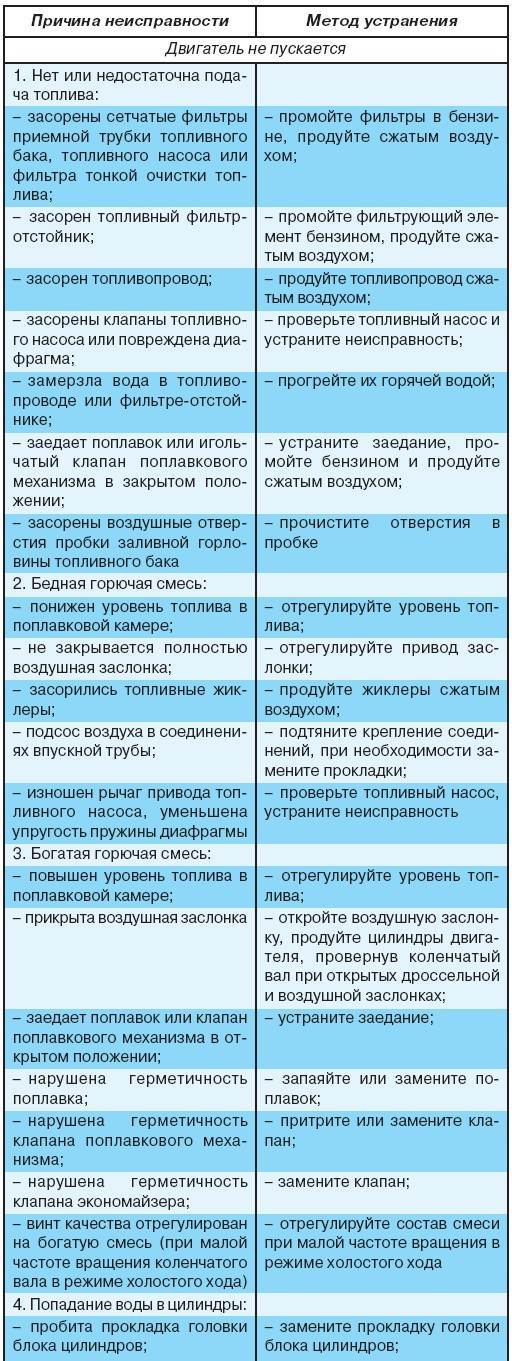

- Reasons for flushing

- How to start the device correctly

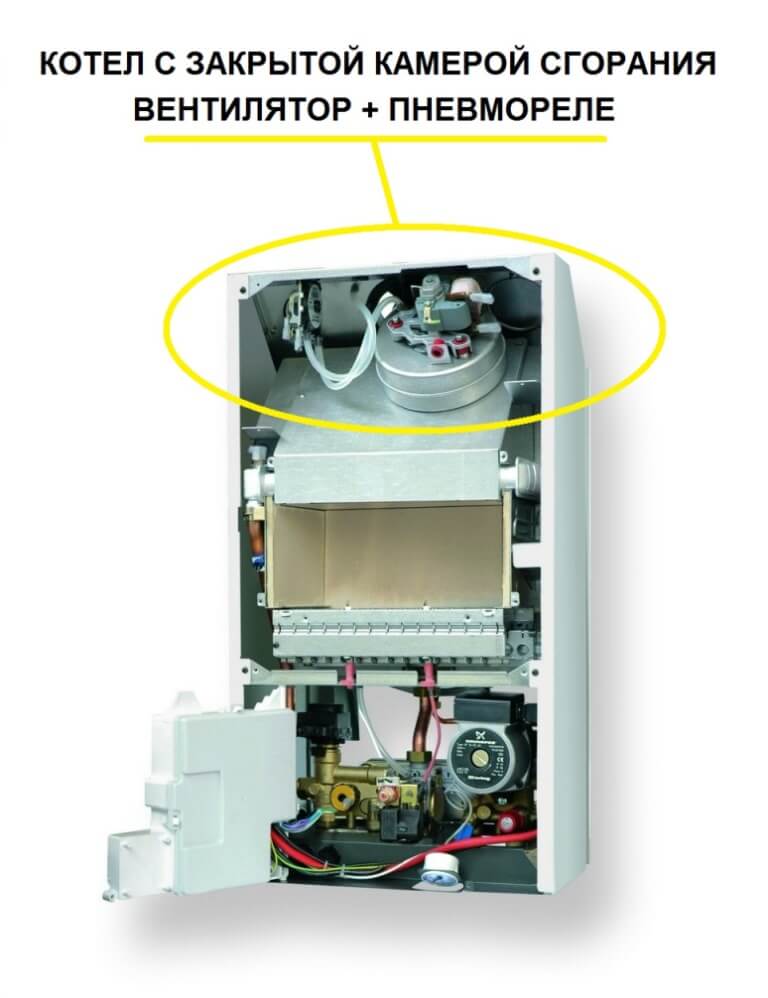

- Diagnostic procedure for a turbocharged boiler

- Measures to prevent scale in steam boilers

- We service household and industrial electric boilers in Moscow and the Moscow region

- Proper operation of the boiler

- When a major overhaul is needed

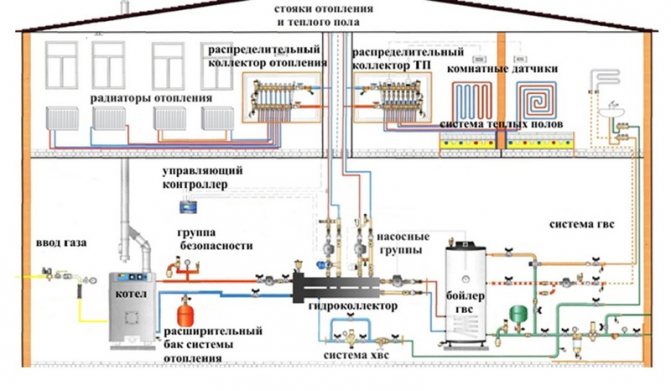

- Boiler assembly

- Nuances that arise during operation

- Prevention of breakdowns of heating equipment

- Types of boilers, characteristics of models

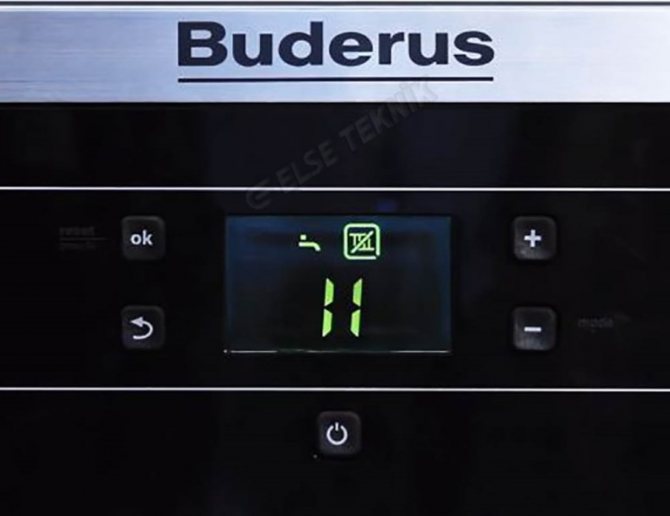

- Error codes and instructions for their elimination

- Types of descaling

- Collapsible view

- Non-separable view

- Buderus: what you need to know about the company

- What do you need to know about your equipment?

- Heating the house with electric heaters

- Frequency and duration of maintenance

- User manual

Reasons for flushing

- Reducing the quality and quantity of heat supplied to the premises at the same temperature of the network and ambient air, i.e. lack of comfortable living conditions;

- Increase in consumption of thermal energy over a period of time, in comparison with previous similar periods;

- An increase in the hydraulic resistance of the system, as a result of noise in the pipes;

- Changed color and quality of water, coolant, possible leaks, the appearance of an unpleasant odor;

- Significantly improved fuel consumption compared to the original system, especially in the first year of operation.

How to start the device correctly

The first start is made after connecting all pipelines:

- Direct (left) and return (right) lines of the heating circuit.

- Hot water supply.

- Gas pipeline.

In addition, it is necessary to connect the power supply using a special socket with a ground electrode.

The boiler electronics are very sensitive to voltage drops or surges, so it is important to protect the control board from them. It is necessary to use a standard voltage regulator manufactured by Buderus, or similar to it (which is somewhat worse)

It is necessary to use a regular voltage regulator manufactured by Buderus, or similar to it (which is somewhat worse).

The boiler is started either at the first start or after the summer break.

In both cases, you must first fill the system with water. Referring to the readings of the pressure gauge, the system is filled to a value of 0.8 bar. The standard working pressure is from 1 to 2 bar, but it must be borne in mind that when heated, the volume of water will increase, which will cause a rise in pressure.

After that, the required coolant temperature is set on the control panel, which will cause the burner to start and the boiler to start working.

Before switching on, be sure to lower air from radiators using Mayevsky cranes., otherwise an error will appear at startup. It is reset by pressing and holding the OK button, after which the attempts are repeated until a positive result is obtained.

Do not fill a hot heat exchanger with water, as this can lead to cracks and failure of the unit.Before filling, you must wait until the boiler has cooled down, and only then fill the system.

Diagnostic procedure for a turbocharged boiler

In a boiler that is equipped with a fan to remove combustion products, ensuring safe operation is somewhat more difficult. The draft is checked by an external device - a pneumatic relay. In the chimney, a device for measuring the air flow (Venturi device or Pitot tube) is also installed, which is connected to the pneumatic relay through plastic tubes. That is, in this case, the draft control principle is as follows: if the air flow generated by the fan in the exhaust duct is greater than the minimum value to which the pneumatic relay is set, then the relay contacts close and the board gives a signal to ignite, if the air flow is less (draft is not sufficient) - the contacts open and the boiler will be stopped.

That is, in a typical smoke exhaust scheme for such a boiler there will be:

-

inlet pipeline

-

fan

-

control devices

-

exhaust pipeline

The inlet pipeline is a pipe through which air enters the combustion chamber (it is closed in a turbocharged boiler). If, for example, the head of the pipe is covered with frost in winter, there will be no inflow, while the fan is characteristically quieter - the boiler will not start. Provided that everything is in order with the exhaust pipe and there are no other problems - if you open the combustion chamber, then the boiler will start in normal mode.

The operation of the fan can be assessed visually (the blades are visible without dismantling). If the fan does not start when the boiler is turned on, then in most cases either no signal is received from the board (the board is faulty), or the fan itself is faulty. Wiring damage occurs occasionally, but rarely.Service workers check the operation of the fan directly by applying voltage to it. If the fan works, most likely, diagnostics and repair of the control board will be required.

If the fan turns on and air enters the combustion chamber normally, but the boiler does not start due to a smoke exhaust error, you need to check whether the pneumatic relay is working. You can check that the relay is triggered visually (the relay makes a characteristic click), or even better with a tester - check the closure of the contacts in the wiring, because. the relay may work, but for some reason the signal does not reach the control board.

If the pneumatic relay does not work, you need to make sure that there is no pollution or condensate in the supply pipes, they are not damaged. Alternatively, you can create a vacuum in the supply pipe yourself and make sure that the relay works. If it does not work, it is likely that it is faulty and must be replaced (in most cases they are not collapsible and cannot be repaired).

In the event that the relay is forced to work, but normally, when the boiler is started, it does not, then the Venturi (or Pitot) device should be inspected for damage or contamination. The slightest deformation or contamination can lead to a malfunction.

Since the Venturi device is located in the exhaust pipe, it could be deformed by the high temperature of the exhaust gases.

Problems with the exhaust pipeline may be the same as with the intake pipeline, but it is possible to verify that there is no blockage, perhaps only visually or by measuring the actual vacuum with the device through specially provided control holes.

The air flow control device is installed inside the exhaust piping.There is a possibility of heat damage (tube deformation) or contamination.

In some modern boilers, fans with adjustable speed can be installed, which is set in the settings depending on the type of chimney used and its length (for example, in some Buderus and Ariston models). Therefore, it would not be superfluous to study the operating instructions for the equipment, since in practice there were cases when incorrect board settings were the source of the problem.

This article describes the most common and obvious causes of gas boiler failures related to the removal of combustion products. Different boilers can be equipped with different control schemes - we have considered the most popular ones.

Also, please note that it is unacceptable to turn off control devices - they are all provided for the safe operation of the equipment. If there is a problem, it must be fixed!

Measures to prevent scale in steam boilers

The amount of scale in boilers can be reduced by using measures to prevent its formation:

- install aluminum heating elements with heating power up to 2400 W;

- carry out regular maintenance;

- check the condition of protective coatings on internal parts;

- follow the manufacturer's recommendations regarding the quality of the water used;

- use water softeners: chemical compositions, magnetic converters, etc.

Before descaling the boiler, it is necessary to evaluate the thickness and composition of the layer, the technical conditions for the work, and then choose the appropriate method. Not only the efficiency of removing deposits will depend on this, but also the safety of the protective inner coating of the walls and surface of the heat exchanger.Only a competent approach to solving the problem will ensure the maximum service life of the boiler without breakdowns and with high efficiency.

We service household and industrial electric boilers in Moscow and the Moscow region

Repair of electric heating boilers is carried out in strict accordance with the regulations of the equipment manufacturer

During its implementation, special attention is paid to the following points:

- assessment of the tightness of communications;

- network pressure check;

- inspection and, if necessary, replacement of the filter;

- checking electrical wiring for damage;

- inspection and evaluation of heating elements and their insulation;

- fuse control.

In case of malfunctions in the operation of the boiler, the specialists of the center perform work in the following sequence:

- diagnostics and testing;

- replacement or repair of failed elements;

- commissioning works;

- checking the performance of boiler equipment.

The center's engineers use the latest software and specialized equipment when carrying out repairs.

Emergency repairs on site are possible due to the availability of the most popular parts, rare spare parts, and our own transport service. Repair of the boiler will be carried out promptly, regardless of the complexity of the breakdown. Urgent departure and quick restoration of the boiler equipment will allow you to avoid forced downtime in the cold season.

We not only carry out urgent repairs of boilers, but also undertake service obligations. We provide a full range of services related to the design, installation, commissioning of boiler equipment for industrial and domestic purposes.

The most common cause of failure of boiler equipment are errors made during design or installation. We will check the circuits, correct installation, diagnose the operation of the boiler and eliminate the identified malfunctions.

Proper operation of the boiler

The list of maintenance work carried out by the service organization necessarily includes operations to check the correct operation of the boiler. This is an important element of diagnostics, since it affects the durability of the equipment.

For this type of diagnosis of Rinnai boilers, the following operations are performed:

- They check the availability of protocols for testing gas boilers at the plant and the terms of overhaul maintenance.

- Check the quality of installation and the condition of the ventilation systems. They must be in good condition, and the air intake slots must be free.

- They check the quality of the piping for gas, water and smoke exhaust systems in accordance with the design documentation and the manufacturer's instructions.

- Check the presence and serviceability of the safety group and shut-off and control valves.

- Check the heating circuit for integrity and compliance with the thermal power of the device.

- Check the smoke exhaust system and the cleanliness of the passage of channels along the sections.

- Check the condition of the electrical equipment and the grounding system.

- Check the control unit of the device.

After all maintenance work has been completed, the service specialist makes an entry in the technical passport of the device, and the date for the next inspection is set.

In addition, a thorough user briefing is carried out regarding the changes made and the correct operation of the boiler equipment.

When a major overhaul is needed

A boiler overhaul is a set of restoration works to replace at least 30% of its working units, which is carried out to increase the normal operation life.

The overhaul period is set by the equipment manufacturer and usually it should be carried out after the expiration of the operating life indicated in the unit's data sheet.

Therefore, after the completion of the standard operating life, the boiler must be subject to technical diagnostics. As a result of which the possibility of subsequent use of boiler equipment is determined.

Major repairs can be carried out ahead of schedule if the basic devices fail abnormally. In the process of its execution, worn components are replaced. The overhaul of gas boilers is completed by flushing and cleaning the internal heating surfaces of the boiler.

After the completion of the overhaul, the service organization establishes a new service life of the equipment and periods of technical inspections.

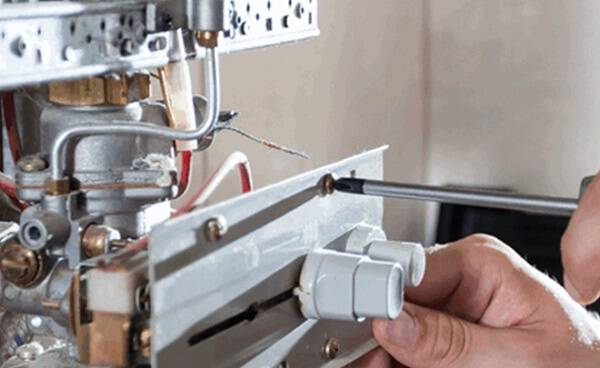

Boiler assembly

To clean the water heater from scale, follow a few sequential steps.

Disconnect the device from the water supply. To do this, turn off the cold water supply.

Unscrew the pipe from the hot fluid outlet by attaching a hose to it, the end of which is placed in a sink or bathtub.

Unscrew the cold water supply pipe. Liquid comes out of the hole.

Disconnect the panel, then the power terminals.

Unscrew the ground and electrical wire. For subsequent installation, it is better to photograph the connection diagram.

Loosen the bolts

Next, you need to remove the flange with the heating element.

If the boiler is wall-mounted in the bathroom, remove it and carefully place it on a thick cloth in the tub with the faucets up.After loosen the clamping bracket and remove ten.

Next, consider how to clean the heating element of the water heater.

Installation of heating equipment is carried out in the reverse order:

- inspect the rubber seal - it should be free of plaque and mechanical damage;

- lubricate the rubber parts with sealant to prevent the boiler from leaking;

- fix the heating element, hang the heater in its original place;

- connect the device to the pipeline;

- open the hot water tap, and then - cold;

- after filling the tank, check the tightness;

- insert the thermostat, connect the wires, install the safety cover;

- connect the device to the network.

Interruptions in the operation of the water heater begin after 2-3 years from the start of its operation. The heating element located in the storage boiler is covered with a layer of lime, increasing in thickness day by day.

The following signs also indicate the need for cleaning:

- increased heating time and, accordingly, power consumption;

- the device makes uncharacteristic extraneous sounds, most often hissing of varying volume;

- the water has acquired a yellowish tint;

- a characteristic hydrogen sulfide smell emanates from the water;

- yellowish flakes are visible in the water - pieces of scale;

- the outer walls of the tank began to overheat.

Assembly must be done in the reverse order to achieve operability, if your device has lost functionality, then you have assembled it incorrectly. Examine the rubber part, it should not have cracks, plaque and other damage, if any, it must be replaced.

Fill the tank by first opening the hot water tap, and then cold.After the boiler is filled, check its tightness for water leakage somewhere. If everything is in order, finish the assembly - connect the thermostat, connect the panel, screw in the cover. The cleaning procedure is completed, you can turn on the power supply. The boiler is ready to go.

We offer you to familiarize yourself with black home bugs

Nuances that arise during operation

In the heating system, you should try to prevent the appearance of corrosion, and when it occurs, you need to get rid of its foci. This is facilitated by the removal of air from the lines and radiators. Most of all it concerns open heating systems.

In order to remove rust particles, you need to use special inhibitors.

(additives

that enter into a chemical reaction in problem areas).

In the summer, you need to monitor the system to see if there is air. Many users use for closed systems and for open systems. Practice shows that such procedures are quite effective.

If there are frequent pressure drops in the heating system, then you need to urgently look for the root of the problem.

If you do not pay attention to this and delay the time, then your heater may simply fail. The reasons for this may be:

- Shortcomings in the installation of the system, in the case when the required slopes are not observed, in connection with this, the radiators are aired.

- Wrong points for mounting automatic air vents.

To ensure stable pressure in the system, it is necessary to choose the right expansion tank. For a coolant volume of 60 liters, a tank will be required, the volume of which will be 6 liters.If the amount of water exceeds the norm, then pressure drops may occur during the cooling / heating cycles, which will negatively affect the characteristics of the parts included in the system.

Thus, only compliance with all operating rules can extend the life of a gas boiler.

A gas boiler of even the simplest design works perfectly only if the components work smoothly. When the equipment is set up and debugged, the result is always perfect, the house is warm, and the equipment does not require constant attention from the residents. However, any device over time spends a resource of strength and reliability, therefore, maintenance of gas boilers is required with a complete check of the performance of the units of the unit, cleaning, adjustment, etc.

Do not trust the maintenance of gas equipment to a non-specialist. The first and most important reason is the preservation of the guarantee for boiler equipment. The manufacturer agrees to comply with the warranty obligations only if the installation and maintenance of the boiler equipment is carried out by one of the service centers with the appropriate license and permission to carry out installation and operational activities.

The main advantage of a service contract in a licensed service center is a guarantee of the quality of work performed and a reduction in operating costs over the period of operation of the boiler. Service workers are trained by manufacturers and are supplied with all the necessary diagnostic and repair equipment. This means that the visits of service workers will not be delayed, and the boiler will always be in excellent condition.

Breakdowns in a gas boiler can be due to a defect that was not detected during the standard production testing procedure or due to improper operation, lack of proper care, when accumulated problems lead to a breakdown. Warranty and post-warranty service protect against both problems, and the house is provided with high-quality heating for many years.

Prevention of breakdowns of heating equipment

The heating system must be regularly inspected and checked for leaks.

Compliance with the rules of operation of a particular equipment is likely to extend its service life. Of course, slight fluctuations in the parameters are possible, since usually all technologically sophisticated equipment has a "margin of safety". But it's not worth experimenting.

Servicing and periodic cleaning of heating boilers will also help prevent serious breakdowns. For some manufacturers, an annual service inspection is included in the price of the equipment. If this is not the case in your case, then perhaps you should invest in preventive examination and diagnostics once a year so that you do not have to invest more serious sums in repairs later. It is better to do this in the summer, or, in any case, after the end of the heating season. The wizard will help identify problems and advise how to solve them. It is quite possible that you can do some minor repairs to the heating boiler, such as replacing sensors, with your own hands. If more complex manipulations are required, then it will be time to contact the service department. Before the start of the next heating season, you need to fix all the problems and check ahead of time whether the system is operating normally.If you regularly carry out such work, then the question of why the heating boiler suddenly does not turn on will not arise at the most inopportune moment.

Preventive measures include cosmetic or planned repairs of the entire heating system. Measures such as checking threaded connections, cleaning ducts and nozzles, and painting pipes will help prevent larger problems.

It is also advisable to replace the heating boiler in the summer or during the repair of the premises. Since when replacing parts of the heating system, in addition to completely turning it off, it is usually necessary to lay pipes through partitions or ceilings. And all additional construction and installation work is best done before the premises are completely renovated.

Types of boilers, characteristics of models

Now there are several models of Buderus boilers on the market, which will be discussed below:

- Cast iron products are classified as long burning. Their main feature is a turbine, which supplies air mass to the furnace to maintain the combustion of solid fuel. For such installations, it is best to use coal, coke or wood, which can be pressed. Depending on the power required for space heating, you can choose one of five modifications. The boiler is installed in pump-type heating systems, and can be both an independent and auxiliary source of heat. A cast iron boiler can be used for heating private houses or warehouses, the size of which does not exceed 400 sq.m. The device has a compact size, so it does not require a lot of space for its installation. It is very economical and reliable.The only drawback in the operation of the unit is the need to load fuel manually, which sometimes takes time.

- Solid fuel boilers with a steel chamber for unloading fuel are divided into 8 types depending on the power: from 12 to 45 kW. This type of fuel takes coal, coke and wood. It can be installed in gravity heating systems as a stand-alone installation or as an auxiliary heating element with existing gas equipment. Units with a steel combustion tank are used for heating apartments, cottages or work premises from 120 to 300 sq.m. Depending on solid fuel cast iron installations, steel ones are slightly cheaper, and therefore more accessible to a wide range of consumers.

- For connoisseurs of comfort, economy and high quality, Buderus boiler models also include pyrolysis-type steel appliances with primary and secondary combustion chambers. The main combustion chamber allows the use of logs up to 58 cm in size, which reduces the time spent on fuel preparation. Such units are manufactured in four modifications with power from 18 to 38 kW. Equipping the boiler with external devices for controlling the air flow and smoke draft allows you to avoid the ingress of burning into the heated room. The performance of this model is 4-7% higher than that of the models presented above, which contributes to economical fuel consumption. Heating a room up to 300 sq.m., the installation practically does not produce burning, which means you can forget about daily cleaning.With all the advantages described, the only drawback is the high cost, up to 100,000 rubles, which is caused by the presence of the functions described earlier. Summarizing the information, it should be noted that almost all Buderus boilers are able to operate on any solid fuel, only those marked with the letter D accept only wood as a raw material .

Error codes and instructions for their elimination

Modern gas boilers are able to inform the user about a malfunction, and fix some breakdowns on their own, by stopping and restarting.

If the unit does not cope, and an error is displayed on the display, you should act according to the instructions, and if necessary, contact the technical service

Error codes are alphanumeric characters that indicate the type of fault. Among them, there are simple ones that require a reboot or cleaning, but there are also complex ones that require diagnostics of all units of the unit. Consider the most significant and frequently occurring errors.

0Y - temperature increase above operating settings (at a rate of +95°С). If the boiler does not automatically turn off, turn it off manually, check the sensors and the settings.

You should also check the pump, connecting it to the main regulator. Adjust pump power.

2P - a sharp increase in the temperature of the hot water supply. Check that the pressure corresponds to the operating parameters, check the operation of the pump, repair if necessary.

H11 - problems with the hot water sensor. Check the operation of the temperature sensor, as well as the contacts of the connecting wires. Replace failed parts.

3A - the fan does not start. Check contacts, wire connections. If the unit is faulty, replace it.

3U - fan speed is too high. Check the operation of the flue duct, clean if necessary.

4C - overheating of the heat exchanger. Carefully inspect the cable and sensors, bleed air from the system, check the pressure in the network. If everything is fine, the problem is in the radiator water assembly or pump, disassembly and repair is required.

6A - no ignition, no flame. Unscrew the gas cock to the maximum, check the pressure.

If you suspect a lack of draft, check if it is in the chimney. You can use a lit match - an even flame indicates contamination of the chimney, a fluctuating one indicates good traction

It is also recommended to diagnose the flow switch, check and, if necessary, clean the electrode contacts, remove plaque from the burners with a brush, and install a new unit if the burner malfunctions.

6C - the system detects a flame when the boiler is turned off and the gas is shut off. It should be checked whether the chimney is working and whether the contacts have oxidized. Perhaps, due to condensate, moisture has appeared on the board, which needs to be dried, and at the same time check the cleanliness of the condensation siphon.

9L - malfunction of the gas fittings. A thorough inspection of fittings and wiring, repair and replacement is required.

After replacing some components - for example, a fan or a pump - the unit must be put into operation. After self-repair of the Buderus gas boiler, it is not always possible to get it to work correctly due to “flying” settings. We advise you to call a wizard who will check the correct connection and reconfigure the unit.

Types of descaling

Boiler cleaning scaling can be done in two ways:

- collapsible, when its amount has reached critical volumes that cannot be removed in any other way, and further operation of the device is also impossible;

- non-separable, which allows you to prevent the appearance of deposits on the inner walls of the case in advance, as well as get rid of them, provided that effective cleaning agents are used.

Collapsible view

The collapsible method is the most effective, but time consuming. It allows not only to assess the current state of the boiler, but also to completely get rid of scale in any suitable way: mechanical or chemical.

A step-by-step analysis of the structure is performed as follows:

We study the instructions for parsing, if it is offered by the manufacturer, or the diagram of the device. We select the necessary tools. We prepare cleaning products and consumables for maintenance.

Disconnect the boiler from the power supply and wait until it cools down to room temperature.

We close the valves on the inlet and outlet pipes of the heating circuit, drain the water from the boiler.

We remove the protective cover by unscrewing the bolts in all places of its fastening.

At the same time, it is important to control the efforts so as not to break the thread.

Remove the top cover and get access to the inner container.

We dismantle the heating element and the heat exchanger (if it is provided for by the design).

The disadvantages of this method are: inapplicability for non-separable welded sealed structures, the likelihood of improper assembly or damage to the heat-resistant coating.

Non-separable view

The non-separable method is used to reduce and eliminate scale formation on your own without the likelihood of serious consequences for the operation of the equipment.Its advantage is the absence of the need to involve specialists. In some cases, for its implementation, it is not necessary to turn off the boiler, and then start it again.

This type of scale control has a number of disadvantages:

- cleaning efficiency can only be assessed by indirect signs: stabilization of temperature indicators, uniformity of heating, etc.;

- the inability to control how much scale is left in the boilers and whether its further removal is required;

- the difficulty of selecting the most effective agent due to the unknown chemical composition of scale;

- instability of the boiler during cleaning.

Buderus: what you need to know about the company

Buderus positions itself as a comprehensive manufacturer of heating equipment and climate systems according to the latest standards of energy efficiency, environmental friendliness and energy saving. The company has existed since the 18th century. In the last century, the German factory has seriously expanded production. In 2003, Buderus became part of the world famous Bosch brand, significantly strengthening its position in the global market. A year later, the corporation entered the Russian market. Today it offers Russian customers a wide range of domestic and industrial boilers:

- gas and gas-condensation, with a capacity of up to 38 MW;

- liquid fuel;

- pyrolysis;

Boiler Buderus Logano G244

- solid fuel;

- high and low pressure steam generators.

Buderus boilers for heating systems have a wide range of applications:

- Multi-story houses.

- Private sector, suburban and suburban construction.

- Office and retail space, service establishments.

- Industrial objects.

- social objects.

In addition, the company supplies to the domestic market:

- burners;

- boilers of various modifications, with a capacity of up to 6 thousand cubic metersl, direct and indirect heating;

- devices for automatic control of heating systems;

- panel radiators;

- heat pumps;

- other components: chimneys, expansion tanks, fittings, fittings, etc.;

- solar collectors;

- BHKW - block combined power plants with a capacity of up to 4.5 MW.

Attention! Features of the company's philosophy - a centralized network of offices and a large branch network of service centers and warehouses.

What do you need to know about your equipment?

Many issues of operation and maintenance are covered in the instructions for the equipment. Serious manufacturers usually give recommendations for each model, pointing out its features. So often the instructions describe possible breakdowns or malfunctions that can be diagnosed (and sometimes eliminated) on their own. Therefore, if you have a question why the heating boiler does not work or how to clean it, refer to the instructions. Perhaps you will find the answer there. Moreover, almost all models are equipped with numerous sensors - combustion, temperature, water level, pressure and others. And even if they are not included, it makes sense to install them as an option. After all, it is the operational monitoring of the condition of the equipment and the system as a whole that helps prevent serious breakdowns that may lead to the need to replace the heating boiler.

Heating the house with electric heaters

The following electrical appliances are used for air heating:

Air convectors are devices consisting of a housing, inside of which a heating element is located. During operation, cold air enters the convector, heats up with a heating element and naturally exits through the grate located in the upper part.Depending on the location, convectors are floor and wall.

Electric convector

Oil heaters - the heating of the room by such electrical appliances occurs due to the heating of the hermetic housing (radiator) filled with oil, located inside the heating elements.

Oil electric heater

Ceramic heating panels are devices that heat rooms by convection of warm air with a ceramic surface heated by tubular or flat electric heat-generating elements located under it (heating elements, heating cable).

Ceramic heating panel

Infrared emitters - heaters that heat the room by heating the emitted infrared rays of objects located in the area of the device with further transfer of part of the heat to the surrounding air. A classic device of this type is a case with a quartz transparent tube, inside of which there is a spiral of nichrome or tungsten wire that heats up and emits infrared rays.

infrared emitter

Frequency and duration of maintenance

Schedule maintenance Bosch gas boilers are carried out in accordance with the PTE of boilers and gas supply systems, as well as factory instructions. The required operations and their frequency depend on the purpose and completeness of the boiler.

As a rule, maintenance of gas boilers is carried out at least once a year. In most cases, this is done on the eve of the heating season.

Descaling of the heat exchanger should be carried out 5 years after the unit is put into operation, if it operates on softened water.If the water is hard, then the cleaning period will be determined by its composition, it may be necessary to flush the boiler twice per season.

In this case, the user needs to think about installing a pre-boiler water treatment system. Since frequent chemical flushing of the apparatus can damage the heat exchanger. Carrying out its repair is an inefficient and expensive procedure, in many cases it is more profitable to buy a new unit.

User manual

The boiler is connected immediately after installation in a pre-designated place.

The necessary communications are connected:

- Direct and return pipelines of system of heating.

- Water supply pipeline.

- Gas pipe.

- Power supply.

After connecting all pipelines, the tightness of the connections is checked, in particular, attention should be paid to the gas pipes. The system is then filled with water.

This situation occurs not only at the first start, but also after switching the unit to the winter period. When filling, they are guided by the readings of the pressure gauge - the working pressure is in the range of 1-2 Bar, but it is only necessary to fill in water to a minimum so that, expanding when heated, the liquid does not break the boiler

Then the system is filled with water. This situation occurs not only at the first start, but also after switching the unit to the winter period. When filling, they are guided by the readings of the pressure gauge - the working pressure is in the range of 1-2 Bar, but it is only necessary to fill in water to a minimum so that, expanding when heated, the liquid does not break the boiler.

Do not fill a hot boiler with cold water. This will cause the destruction of the heat exchanger, the occurrence of deformations or cracks.

After filling the system, the desired coolant temperature is dialed on the display.This will start the burner and start the boiler. The mode is adjusted in working order, switching from summer to winter is performed when the appropriate weather and climatic conditions occur.