- Reasons and timing of septic tank maintenance

- Evaluation of the operation of the device by water quality

- Supply of electricity to the septic tank

- Using the Topas septic tank in winter (cold season)

- How to serve Topas in winter?

- Knocks out Topas' automatic fuse

- Reasons and timing of septic tank maintenance

- Servicing a septic tank

- How to understand that the septic tank is not all right?

- How to understand that the Topas WOSV is working properly?

- Do-it-yourself Topas station cleaning

- What is septic maintenance?

- WARMING OF THE SEPTIC

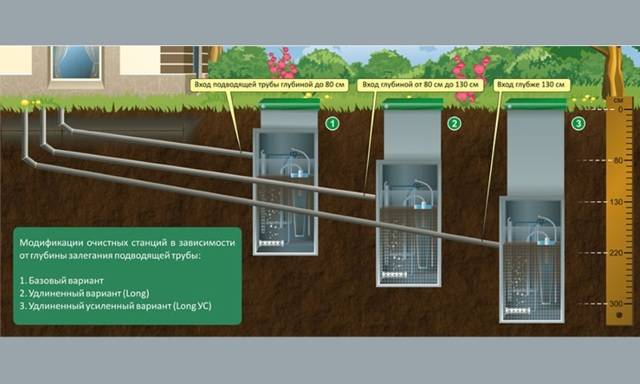

- Consider the most common options:

- Modern methods of insulation

Reasons and timing of septic tank maintenance

All local treatment facilities are subject to regular cleaning and inspection. They can be aerobic or anaerobic, but they still need to be checked and maintained. The terms of maintenance and pumping out of silt deposits for each model of a septic tank are set by the manufacturer. But much here depends on the capacity of the storage tank and the volume of effluents entering it.

The larger the internal volume of the septic tank and the less wastewater enters it, the less often it will be necessary to pump out sludge, but it still needs to be inspected on an ongoing basis every few months

At a minimum, it is recommended to check the performance of all internal systems in LOS in spring and autumn.The accumulated sludge should also be pumped out twice a year. But if the intensity of the use of the septic tank is high, then you will have to call the sewers more often.

According to manufacturers, aerobic self-contained sewers require less frequent pumping of sludge than anaerobic counterparts. However, the volume of effluents and their composition play an important role here. Residents of private houses often flush not only organic food residues, but also solid non-decomposing materials and objects with water into sinks and toilet bowls.

Another problem is the discharge of chlorine-containing and highly acidic liquids into the septic tank. They destroy the microflora of activated sludge. The number of microorganisms is sharply reduced, organics in wastewater are not processed, but only accumulated in the metatank. In this case, the filling of the VOC occurs much faster, so cleaning has to be done more often.

Evaluation of the operation of the device by water quality

A serviceable treatment plant at the outlet produces practically pure water without impurities and foreign odors. It can be used for watering lawns, flower beds, gardens. If the water from the device is cloudy, this indicates poor cleaning.

The culprit for this may be the short period of operation of the station (up to one month): the new equipment does not have a sufficient amount of biologically active sludge, which plays a major role in wastewater treatment. Biological balance can be established faster by adding activated sludge from an already operating station.

This also happens due to changes in external conditions: a sharp drop in temperature, indicating an increased acidity of the pH of the wastewater or draining chemicals into them (for example, containing chlorine).Usually, when these causes are eliminated, the situation normalizes by itself.

If the turbidity of the outgoing effluents is observed constantly, then the most likely reasons are an increase in the amount of effluents, insufficient aeration. The latter sometimes happens due to damage to the distribution tubes and oxygen leakage.

The quality of water treatment can be determined visually by taking a sample. To do this, a bubbling liquid is collected from a working device in the aerotank compartment into a glass container with a volume of about 1 liter. A properly operating plant will have a ratio of settled sludge to clear water of 2:8.

If there is less sludge, it means that the installation is not yet fully ready for operation or is not sufficiently loaded with wastewater. If more, this may mean that the system cannot cope with a large amount of liquid household waste or the float switch is set low in the compartment and there is no switch to recirculation mode.

The selected mixture is allowed to stand for about half an hour. By this time, activated sludge settles, and clear water rises to the top.

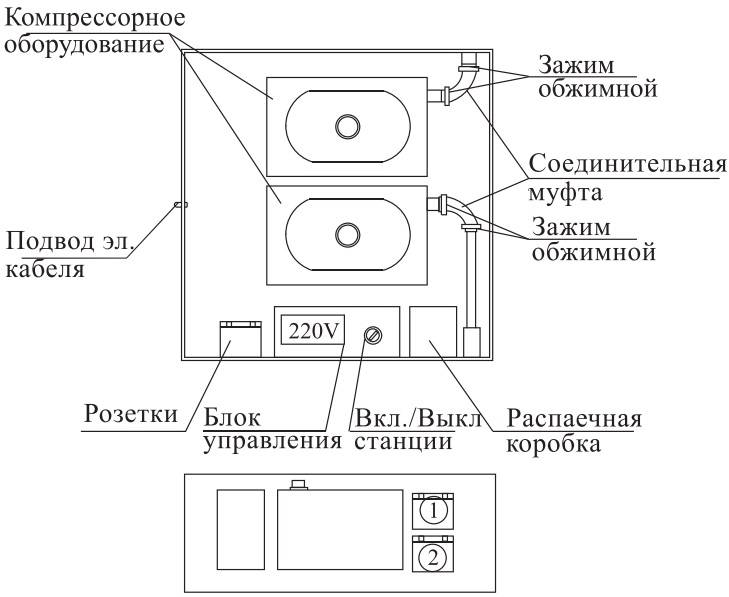

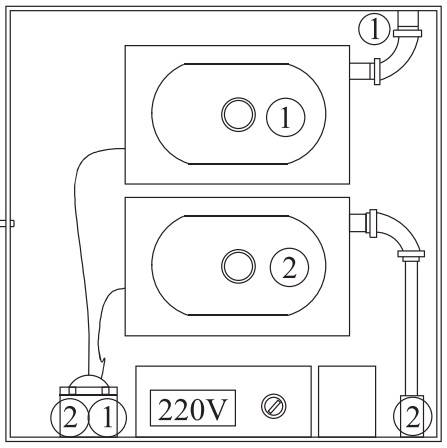

Supply of electricity to the septic tank

To connect the Topas wastewater treatment plant, install a separate switch on the switchboard. The power supply of the cleaning station must not be provided from the socket and connected at the same time with other electrical devices.

Compressor equipment connection diagram

This treatment plant will be able to operate at a voltage that deviates from the nominal by no more than 5% in any direction. If the electricity is turned off for no more than 4 hours, then this will not disrupt the operation of the septic tank.But if this period is exceeded, there is a risk of problems associated with anaerobic fermentation processes. You can understand that the work of the Topas station has been disrupted by the unpleasant smell that will begin to stand out. There is also a risk that the device will overflow, causing the sewer line connected to it to overflow.

Compressor No. 1 is connected to outlet No. 1, with a rubber outlet to nozzle No. 1 and crimped with the supplied crimp clamps; compressor No. 2 is connected to outlet No. 2, with a rubber outlet to nozzle No. 2 and crimped with the included crimp clamps.

You can connect your sewage treatment plant to an uninterruptible power generator.

If you anticipate or are planning a power outage in the near future, then be sure to limit the flow of drains to the septic tank.

The Topas septic tank operates at a nominal voltage of 220V (plus-minutes 5%). If the voltage in your mains is subject to fluctuations, use a stabilizer.

Using the Topas septic tank in winter (cold season)

To ensure uninterrupted and reliable operation of the system, it is necessary that the temperature of the liquids does not fall below 3 degrees above zero.

It should be noted that no additional procedures are required to ensure the operation of the Topas station in winter, if the temperature does not fall below 25 degrees below zero and at the same time at least 20% of household and fecal effluents are supplied to the system.

We also note that if sewage does not enter the system at all, then it will begin to be preserved and will also lead to the death of bacteria for the septic tank.

What to do if the ambient temperature is below the acceptable threshold required for optimal operation of the treatment plant (ie below 25 degrees below zero)?

In this case, it is recommended to implement additional VOC protection measures and not let everything take its course. To do this, a special insulated cover is prepared, which is installed on top of the cleaning station to ensure the temperature required for its uninterrupted operation.

How to serve Topas in winter?

In winter, Topas septic tanks operate with approximately the same efficiency as in summer. However, in regions with average thermometer readings below -20º in the winter months, the structure should be insulated to the depth of seasonal freezing in the region. In any case, the cover should be equipped with thermal insulation.

If the thermometer does not show below -20º, and at least 20% of water with domestic pollution enters the station for processing, measures to warm the skeptic for the winter can be omitted.

The devices inside the unit that are most sensitive to low temperatures are the compressors and the pump, if used. A noticeable cooling of the air surrounding them can cause an overload in the operation of the devices and even their breakdown.

If winter operation is expected, then with a thermometer reading below -15º, you should not open the cover of the device without urgent need.

Even before the onset of cold weather, it is recommended to perform a full range of maintenance of the Topas septic tank: pump out silt, clean filters, rinse the device, etc.

If the average temperature during the winter months varies in the range of -5º (-10º), there is no need for thermal insulation of the body.

The container is made of durable polypropylene, and this material has a reduced ability to transfer heat. This allows you to keep the temperature inside the septic tank almost unchanged even with the onset of slight frosts.

Additional external insulation of the cover of the Topas septic tank can be performed using modern heat-insulating materials or a large amount of rags, but you must definitely take care of sewer ventilation

Inside the septic tank itself there is its own source of thermal energy. These are aerobic bacteria that actively generate heat during the processing of waste, as mentioned earlier.

In addition, the lid of the septic tank is additionally insulated with extruded polystyrene foam - a reliable and modern insulating material. Therefore, Topas usually does not require special preparation for winter, and its maintenance is carried out in the same way as in the warmer season.

At the bottom of the Topas septic tank, the so-called neutral sludge accumulates, which is recommended to be pumped out every three months. This procedure must also be performed before storing the device and when preparing it for winter.

However, in areas with a harsh climate, or if there is a possibility of freezing of the septic tank due to special operating conditions, it is still worth taking some additional measures to protect the device from frost. The selection of heat-insulating material is made in accordance with the actual climatic conditions in a particular region.

The cover of the Topas septic tank is protected from the cold by a layer of insulation, but during severe frosts additional external thermal insulation will not interfere

An important condition is good ventilation of the septic tank. The access of fresh air to the device must be constant, otherwise the aerobic bacteria inside will simply die

This situation is simply unacceptable, because if the fermentation process stops, an unpleasant smell will come from the device, serious pollution will have to be eliminated.

Another significant moment in the winter is the overflow of the septic tank. Do not allow this, as this can cause damage to the mechanisms of the device. This situation is also dangerous in summer, but it is much easier to repair a septic tank in the warm season than when frost sets in.

Regular flushing of the Topas septic tank improves its performance. It is necessary when preparing the device for cold weather or before its preservation.

In the first year of operation of the septic tank, you should especially carefully monitor its operation. With the onset of severe cold, flaws made during installation and not previously detected may appear. Such breakdowns should be repaired immediately so that the septic tank does not completely fail.

A lot of problems can also arise as a result of the influence of third-party factors, for example, due to improper installation of a sewer pipe or in the absence of its high-quality insulation. If the preservation of the sewerage system based on the Topas septic tank is not carried out, then it must be serviced at least once every three months.

The following article, which we recommend for reading, will acquaint you with the details and rules for servicing septic tanks operated in the winter.

Knocks out Topas' automatic fuse

Solution As they say: electrical is the science of contacts. The machine knocks out - it means that the load current has exceeded. It is necessary to look for a malfunction in the electrical part of Topas

Pay special attention to the control unit of the treatment plant. 90% of the time it's the problem. For some reason, manufacturers do not pay enough attention to the tightness of the block, due to which the contacts of the terminal block are oxidized, and when overfilled, it immediately floods

Knowing this problem, our company has developed a universal control unit with an IP54 degree of protection, which fits almost all topas models and analogues.

For some reason, manufacturers do not pay enough attention to the tightness of the block, due to which the contacts of the terminal block are oxidized, and when overfilled, it is immediately flooded. Knowing this problem, our company has developed a universal control unit with an IP54 degree of protection, which fits almost all topas models and analogues.

Electrical diagrams can be found here.

Reasons and timing of septic tank maintenance

All local treatment facilities are subject to regular cleaning and inspection. They can be aerobic or anaerobic, but they still need to be checked and maintained. The terms of maintenance and pumping out of silt deposits for each model of a septic tank are set by the manufacturer. But much here depends on the capacity of the storage tank and the volume of effluents entering it.

At a minimum, it is recommended to check the performance of all internal systems in LOS in spring and autumn. The accumulated sludge should also be pumped out twice a year. But if the intensity of the use of the septic tank is high, then you will have to call the sewers more often.

According to manufacturers, aerobic self-contained sewers require less frequent pumping of sludge than anaerobic counterparts. However, the volume of effluents and their composition play an important role here. Residents of private houses often flush not only organic food residues, but also solid non-decomposing materials and objects with water into sinks and toilet bowls.

Another problem is the discharge of chlorine-containing and highly acidic liquids into the septic tank. They destroy the microflora of activated sludge. The number of microorganisms is sharply reduced, organics in wastewater are not processed, but only accumulated in the metatank. In this case, the filling of the VOC occurs much faster, so cleaning has to be done more often.

Servicing a septic tank

Wastewater treatment in such a tank occurs in several directions. Organic waste decomposes inside the tank, mineralization decreases, mechanical impurities are removed. As a result, water is purified by 98%, which is then used for technical purposes.

Wastewater treatment in such a tank occurs in several directions. Organic waste decomposes inside the tank, mineralization decreases, mechanical impurities are removed. As a result, water is purified by 98%, which is then used for technical purposes.

The first stage of cleaning takes place in the receiving chamber of the septic tank, where mechanical particles are deposited. The airlift then pumps the partially purified water into the aeration tank for the treatment of organic compounds by the vital activity of bacteria settled in the activated sludge. In the next compartment, silt suspensions are deposited, coming with deep-cleaning water. Then the purified water mass is removed from the system, and the sludge is returned for reuse.

Maintenance of the septic tank is carried out in the course of carrying out activities to check the functionality of the compressor and diagnose the operation of the equipment.

Sludge removal

Once a quarter, it is necessary to remove the silt, check the coarse filter and carry out the removal of non-recycled waste. It is impossible to allow complete removal of sludge from the chambers of the septic tank, since biological treatment occurs with its use. To prevent the formation of a dense layer of silt at the bottom of the sludge, it should be regularly pumped out using an airlift.

The sequence of maintenance of the septic tank:

- the airlift plug is removed;

- the pump hose is connected to the drain tank;

- sludge pumping starts after the pump is started. When operating the equipment, it should be ensured that the sludge fills the chamber by one third;

- fresh water is supplied to the sludge receptacle to the required level.

Sometimes septic tank maintenance cannot be performed due to a malfunctioning airlift. Usually, a breakdown occurs due to a clogged equipment, so it is removed and washed. Then the pump is mounted in place and the operation is repeated. If it is not possible to remove the bottom of the sludge with an airlift, a sump pump must be used.

Servicing the coarse filter

Once every three months, the filter element of the septic tank should be checked and cleaned of large particles. In this case, you need to completely turn off the system and carry out work in the following sequence:

- disconnect the hoses supplying air from the nozzles to the airlifts. Often they are difficult to remove due to hardening of the endings. In this case, preheat the hose with a lighter or a building hair dryer;

- after removing the fasteners, dismantle the airlift of the main pump of the septic tank;

- take out the coarse filter. To do this, unfasten the clips that fix it to the body;

- all parts of the equipment and hoses are flushed with a high pressure pump;

- clean the air nozzles (you can use a regular needle);

- the assembly is carried out in the reverse order;

- nozzles are connected;

- the system is starting up.

When connecting airlifts, the hoses must be installed correctly, otherwise the septic tank will not work correctly.

Garbage removal during maintenance

When operating the Topas system, it is not recommended to drain inorganic waste into the sewer. However, in the course of economic activity it is not possible to avoid the penetration of such contaminants. Garbage that has not been processed by microorganisms accumulates in a special chamber installed by the manufacturer. To clean this compartment, the septic tank is turned off, the garbage collection device (another name is “comb”) is removed and washed with a high-pressure pump or under a directed stream of water. Then all parts of the installation are mounted in the reverse order and put into operation.

How to understand that the septic tank is not all right?

Wastewater treatment plants operate automatically and do not require daily maintenance. During operation, household wastewater entering the receiving chamber is processed aerobically into sludge and technically pure water, which is then drained through the outlet pipes into the ground, a special reservoir, a drain ditch or drainage. At the outlet, the liquid oxidized by activated sludge should be transparent, without turbidity, sediment and odor.

The main symptom of a malfunction of the Topas septic tank is the appearance of turbidity or a specific smell. This is possible as a result of the death of biologically active microorganisms that decompose all waste during normal functioning.The incoming organic matter does not break down, accumulates in a closed container and rots.

Reasons for the death of bacteria:

1. Power outage for a long time. Lack of light for less than 6 hours does not affect the functionality of the equipment. In this case, water consumption is limited due to possible overflow of the receiving chamber and a backup power source is connected. If the power supply is turned off for more than a day, the compressor does not provide oxygen supply, microorganisms gradually die, and the water becomes cloudy.

2. The presence in sewage of materials and chemicals that aggressively affect aerobic bacteria and are not subject to biological decomposition. The instructions prescribe the rules for the use and maintenance of the Topas septic tank, which must be observed. It is forbidden to dump into the system:

- construction debris, lime, sand, elements of paint and varnish coatings;

- medicines, alkalis, industrial oil;

- wool, hair;

- cigarettes, plastic bags.

3. Excess fat in wastewater. Small inclusions of a spherical shape enter the receiving chamber and, without dissolving, stick to the walls of the container, reduce the throughput of the airlift and lead to breakdowns. Many users install a grease trap when installing the device under the sink.

You can also identify problems in the system by signs such as flooding of containers and leakage of water from the chambers. With an increased level of sewage in the compartment, an emergency float rises, an alarm is triggered, and the user learns about the failure of the equipment. Depending on the type of installation (forced or gravity) and the type of malfunction, Topas is repaired.

How to understand that the Topas WOSV is working properly?

A properly functioning wastewater treatment plant will produce water that is clean to the eye and does not emit harsh odours.

If your water treatment plant is turbid, it means that:

- It's not clean enough. Probably, you have recently purchased a Topas SWWTP, and it has not yet accumulated enough sludge to carry out a full cleaning. When serving a minimum number of people, it will accumulate all the silt needed for work in about a month.

- Something is wrong with the wastewater that has entered the device. For example, they have a reduced acidity index, they have undergone a sharp drop in temperature or contamination with household chemicals (washing powder, chlorine bleach, dishwashing detergent). In this situation, the problem of muddy drains will quickly resolve itself.

- If you constantly see turbid effluents at the outlet, this means that the WWTP is chronically overloaded, or that too much effluent was discharged there at one time, or that there was a depressurization of the air network or compressor failure, as a result of which there is not enough oxygen in the septic tank.

To further check the operation of the septic tank, you can take a sample of purified water leaving it.

Do-it-yourself Topas station cleaning

Like any mechanism, aeration stations need scheduled maintenance to maintain overall performance and the required degree of purification of incoming domestic wastewater. Since the main users of this type of sewage are people living in private homes, it is structurally possible to carry out maintenance of Topas stations with their own hands.

Here we will walk through the entire process of necessary service work step by step, which will allow you to operate your cleaning station in normal mode for a long time.

Before you start cleaning Topas with your own hands, you need to know the frequency with which it should be done:

- Once a quarter. With a daily residence of a nominal number of users (for example, when using the Topas 5 station by five users) all year round.

- Once every six months. With daily living during the summer season (the first time in the middle of the season, the second, with conservation - at the end of the season).

- Once a year. For weekend stays during the summer season (with conservation at the end of the season).

Having decided on the frequency of the service, we proceed to its step-by-step execution:

1) We remove the spent sludge from the activated sludge stabilizer. This can be done in two ways:

a. Using the built-in mamut pump.

With the unit turned off, remove the mamut pump hose from the fixing clip and lead it outside the station, remove the plug by loosening the metal clamp at the end of the hose. We turn on the installation in the direct phase (the float switch in the receiving chamber is forcibly raised). After pumping out about 50% of the volume (about 1 meter of liquid column) of the chamber into a previously prepared container, we turn off the installation. we fix the plug and fix the hose in its original position.

b. Using a sump pump.

We lower the pump with a hose to the bottom of the sludge stabilizer chamber, lower the end of the hose into a previously prepared container for collecting sludge or directly into the compost pit. We turn on the pump and pump out about 50% of the volume (about 1 meter of liquid column).We wash the walls of the sludge stabilizer from precipitation and fill it with clean water to the original level.

It is best to clean the walls of the chambers with high-pressure mini-washers, having previously covered the compressor compartment from water entering it during the washing process.

2) Using a drainage pump, we pump out about 20-30 cm of liquid from the bottom of the aerotank. We wash the walls of the aeration tank and the secondary sump from sediments and fill it with clean water to the original level. Remove from the fixing clips and clean the hair collector.

3) We wash the walls of the receiving chamber.

4) With the help of a net, we remove all non-decomposable mechanical debris from the station.

5) We clean the main mamut pump. We disconnect the air hose and the main mamut - a pump that pumps from the receiving chamber to the aerotank and take it out by removing it from the fixing clip. We wash the mamut pump from the outside and clean it by supplying a pressure jet of water into the pump tube.

6) We clean the filter of coarse fractions. We disconnect the air hose and the coarse fraction filter, remove it by removing it from the fixing clip. We wash the filter from the outside and clean it by supplying a pressure jet of water into the filter pipe. We install the coarse filter and the main mamut pump in place, fixing them on the clips and connecting them to the air hoses.

In order not to confuse the hoses of the pump and the filter, they should be marked, for example, with electrical tape.

7) Clean the compressor air filter. To do this, unscrew the screw located on the top of the compressor, remove the cover and take out the air filter. We clean the filter by shaking it. Install the filter in place.Similarly, we clean the filter of the second compressor.

If the air filter is excessively dirty, it must be washed in water and reinstalled after drying.

After completing all the above steps, turn on the installation

As you can see, Topas maintenance can be freely done by hand. Nevertheless, we strongly recommend that the first service be carried out by the efforts of specialists, as they say: “It is better to see once than read a hundred times on the Internet! » ))

What is septic maintenance?

The Topas sewer system, like other devices, needs regular monitoring, otherwise the wastewater will hardly pass through the filters, their purification will become insufficient. In the worst case, an emergency situation may occur, and then the system will need to be repaired. To avoid negative consequences, it is recommended to do the following:

- Every 3 months, remove excess sludge, clean nozzles, airlifts and filters from large fractions of dirt, and also get rid of garbage that is not processed by the septic tank.

- Clean compressor air filters once a year.

- Change compressor filters twice a year.

- Clean the bottom of the receiving chamber and aeration tank approximately once every 5 years.

- Replace aerators once every 15 years.

If there is no desire to independently carry out the cleaning work of an autonomous sewer, then you can contact a specialized company that services Topas septic tanks. You can conclude an agreement with it and, without a reminder, specialists will come to the site for planned events

It is important to note that most companies that sell autonomous sewers additionally offer to draw up an agreement for regular maintenance of the septic tank.

WARMING OF THE SEPTIC

The rules for installing septic tanks require its operation without long interruptions. The installation depth exceeds the freezing depth of the soil, the sewer pipe system has a positive slope that prevents stagnation and freezing of water, warm sewage and the fermentation process that generates heat - all these factors suggest year-round operation without additional insulation.

But even with the correct installation of the septic tank, emergency situations are likely, for example, in the event of a harsh winter and an increase in the depth of freezing of the soil or a possible change in the slope of the drain pipes in the event of soil deformation caused by frost heaving forces, prolonged power outages, seasonal intermittent use of sewage. Therefore, it is better to play it safe and insulate the septic tank for the winter in order to avoid unforeseen problems.

The most vulnerable is the entrance of the sewer pipe and the upper part of the septic tank. The decision on how to insulate a septic tank depends on your financial capabilities and preferences. Experts advise not to use organic heaters (sawdust, straw) for these purposes, which will rot and in 1-2 years you will have to return to this issue.

Consider the most common options:

- Expanded clay is considered the most optimal material, which has fairly good thermal characteristics. This material is poured between the walls of the installation and the slopes of the pit, while the thickness of the insulation should not be less than 20 cm. The upper part of the septic tank and part of the inlet sewer pipe are also filled up.

- Mineral or glass wool insulation. This method is somewhat more expensive, but it can also be attributed to budget options.Before insulating a septic tank, it is necessary to consider the method of waterproofing the coating. The fact is that materials of this class, when wet, lose their heat-insulating properties. It is best to use roll materials, they are easier to mount. The sewer pipe and septic tank are simply wrapped with thermal insulation, which can be secured with synthetic twine or wire. Waterproofing is carried out using roofing material or other roll materials. At the same time, one should not forget about the normalized overlaps of individual canvases. Fastening is also carried out using wire tying. The use of such materials, of course, is not the best option; it is chosen solely because of the low cost.

- Insulation with expanded polystyrene. This material is used quite often. Preference should be given to extruded polystyrene foam, which has a higher mechanical strength that allows it to withstand a significant load from the ground. In addition, it has minimal moisture absorption. To insulate sewer pipes, a special foam shell is used, and the septic tank is lined with sheets of material. It can be glued to the installation surface using various compositions.

Do not forget that septic tanks contain living microorganisms - aerobic and anaerobic bacteria, they need access to fresh air filled with oxygen. If the septic tank is not mothballed, a series of small holes should be made in the insulation for ventilation. From above, expanded polystyrene can be covered with polyethylene, in which holes are also needed.

Modern methods of insulation

- The electric heating cable for the septic tank allows active protection of the treatment plant.The thermal energy released during the heating of the cable is quite enough to ensure reliable thermal insulation of the installation and the sewer pipe. It should be remembered that the heating cable must be covered with a layer of insulation and waterproofing. It is advisable to use such systems for heating septic tanks with aerators, in this case it is not necessary to resolve the issue of supplying electricity.

- Another material that has been gaining more and more popularity lately is polyurethane foam. Two-component polyurethane foam has high thermal insulation properties, minimal moisture absorption and vapor permeability. It has high adhesion, can be applied to any materials, and does not require the use of additional fasteners.

After warming by any of the listed methods, backfilling of the pit with soil is performed.