run sensor and the thermal relay sensor. It also protects equipment from power surges.

Proper arrangement of the well will be the key to its long and proper operation.

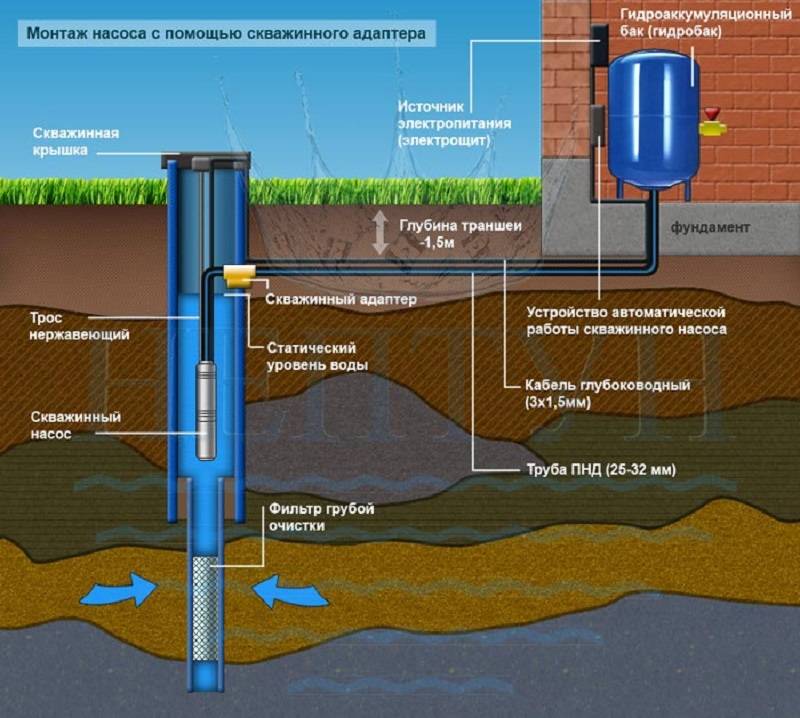

Yard highway conducting water supply from the well

tools and materials

For conducting water supply on the site, you can use different types of pipes:

- Copper pipes are the most expensive, but also the most reliable pipes. The material is not susceptible to corrosion, aggressive biological environment and ultraviolet radiation, has good heat transfer.

❝Diameter of the pipeline from the well should be 32mm❞

Piping tools:

- For installation of steel or copper plumbing:

adjustable, gas and wrenches;

the sequence of laying and warming the water supply

The pipeline can be laid in two ways:

In the first case, a trench is dug at a depth of 2 meters and a pipeline is laid. The pipe in the lifting points must be insulated (especially near the foundation). This can be done with a self-regulating heating cable.

❝The foundation of the house to which the water supply is connected must be insulated at least to a depth of 1 meter❞

If the water supply is laid on top, then a heating cable (9 W / meter) must be connected to the pipe. In addition, the entire pipe is thoroughly insulated with heat-insulating material - a layer of insulation of at least 10 cm.

You can use energy flex and cotton wool. The joints between the heaters must be wrapped with reinforced tape - this will improve the sealing between the layers.

❝The pipe must be insulated along the entire length of the yard main: from the house to the well❞

The entire "pie" of the water supply is placed in a large corrugated or sewer pipe. Such measures will avoid freezing of the water supply and use the well in winter.

Together with the pipe, the supply cable for the pump can also be laid at the same time. It is better to use a 4-core cable with a cross section of 2.5.

After installing the pump and laying the water supply to the house, it is necessary to assemble an automatic water supply system according to the scheme.

Well adapter

The best way to improve a well is to use a pavilion or caisson. It is these structures that can most reliably protect the source of water supply. The disadvantage of these solutions is their high cost. If the task is to equip a well on the site of a solid cottage, such expenses are quite understandable.Another thing is when a well provides for the needs of a small rural house or cottage. As a rule, the owners of such buildings cannot boast of huge funds.

A budget option for a well device at a site is a well adapter. It makes it possible to switch the supply pipe directly with the well casing. This eliminates the use of a caisson. There is also an inconvenience: in the event of a need for repair, the adapter needs to be dug up (it is placed in a trench during installation). As practice shows, this reliable element rarely fails.

The downhole adapter consists of two main blocks:

- Outer. It is located on the outer side of the casing pipe. Its purpose is to provide switching with a water supply system that supplies liquid to the house.

- Interior. Serves to connect the pipe from the pump.

The outer and inner blocks have a radius configuration that follows the shape of the trunk. To switch the elements together, a paired hermetic seal is used. To equip a well with your own hands, you need to install the adapter below the depth of soil freezing.

During installation, the following steps must be clearly followed:

- The casing pipe must be removed so that its end is at a small height above ground level.

- To protect the casing from contamination, the upper edge is formed by a cover with a hole for the electric cable supplying the submersible pump.

- In winter, in case of a significant drop in temperature, there is a real threat of cold penetration into the well: it begins to move along the casing pipe.In regions with severe winters (where frost reaches -20 degrees), additional well insulation is practiced. To do this, it is covered with spruce branches, hay, straw and other natural materials for the winter.

This option, how to equip a well with your own hands, surpasses the use of a caisson with its cheapness. The weaknesses of using the adapter include the complexity of maintenance, the risk of mechanical damage to the electrical wiring and the not very reliable fastening of the pump. In this case, instead of the traditional cable, direct fixation on the water pipe is used. The equipment used can only be placed inside the house. Before you equip a well with your own hands using an adapter, you need to get a special key with a long nozzle. To implement the process, a certain technical experience and accuracy will be required.

The order of the device head

Header provides:

- Protection of the well from floods and melt water.

- Protection from third-party debris and groundwater.

- Protection against theft of equipment and well wells.

- Frost protection during cold weather.

- It makes the cable attachment more secure.

- Contributes to facilitating the use of a well well for water.

- Makes submersion of the pump as convenient as possible thanks to the winch.

Scheme of mounting the head for the well.

This device consists of several parts, namely:

- Carbine and flange.

- Rubber rings.

- Special fasteners.

- Protective cover.

The inner side of the cover is equipped with one eyebolt, the outer side with two. A metal product can withstand a weight of up to 0.5 tons, and a plastic one - no more than 200 kg.

During the installation of the head, it will be necessary to cut the casing, clean it and cover it with an anti-corrosion compound. Lead the pump cable and water pipe through the head cover. Connect the pump to the pipe. Attach the free end of the rope to the carabiner. This should be done through the eyebolt on the inside of the protective cover. Place the flange and rubber ring on the casing.

Place the pump in the well and install the head cover. This is done very simply: you just need to lift the flange and the rubber ring for the cover and compress all these parts with bolts. On this, the installation of the head is considered completely completed.

Selection and installation of pumping equipment

For arrangement you will need:

- A water pump of sufficient power to pump water out of the well and create the required pressure in the pipeline.

- Automation that allows the system to work autonomously, without human intervention, activating the system as needed.

- The system for protecting equipment from overheating and overload, which will turn it off, eliminating breakage.

- A hydraulic accumulator that maintains pressure in the pipeline constant, eliminating drops.

In this case, pumps of various types are used, which have characteristic operational features.

Surface pump for shallow well

Such pumping equipment costs less. It is easy to maintain and repair, as there is unhindered access to the unit. For arranging a country well, this is the best option, since the surface pump can be removed for the winter. And if you buy a pumping station, you do not have to select components based on the compliance of operating parameters. This is a pump that is equipped with a hydraulic tank and a control unit.

If we are talking about a shallow well, the use of a pumping station is the best option, since only a flexible hose is lowered into the source itself, and all mechanical and electrical components remain on the surface (next to the well, in a special technical building or in the house). The only disadvantage of such a scheme is the inability to raise water from a great depth. As a rule, it is 8-10 meters, no more.

Deep well submersible pump

At its core, this is a pump that descends into the casing pipe below the depth of the water reservoirs. In this case, all other components and mechanisms must be mounted on the surface. Hydraulic tank and pressure switch, filtration station, control unit and other equipment for installation in the house. The remoteness of the source has practically no effect on system performance.

In this case, it is necessary to correctly calculate the required parameters of pumping equipment for a well for water. The power of the pump must be sufficient to raise water through the hose to the surface, and then through the pipeline to the house and through the wiring to consumers. At the same time, there must be enough pressure in the pipes to ensure the smooth operation of household plumbing fixtures. Moreover, all equipment must be protected from cold and rain.