- Well in the yard - to be or not to be

- The choice of the type of well depending on the remoteness of the water basin

- Prices for pumping stations

- Check frequency

- Supervising the work of repairmen

- To wash or not to wash?

- Description of the work technology

- Choosing the Right Pump

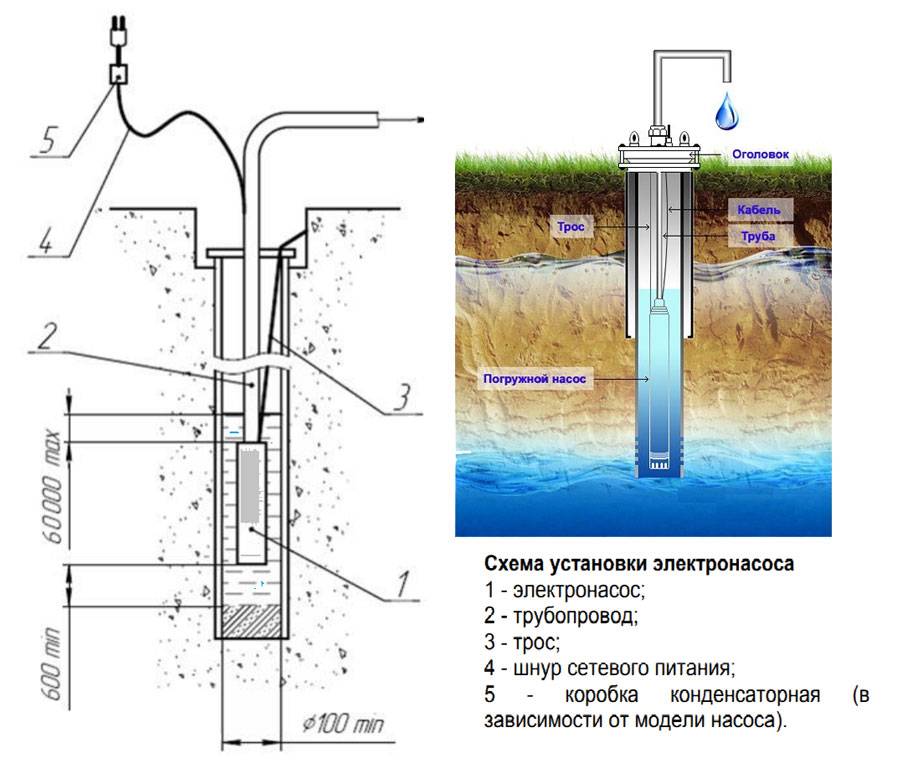

- Suspension of the pump

- Time required for buildup

- Mistakes to Avoid

- Well maintenance in winter

- Why do you need water well maintenance?

- Well buildup

- What is included in the maintenance of water intake facilities?

- Well diagnostics and workover

- What is this study and when is it needed?

- Maintenance of water lifting equipment

- Well commissioning - rules

- Site preparation

- Determining the type of work and the cost of services

- Preparatory stage

- Maintenance of hydraulic structures in winter

- Well operation

- Well operation methods

- What is tamponage

- Complications during well operation

- Causes of breakdowns in which it is pointless to repair a well

- Breakdowns that can be repaired

- Maintenance of pumping equipment: how is it done

Well in the yard - to be or not to be

Drilling a well is a laborious and dirty business, and the desire of land owners to carry it out independently is dictated solely by the need to save money.There are, of course, specialized organizations that will do everything quickly and efficiently, but such a service will cost almost the same price as the material. Hence the desire - and sometimes unreasonable confidence in the expediency of an unprofessional approach to this action.

The drilling rig will easily pass even rocky ground

The drilling rig will easily pass even rocky ground

When can it be a waste of time? For example, when the water surface of the ground basin is far from the surface. In order to take on the extraction of underground water, you must be sure that it is there. And even when it is close (it happens that it is even one meter from the surface), it is not a fact that its quality will be drinkable.

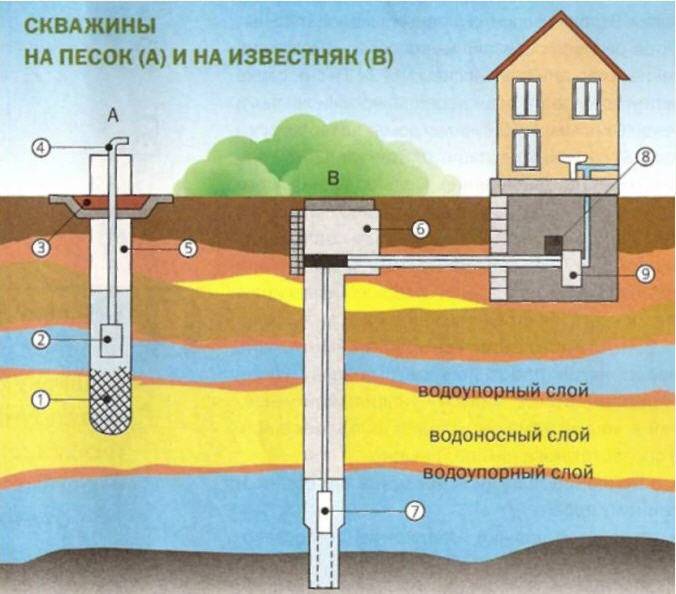

Most likely, this is perched water - a focal zone of loose soil, voids in which are filled with rain or melt water. She can only water the beds or wash the car. In addition, the top water is unstable, and in the summer the water can leave it completely. What is the water supply then?

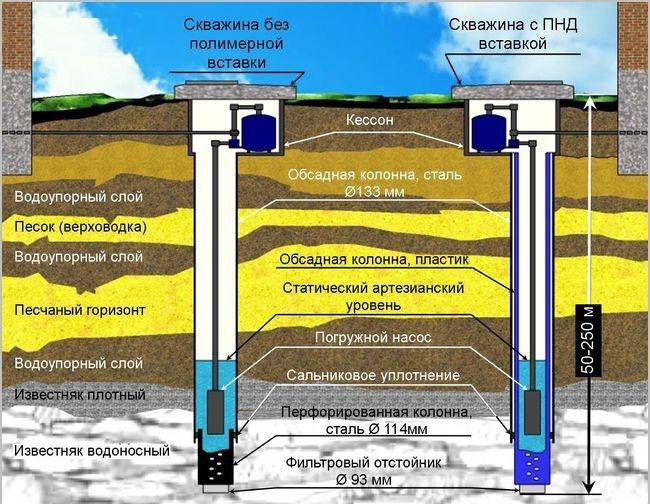

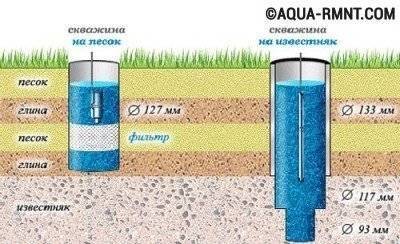

Approximate scheme of water occurrence

The water level is more stable in the ground basin, which lies below the perch, in the first sandy layer underlain by a clay aquiclude. It is in this horizon that water is taken for wells and ordinary wells (referred to as "on the sand"). By law, this can be done for free and without any permission, if you have not gone further than this layer.

However, extracting water from the sandy, water-saturated layer closest to the earth's surface can also be problematic. For example, because of its strong remoteness, which can be 30 or more meters. For professional drillers, this is just a trifle, but for a person with a homemade drill, it is a real hard labor.

The choice of the type of well depending on the remoteness of the water basin

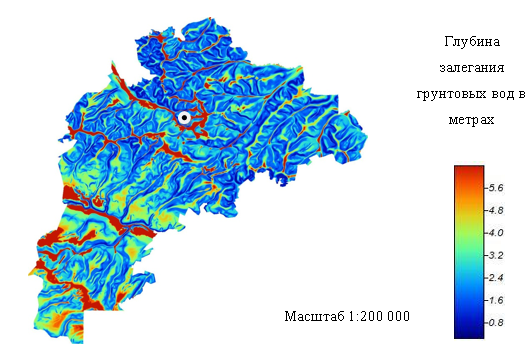

By itself, the question arises: how to find out at what level the water is? The easiest way is when your neighbors already have a water intake - you can navigate by its depth. If this is not possible, contact your local geological party - they should have data, and annually updated.

An example of mapping with water depth data

An example of mapping with water depth data

If nothing worked out here either, you will have to rely on the old-fashioned ways of finding water. And they, by the way, also work: where water is closer, grass grows wildly - and L-shaped metal rods also cross. You still won’t get an answer to the question about the exact depth of its occurrence by such methods, and it depends on what type of well you need to drill. And in this case there can be only two of them.

Option number 1. Mini-well (Abyssinian, well-needle, tubular well)

Such a water intake has a diameter of less than 3 inches, and a depth of no more than 8 meters. Its advantage is that it can be located not on the site, but in the underground of the house, and not bother about the insulation of the mouth and surface equipment.

The depth limitation is due to the fact that no submersible pump will enter such a penetration, since their diameters, from these same 3 inches, are just starting. And surface pumps cannot get water from a greater depth than 7-8 m.

Extraction of water by a household pumping station from a mini-well

Extraction of water by a household pumping station from a mini-well

Prices for pumping stations

Pumping stations

Abyssinian well service

Abyssinian well service

Option number 2. Well in the sand

It has a diameter of 80 mm or more, the depth can reach 40-50 m - in accordance with the level of the water table under the ground. You can also drill it yourself - provided that it is not too deep.

A full well has a larger diameter

A full well has a larger diameter

Driving a length of 15-20 meters is quite real, but again, the complexity of the work depends on the diameter of the pit, and on the type of soil removed from it. If it is predominantly rocky, you will most likely regret taking on such a job. And it will be doubly insulting if it turns out that there is little water in the horizon found.

If everything works out, you can install the pump not on the surface, but in the wellbore, and the water in it will certainly be cleaner, as it has passed through thicker layers of soil.

The advantages of such water intake include the possibility of deepening the trunk in case of depletion of water reserves in the exploited horizon.

Well structure on sand

Well structure on sand

Check frequency

The order and frequency of analysis of drinking water in wells and other water intake systems is regulated by SanPiNs 2.1.4.1074-01 and 2.1.4.1175-02, norms MPC 2.1.5.1315-03.

According to them, mandatory control of drinking water is carried out:

- when putting a newly drilled well into operation;

- its repair;

- reconstruction and re-equipment;

- change in cleaning technology.

During the first year of operation of the well, water testing should be carried out four times (each season), in the future - once a year. Water in individual wells is recommended to be checked at least once every few years.

Supervising the work of repairmen

Having entrusted repair work to professionals, the owners are unlikely to be able to relax.After all, they will be interested in whether the money spent will pay off - whether the repair will be done efficiently.

A professional approach to repair includes several stages:

- Depth measurement and determination of the water level - that is, a visual inspection.

- Checking all connections and condition of pipes with a special probe - the use of the so-called geophysical diagnostic method.

- Re-examination with a video camera (lowered on a special cable) is carried out in order to clarify the results of geophysical diagnostics.

- Cleaning and washing is carried out using several types of ruffs and scrapers of different diameters, as well as traps for collecting dirt.

To wash or not to wash?

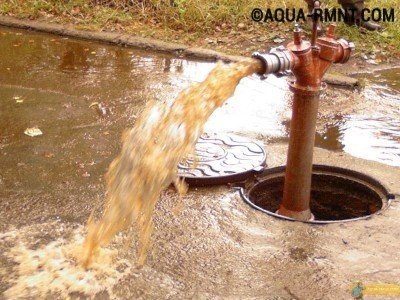

Sometimes homeowners are sure that the well needs to be flushed regularly. However, experts note that this procedure is necessary only in specific cases, for example, when a well is silted. In fact, if the facility is used regularly, flushing occurs naturally.

But in situations where the well is used irregularly, for example, only in the summer in a summer cottage, silting can occur with a very high degree of probability. In this case, the well must simply be pumped so that the sediment comes out with water.

In some cases, flushing a well, even with the help of an invited team, is unlikely to give results. For example, if the quality of the water entering the house has deteriorated, and fine filters have to be replaced more often, probably in well is out of order filter, it will need to be completely replaced. Another way to diagnose this problem is to take some water up to the filters and let the water settle. Soon a sandy sediment will appear at the bottom.

If such problems occur with a well that is used regularly, it is possible that the well head is flooded with sewage, or the integrity of the casing string is broken.

If the water well pump is clogged, it must be cleaned or replaced

It happens that the water remains clean, but comes in insufficient quantities. In this situation, the filter is most likely just clogged. To restore the functioning of the well, it must be cleaned. Thus, by constantly monitoring the operation of the equipment, as well as observing the quantity and quality of incoming water, it is possible to identify the problem at an early stage and quickly eliminate it.

Description of the work technology

Actually pumping a well is an ordinary pumping of water

However, there are several aspects to which special attention should be paid.

Choosing the Right Pump

Even if the owner has prepared a powerful water supply device, you should not lower it into the well. Experience shows that high-quality expensive equipment will come in handy later, for pumping clean water. Whereas it is advisable to purchase an inexpensive submersible pump specifically for the buildup process. Most likely, he will regularly fail, pumping a muddy suspension, but he will bring his work to an end. At the same time, the more expensive “permanent” option will remain unscathed and will be able to work perfectly on clean water. Another caveat: the “temporary” pump must be a submersible centrifugal pump, since vibration models simply cannot cope with such a load.

Suspension of the pump

Thinking how pump the well after drilling, it is worth paying special attention to the height of the pump. It should be close to the line of the bottom of the well, 70-80 cm above its mark, practically on the same level with the gravel pack. In this case, the sludge will be captured and actively removed to the outside.

In order for the pump to work in this mode for as long as possible, it must be periodically stopped, removed and washed, passing clean water through it.

In this case, the sludge will be captured and actively removed to the outside. In order for the pump to work in this mode for as long as possible, it must be periodically stopped, removed and washed, passing clean water through it.

Time required for buildup

It is difficult to say right away exactly how many hours or days it will take to pump the well.

The process should continue until clean water appears. The intensity of the swing directly affects the result. The more water is pumped out, the more sand and other small particles go with it. Coarse sand that has not passed through the filter settles to the bottom, forming an additional filter layer.

The duration of the buildup process depends on the composition of the soil on which the well is equipped

Experts say that in order to completely clean the well, more than a dozen tons of water must be pumped out of it. On average, with a structure depth of 50 to 500 m, the process should take at least 48 hours, with a smaller depth, respectively, less.

Mistakes to Avoid

In the behavior of the buildup of a new well, errors occur that disrupt the cleaning process. The most typical of them are:

-

- Pump too high. It should not be placed near the surface of the water.Otherwise, the use of the equipment will be useless: it will not be able to capture fine particles, which are most abundant in the bottom part of the well. In this case, despite the measures taken to build up, the well will quickly silt up and stop producing water.

- Pump set too low. A buried device will not be able to function properly. It will very quickly clog with suspension and stop. In addition, the pump can "burrow" in the silt. It is very difficult to extract the apparatus pulled into the ground to the surface.

Illiterate water disposal. Pumped out dirty water should be discharged as far as possible. Otherwise, it can again fall into the well, and then the buildup process can last almost indefinitely.

When pumping, it is important to divert contaminated water as far as possible, otherwise it will return to the well and the process will last indefinitely

Descent of the pump on an insufficiently strong cord supplied with it. It's better not to. The device can get stuck in the well or be sucked into the silt. In this case, pulling it out by the cord is unlikely to succeed. It is worth buying a strong thin cable and using it to lower the pump for buildup.

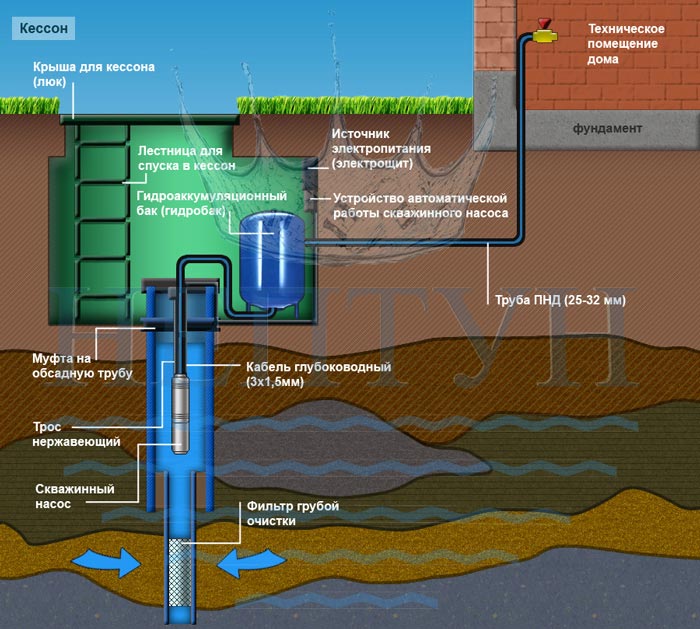

Well maintenance in winter

Quite often, water wells are operated in the winter, which involves preliminary preparation. To prevent freezing of the liquid in the casing, insulate it to the level of soil freezing. The depth of freezing can reach 2.5 meters.

The warming process is carried out in this way:

- when drilling a hole, a ditch is dug around the installation (in other words, rust);

- a caisson-type device is mounted in the rust to protect the well from freezing;

- the caisson device is equipped with an impenetrable special hatch and clamps to prevent water from entering inside.

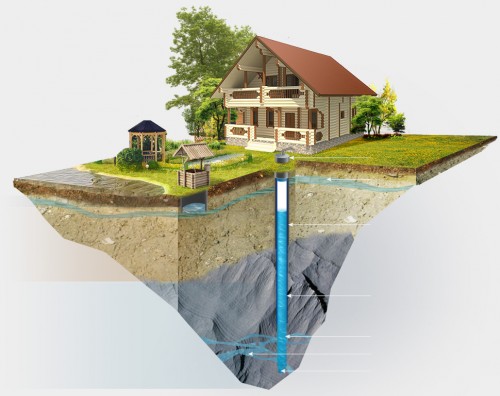

Why do you need water well maintenance?

Maintenance of the well consists in maintaining its cleanliness and operability of pumping equipment.

Maintenance of the well consists in maintaining its cleanliness and operability of pumping equipment.

The efficiency and service life of a hydraulic structure is determined not only by proper installation, but also by compliance with the operating rules.

In whatever land water intake is carried out, the smallest particles of soil inevitably fall into it. Mechanical impurities can adversely affect the operation of the pump, and chemical elements that are deposited on the walls of pipes and in pressure equipment lead to rust, which causes depressurization of the joints.

The operation of the equipment is negatively affected by power voltage fluctuations that can lead to a violation of the insulation of the pump motor windings.

To avoid expensive repairs, it is necessary to systematically carry out preventive inspection of all elements of the system. It facilitates the detection of minor faults and their elimination.

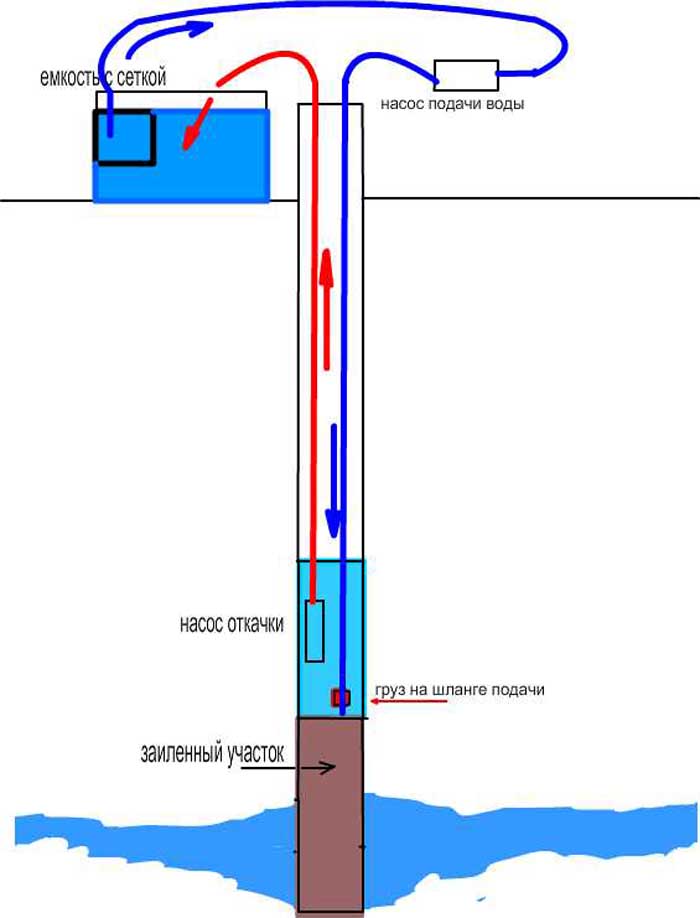

Well buildup

Upon completion of the installation work, they begin to build up the source. To do this, the deep pump is started, after lowering it to the bottom of the mine. He will pump out the sludge and sand into the receiving barrel. Next, pressure equipment is launched, pumping liquid to the bottom. The high pressure of the pump will wash away all accumulations of silt and hard rocks. After two hours, all the layers that pollute the water will settle at the bottom of the receiving vat.

If the flushing work turned out to be ineffective, the buildup procedure is repeated.For this, a powerful submersible pump is used, which will draw water and bring dirty streams to the surface.

This method of distillation of water should last for 6 hours. The result of the well clean-up will be the formation of a layer of coarse-grained sand around the perimeter of the filter mesh of the casing string, which serves as an additional filter.

In the event that clean water comes out during water intake, but the flow rate is below the norm, it is necessary to check the bottom filter. To resume the functionality of the water artery, the filters are removed and cleaned.

If the water intake is carried out constantly, but the well is clogged with a silt or sand plug, the tightness of the casing pipeline may be broken. Timely maintenance of private wells and repair of water communications will help to detect the problem at an early stage and fix it in time.

What is included in the maintenance of water intake facilities?

Mandatory maintenance of sources includes a washing procedure. With its help, the productivity of the source is restored, and the quality of the water is also improved. Well flushing sequence:

- A three-hundred-liter barrel is installed near the well.

- A deep pump is lowered to the very bottom of the well. At the same time, at least 10 cm should remain before the silt.

- Then the pipes coming from the deep pump are connected to the barrel. Moreover, they should enter the tank in its lower part (near the bottom).

- After that, a second pump unit is installed next to the barrel. It connects at the top of the barrel.

- A filter device is installed on the pipe pumping water from the barrel. Purified water is fed back into the well.

- When the entire system is assembled, they begin to flush the well. To do this, a deep pumping device is first launched, which will pump out all the silted water into the barrel. Then another pump with a filter device is turned on and supplies purified water to the well. In this case, the flow of supplied water will more strongly wash away the layer of silt.

- After that, the procedure is repeated. As a result, after a couple of hours, the sand and silt raised from the bottom will settle at the bottom of the barrel, and the water in the well will be cleared.

- When the maintenance of the wells is completed, crushed stone is poured to the bottom of the structures. It will work as an additional filter, so that large particles of silt will not fall into the water.

If flushing of the hydraulic structure did not help to purify the water, then re-swinging of the water intake structure is used. To do this, a deep pumping device is introduced into the well, which will pump out water away from the tip.

However, the flushing and re-swinging procedure will only work if the intake is relatively young. Old hydraulic structures will have to be washed 3 times. If after that the water quality is not at the proper level, then you can do the following:

- move the building to another place;

- remove the casing pipe, replace the reinforcing frame and the filtering part;

- install a deep-well pump with an effective filter.

Well diagnostics and workover

Basically, a well is drilled when the upper water carriers do not provide fresh water of the required quality and in the required quantity.The customer, counting on a practically unlimited volume of water, reluctantly gives tens of thousands of rubles, but in the end he can get a small flow rate or even a dry well after a few months of use. If this happened, then, most likely, the team incorrectly identified the aquifer and did not reach the free-flowing vein horizons.

There is a positive side to this situation. Usually, debit problems are clarified before the end of the warranty period, if one was provided. A company that cares about its reputation will fix its joint for free. Another thing is if the work was performed by seasonal workers. Then the owner will have to hire another team at his own expense. Most often the problem is solved by drilling a new well in another place, and conservation of the old.

According to the degree of complexity, problems with a well can be divided into two types:

- Periodic - occur during operation due to wear of components (filter overgrowth, fistulas in pipes, destruction of cementing, corrosion);

- Irreversible - severe damage to the column or problems with the aquifer, which lead to a complete loss of performance.

A well, like a well, signals a problem with a decrease in flow rate and / or deterioration in water quality. If the water goes through several stages of purification before being supplied, then the owner may notice a malfunction after the failure of the water treatment system. For diagnostics, you need to call a specialist, it is impossible to independently determine what is happening at a depth of 40-60 meters.

The obligatory moment of acceptance of the finished well is the presence of its passport, which is handed over to the customer. It contains all the specifications: depth, diameter, type of pipes, soil type, etc.This document is used for the correct selection of pumping equipment and serves as a starting point for repairs

One problem can have multiple causes. To determine the malfunction, the pump is removed, it is checked whether it is in good condition, and then the mine is examined. Now drilling companies are logging wells using a video camera. This allows you to get comprehensive information about the condition of the casing string and the presence of defects. Video diagnostics reveals the cause of the breakdown, foreign objects and the degree of general wear of the pipes.

After the inspection, the company must issue a defective act, which contains information about the identified malfunctions and violations. Professional overhaul is carried out only after receiving such a document. The conclusion about the state of the well includes the characteristics of the object, wear indicators, the technical possibility of recovery and recommendations for repairs.

Repair work consists of several stages:

- Decontamination;

- Checking the depth and height of the water column and comparing the data obtained with the well passport;

- Repair work.

What is this study and when is it needed?

Analysis of borehole water is a complex of physical and chemical. laboratory activities aimed at confirming or refuting the safety of water in chemical and bacterial (epidemic) terms.

It is carried out for the following purposes:

It is carried out for the following purposes:

- determination of the suitability of water for drinking, its harmlessness;

- obtaining information of interest about the chemical and bacteriological composition of water;

- to select a filter system and determine its effectiveness.

In addition, the basis for the study can serve as:

- sale or purchase of real estate;

- the appearance of problems with digestion and allergies;

- change in appearance, taste and smell of water;

- deterioration of environmental conditions in the area of residence.

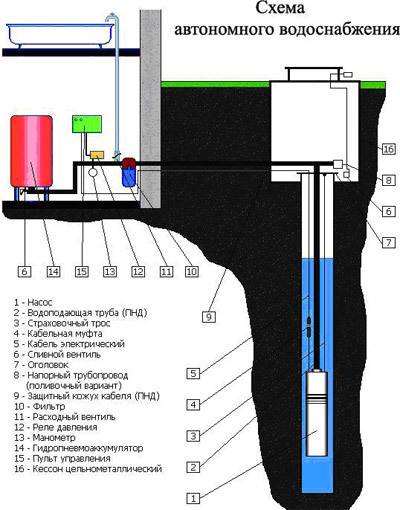

Maintenance of water lifting equipment

The earlier a problem is identified, the easier it is to fix it, therefore, even if the operation of a water well is quite safe, it is recommended to regularly check the operation of the system. To do this, at least once every six months, you should:

- Inspect piping and equipment for possible leaks.

- Check the pressure in the system: with the pump turned off and the water intake valve open, the indicator should drop to zero.

- Using a car pressure gauge, measure the pressure in the hydraulic tank. (For this, the device is connected to the hydraulic tank spool located under the plastic cap.) Normally, the indicator should be 10% lower than when the pump is turned on.

- After that, you need to connect the pump and check its operation. The pump should turn off after the pressure in the system reaches the value set on the relay.

- The next step is to check the pressure in the system when there is no consumption. To do this, the pump is turned off again and the readings are checked. The pressure level in the system must correspond to the red arrow located on the pressure switch.

It remains to close the valve and check the corresponding pressure in the system and turn off the pump. If there are no violations in the operation of the equipment, it can be considered serviceable.

To restore the normal operation of the well, sometimes you just need to flush it.

This is an approximate scheme for checking the operation of water intake equipment. The same principles can be used to test the performance of structures with slightly modified configurations.Some experts recommend that such well maintenance be carried out at least every three months.

Well commissioning - rules

Installing a water intake system properly is only half the task. After installation, the system needs to be prepared for the subsequent regime, or rather, a test operation of the well. To do this, carry out a series of actions, observing the rules and recommendations described below:

- Prolonged inactivity of the constructed well negatively affects its productivity, so install a production hoist as soon as possible after drilling.

- In a drilling rig that has not been in operation for more than a month, perform a repeated test pumping of water until the liquid becomes clear.

- In the absence of pump installation, after drilling and inspection, close the wellhead tightly.

- When turning on the pump for the first time, do it smoothly with the lowest productivity, gradually increasing the water intake to the maximum mark.

- The first water sampling spend at least two hours.

- At the beginning and throughout the operation, experts do not recommend short-term or excessively frequent switching on of the pump, as this can adversely affect the pumping equipment and the condition of the well as a whole.

- Upon completion of drilling, do a general chemical analysis of the fluid in order to choose the right water treatment system, since the quality of the water may not meet the standards, due to the unbalanced content of fluorine, iron, salts, etc.

- For sustainable abstraction, determine the amount of water to be supplied. Take a certain container (for example, a bucket of 10 liters) and record the time it was filled.Then divide the first value by the second - this will be the amount of incoming water per unit of time. Compare the obtained indicator with the norm and correct the operation of the pump.

- If after some time you find air leakage, water level fluctuations or intermittent water supply, immediately stop using the pump. This situation may indicate an incorrect assembly of the device and requires repair work.

Site preparation

This point deserves special attention, since many performers neglect it. At this stage, access roads are being prepared so that drilling equipment can arrive at the work site without interference, without damaging the site and the objects located on it. In addition, the site is being backfilled, and, if necessary, electricity and water are also supplied to it.

Determining the type of work and the cost of services

After receiving the order, the company sends a specialist to you, who studies the location of future work and the type of soil, determines the expected depth of the aquifer. After analyzing these data, we can assume to what depth the well will have to be drilled, and, accordingly, how much it will cost the customer. Employees of such companies, as a rule, have sufficient experience, so that the previously announced prices in most cases practically do not differ from the final price.

Preparatory stage

At this stage, a team of specialists in drilling with all necessary equipment sent to your site.Workers prepare the site and place the drilling rig on it. Machinery and equipment, if necessary, is connected to the power grid, drilling equipment is connected.

Maintenance of hydraulic structures in winter

If the water intake facility is operated in winter, then its appropriate preparation is assumed. The casing pipe must be insulated to the level of soil freezing corresponding to your climatic zone. This will prevent the water from freezing in the casing. It is worth remembering that in some regions of our country the depth of soil freezing can reach up to 2.5 m.

The warming process is carried out in the following sequence:

- During the drilling of a well, a ditch is made around the structure.

- Then a special caisson-type device is installed in this ditch to protect it from freezing. Usually this design consists of plastic and metal elements.

- This device is equipped with a special impenetrable hatch on the clamps. It will protect the entire structure from water ingress.

Having decided to install an autonomous water supply on the site, it is worthwhile to understand that the efficiency and duration of its operation depends not only on the correct installation, but also on timely maintenance, as well as compliance with the operating rules.

Well operation

Using the well is very simple - to supply drinking water, you just need to turn on the pump. However, in practice there are a number of recommendations, the observance of which will extend the life of the well.

So, the instructions for using the water supply system are as follows:

The first time you turn on the pump very smoothly.To do this, adjust the amount of water withdrawal by turning the valve on the head, from a lower value of water withdrawal to the recommended value. Moreover, in this way, the device should be started for the first ten times.

It is not recommended to turn on the pump too often, as well as briefly during the entire period of its operation. This can negatively affect not only the operation of the pump itself, but also the condition of the entire well.

The first time the water intake should last at least one and a half to two hours.

Also, it is necessary to determine the amount of incoming water per unit of time and compare this indicator with the recommended passport data.

If necessary, the operation of the equipment should be adjusted.

An important condition for the normal functioning of the entire structure is checking the chemical composition of water. To do this, a clean sample is taken and an analysis is ordered in a special laboratory.

If significant drops in water level are noticed or water is supplied intermittently, there is air leakage, then the operation of the water supply system must be immediately stopped in order to prevent serious damage to equipment

After that, you need to perform the necessary repair of the well with your own hands or seek help from specialists.

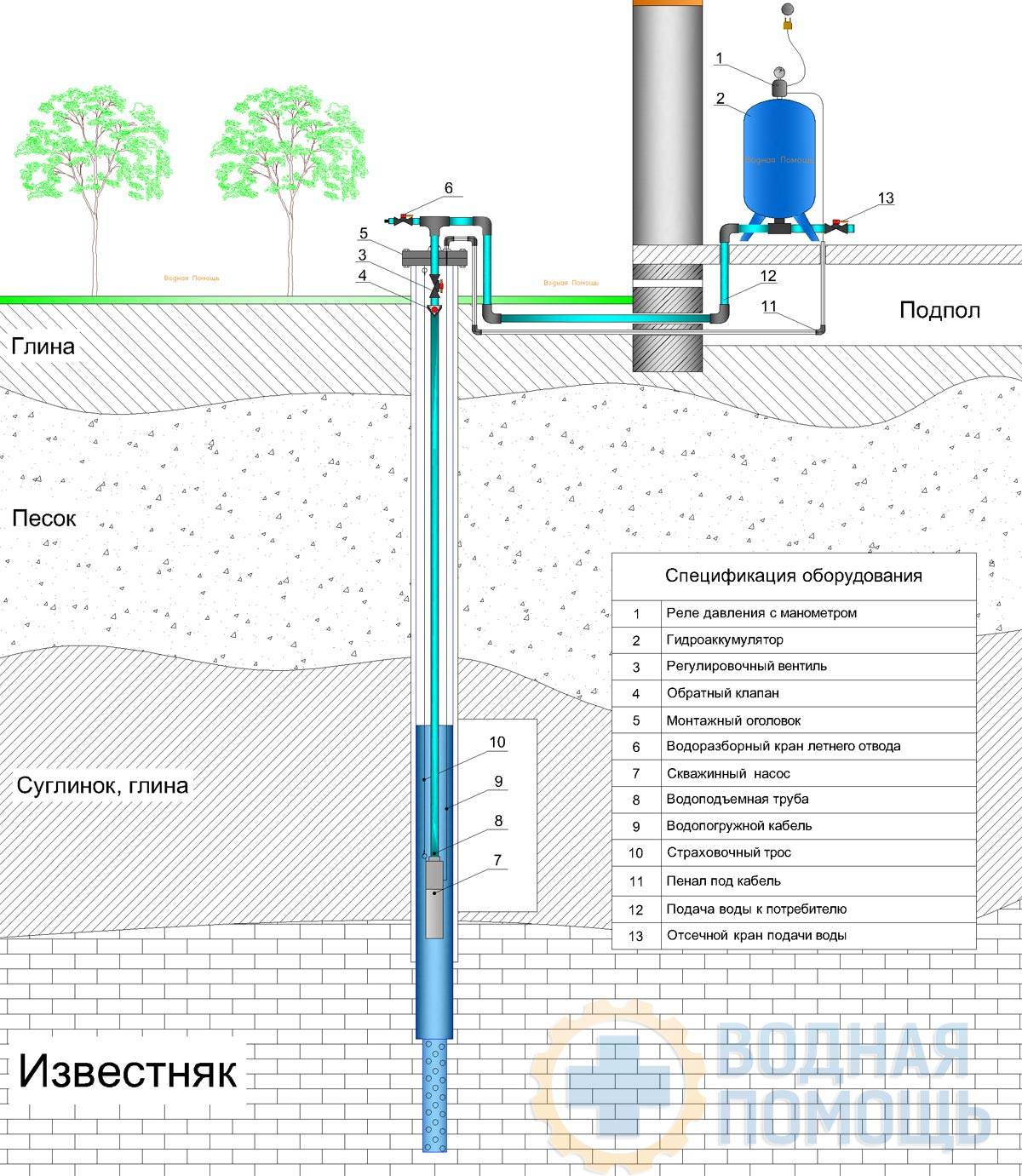

Diagram of an autonomous water supply device

Well operation methods

Considering the characteristics of the soil, the volume of produced fluid and your financial capabilities, select the appropriate type of well operation for water intake.

Main uses:

- gushing - to raise the liquid to the surface, only reservoir energy is enough;

- gas lift - there is not enough reservoir energy to lift water, so compressed gas is injected into the hole;

- mechanized - consists in the transfer of mechanical energy by a deep pump to the flow of liquid rising to the surface. This method is used when there is a shortage of reservoir energy, and when the gas lift method is unprofitable.

Important! In domestic wells, mainly pumping operation of the well for water is used. A suitable method is determined by specialized specialists when preparing wells for operation.

What is tamponage

Plugging (cementing) of a well according to GOST is the separation of water layers exposed by drilling by installing cement bridges.

In the underground horizons there are several aquifers separated by rocks or clay castles - mixing of different layers in this case is excluded.

The drilled holes cross several aquifers. During operation or after the liquidation of an artesian well, casing pipes may be destroyed. Along them, aquifers flow into each other, which leads to pollution of clean water with runoff.

Dividing pipes into isolated sections will prevent overflow.

Complications during well operation

During the operation of a water well, there is a possibility of a number of breakdowns, the characteristic features of which are classified depending on the possibility of their elimination.

Causes of breakdowns in which it is pointless to repair a well

Non-compliance with the regulations / technology for drilling a water intake:

- discrepancy between the diameters of the casing string and the pilot hole;

- poor-quality insulation, lying above the aquifers;

- application of a non-threaded pipe connection method;

- insufficient number of water intake filters and their incorrect selection;

- violation of the tightness of the sump plug;

- use of corrosive materials;

- poor fixation of the casing pipe.

Violation of the rules for installing pumping equipment:

- improperly selected pump and riser pipe;

- lack of tightness of the pump-cable joint;

- lack of "winter" drain;

- incorrect setting of the system control relay;

- wrong accumulator.

Breakdowns that can be repaired

- Ingress of sand at the bottom of the well into the water. This is due to the hanging position of the casing string. To solve this problem, the well is cleaned with a bailer, the casing string is crushed into water-resistant clay, covered with gravel and the liquid is pumped out until a clean state is obtained.

- Violation of the integrity of the filter. The reason for this is the small particles of sand that are contained in the water. In the event of a breakdown, replace the filter. This method of troubleshooting is often impractical, since it is not always possible to lift and dismantle the casing without collapsing the walls of the well.

- Ingress of foreign objects into the drilling rig. Sometimes there is a clogging of the barrel or improper installation, after which, the hose or cable that fixes the pump breaks, leaving it in the well. In such a situation, the pump is removed using a special tool and tools.

Maintenance of pumping equipment: how is it done

Uninterrupted water supply is ensured not only by the debit of the well, but also by pressure equipment - a pump or station that pumps fluid from a source. Therefore, long-term and trouble-free operation of the water supply system forces us to worry about the "health" of the pump and other components of water-lifting equipment.

Pump equipment

And this care is manifested in the form of the following repair and preventive measures:

- First, you need to periodically (at least once every two years) inspect both the pipes and the pump, removing the entire water pressure system to the surface.

- Secondly, control the pressure in the system. It should not exceed 6.5 atmospheres and should not fall below 1.5 atmospheres. Moreover, the pressure can be checked with a conventional pressure gauge. It is mounted on a five-way hydraulic accumulator manifold.

In addition, you need to check the performance of the pump itself, measuring the pressure in the following cases:

- With the unit turned off and the tap open (it should drop to zero).

- With the valve closed and the pump turned on (the unit should turn off when it reaches the pressure indicated as peak on the control relay).

- With the tap closed and the pump not running and the accumulator filled (pressure must not drop).

If all three conditions are met, then the system functions without interruption.