- Arrangement of a water well using an adapter

- Protective head mounting

- Do-it-yourself installation steps for caissons

- Caisson from reinforced concrete rings

- brick caisson

- Polymer caisson

- Important nuances

- Advantages of a well with a caisson

- Caisson or adapter - in what type of wells are they installed

- Laying water pipes

- Types and features of installation of caissons

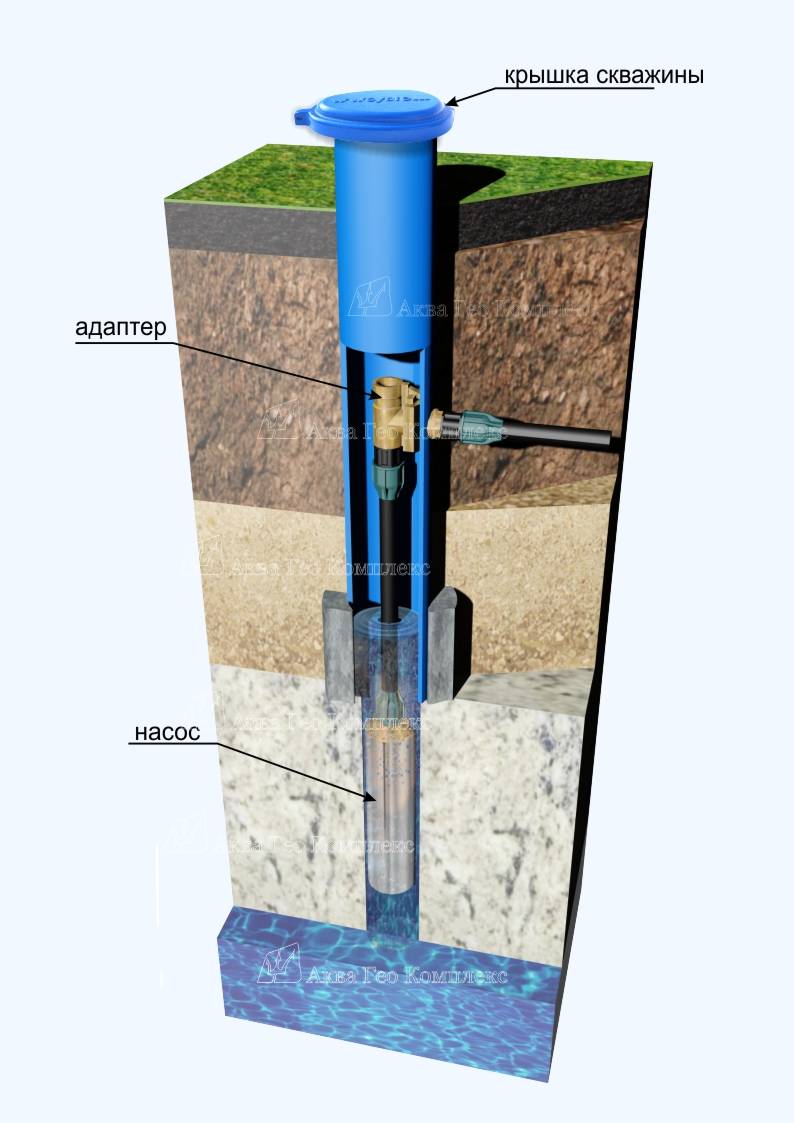

Arrangement of a water well using an adapter

Installation of the product in the well is carried out in the following sequence:

- A hole of the desired diameter is drilled in the casing string. At the same time, it must be remembered that the place for it is chosen in such a way that the connected water supply is below the freezing mark in the area.

- Half of the installed device is inserted into the hole formed (from the inside) so that a threaded pipe protrudes from the side of the outer wall of the column. A plastic pipe for a water pipe, laid at the depth of the hole, is joined to it.

- The next step is to connect the remaining half of the pitless adapter to the pipe intended for lifting water, which, together with the downhole pump and pipe connected to it, gently lowers into the well.

- There, both parts of the device are joined, for which a special lock is provided in their designs.The fact that the lock has worked is indicated by a sharp characteristic click.

- Then the safety cable, which is attached to the pump, and the electrical wiring connected to it, are brought out to the head.

- The performance of the assembled system and the tightness of all its elements are checked. The well is then backfilled.

Video with step-by-step instructions for installing a downhole adapter:

When performing these works, it is important not to forget that the part of the installed adapter, built into the wall of the casing string present in the well, will occupy at least 30 mm of the well clearance. This makes it necessary to choose a submersible pump model, taking into account its geometric dimensions, which should be 40 or more millimeters less than the inner diameter of the installed casing.

If this is not taken into account, then the pump simply cannot be lowered / raised.

It is possible to dismantle a deep-well pump installed in a well using a metal pipe specially designed for this, one of the ends of which is threaded. By screwing it into a special socket on the removable part of the device, you can remove the pump to the surface.

Protective head mounting

Structurally, the head consists of the following parts:

- carabiner and flange connector;

- dense rubber rings;

- fasteners;

- covers.

You can ennoble the well with a head in the following order:

- During installation, the column is cut, cleaned and treated with a protective composition against corrosion and decay.

- The supply cable of the pump and the water pipe are passed through the inlet cover of the structure.

- Pumping equipment is joined to the pipe. The hanging end of the cable is fixed to the carabiner with an eye bolt located inside the cover.A flange and a sealing ring are fixed to the column.

- The pump is immersed to the bottom of the well, a cover is fixed on top of the fixing bolts.

Do-it-yourself installation steps for caissons

Installation of a monolithic concrete caisson

A monolithic concrete tank is poured in this way:

- Formwork is installed on the prepared base, stepping back from the walls of the pit left 20-30 cm. You can drive the frame out of the boards gradually (30 cm each) or immediately to the full height.

- A reinforcing mesh is installed in the formwork.

- Prepare a solution of cement, sand and gravel in a ratio of 1:3:5, respectively. Bulk is diluted with water until a mixture of a creamy thick consistency is obtained.

- The finished solution is poured into the formwork in portions and gently rammed with a metal bar to drive out the remaining air.

- As soon as the tank completely hardens, the formwork is removed and holes are made in the walls with a puncher for the output of cables and water mains. All technical gaps are sealed with cement-sand mortar.

- The outer walls of the finished caisson are coated with bituminous mastic.

The top of the chamber can be equipped with a wooden shield covered with roofing felt, or a monolithic slab can be poured, first installing a wooden formwork made of durable boards

It is important to leave a hole in the slab for the hatch

Caisson from reinforced concrete rings

Because to do concrete well caisson rings with your own hands is difficult, here you will need the help of special equipment. Before installation, the elements must be treated on both sides with bituminous mastic. After it dries, the rings are alternately lowered into the pit on a pre-prepared base. It is advisable to coat all joints with mounting foam and, after it dries, go through the mastic again.

With the help of a perforator, technical side holes are made, and the gaps are sealed.

The top of the caisson from the rings can be made of a concrete slab with a hatch or just a welded metal shield.

brick caisson

Taking into account the fact that the bottom of the pit has already been prepared (there is a concrete platform), strips of roofing material should be laid along the perimeter of the future masonry. Only after that they start laying. You need to lay a brick from the corner, moving towards the opposite from one side and the other. The thickness of the solution between the blocks is 1-1.5 cm

It is important to install metal sleeves where the outlets of the water pipes and cables are supposed to be. Then the walls of the caisson are driven out to the desired level. As soon as the chamber is completely dry, it is plastered and coated with bituminous mastic from the outside and from the inside.

After the waterproofing has dried, the chamber is backfilled

As soon as the chamber is completely dry, it is plastered and coated with bituminous mastic outside and inside. After the waterproofing has dried, the chamber is backfilled.

Polymer caisson

Plastic caisson with stiffeners

Plastic caisson with stiffeners

You can make a caisson for a well from a plastic barrel or buy a ready-made durable structure with stiffeners. The second option is preferable, since the tank will be able to withstand the pressure of heaving soil.

Often, it is permissible not to make a powerful concrete base for the installation of a polymer tank. Enough sand bedding 10-15 cm thick.

Polymer caisson installation technology:

- The camera is installed on wooden beams, having previously formed a technical hole in the bottom for the casing string.

- Carefully put the caisson on the pipe and lower it down.

- Under the output of pipes and cables, it is desirable to make additional holes immediately on the surface.

- The backfill of the polymer chamber is made from a sand-cement mixture. It is slightly moistened and compacted well in layers.

- Equipment in a plastic caisson is best placed 10 cm from the walls of the tank.

Important nuances

If the land on the site is fertile, and in case of destruction the surface layer will have to be restored, it is preferable to use cluster drilling. Pad drilling reduces backfilling and reduces the cost of resource extraction. Any work on the site can be started only after studying the level of groundwater. If this level is high, it is better to place the protective room on the surface, rather than deepen it underground.

It is extremely important to choose and fix the pump correctly. The role of equipment is extremely important for an autonomous water supply system

For wells, it is customary to choose submersible pumps, as they have better performance. But when choosing, it is important not to overdo it, since the size of the hydraulic structure itself will be an important parameter. The length of the drains is also taken into account. For example, with a water intake structure height of 33 meters, the pressure in the system should be from 1.4 to 3 atmospheres.

For constant support and the possibility of changing the working pressure, a hydraulic accumulator is needed. The tank will provide storage of the minimum water reserve. Modern equipment of this type is a single design, the main distinguishing feature of which is capacity. For example, for summer cottages, a capacity of up to 55 liters is sufficient, and for hotels and boarding houses, devices from 100 to 950 liters are selected.

An important protective device of the well is the head. Usually the device is equipped with holes for installing water pipes, as well as power cables.

The cap protects the structure from biological and other contamination.

The design of the head includes such parts as:

- carabiner, flange;

- rubber rings;

- fasteners;

- covers.

If the well is equipped with a cap, then the column is cut off during installation. The cut is cleaned and treated with anti-corrosion agents.

- The supply cable of the pump is inserted through the inlet cover of the water pipe.

- The pump is connected to the pipe, and the hanging end of the cable is fixed with a carabiner.

- The flange is fixed to the column, and a sealing ring is installed on top.

- Next, the pump is immersed to the bottom of the well, and the head cover is fixed with bolts.

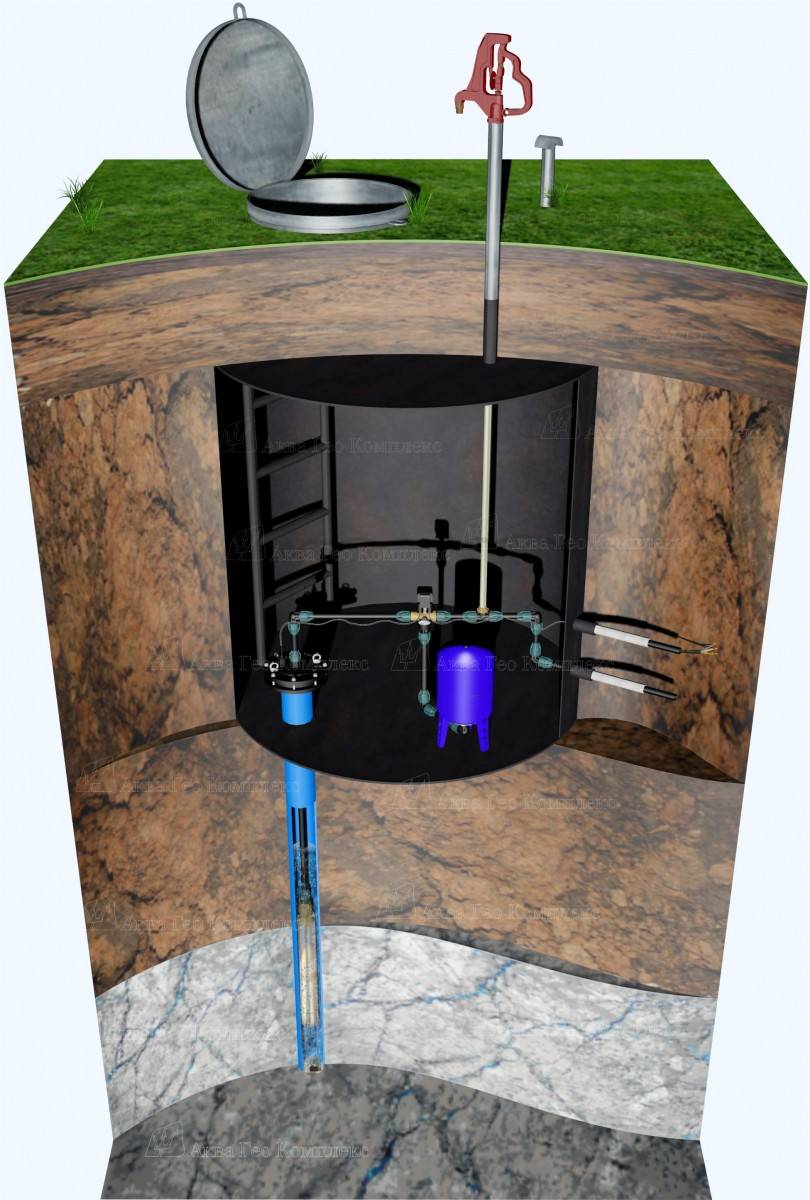

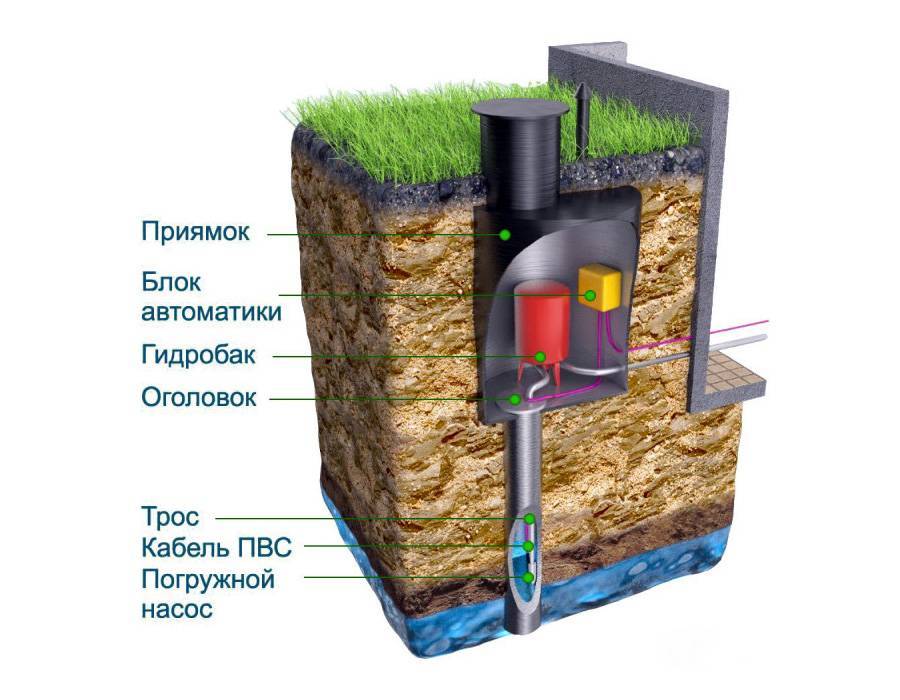

Advantages of a well with a caisson

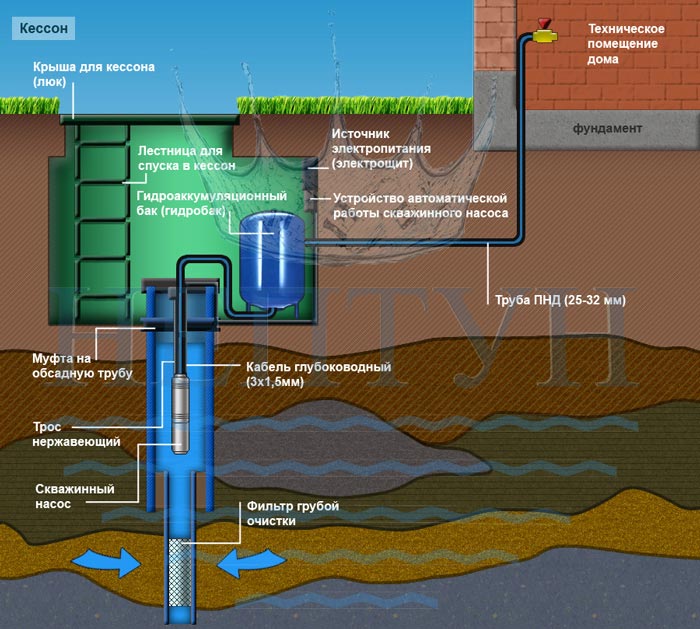

With year-round use of the well, one cannot do without installing a caisson at its mouth. This enclosing structure is a waterproof chamber located in water-saturated soil. From the point of view of ease of maintenance and operation, a well with a caisson is the best option.

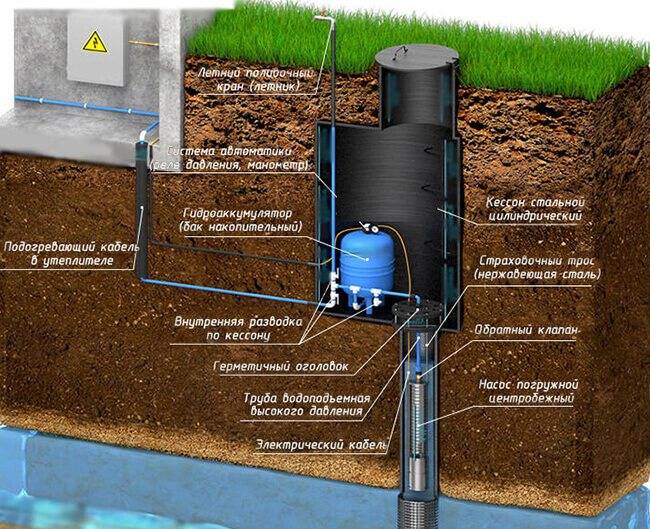

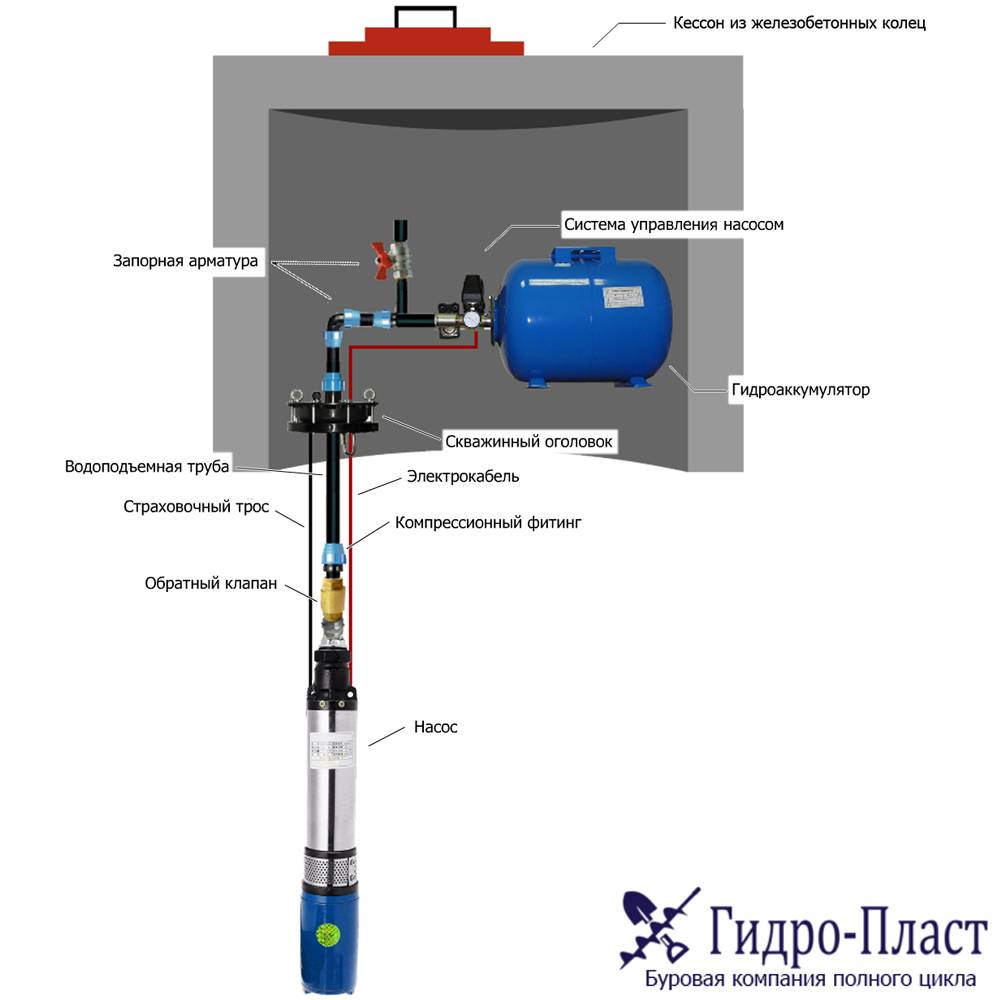

In addition to the caisson, the integral elements of a water well are a hydraulic accumulator, a surface or submersible type pump, pipes, shut-off and control valves, if desired by the owners and a head.

In winter, a stable temperature is maintained inside the caisson. It usually does not fall below 0°C. In such conditions, pumping equipment can be operated all year round.

This solution has a number of advantages:

- All plumbing equipment is placed compactly in the chamber and there is no need to allocate a separate place for it in the house.As in the case of central water supply, only a pipe will need to be brought into the house, as well as a supply cable for the pump.

- If the house is intended exclusively for summer living, then to remove water from the water supply for the winter, you only need to open the drain valve located in the caisson.

- When it is necessary to supply input at several points on the site, then this idea is very simple to implement by removing the required number of pipelines from the caisson. The regulation of the process is carried out by means of valves.

- A winch mounted in the upper section of the chamber will simplify the process of extracting the pump from a deep well in case it needs to be repaired or replaced.

- The chamber will protect the downhole equipment located in it from freezing. If the installation of the caisson is done correctly, you can not worry about the safety of its filling even at a temperature of -35°C.

Thus, in the presence of a caisson, adverse external factors will not affect the quality of the water supply at home.

The main requirement for the caisson is tightness. If this condition is violated, dirty water from the chamber can get into the aquifer through the casing pipe. Pollution of the aquifer is unacceptable, so the head of the well and the caisson must always remain dry.

To supply water to a house and a personal plot, the best option for a caisson is plastic. It provides 100% tightness. Simplifies its delivery and installation light weight

When calculating the height of this structure, one should proceed from the depth of soil freezing. In order for the caisson to be guaranteed to be below this point, the size is assumed to be two meters.For the convenience of performing work inside the caisson, the diameter of the internal space should be within 1–1.5 m.

The chamber is made of metal, plastic, brick or reinforced concrete rings. In its bottom there is a place for fixing the structure on the casing string. Branch pipes for removing pipes and cables are located in the walls. To provide convenient access to the equipment, the caisson is often equipped with a ladder. The chamber is sealed with a sealed lid.

This is interesting: How to choose a pump for a well: types of equipment, what parameters are important to know when buying + video

Caisson or adapter - in what type of wells are they installed

To provide water to individual houses, wells are drilled, which are conditionally divided into three categories:

Abyssinian. This type of wells is arranged at a shallow depth of aquifers from the surface, private individuals and organizations are engaged in hydraulic drilling. The Abyssinian well is passed during the day, instead of casing pipes, a piece of HDPE pipe with a filter at the end is taken. The depth of the Abyssinian depends on the location of the aquifer and lies in the range of 5–30 m. The water surface in the Abyssinian should not fall below 9 m, external centrifugal electric pumps or stations are used to draw water, which are located in the immediate vicinity of the source.

Wells in the sand. This is the main type with a water table from the ground level below 9 m, the depth of the wells lies in the range from 20 to 60 m, a submersible pump is used for sampling. When installing a deep-well electric pump, it is easier and more cost-effective to connect it through an adapter screwed on the side of the casing pipe wall, while the caisson is not mounted.

Artesian.To access artesian water basins, a well is drilled with an average depth of 100 m, in household water sources it can be more, but at depths of more than 200 m, the already significant costs increase dramatically due to the use of industrial technology for driving such distances.

Due to the pressure of the earth layers on the deep water basin, water from artesian wells often rises to a great height and even comes to the surface, a surface electric pump is used for supply and, accordingly, a caisson well is mounted. Nobody forbids extracting water from an artesian source with a deep pump, which has higher efficiency and characteristics; when it is installed, it is more economical to use a borehole adapter to drain water into a house.

Although the use of an adapter is more rational when operating deep-well pumps for water intake, a caisson well has the advantages of convenience in the need to remove and maintain a submersible electric pump, besides, it protects the well channel from freezing in winter. Therefore, the caisson is often placed when water is raised by a submersible pump, placing automation in it: a pressure switch and a dry run, a pressure gauge, a hydraulic accumulator.

Laying water pipes

Fine crushed stone and sand are poured into the bottom of the structure, the thickness of each layer should be at least 12 cm.

To prevent possible silting of the bottom, the finished well in the country is cleaned with a bailer.

Next, the laying of the first pipe is carried out, which will prevent the shedding of the internal walls of the mine.

It is recommended to make small holes around the entire perimeter of the pipe at a level of 20 cm from the bottom of the structure to increase the water pressure. A mesh filter is installed in the end part of the pipe.

For the arrangement of the mine, a water pipe with a length of 2 to 2.5 meters and one connecting elbow is used. The first pipe is installed at the required depth of the well so that the emphasis is on the bottom of the pit. Next, the installation of the next pipe is carried out with fixation to the first element by screwing onto the thread.

Types and features of installation of caissons

The uninterrupted operation of the well is designed to provide a caisson, an insulated waterproof container with the necessary equipment inside.

Usually a pump, shut-off valves, measuring instruments, automation, filters, etc. are mounted in it. Buildings are made from different materials. The most common:

Plastic. They are distinguished by excellent thermal insulation, which allows even without additional insulation to maintain the temperature inside the caisson at the level of 5C. Durability, excellent waterproofing characteristics, which makes it possible to avoid additional costs for insulation work, reasonable price, especially in comparison with other options. In addition, the system is quite easy to install due to its low weight. The main disadvantage is low rigidity, which can provoke deformation of the structure and damage to equipment. However, it is easy to deal with it by filling the container around the perimeter with cement mortar with a layer of 80-100 mm.

Plastic caissons have excellent thermal insulation, which allows them to be installed without additional insulation.

Steel. Most often, the arrangement of a water well is carried out with just such a design. The material allows you to make a caisson of any desired shape, while not requiring much effort.It will be enough just to weld the parts together and treat the structure from the inside and outside with a special anti-corrosion coating. For a high-quality container, metal 4 mm thick will be quite enough. You can also find ready-made structures on sale, but their purchase will cost much more than self-production.

There are various forms of steel caissons - for various needs

Reinforced concrete. Very strong and durable installations, previously extremely common. Due to their shortcomings, today they are used much less frequently. Their cost is very high, and special equipment is required for installation, which is due to the large weight of the equipment. For the same reason, over time, the concrete caisson sags, deforming the pipelines inside it.

Concrete has insufficient thermal insulation, which can cause water in the pump to freeze in severe frosts, and poor waterproofing, since concrete is hygroscopic

Here is an approximate scheme for installing equipment in a caisson and connecting communications:

Scheme of installation of equipment in the caisson

If you are going to complete the arrangement of the well with your own hands, it is worth getting acquainted with the stages of installing the caisson. They are almost the same for any type of structure, with slight nuances depending on the material of the equipment. Let's consider the stages of installing a steel tank:

Pit preparation. We dig a hole, the diameter of which is 20-30 cm greater than the diameter of the caisson. The depth must be calculated so that the neck of the structure rises about 15 cm above ground level. This way, it will be possible to avoid flooding the tank during the flood and heavy rainfall.

Casing sleeve installation. We make a hole in the bottom of the container.It can be positioned traditionally in the center or shifted as needed for equipment installation. A sleeve 10-15 cm long must be welded to the hole. Its diameter must be greater than the diameter of the casing pipe. Be sure to check that the sleeve can be easily put on the pipe.

Installation of nipples for the withdrawal of water pipes. We weld them into the wall of the container.

Caisson installation. We cut the casing pipe at ground level. We put the container on the bars above the pit so that the sleeve on the bottom of the container “dresses” on the pipe

We check that the axes of the caisson and the casing exactly match, then carefully remove the bars and carefully lower the structure down the casing. We install the container in the pit strictly vertically and fix it with bars. We weld the pipe to the bottom, while sealing the caisson

Through the nipples we start water pipes into the structure

We weld a pipe to the bottom, while sealing the caisson. Through the nipples we start water pipes into the structure.

Backfilling of the building.

The caisson is “put on” on the casing pipe and carefully lowered into the pit

It should be noted that, in principle, it is possible to equip a well without a caisson, but only if a heated building is located near it, in which the equipment is located.

The convenience of such a system is undeniable - all nodes are easily accessible. However, the disadvantages are also significant: it takes up a lot of space in the room and most often makes a lot of noise.