- 3.3. Requirements for the device of mine wells

- Turning on and off

- Operation of oil wells with rod pumps

- Maintenance of hydraulic structures in winter

- Maintenance

- How to properly operate a well?

- Causes of silting and how to eliminate it

- Frequent breakdowns and solutions

- Sand getting into the water at the bottom of the well

- Filter obstruction

- Ingress of foreign objects

- Maintenance of water intake equipment

- Options for arranging water supply from a well

- To wash or not to wash?

- Frequent breakdowns and solutions

- Sand getting into the water at the bottom of the well

- Filter obstruction

- Ingress of foreign objects

- Rules for operation and maintenance

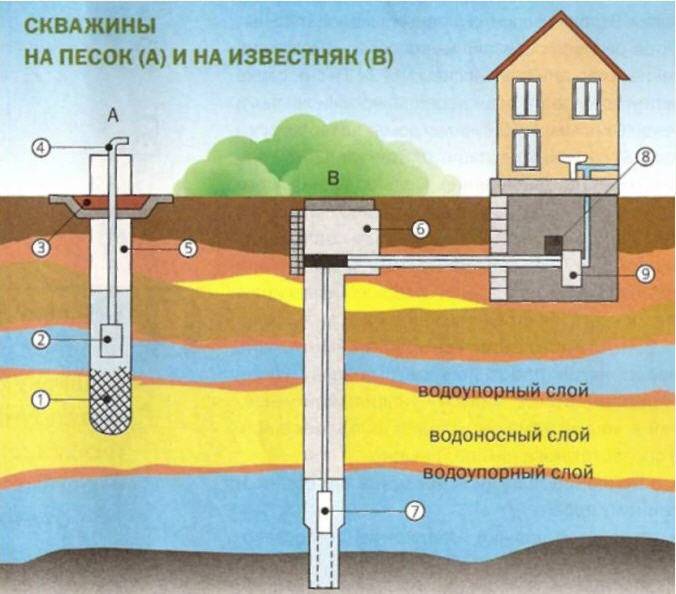

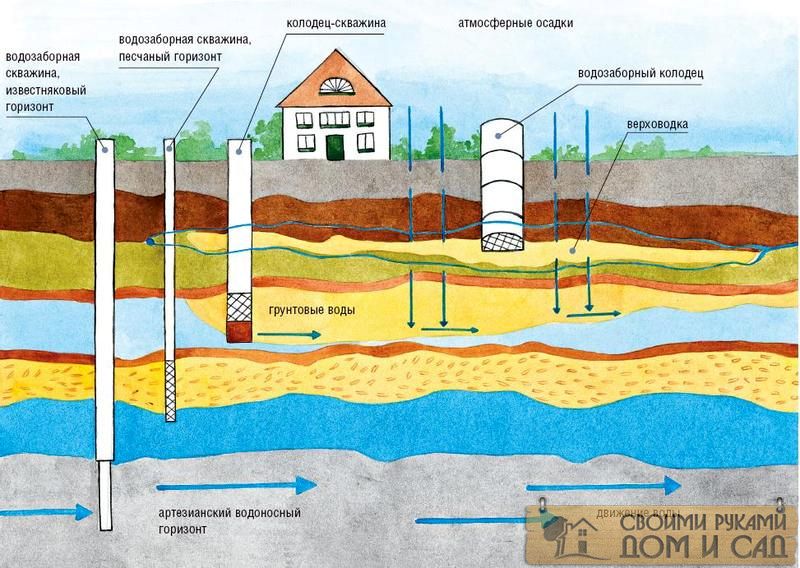

- sand wells

- When do you need a license?

- When is a repair not possible?

- well drilling

3.3. Requirements for the device of mine wells

3.3.1. mine wells

designed to receive groundwater from the first free-flow from the surface

aquifer. Such wells are a round or

square shape and consist of a head, a trunk and a water intake.

If it is impossible to maintain this distance, the place

location of water intake facilities in each case is consistent with

Center for State Sanitary and Epidemiological Surveillance.

3.3.2. headroom

(above-ground part of the well) serves to protect the mine from clogging and pollution, and

also for observation, water lifting, water intake and must have at least

0.7 - 0.8 m above the ground.

3.3.3. well head

must have a cover or a reinforced concrete floor with a hatch, also closed

lid. From above, the head is covered with a canopy or placed in a booth.

3.3.5. Shaft (mine)

serves for the passage of water-lifting devices (buckets, pails, scoops and

etc.), as well as in some cases for the placement of water-lifting mechanisms. Walls

the shafts must be tight, well insulating the well from penetration

surface runoff, as well as perched water.

3.3.8. Water intake part

the well serves for the inflow and accumulation of groundwater. It should be buried in

aquifer for better opening of the reservoir and increase in flow rate. For

ensuring a large influx of water into the well, the lower part of its walls may have

holes or set up in the form of a tent.

3.3.9. For a warning

bulging of soil from the bottom of the well by ascending flows of groundwater, the appearance

turbidity in the water and facilitate cleaning at the bottom of the well, a return

filter.

3.3.10. To descend into

the well during repair and cleaning, cast-iron brackets must be embedded in its walls,

which are located in a checkerboard pattern at a distance of 30 cm from each other.

3.3.11. The rise of water from

shaft wells is carried out using various devices and

mechanisms. The most acceptable from a hygienic point of view is

use of pumps of various designs (manual and electric). At

the impossibility of equipping the well with a pump, a gate device is allowed

with one or two handles, gate with a wheel for one or two buckets, "crane"

with a public, firmly attached bucket, etc. The size of the bucket should be approximately

correspond to the volume of the bucket so that the pouring of water from it into the buckets does not

presented difficulties.

Turning on and off

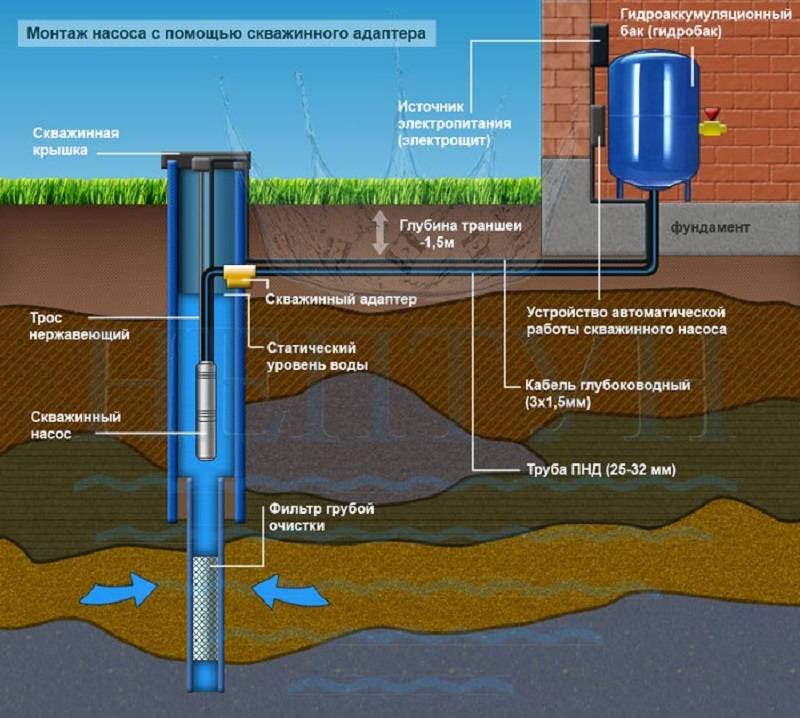

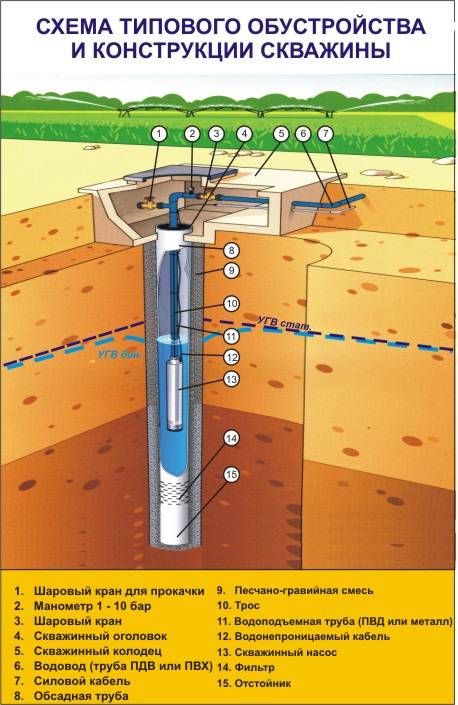

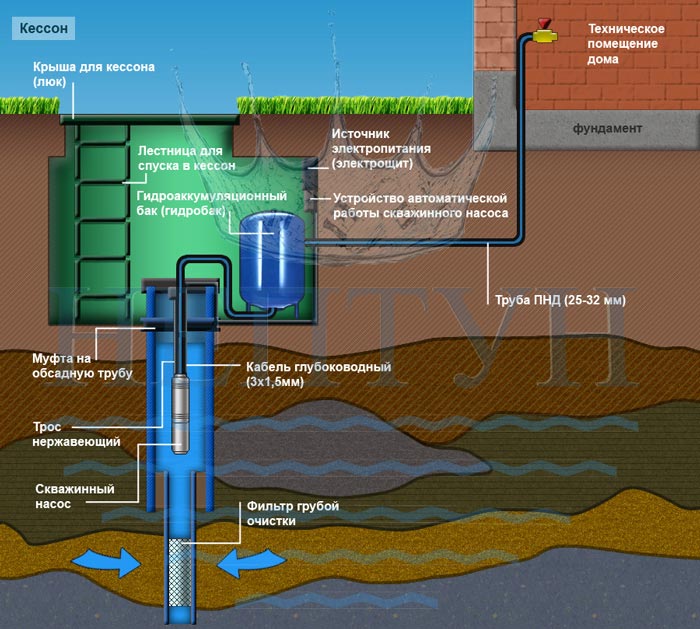

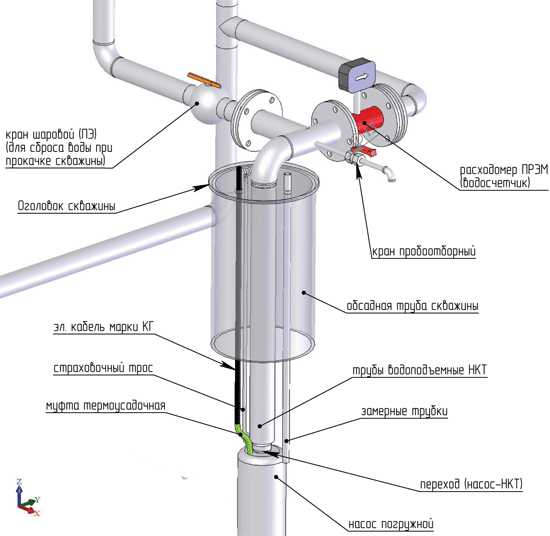

Scheme of the water intake.

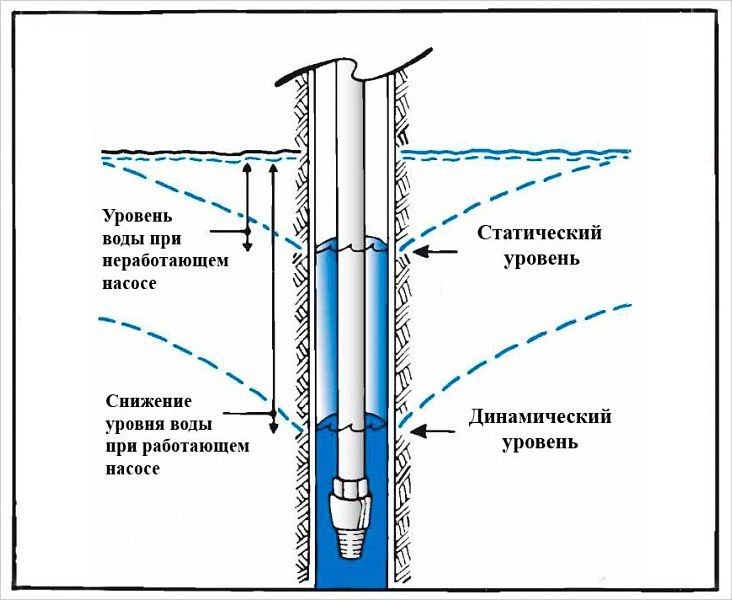

When operating wells, it is important to properly use pumping equipment that provides water to the top. After the source is put into operation, you must immediately set the on / off mode. Otherwise, the pumps will become unusable, the likelihood of emergency situations is not excluded.

Otherwise, the pumps will become unusable, the likelihood of emergency situations is not ruled out.

If the existing flow rate does not satisfy all water needs, then it is necessary not to increase the water supply capacity. You should immediately contact the service organization, whose specialists will conduct the necessary research to determine methods for increasing water volumes.

Usually the equipment works smoothly, it is necessary to turn it off only in such cases:

Well cleaning with a bailer.

The equipment at normal voltage uses a current that is 20% higher than the rated value. In this case, it is necessary to stop the equipment, after which it is necessary to carry out diagnostics and perform appropriate repairs.

If the overall productivity of the well drops by 20%, it is necessary to stop the pump, and then inspect the well. It is possible that it will need to be thoroughly cleaned. Usually, after cleaning, the problem resolves itself.

If the pumping equipment begins to make sounds during operation that are not characteristic of it, then urgent action should be taken.

If vibration occurs during operation.

When the amount of sand in the water is from 2% percent, the equipment must be turned off, the well should be cleaned, and the filters inspected.

If the control equipment shows that the flow rate is falling, the dynamic level of the well changes greatly, the pump stops, then it is necessary to inspect the well, filters, equipment

It is possible that cleaning, replacement of filter cartridges is required.

If during the control samples a change in the chemical composition of water is recorded, then it is important to find out the reason for such a change.

The terms of operation of the equipment may be different, but they completely depend on how exactly the service will be carried out. At least 2 times a year, it is necessary to stop the equipment, after which it is necessary to clean, inspect, replace all worn parts if necessary. If the installations do not work constantly, then the period between checks can be increased from 6 months to 9, this will be quite enough.

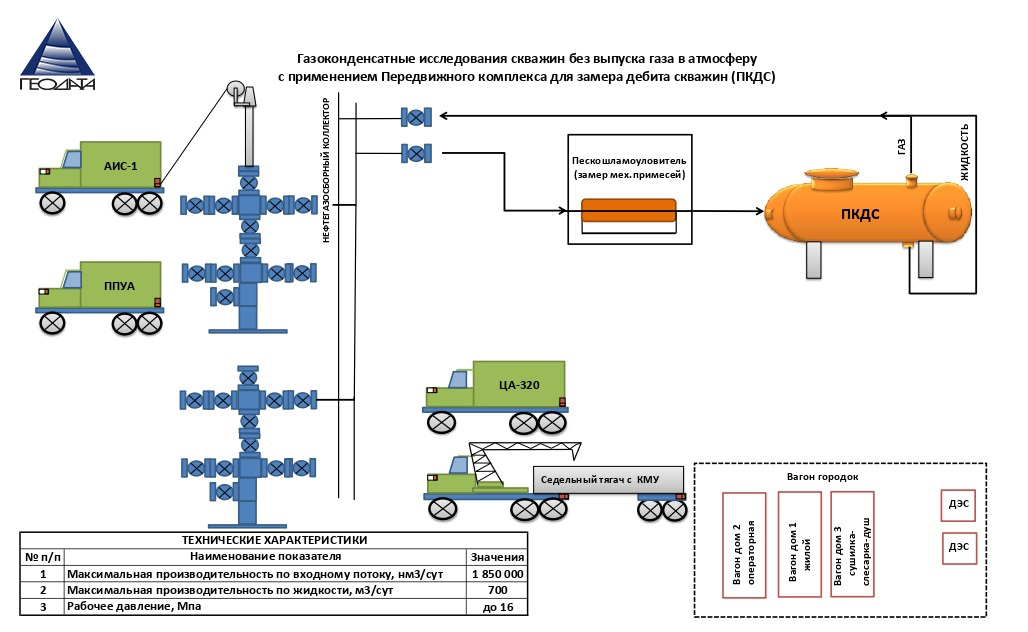

Operation of oil wells with rod pumps

More than half of all currently operating gas and oil wells use sucker rod pumping stations. It should be said that the use of such equipment allows its repair directly in the process of its operation, without dismantling and transportation to special service centers, and all existing types of drives can be used as a primary motor. The rod pump is able to work in rather difficult conditions, including the presence of sand and liquids with high corrosiveness.

The disadvantages of using such equipment include:

- low level of supply;

- the presence of restrictions on the descent of equipment;

- the presence of restrictions associated with the angle of inclination of the wellbore.

A simple rod pump has the following main structural elements: a cylinder and a plunger equipped with a ball-seat valve, which ensure the rise of the extracted resource, while preventing its backflow. Also, the design can be equipped with a suction valve, which is placed below the cylinder. The operation of the rod pump is ensured by the movement of the plunger under the action of the drive device. In such a pump there is an upper rod, which is mounted on the head of the balancing element.

The main structural elements of a rod-type pump:

- frame;

- pyramid-shaped rack with four faces;

- balancing element;

- gearbox equipped with a counterweight;

- traverse;

- swivel sled.

The first type is lowered into the wellbore in finished form, and before that, the lock is lowered down the tubing. To replace such equipment, lowering and raising pipes several times is not required. Non-inserted rod pumps are lowered into the well in a semi-finished form. If such a pump requires repair or replacement, then it is lifted in parts: first - the plunger, and then the tubing. Both types of rod devices have both their advantages and disadvantages, so the choice is made based on the specific conditions of the planned operation.

Maintenance of hydraulic structures in winter

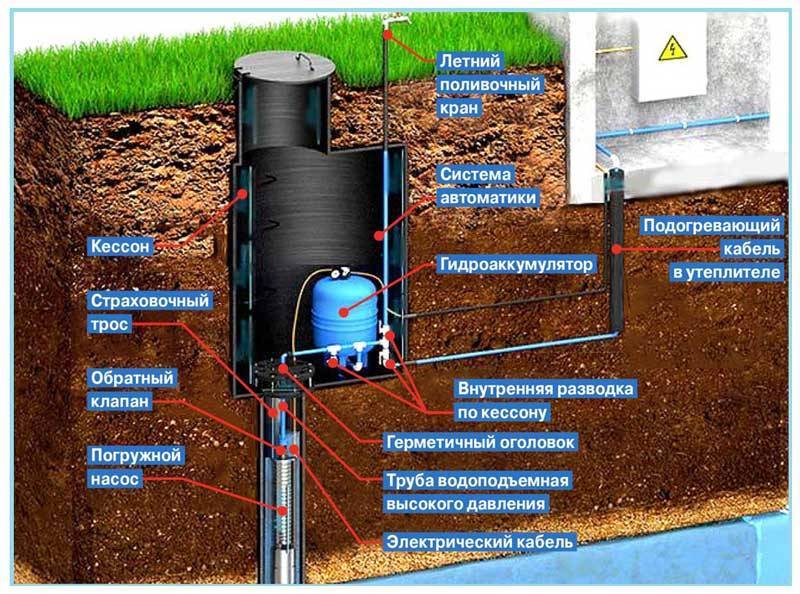

An example of insulation of a caisson and a pipe with mineral wool

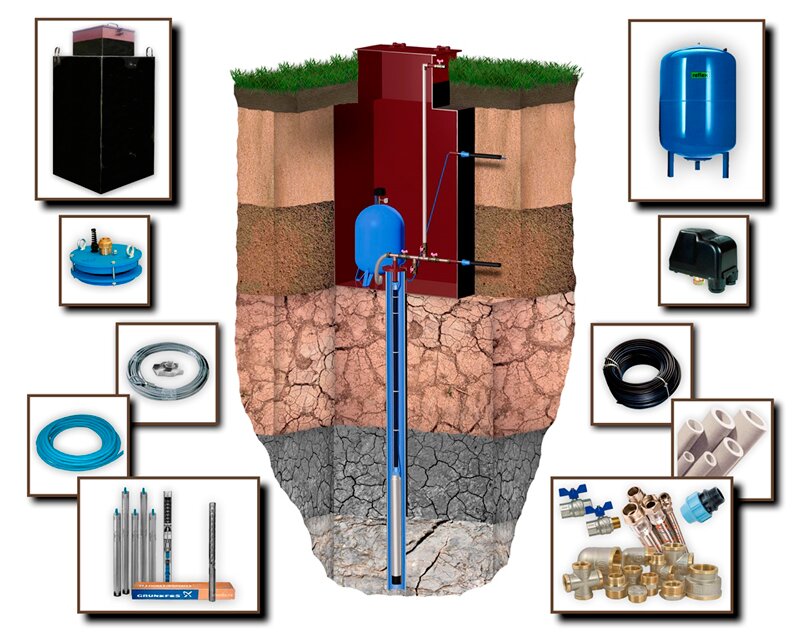

If the water intake facility is operated in winter, then its appropriate preparation is assumed. The casing pipe must be insulated to the level of soil freezing corresponding to your climatic zone. This will prevent the water from freezing in the casing. It is worth remembering that in some regions of our country the depth of soil freezing can reach up to 2.5 m.

The warming process is carried out in the following sequence:

- During the drilling of a well, a ditch is made around the structure.

- Then a special caisson-type device is installed in this ditch to protect it from freezing. Usually this design consists of plastic and metal elements.

- This device is equipped with a special impenetrable hatch on the clamps. It will protect the entire structure from water ingress.

Having decided to install an autonomous water supply on the site, it is worthwhile to understand that the efficiency and duration of its operation depends not only on the correct installation, but also on timely maintenance, as well as compliance with the operating rules.

Maintenance

These works include:

- restoration of the working potential of tools and equipment;

- a change in the operating mode of an oil and gas well associated with a change in the intensity and conditions of production, as well as with any other reasons;

- cleaning of various levels of the trunk from layers and deposits that appeared during many years of operation;

- cleaning of equipment used in the field.

Prevention makes it possible to prevent the risks associated with both a decrease in the volume of extracted, with the possible destruction of the working shaft, with watering, blockages and other negative factors.The frequency of such work depends on the operating conditions of the equipment. Prudent mining companies carry out preventive maintenance of wells on a regular basis.

Current planned activities include:

| № | Useful information |

|---|---|

| 1 | cleaning oil wells by washing, bailers or mechanically from sand blockages |

| 2 | replacement of individual parts of the pump structure or replacement of the entire pumping station |

| 3 | elimination of minor pipe faults |

| 4 | replacement of broken pipes |

| 5 | replacement of worn supports and rods |

| 6 | making changes to the conditions for lowering the tubing |

| 7 | cleaning, maintenance or replacement of the sand anchor |

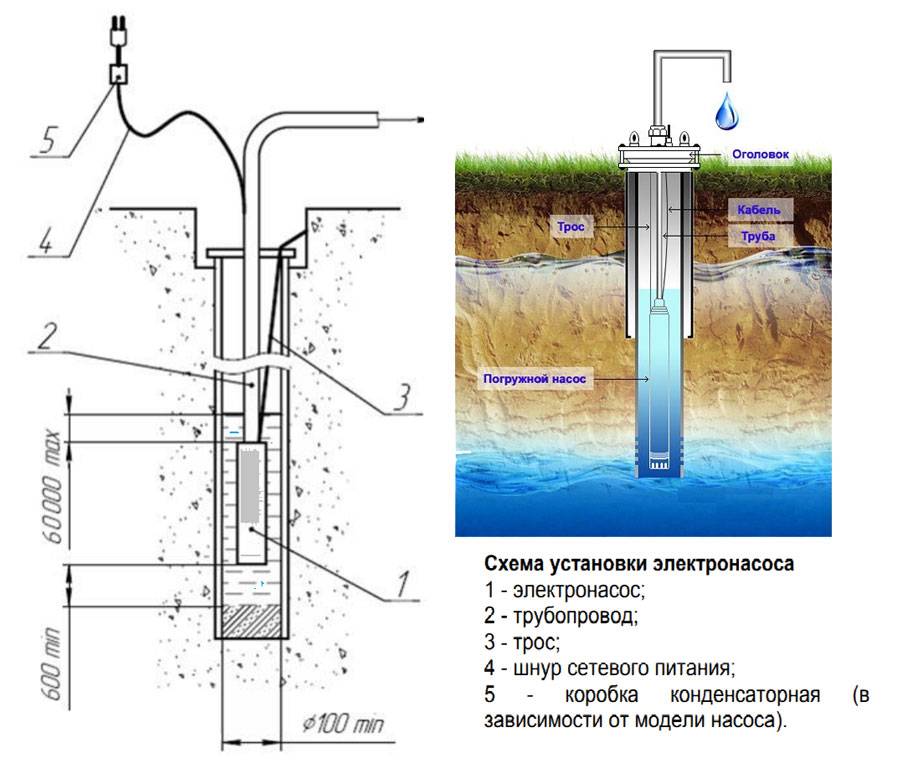

How to properly operate a well?

A conventional well with a pump works very simply. You need to turn on the pump and get the required amount of clean drinking water. In practice, there are a number of recommendations with which you can improve the condition of the equipment.

Before starting well maintenance, you should study the water supply scheme at home (click to enlarge)

Drilling specialists usually provide instructions for operating the water well that they have created.

These tips will also be useful to those who made such a device on their own:

- When turning on the pump for the first time, it is necessary to do it very smoothly. To do this, the amount of water withdrawal is regulated by turning the valve on the head, starting from the smallest value of water withdrawal to the recommended value. In the same way, the pump should be started for the first ten starts.

- The duration of the first water intake should be at least one and a half to two hours.

With sustainable water withdrawal, the flow rate of incoming water should be determined.To do this, take a container of a certain volume (for example, a ten-liter bucket) and use a stopwatch to find out the time of its filling. It remains to divide the first value by the second to determine the amount of water coming from the well during a unit of time, for example, the number of cubic meters per hour

This indicator must be compared with the recommended one and the operation of the equipment must be adjusted.

An important condition for the successful functioning of the well is checking the quality of the water. To do this, a clean sample is taken and an analysis is ordered in a special laboratory.

Causes of silting and how to eliminate it

When silting or sanding, cleaning the well can be carried out by various methods. As a preventive measure, after some downtime or if a slight silting is detected, it is enough to turn on the pump for several hours and pump out water with accumulated sludge. The problems are evidenced by a slight decrease in the debit of the well.

Finding out how to download correctly new well, you can find various recommendations, some of which are applicable to the cleaning of already finished and commissioned facilities. For example, there is a method of cleaning a well with a fire truck.

At the same time, a large amount of water under pressure is supplied inside the well, which makes it possible to break up the contaminants accumulated there, partially wash them out and facilitate further cleaning of the water source.

The idea is interesting, but it refers to structures that are already in operation and for some reason need to be cleaned again. It is difficult to pump a well immediately after completion of drilling operations in this way.

The same can be said about the work with the bailer.This is a manual method of cleaning, in which a special bailer (a heavy metal product) is thrown to the bottom of the well in such a way that it breaks and scoops up the dirt and sand accumulated at the bottom. The bailer is taken out, freed from sediment and again thrown to the bottom of the well.

Wells are also pumped with the help of a motor pump: Caiman, Hitachi, Honda, etc. The cost of such a unit can be about a thousand dollars, or even two or three thousand, depending on the model.

This method, like those described above, will come in handy in the future if you need to reanimate the finished well and clean it of dirt, sand or silt. But at the end of drilling, pumping equipment should be used.

Frequent breakdowns and solutions

During the operation of a hydraulic structure, there is always the possibility of breakdowns. Some of them can be eliminated on their own, without resorting to the services of expensive specialists.

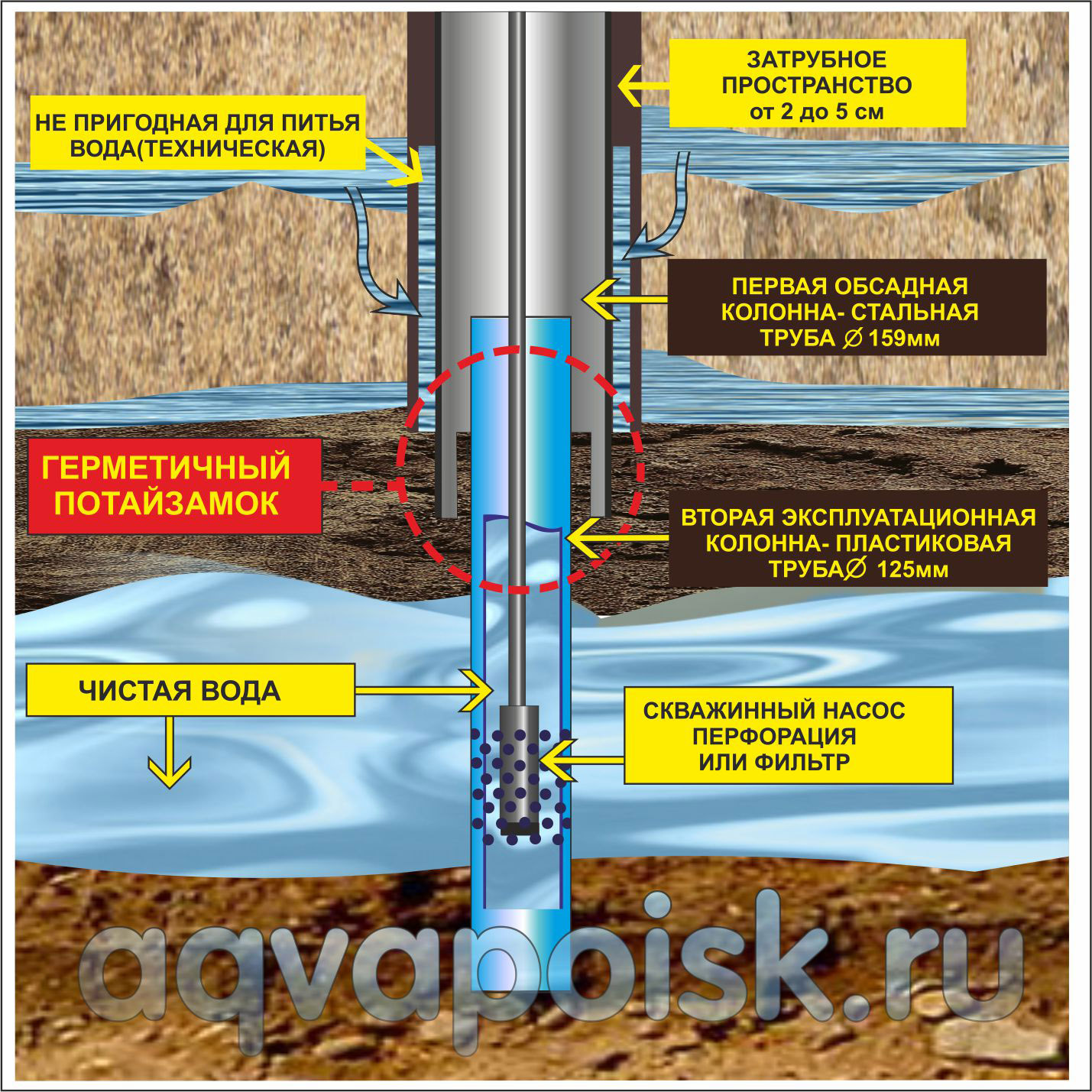

Sand getting into the water at the bottom of the well

This can happen due to a violation of the tightness of the casing, or if the wellhead is periodically flooded with sewage. This will be confirmed by the appearance of new impurities and turbidity in the water.

Cleaning the barrel with a cylindrical bailer helps to solve the problem.

Having scooped up silt and sand with a metal bailer, the well is pumped with a pump until clean water appears. In the future, in order to prevent a recurrence of the situation, on the outside of the walls of the casing, the voids are filled with water-resistant clay, covered with a layer of gravel or filled with cement mortar.

Filter obstruction

The reason for this is all the same small particles of sand or gravel that clog the holes.This problem usually occurs a couple of years after the start of a sand well.

In the event of a violation of the integrity of the filter or a critical drop in throughput, the problem is solved by replacing it. But this method is used quite rarely, only as a last resort, since it is not always possible to dismantle the casing pipe without collapsing the walls of the structure.

Ingress of foreign objects

It often happens that due to improper installation, the cables and hoses fixing the pump under the influence of load and vibration break during the operation of the equipment. Or a stone or bolt that accidentally fell into the well and fell into the gap between the pump unit and the wall jams the equipment and causes the device to get stuck.

You can remove the pump and fasteners using hooks or a cat-type device.

The extraction operation should be carried out with the utmost care. If, during the lifting process, the devices break off and remain in the wellbore, the task of extracting the device will become several times more complicated.

If the unit is stuck tightly, the best solution is to call a team of specialists. Using an underwater video camera and other equipment, they will be able to diagnose the problem and fix it without damaging the structure.

Most often, when the pumping device is jammed in the second or third link of the casing string from the top, it is partially removed from the mine. Then the pipes are disconnected from the shaft to the place of clogging and the pump is taken out. If necessary, damaged links are replaced with new pipes of the same diameter.

Maintenance of water intake equipment

To avoid breakdown of pumping equipment, experts recommend checking its performance once every six months, even with successful operation. To do this, perform the following series of actions:

- Inspect equipment and piping for leaks.

- Turn off the pump, open the water inlet valve and measure the pressure in the system, which is usually 0.

- To check the pressure in the hydraulic tank, connect a car pressure gauge to the nipple of the hydraulic reservoir. This figure is often 10% lower than when the pump is on. If necessary, pump air through the nipple with a conventional pump.

- Connect the pump and check its operation. The pump will turn off if the desired pressure is reached, which you set on the switch-on switch.

- Check the pressure in the system with the pumping equipment turned off. The indicator of the relay should be at the mark of the maximum pressure you set.

- To check the operation of the pump, open the water tap, and when the indicator reaches the green mark, the pump should turn on to restore pressure in the system.

- Close the tap, check the pressure level and turn off the pump.

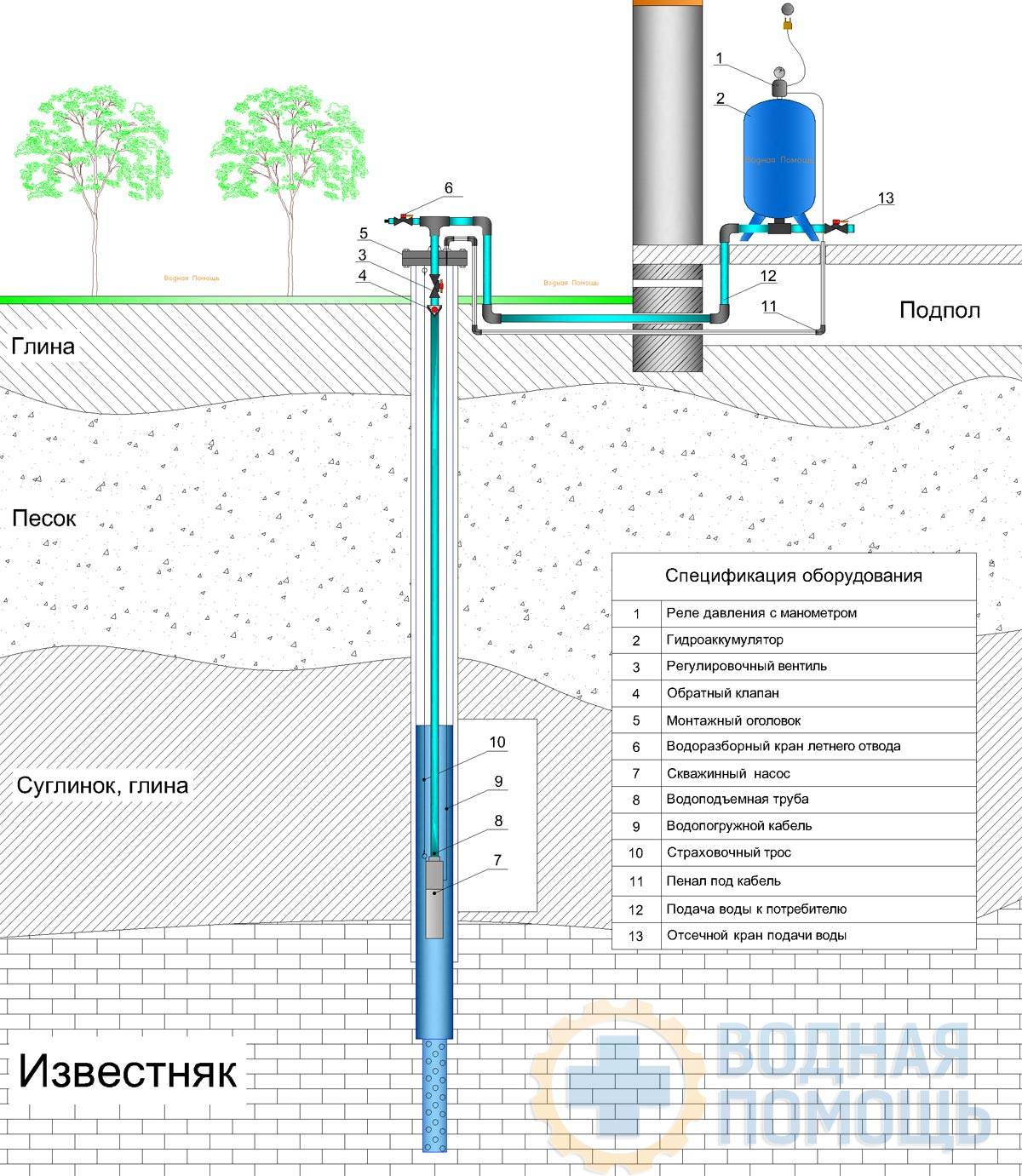

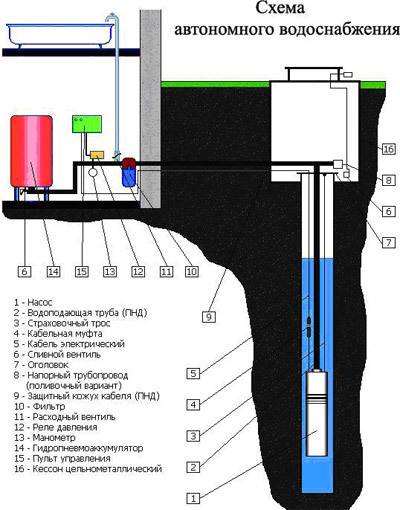

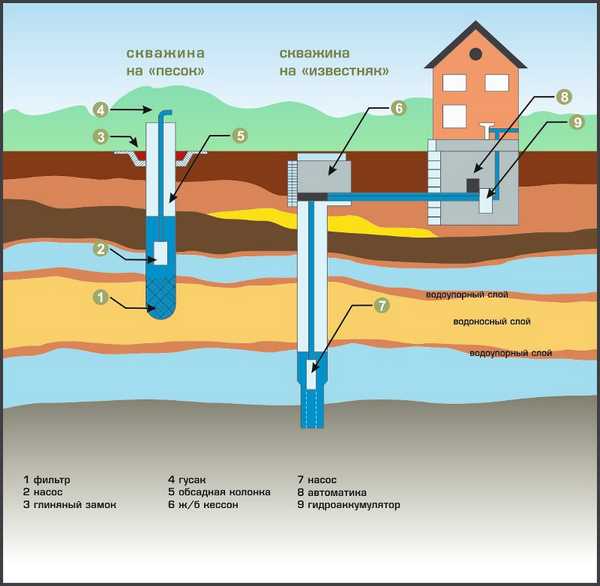

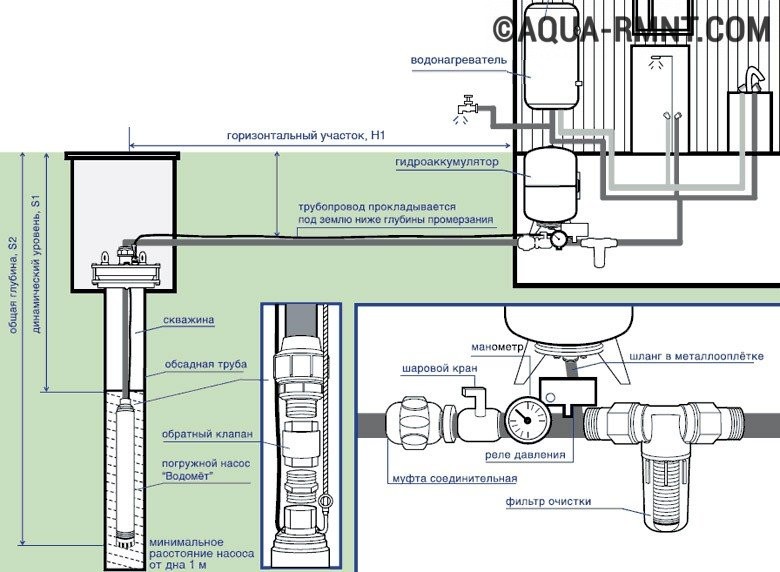

Options for arranging water supply from a well

Method number 1 - eyeliner with an automated pumping station. If the site has a shallow well, and if its water level allows, you can install a hand pump or a pumping station. The principle of operation of this system is that with the help of a submersible pump, water is pumped into a hydropneumatic tank, its capacity can be from 100 to 500 liters.

While working with a shallow sand well, one of the best options is to equip an automated water supply system that ensures uninterrupted water supply to the house.

The storage tank itself has a rubber membrane and relays that regulate the water pressure inside the tank. If the tank is full, the pump is turned off, at the moment when water begins to be consumed, the relay sends a signal to the pump to turn on and it starts pumping water from the well.

This means that such a pump can work both directly, supplying water to the system, and after the pressure in the system drops to a certain level, in order to replenish the “reserve” in the hydropneumatic tank.

The receiver itself (hydraulic tank) must be placed in any most convenient place in the house in order to bring the pipeline, usually this is a utility room. From the caisson to the place where the pipe enters the house, a trench breaks out, to the bottom of which a water pipe and an electric power cable for the pump are thrown.

Method number 2 - with the installation of a deep pump. During this method of water supply, the task of the deep pump is to pump water from the well into the storage tank, which is located at the highest point of the house. As a rule, for the arrangement of the storage tank, a place is allocated in the attic or on the second floor of the house.

If a decision is made to place the tank in the attic, it is necessary to insulate its walls, which will prevent water from freezing in it in winter. Due to the location of the tank at a high point, the effect of a water tower is created, during which, due to the height difference between the hydraulic tank and the connection points, pressure arises, in this case 1 m of water column equals 0.1 atmospheres.

Deep well pumps are used when the distance to the water level in the well is more than 9 meters. When choosing a pump, it is necessary to take into account the productivity of the well. Despite the fact that only the rate of accumulation of the water storage tank will depend on the power of the device, it is better to be guided by the mark of the maximum water consumption in the house during the acquisition.

The deep-well pump, together with the pipe and electric cable, is lowered into the well, hanging it with a winch on a galvanized cable; the winch must also be installed inside the caisson. In order to maintain the required level of pressure inside the system and so that water is not pumped back into the well, a check valve is mounted above the pump. After all the elements of the system are installed, it is only necessary to check the internal wiring to the connection points, and then connect the equipment to the control panel.

To wash or not to wash?

Often, the owners of a well face the question of whether it is necessary to flush it. If the design is used regularly, then it is flushed naturally.

If the use is rare, then there is a high probability of silting. In this situation, the mine is pumped. In this case, the precipitate comes out with water.

Source maintenance involves water quality control. If the water quality deteriorates and you often have to change thin filters, then a complete replacement of the filtration system will be required.

If you choose water before the filters and let it settle, then a sediment of sand will appear at the bottom.

When the pumping station becomes clogged, it will need to be replaced.

In cases where water enters in small quantities, it will be necessary to clean the filter.

WATCH VIDEO

The well is a great way to provide water for the whole family in a country house

It is important to constantly monitor the condition of the installation and timely eliminate breakdowns.

Frequent breakdowns and solutions

During the operation of a hydraulic structure, there is always the possibility of breakdowns. Some of them can be eliminated on their own, without resorting to the services of expensive specialists.

Sand getting into the water at the bottom of the well

This can happen due to a violation of the tightness of the casing, or if the wellhead is periodically flooded with sewage. This will be confirmed by the appearance of new impurities and turbidity in the water.

Cleaning the barrel with a cylindrical bailer helps to solve the problem.

To scoop sand out of the well, the bailer on a strong cable is lowered to the bottom of the structure, and then several times alternately, then lifted by half a meter, then sharply lowered down

Having scooped up silt and sand with a metal bailer, the well is pumped with a pump until clean water appears. In the future, in order to prevent a recurrence of the situation, on the outside of the walls of the casing, the voids are filled with water-resistant clay, covered with a layer of gravel or filled with cement mortar.

Filter obstruction

The reason for this is all the same small particles of sand or gravel that clog the holes. This problem usually occurs a couple of years after the start of a sand well.

Silt and sand mostly settle only on primary filters, but some particles can also enter fine filters, clogging them over time

In the event of a violation of the integrity of the filter or a critical drop in throughput, the problem is solved by replacing it.But this method is used quite rarely, only as a last resort, since it is not always possible to dismantle the casing pipe without collapsing the walls of the structure.

Ingress of foreign objects

It often happens that due to improper installation, the cables and hoses fixing the pump under the influence of load and vibration break during the operation of the equipment. Or a stone or bolt that accidentally fell into the well and fell into the gap between the pump unit and the wall jams the equipment and causes the device to get stuck.

Since the clearance between the equipment and the walls of the well is only a couple of centimeters, the pump can be freely pulled out only with the help of special tools.

You can remove the pump and fasteners using hooks or a cat-type device.

The extraction operation should be carried out with the utmost care.

If, during the lifting process, the devices break off and remain in the wellbore, the task of extracting the device will become several times more complicated.

If the unit is stuck tightly, the best solution is to call a team of specialists. Using an underwater video camera and other equipment, they will be able to diagnose the problem and fix it without damaging the structure.

Most often, when the pumping device is jammed in the second or third link of the casing string from the top, it is partially removed from the mine. Then the pipes are disconnected from the shaft to the place of clogging and the pump is taken out. If necessary, damaged links are replaced with new pipes of the same diameter.

Rules for operation and maintenance

To avoid premature failure of water-producing pumps, it is worthwhile to service them every six months and check the main performance indicators. To do this, do the following:

- Injection pumps, pipes and filtration equipment are taken to the surface and checked for structural integrity.

- Check the pressure in the system with the pump turned off and the tap open. It must be zero.

- To check the pressure in the hydraulic tank, you can use a conventional pressure gauge. It is connected to the tank nipple. Normal pressure readings should be 10 percent lower than when the unit is running. To combat low pressure, air is pumped using a pump through the same nipple.

- The switched on pump should turn off when the lower pressure indicator on the relay is reached.

- When the production pumps are turned off, the pressure indicator should be at the maximum mark.

- With the tap open, upon reaching the green mark on the relay, the pumping equipment should turn on to stabilize the pressure in the system.

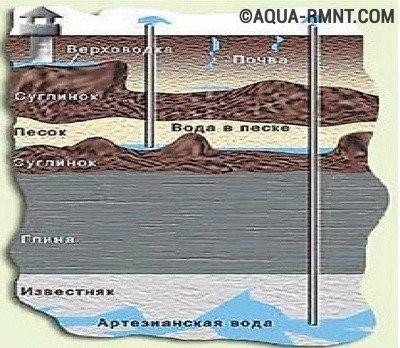

sand wells

Only sand wells need to be checked for silting. Signs of sedimentation can be a drop in well performance, dirty tap water, sandy water. Various methods are used for cleaning: these are high pressure water washings, sediment removal and others. So that sediment does not accumulate in the intake of sand wells, it must be used regularly. If you use water only in the summer, in the winter you need to come to the cottage and turn on the pump. It happens that the well cannot be restored to work after the accumulation of silt, if this is the case, then a new one needs to be drilled.

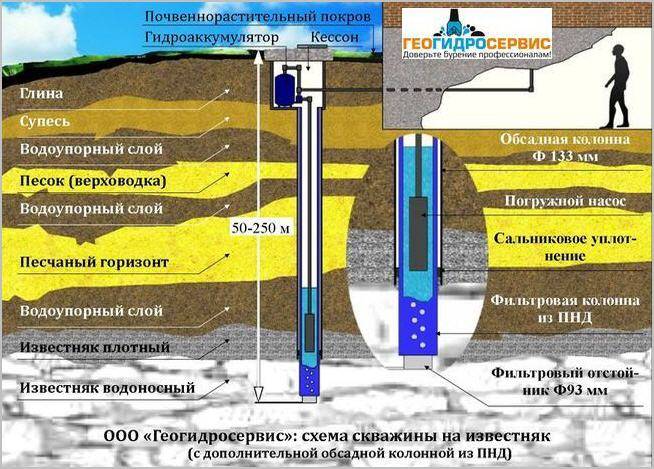

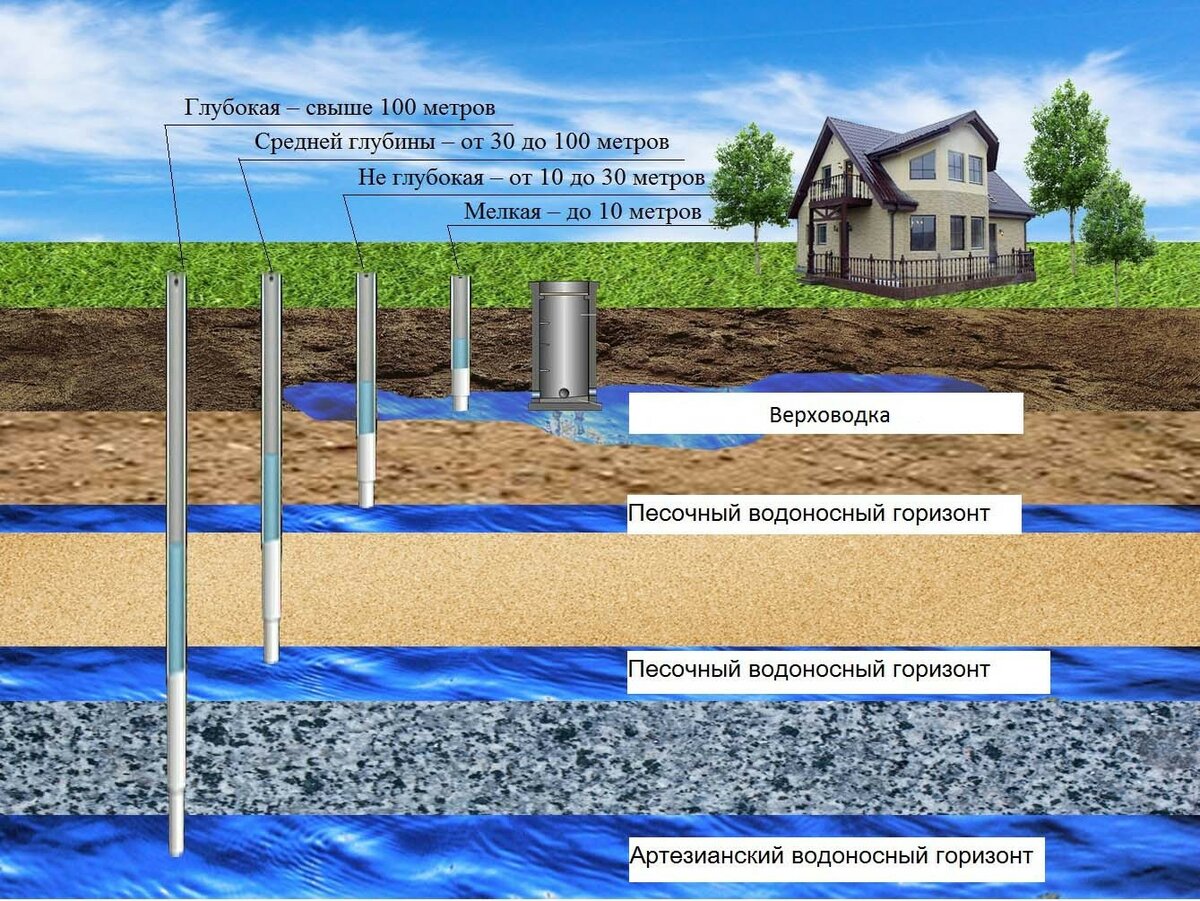

When do you need a license?

If you plan to use deep waters on your site and you need to drill an artesian well for this purpose, a license permit will be required. In accordance with the Subsoil Law, you should obtain the right to drill a well and use artesian water obtained from the subsoil.

An artesian well differs from a well "on sand" in the depth of drilling and the quality of the water that is eventually extracted from the surface.

The fundamental difference between artesian water and ground water is its location between two dense layers that do not contain water. It is perfectly protected from the penetration of atmospheric precipitation and sewage, and is saturated with minerals. Artesian water is pure by nature, so you must have the right to use it and a permit confirming the feasibility of extracting it.

When is a repair not possible?

In some cases, repair is impossible or it costs more than drilling a new well. For example, if the filters were installed incorrectly (above the water level).

Irreversible damage includes:

- incorrect installation of the strainer;

- no gravel filter;

- non-removable filter (impossibility of its replacement);

- low water level;

- use of a disposable whistle-type design (such a well lasts up to 7 years).

In order for the water well to serve as long as possible, experts advise the owners of such water sources not to forget about maintenance and preventive maintenance.

Ideally, well inspections should be carried out once a year. And to maintain the flow rate, regular flushing is necessary. Wells located in sandy soil are washed out once every five years. Artesian sources are reanimated no more than once every ten to fifteen years.After competently carried out works on cleaning, the increase in water usually lasts for up to seven years.

Modern equipment allows for complete dismantling of the well. After carrying out all the necessary repairs, it is installed in its original place at the same or greater depth.

The decisive factor influencing the purity of the water obtained is the place of laying and the chosen drilling depth. Destruction is often associated with the aggressiveness of wastewater. If sewerage, mine or quarry drains, non-working wells are located nearby, the casing string cannot withstand the loads and begins to collapse. The same happens when using vibration type pumps. Experts strongly recommend installing centrifugal pumps in the well.

Another of the most common mistakes is the insufficient thickness of the gravel pack (filling). Water quickly washes out the gravel, the well loses its tightness and silt and sand appear in it. To prevent bacterial contamination, it is recommended to install additional disinfecting filters or regularly perform chlorination.

Tell us about your own experience gained during the restoration of the well, share only the nuances of the work known to you. Please write comments in the box below. Ask questions about the topic of the article.

well drilling

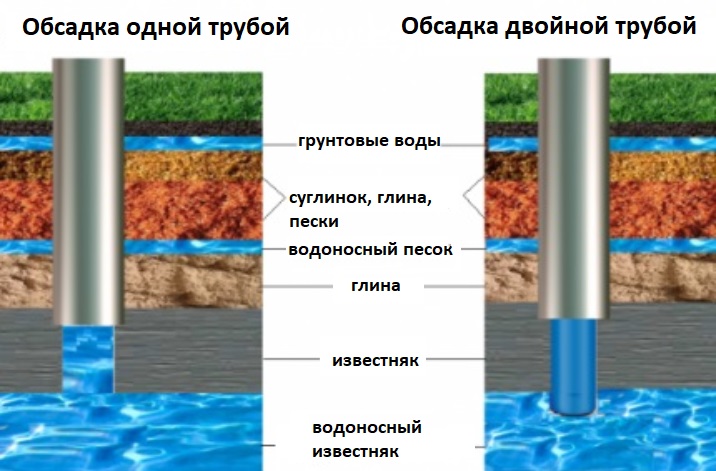

So, the most crucial moment comes - the direct drilling of the well. However, the creation of the water well itself is preceded by the process of exploratory drilling, which helps the craftsmen determine the location and the estimated productivity of the aquifer. And only after that, specialists begin to drill a production well.Then the column is cased with special pipes, a filter is installed in its lower part, and a clay lock is installed in the upper part, which protects the well from foreign water. Thanks to this technology, the well will produce clean and clear water.

Well drilling is carried out using stationary hydraulic or small-sized mobile units. After the well is drilled, it is necessary to strengthen its walls. This prevents them from shedding, and also prevents dirty water from the upper layers of the soil from getting inside the well. As a rule, the walls are strengthened by casing the column with steel or plastic pipes.