- Step by step instructions for arrangement

- Well type selection

- The nuances of installing casing pipes

- Installation of a hydraulic accumulator and other control systems

- The procedure for installing the accumulator

- Installation of an underground caisson

- underground pipeline

- Sand well for water

- Advantages and disadvantages

- How to choose water supply equipment

- Types of wells for a private water supply

- How to make a drilling tool

- Spiral and spoon drill

- Bailer and glass

- Making a needle for an Abyssinian puncture

- Rental of a mobile drilling rig

- Ensuring the tightness of the casing

Step by step instructions for arrangement

It all starts with choosing a place for a well and choosing a method for arranging a water source.

Technology arranging a source of water supply consists of a number of consistent and responsible steps:

- Well. The first stage is drilling the well itself.

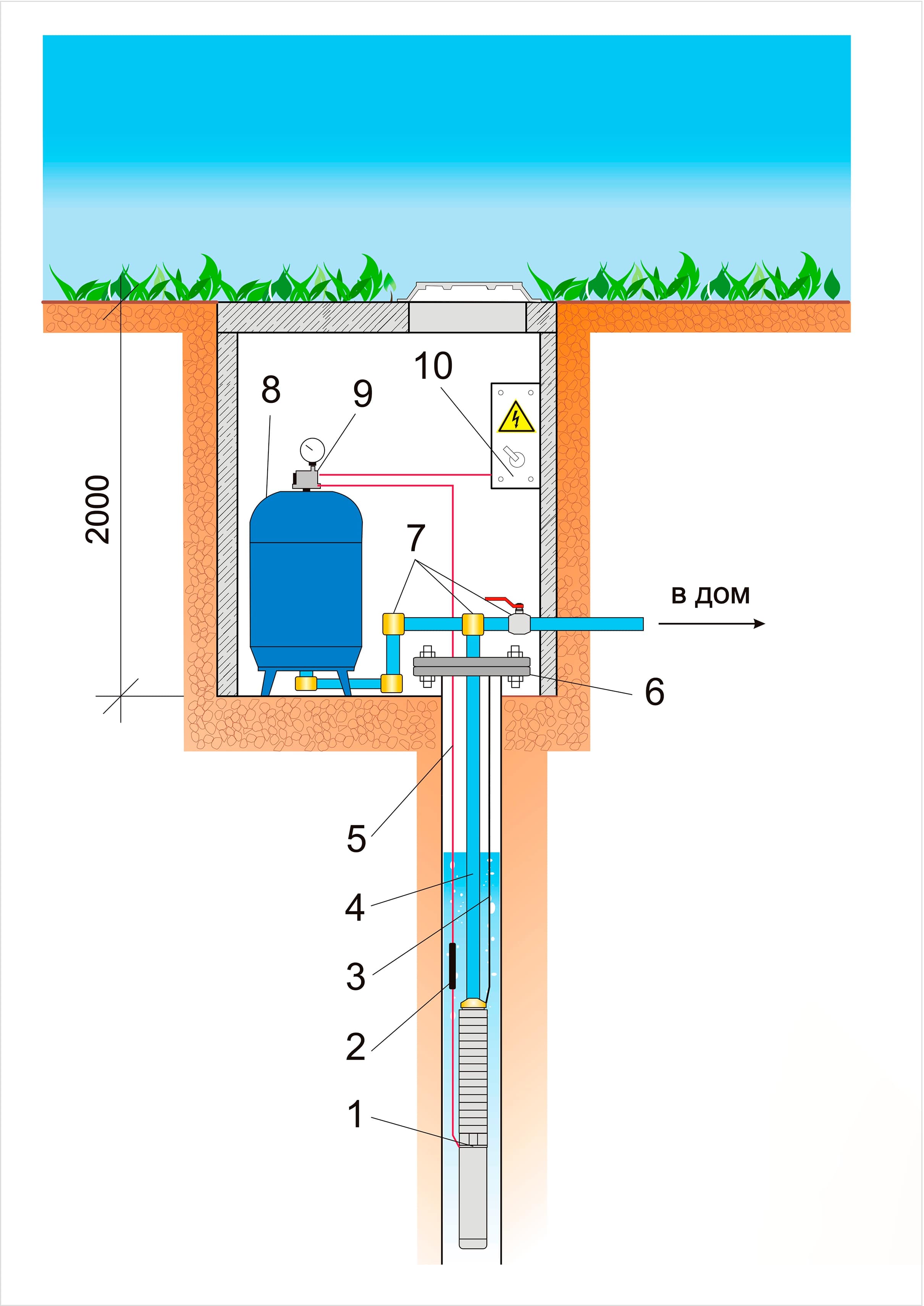

- Caisson. The second step is to start the installation process of the caisson.

- Warming. The third stage is that they fill the pit with earth to the very cover, then the hatch is insulated.

- Installation of equipment. Stage four - after completion of work, they begin to install equipment that should ensure uninterrupted and efficient water supply to the house and to the site.

The installation process of the caisson structure also consists of several operations.

Let's consider the main ones:

- In the bottom of the caisson, with some shift from its center, a hole is made for the subsequent installation of the sleeve under the casing string. The diameter of the sleeve must exceed the corresponding parameter of the pipe, measured along the outer contour, by 10-15 millimeters.

- Branch pipes for water pipes and cables are welded into the side walls of the caisson.

- They dig a pit in such a way that the neck, after installation is completed, rises above the ground by no more than 20 cm. For the convenience of docking the chamber with the casing, the diameter of the pit should be 0.2-0.3 m larger than its own corresponding size.

- Cut the casing at ground level.

- Lay supports in the form of beams on the foundation pit. A caisson is placed on them.

- The casing pipe is joined with the caisson sleeve, the structure is adjusted horizontally, and then hermetically welded.

- The bars are removed from under the chamber, lowered into the well.

- Pipes and cables are inserted into the corresponding nipples.

The water in a freshly drilled well is always dirty, so pumping should be done to clean it. Drillers are advised not to use equipment purchased for permanent use for this purpose. The cheapest temporary pump will do just fine with this work, and when the well is pumped, you can start a permanent one.

When choosing a well arrangement option, in order to avoid irrational costs, it is better to get advice from specialists. They will take into account all the factors and justify the feasibility of implementing a particular project.

When choosing a well arrangement option, in order to avoid irrational costs, it is better to get advice from specialists. They will take into account all the factors and justify the feasibility of implementing a particular project.

It should be noted that the installation of such a protective container as a caisson is not always necessary.It happens that a room suitable for accommodating equipment already exists in the area where the well is located.

In this case, a more rational solution would be to use it for its intended purpose and save on the installation of the caisson.

Well type selection

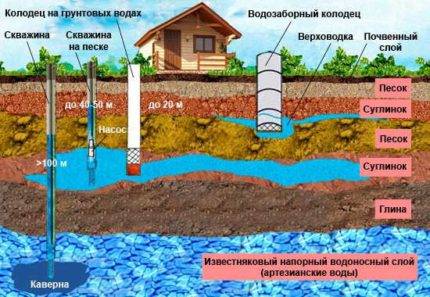

First of all, we need to decide on our goal, in particular, to what level we will deepen.

The following options are likely:

- Well. A depth of 5-8 m is enough. When it hits a good spring, it will quickly fill up and provide water for irrigating crops. Before consumption, such water will need to be meticulously purified, since its natural filtration is not very strong. Satisfaction of all domestic needs except this remains in doubt due to the low debit for the source. This option is characterized by the lowest selling price.

- Well in the sand. The depth of immersion can vary from 10 to 40 meters. In most cases, it turns out to perform drilling with an auger drill independently without calling a special team. Quality level H2O much better than a well, but sewage infiltration is still likely. The price of arranging such a well is fully affordable, and the performance allows you to provide a small house with a garden.

- Artesian mine. This is a guarantee of quality water a lot. But the occurrence of the limestone aquifer occurs at a depth of 50 to 300 meters. It is amazingly difficult to overcome such a distance manually, and suddenly a hard layer of moraine is encountered on the way, it is completely unrealistic. Based on this, one cannot do without specialists with special drilling equipment. arrangement and drilling of such a well design is very costly.

From the above, it is possible to conclude that do-it-yourself well installation is the most optimal for sandstone. This is due to the relative purity of the waters and the availability of drilling operations.

The nuances of installing casing pipes

It can be metal, asbestos cement or plastic. Each of the materials has its own advantages and disadvantages. Concrete casing pipes are rarely used. This is usually production. The material is heavy, brittle, prone to splitting. Therefore, in the process of drilling wells, either steel or HDPE is used.

The metal oxidizes unless it is stainless steel, which is expensive. Oxide causes deterioration in water quality. Over time, it becomes brown and has a metallic taste. You will have to install a filter and clean the well. Connections are welded. It is they who are the weak point, and after depressurization, groundwater with dirt enters the casing pipe.

Low pressure plastic (HDPE) is lightweight, which simplifies installation. The inner surface is smooth and no deposits appear on it. Corrosion is not terrible, connections are tight. The sections are twisted by means of the provided thread, and no special tools are required for this. The only drawback is the limitation on the depth of the well. This material is not suitable for an artesian well.

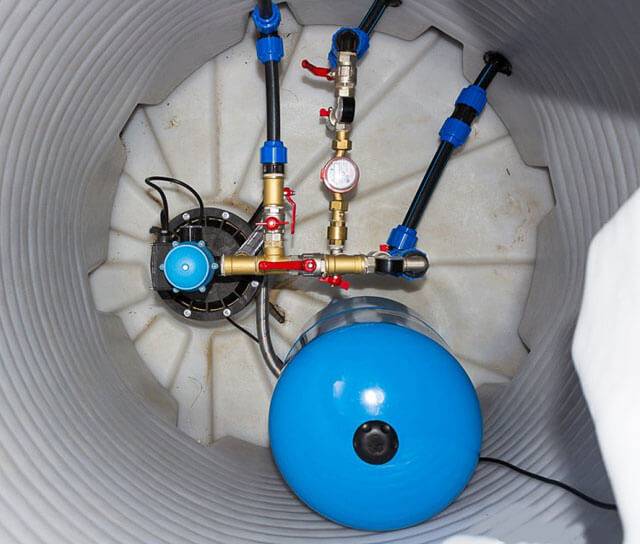

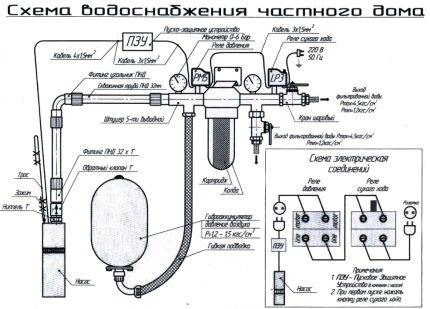

Installation of a hydraulic accumulator and other control systems

Hydraulic accumulator in the caisson

Hydraulic accumulator in the caisson

It will be unthinkable to ensure an uninterrupted supply of water when arranging a well with your own hands if a hydraulic accumulator is not connected. You can install this equipment both in the basement of the room and in the caisson itself.What is this device for? Thanks to its work, pressure is maintained in the system, because when the pump is turned on, the tank is filled with water, and it enters the house not directly from the well, but from the accumulator, which, by pumping water into the tank, maintains a constant pressure in it. Depending on the individual needs of a person, the installed tank volume can be from 10 to 1000 liters. This affects where it will be installed, as there should always be room for free access to it, in case the need arises for repair or replacement.

Now it's time to install and configure automatic control systems, which maintain the desired pressure in the system. This occupation is not easy, and requires certain knowledge and experience. In addition, working with electricity is associated with the possibility of electric shock. Therefore, if you do not really understand what is at stake, and do not have experience with connecting electrical appliances, then it is better to leave this lesson to a specialist.

If you approach this issue responsibly and do everything right, you will be able to use clean water for many years.

The procedure for installing the accumulator

In order for water to be supplied without interruption, it is necessary to install a hydraulic accumulator. Its installation can be performed directly in the caisson or in the basement of the house. The system works very simply:

Hydraulic accumulator connection diagram.

- The pump turns on, water enters the empty tank and fills it.

- Someone in the house opens a faucet, and water flows into it from a hydraulic accumulator, and not straight from a well.

- If necessary, the pump will turn itself on and fill the accumulator with water.

The container must be built into the system in such a way that nothing will prevent its repair or replacement in the future. The system provides for the mandatory installation of a check valve. It is built into the tank installation site, along the water flow. A drain cock is installed before and after the tank. The accumulator is best fixed with a rubber seal. Due to this, the vibration will be less pronounced.

Installation of an underground caisson

The most common way to equip a well in a country house with your own hands is to use a protective well above the well. In technical language, it is called a caisson. The advantage of such a well lies in the absence of cluttering up the territory: only a small hatch remains on the surface of the earth. For the thermal insulation of an underground structure, they spend an order of magnitude less money than in the case of a ground pavilion. The installation technology of the caisson implies its deepening below the level of soil freezing. As a result, in winter the object will be partially heated by heat from the ground.

Ready-made caissons of factory production in a wide range are on sale. To reduce the cost of the task of how to equip a well for water, they build a well on their own (read: “How to make a well for a well with your own hands - instructions”). Factory models do not require additional preparation before installation. All that is needed is to dig a hole of the required depth and lower the structure there. The tank is already equipped with special technological holes. Using sealed cuffs, plumbing and power wiring are laid inside them.

The material for the manufacture of finished wells is steel or polymers. Metal products demonstrate greater strength, resistance to frost heaving and impact. They are allowed to be installed in areas with unstable soils, which sometimes shift. Plastic containers are not afraid of corrosion, exposure to moisture and condensate. The only drawback of ready-made caissons for well improvement is their cost. This is compensated by quick installation and no need for additional waterproofing.

To save money, some well owners decide to build a caisson on their own. If everything is done correctly, this design will be even stronger than its factory counterpart. However, it is necessary to prepare in advance for significant time and labor costs. The easiest way to equip a well at home is to immerse two well rings made of concrete into the soil. The structure is decorated with a lid on top: it is more convenient if it has a hatch with a neck. A layer of concrete is laid at the bottom.

The procedure for waterproofing a reinforced concrete caisson usually causes problems. For outdoor installation, bitumen rolls or high-quality mastic are used. To implement this approach, the pit must be much wider than the size of the caisson. With internal insulation, high-quality sealing of seams and processing of walls, bottom and covers is carried out. For these purposes, polymer-cement material is used.

You can equip a well with your own hands not only with the help of factory rings. Sometimes monolithic or brick structures made of high-quality burnt red brick are used.Another budget option on how to properly equip a well is to use small-sized blocks of concrete. An old metal barrel will also work for this.

underground pipeline

Scheme of an external pipeline with a pipe heating system.

Also useful is a swivel for HDPE pipes and a set of additional fittings. Use only high-quality products, we recommend choosing Italian manufacturers.

So, instructions for laying pipes from the well to the house:

To the depth of soil freezing (each region has its own, the middle strip of Russia is about 5 meters), we dig a trench from the well to the house. It is better to lay communication along the shortest straight line, since then rotary docking nodes will not be needed, and the consumption of materials will be lower;

We carry out earthworks

We pour a layer of sand 10–20 cm high at the bottom of the trench, with a slight slope towards the well (1% will be enough). We lay a pipe on this backfill;

We lay the pipe on a sand cushion.

We put one end of the hose into the caisson and connect it with the help of an elbow and fittings with a water pipe;

We put the pipe into the caisson and connect it to the lifting branch.

We lead the second end into a special hole in the foundation of the house or basement, supply the entry point with a plastic sleeve and carefully seal it with silicone or other sealant;

We make an input through the wall of the foundation or basement.

We cover the pipe with a layer of sand so that it is covered to a height of 15 cm, then we fill the trench with earth. Stones in the ground should not come across, it is impossible to ram the backfill.

We sprinkle the pipe and bury the trench.

In the lower part of the pipe, it is better to provide a drainage valve for draining water from the well in case of conservation of the site for the winter.

At the bottom of a horizontal pipe or in a vertical section inside the well, a tap can be inserted to drain the water.

Sand well for water

A deeper and more efficient design - a sand well - is designed for the use of special equipment and provides water lifting from a depth of 14 ... 40 m. The hole diameter is 12 ... 16 cm (casing diameter), while the size of the casing pipes is the same throughout. The design is "placed" on waterproof (waterproof) ground and guarantees the supply due to the infiltration of water under pressure through the lower, perforated part of the product. Additional filtration is carried out by a fine-mesh filter, pressure is provided by submersible vibration pump.

The flow rate of such a device is approximately 1.5 cubic meters per hour, while the quality of the water may suffer due to seepage into the sandy layer of the perch, harmful effluents. Often a filter is installed in a set with pumping equipment. With constant use, the well can “work” up to 15 years (in coarse-grained sands), with periodic use it quickly silts up.

Important: during dry periods, water often leaves the sand layers or the level of the aquifer drops significantly.

Advantages and disadvantages

The use of caissons for a long time was a classic option for the implementation of autonomous sources of water supply. That is why the arrangement wells without caisson with the help of an adapter is still perceived far from unambiguous.Although several years of using this technology in various climatic zones of Russia have proven its effectiveness and right to life.

This method has a number of advantages:

- Installation of this product frees the owner of the well from the need to perform earthworks in such volumes as would be required by installing a caisson. And this is a very significant savings for the family budget.

- There is no need to purchase such an expensive device as a caisson.

- Using an adapter makes it possible to conduct water supply close enough to a gas pipeline or sewer.

- Repair of downhole equipment is greatly simplified.

- Protection of the well from vandalism, since it is not conspicuous in the specified design. And it is possible to dismantle the pump installed in it only using a special device.

well arrangement scheme with adapter

The disadvantages that should be taken into account when making a decision - "caisson or well adapter", relate:

- It is not recommended to use the product if a well of great depth is to be equipped.

- If there is no place to install water supply equipment in the house.

How to choose water supply equipment

Autonomous water supply is completed with the following set of equipment:

- Pump. Submersible or surface models are used to supply water from a well.

- Automation. It is designed to control the pump, which provides engine protection against overloads.

- Hydraulic accumulator. It happens open or closed. Closed membrane tanks are considered more convenient, thanks to which the working pressure is maintained at the same level.To install an open type tank, choose the highest section of the water supply. Most often this is the attic or the ceiling of the last floor. Closed drives have no restrictions on the place of installation.

The procedure for how to equip a water well with your own hands is directly affected by the features of the location of the equipment, and the specific modules that will be used for this.

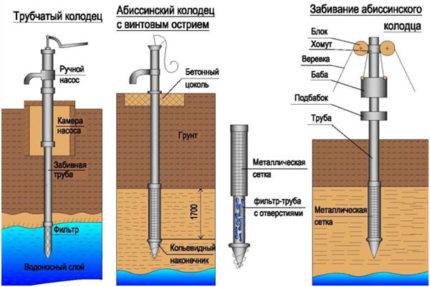

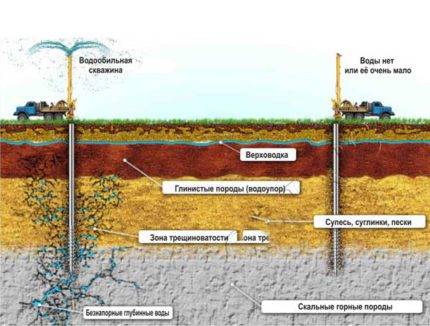

Types of wells for a private water supply

An undrinkable perch is fine for watering the garden, cleaning and similar needs. Get it easier and cheaper by well-needle devices, also called the Abyssinian well. It is a column of thick-walled pipes VGP Ø from 25 to 40 mm.

Abyssinian well - the easiest and cheapest way to get water for temporary supply of a summer cottage

This is the cheapest and easiest way to get water for temporary water supply. For summer residents who need exclusively technical water and only in the summer.

- The needle well, otherwise the Abyssinian well, is the easiest and cheapest way to create a water source for a private house.

- You can drill an Abyssinian well in one day. The only drawback is the average depth of 10-12 m, which rarely allows the use of water for drinking purposes.

- An Abyssinian well can be arranged within the house by placing pumping equipment in the basement or utility room.

- The needle well is great for extracting water for watering a garden with a vegetable garden and caring for a suburban area.

- Sand wells can supply water for both technical and drinking purposes. It all depends on the specific hydrogeological situation in the suburban area.

- If the water carrier covers the layer of water-resistant soils from above, then the water may well turn out to be a drinking discharge.

The soils of the aquiclude, which prevent the penetration of water, prevent the penetration of domestic wastewater. If the water-containing sand does not have natural protection in the form of loam or solid sandy loam, the drinking purpose will most likely have to be forgotten.

The walls of the well are strengthened with a string of steel casing pipes connected to each other by couplings or a welded seam. Recently, polymer casing has been actively used, which is in demand by private traders because of its affordable price and corrosion resistance.

The design of the sand well provides for the installation of a filter that excludes the penetration of gravel and large sand suspension into the wellbore.

The construction of a sand well will cost much more than an Abyssinian well, but cheaper than drilling a working in rocky soils

The working part of the well filter should protrude beyond the aquifer from above and below by at least 50 cm. its length must be equal to the sum of the thickness of the aquifer and at least 1 m of margin.

The filter diameter must be 50 mm smaller than the casing diameter so that it can be freely loaded and removed from the wellbore for cleaning or repair.

Wells, the trunk of which is buried in rocky limestone, can do without a filter and partially without casing. These are the deepest water intake workings, extracting water from cracks in the bedrock.

They serve longer than analogues buried in the sand. They are not characterized by the process of siltation, because. in the thickness of the water-containing soils there is no clay suspension and fine grains of sand.

The risk of drilling an artesian well is that the fracture zone with underground water may not be detected.

At a depth of more than 100 m, it is permissible to use asbestos-cement pipes or drill a well without casing at all, if there is no need to strengthen the rocky walls of the hydraulic structure.

If an artesian well has passed more than 10 m of fractured rock containing groundwater, then a filter is installed. Its working part is obliged to block the entire thickness supplying water.

The scheme of the water supply system of an autonomous house with one filter is typical for artesian wells that do not require multi-stage water purification

How to make a drilling tool

The easiest way is to buy, rent or borrow from friends. But if this is not possible, it is too early to despair. Any drilling device can be made independently. Before you drill a well in the country, you need to include in the estimate the materials that will be required for its manufacture.

Spiral and spoon drill

The bearing element of a design is an iron rod. A number of knives are welded to it. You will also need a disc sawn in half. Its edges are sharpened. Knives beveled at 20 degrees are welded to the rod along the longitudinal axis opposite each other. In this case, it is necessary to ensure that the diameter of the structure exceeds the dimensions of the casing.

Another way is to weld sheet metal in a spiral. For this, a strip is taken that needs to be “wrapped” around a rod or pipe. It is advisable to harden and sharpen the edges of the cutter. Of course, in the garage, with bare hands, this tool is hardly possible to make. But if all the necessary equipment and metalworking skills are available, the procedure will not be difficult.

Bailer and glass

If it is planned to produce do-it-yourself well drilling using a bailer, it can be made from a pipe 2-3 meters long. The wall thickness can reach 1 cm. A shoe with a flap type valve is provided in the lower part. This is a plate of sheet metal, which is pressed by a spring of medium elasticity.

The lower end faces are sharpened inward. The upper end is sealed with an iron mesh. A bracket is attached to the bailer for attaching the cable. In this configuration, at the moment of impact on the ground, the loosened rock enters the glass, and the valve does not allow it to fall out during the lifting process. Every 5-10 lowerings it needs to be cleaned.

Making a needle for an Abyssinian puncture

A thick metal bar made of hard grades of steel is used. The diameter should be such that under shock loads the metal does not break, does not shrink or bend. The tip is hardened and sharpened. The essence of the method is to pierce a rod into the soil with a sledgehammer. You don't have to choose anything. It is enough to remove it after completion of work and insert a casing pipe with a filter.

Rental of a mobile drilling rig

The simplest and least time-consuming method of constructing a well in your own country house is to rent a mobile drilling rig. With its help, it is possible to drill and equip a sole facility for water intake on the site in a couple of days.

The installation will effortlessly pass through the thickness of sedimentary soils and, if desired, the master will open the indigenous ones, but this method cannot be called cheap.

To drill a water intake, you will need a drilling tool. To extract loose rocks, you will need a bailer; clay soils are easier to lift with an auger, a glass or a core pipe.If you have to destroy boulders or rock, you need to stock up on chisels.

As a more affordable alternative, a collapsible manual drilling device is suitable. It includes an auger with a handle for rotational movement during drilling and a set of rods for building up the drill string. Wells of 10-25 m are calmly drilled with a "handbrake". It is possible even deeper, if health and the number of rods allow.

In the absence of a drilling rig or factory-made device, they resort to methods that were not so long ago used in professional drilling. The conversation will focus on the shock-rotational and shock-rope manual method.

Due to the heterogeneity of the geological section, drilling methods are most often used in combination. The difference in the technique of destruction and extraction of rock allows you to go through literally any geological formations in terms of complexity.

Set for hand drilling wells (popular name "handbrake") is the simplest factory-made drilling rig. Designed for auger drilling. For production purposes, it is used where it is not possible to deploy a standard drilling rig tower (+)

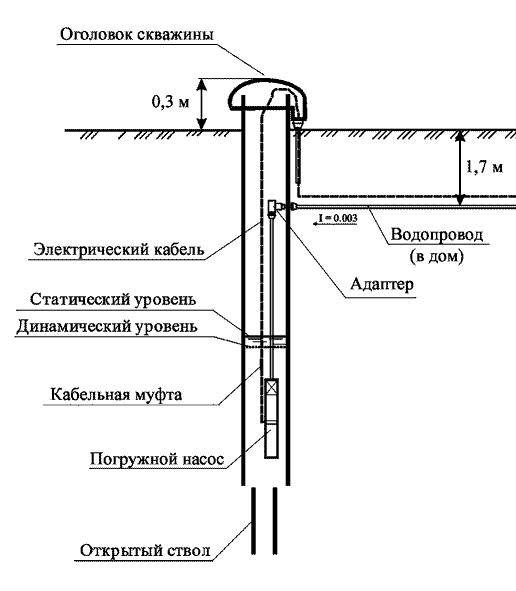

Ensuring the tightness of the casing

Neither dust, nor condensate formed in the caisson, nor, moreover, rain and melt water should get into the well casing that supplies the house with drinking water. If this happens, harmful microorganisms from the surface can get into a clean underground source and it will be difficult and expensive to “treat” it.

For well sealing, fastening the submersible pump and passing communications, use the factory head: it is relatively inexpensive and makes installation of equipment very easy

For well sealing, fastening the submersible pump and passing communications, use the factory head: it is relatively inexpensive and makes installation of equipment very easy

To protect the source, a borehole head is used - a special steel cover equipped with technological holes for passing communications and a reliable hook for hanging the pump. The head is selected according to the diameter of the casing, it has a rubber crimp cuff that seals the casing. The water pipe and electric cable are also introduced through hermetic seals.

We do not recommend cut the tubing close to the floor of the caisson. It is better to leave a section 25-40 cm high above the concrete surface. Firstly, it will be more convenient to mount a pump with a head. Secondly, with a slight flooding of the caisson, water will not enter the wellbore.