- Why checks are carried out

- How to check gas equipment in an apartment

- List of gas equipment

- Basic concepts and definitions of VDGO

- VDGO in private homes

- First start

- Filling the system with coolant

- Checking the supply lines

- Putting the boiler into operation

- Boiler shutdown

- What is included in the maintenance of a gas boiler?

- Inspection of all contours and their individual elements

- Cleaning system elements

- Checking, setting automation

- Rules for the use of equipment

- What Not to Do

- Hardware failure

- How much does maintenance cost

- Is it obligatory to pay for the GO service?

- Process execution

- Inspection of important components

- Decontamination

- Functionality check

Why checks are carried out

There are more than 1.8 million gasified apartments in Moscow, and the equipment in each must be checked on time - this is regulated by law. Maintenance is carried out once a year according to schedules that are agreed with the prefectures.

Over time, gas equipment may malfunction, leaks occur, especially in the places of threaded connections - where the taps are located and the stove is connected. Mosgaz specialists are fixing these leaks and other problems.

Another purpose of scheduled inspections is to explain to residents the rules for using gas appliances. The masters tell you what to do in case of a gas leak, how to properly change the stove, where to go in case of malfunctions.

Tatyana Kiseleva reminds that when buying a gas stove, you cannot connect it yourself or trust the store employees. It is necessary to contact the specialists of Mosgaz. In most cases, when the stoves are connected independently, a gas leak occurs.

How to check gas equipment in an apartment

- the facts were confirmed, the complaint was satisfied. All possible measures are taken to comply with the law and protect the rights and interests of a citizen;

- The facts stated in the complaint did not find their objective confirmation. Complaint rejected;

- the complaint did not contain specific demands to be made by the Prosecutor's Office. The applicant is provided with an explanation of a legal nature;

- Verification of the facts stated in the complaint is entrusted to another organization. Such a decision is made within five days from the date of receipt of the complaint. The applicant is informed who will consider the appeal on the merits and from whom to wait for a response.

Remember! If, as a result of the inspection of the technical condition, such malfunctions of gas appliances are revealed that cannot be eliminated on site, the gas supply is shut off, the supply valve is sealed.

List of gas equipment

When checking an apartment or house, various equipment is serviced in apartments. This list may include the following:

- A device that is designed to account for the consumed gas.

- Gas stove for cooking food.

- A column that allows you to heat water for consumption.

- A gas boiler that heats water as a heating medium for use in a home heating system.

- Faucets with which you can open or block the access of gas to the apartment.

- Gas convectors.

When checking, diagnostics are made in residential buildings and apartments of existing gas appliances.

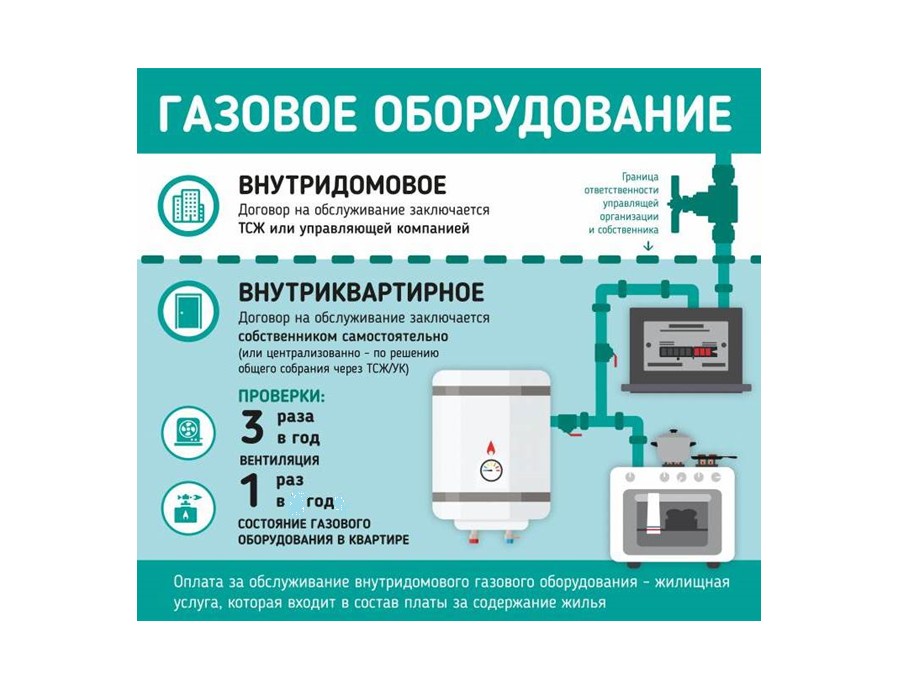

Basic concepts and definitions of VDGO

Intra-house gas equipment in general terms includes pipelines passing from the source of natural gas supply to the locking device inside the dwelling. It is located on the branch of the gas supply to the equipment.

There is another abbreviation - VKGO. It sounds similar, but stands for in-house gas equipment. These are pipelines that run from the locking device to the gas appliance inside the dwelling.

VDGO is a more detailed concept. To give the green light to gas in our homes requires the development of a large-scale system that includes not only a few pipes in the entrance, it is a whole network of gas pipelines that extends far beyond residential spaces.

To ensure that gas is always available to users, there are special storage facilities, distribution stations and laid pipelines.

You can understand what VDGO is in a receipt by understanding the classification of equipment. It can be:

- common use;

- private.

VDGO in private homes

In-house gas equipment of private households includes all pipelines passing through the land. They are laid from a single source to gas appliances in the house.

VDGO also includes additional technical devices, the presence of which is mandatory for the full and safe operation of the entire system as a whole.

First start

Before the first start-up of a gas water heater, it is necessary to check the correctness of installation, installation, in compliance with all instructions. The installed boiler must be inspected by a gas service inspector and sealed. Then you can start preparing for the first launch. Before starting, the automation is set up with the required parameters set, guided by the operating instructions attached to the boiler.

Filling the system with coolant

Step one - the system is filled with water or other coolant. The entire circulation circuit is checked for the presence or absence of "air" plugs in the system.

If available, air plugs must be bled by slowly releasing air through a special valve. Most often this is found on heating elements.

Etching should be carried out with caution, with the readiness to close the valve in time

Checking the supply lines

The second step is to check gas pipes, valves, valves for leaks. The check is carried out by a gas service worker. But if you feel a specific smell of gas, before the arrival of a specialist, you can check it yourself and find the place of the leak. For this, ordinary soapy water is used.

By applying it to the places of welds, to the junction of pipes and valves, you can detect a gas leak.

Putting the boiler into operation

The third step is the direct launch of the gas water heating boiler itself. It is carried out strictly according to the attached instructions. If you can’t figure it out on your own, then it’s better to contact specialists who have access to this kind of work.

Boiler shutdown

At the end of the heating season, if the boiler is not planned for use in the hot water supply system, then it must be turned off for a long period. To do this, follow a few simple steps:

- turn off the gas supply, make sure that the burner in the boiler has gone out completely;

- turn off the power supply to automatic ignition and automation;

- turn off the water supply for heating and water supply.

No special additional steps are required. Do not drain the entire coolant circulation system - to avoid corrosion.

What is included in the maintenance of a gas boiler?

A comprehensive service is carried out in three stages: inspection, cleaning of individual components, testing of automation. At each stage, several types of work are provided. So, what is included in the maintenance of a gas boiler.

Inspection of all contours and their individual elements

The master inspects all the elements in detail in order to form a general opinion about the state of the heating system. Documents, seals, compliance with the installation standards of the unit are checked in accordance with the current SNiPs and operating rules in force in the Russian Federation. The on-site master will assess the integrity of the system, pressure, the operation of the ignition electrodes, the overall performance of all electronics, the serviceability of emergency switches, the pressure in the system, and so on.

Cleaning system elements

The boiler is emptied, the gas burner is inspected, the flame is checked. Next, the selection washer, air sensor, and ignition electrode are removed and thoroughly cleaned. The remaining surfaces are cleaned of soot. For this, special tools, tools, equipment are used. If not cleaned, over time, even durable metal elements can become deformed.

If damaged items or any malfunctions are found during cleaning, they are usually fixed at this stage. Less often additional diagnostics and repairs are required.

Checking, setting automation

All automation components are subject to inspection, adjustment and, if necessary, repair: thermostat, gas valves, fittings, pressure switches, etc. The foreman can simulate an emergency situation in order to check whether the signaling devices are working correctly, whether the shut-off valve is sealed, and so on. At this stage, membrane replacement is often required.

The list of services that are included in the maintenance of a gas boiler can be much longer. Much depends on the model of equipment, its technical features, general condition. Therefore, the terms, as well as the price of current maintenance, are announced by the service departments after the initial inspection.

Rules for the use of equipment

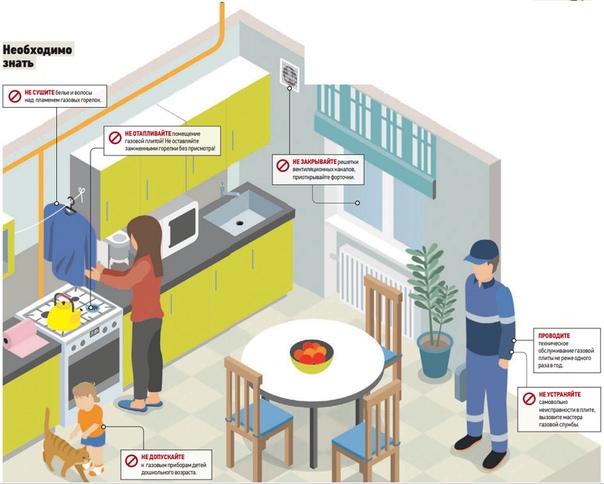

It is necessary not only to regularly undergo verification, but also to follow the rules of safe operation. They include the following:

- It is necessary to control the kind that the flame in the burners has. It should have a color between purple and blue. The flame must be in all burner openings, be strong and even.

- It is impossible to sleep or rest in a room in which gas is supplied.

- When a occupant needs to check for a leak, the safest way to do this is to use a soapy solution. It is strictly forbidden to use a flame for this. As a result, you can not only get burned, but also provoke an explosion.

- Persons who have taken alcoholic beverages must not use the gas for any purpose.

- Small children are not allowed to handle gas appliances.

- Before and after using gas, the kitchen must be ventilated.

- Sometimes the question arises of replacing gas stoves, is it legal to do it yourself. It is forbidden to independently install and connect them to communications. It is also not allowed to carry out repairs or install pipe fasteners.

- It is forbidden to turn on the burner first, and then start looking for a match. Switching on is done only at the moment when a lit match is brought to it.

- The holes in the burners must be clean and well pass the combustion gas.

- When the hostess uses a gas stove, she cannot leave it unattended - she must check it constantly.

- When soot comes from a lit burner, turn off the gas and call a repair service.

In some apartments and houses that are serviced, liquefied gas cylinders are used. It must be installed according to the following rules:

- from the stove should be half a meter;

- to heating appliances should be more than two meters;

- to a source of open fire (except for a stove), the distance cannot be less than two meters.

In cases where it is not possible to put a cylinder in the kitchen in a private house, it is placed outside. To do this, it is necessary to equip a metal box that can be locked with a key with holes through which ventilation occurs.

What Not to Do

Now many citizens, trying to save money, replace or repair gas equipment in their homes on their own. At the same time, they often do not even realize that by doing so they are violating Russian law.

After all, not having the proper qualifications, they endanger not only their own property and life, but also pose a threat to people living nearby.

In accordance with the previously mentioned government decree, the following manipulations with gas equipment can be carried out exclusively by employees of authorized organizations, on the basis of a previously concluded agreement:

- Maintenance;

- replacement;

- repair.

Hardware failure

Any durable goods can break during operation. Not all breakdowns entail the replacement of a gas stove, they can simply be repaired. But device owners must clearly understand the main rule - any detected malfunctions are extremely dangerous and can create an emergency. In the event of a gas leak, breakdowns can lead to fatal consequences, not only for the owner himself, but also for other people and premises.

Each manufacturer of gas stoves has its weak points. Frequent malfunctions during operation are:

- Failure of gas burners. They may not turn on at all or auto-ignition does not work.

- The burner stops its work during operation, the fire goes out due to the breakthrough of the flame, and the gas continues to flow.

- The gas supply is so weak that it is impossible to ignite the burner.

- The flame smokes and burns unevenly.

- The valves that regulate the gas supply do not work well - they do not turn or slip.

- There is no pressure on the oven or it is so low that the burner cannot be ignited.

- When the valve is released, the flame goes out.

- There is a smell of gas.

In all cases, self-repair is prohibited.Before the master arrives, turn off the general gas supply valve and ventilate the room so that the gas does not accumulate when it leaks.

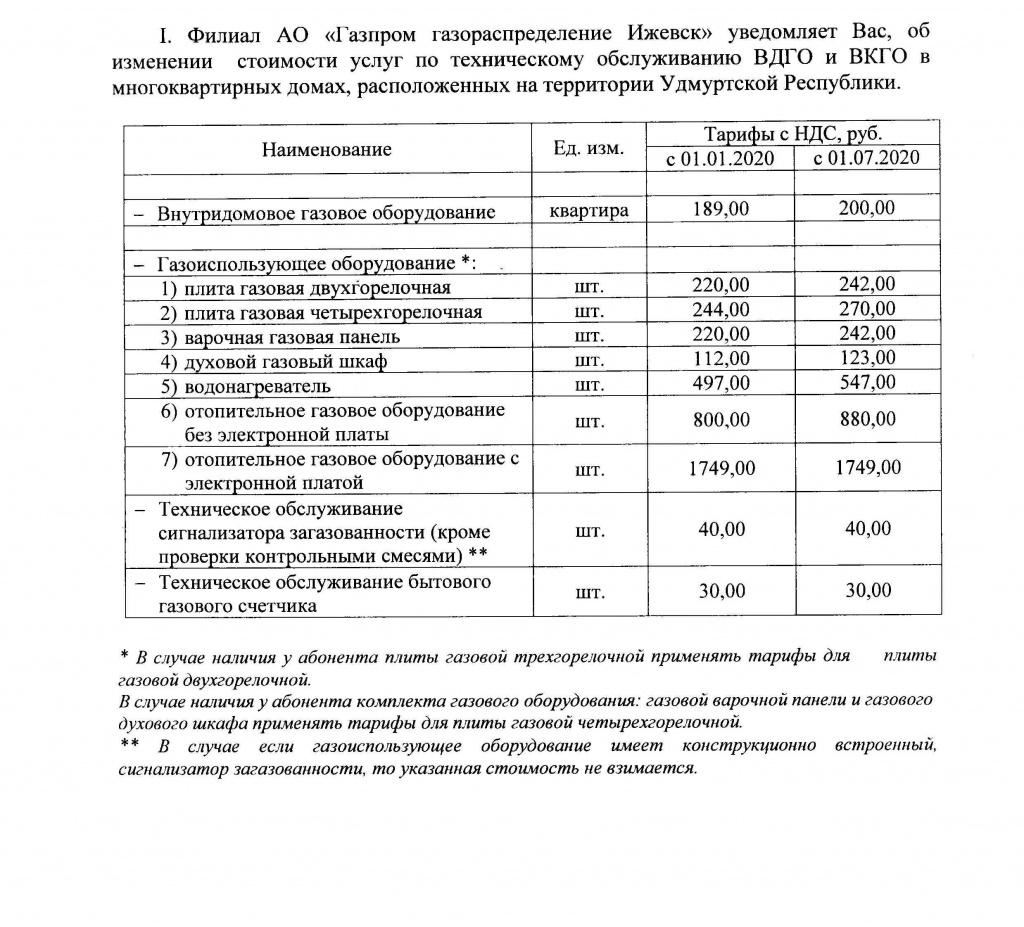

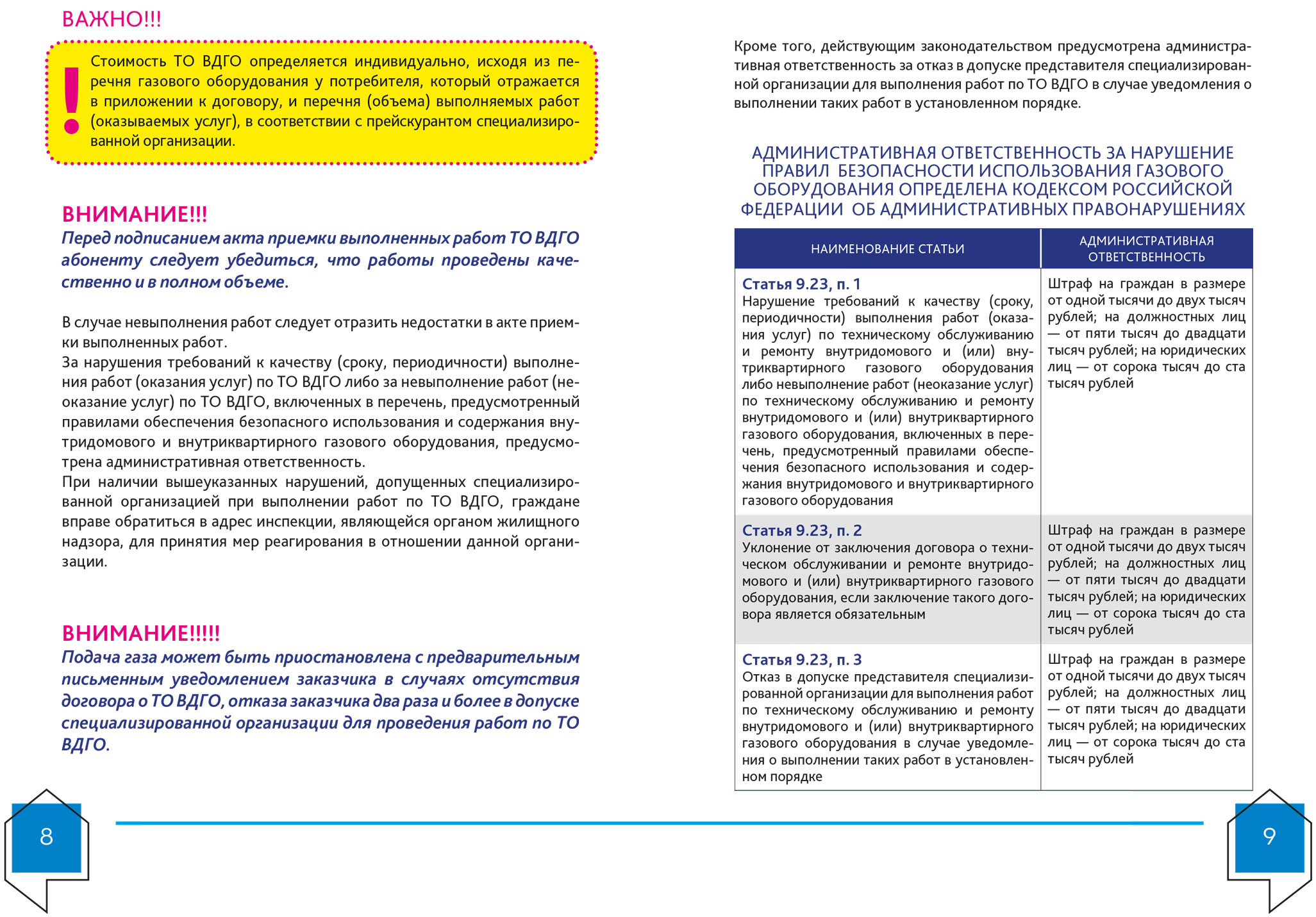

How much does maintenance cost

Tariffs for servicing gas equipment in an apartment building in 2020 are a key issue that interests all users of such equipment. To answer it, you should take into account several factors that affect the final cost of the work:

- Quantity and composition of GO. The more pieces of equipment you need to service, the higher the cost of the service. In addition, depending on the complexity of the various installations, it may be necessary to involve more qualified specialists, which increases the cost of verification.

- General condition and depreciation of the system inside the apartment. The greater the amount of work to be performed by specialists, the more expensive it will cost the consumer.

These rules apply to the maintenance of that part of the system that is located inside a residential area that is the private property of people.

Checking the state of civil defense in common building premises - entrances, basements, attics, and so on - is paid at the expense of funds received from residents. According to the law, the maintenance fee is monthly transferred to the accounts of gas supply organizations. Its size is determined taking into account two main criteria:

- tariff, which is set at the level of the subject of the Federation;

- footage of the occupied space. It should be understood: the more spacious the apartment occupied by a person, the greater the degree of his participation in the maintenance of common house property. That is why the tariff and, as a result, payment for servicing the common house part of the gas pipeline is determined based on 1 m2 of living space.

These provisions are additionally enshrined in, which indicates that the fee for the maintenance and repair of engineering networks is set in the amount necessary for the maintenance of common property.

Is it obligatory to pay for the GO service?

Consumers sometimes have doubts whether or not to pay for the maintenance of gas equipment. Some people often do not pay, because they are sure that in the event of a gas leak, the emergency service will come anyway. However, the tenants do not realize that in this case she will only come to cut off the gas supply.

Another group of people argues whether it is necessary to pay for the fact that gas equipment is serviced poorly or the resource supplying organization does not organize any maintenance at all. You should pay even in such a situation, because failure to make payments is a violation of the contract and will deprive the tenant of good arguments in the event of a conflict with the service company.

If the payment is paid on time and in full, then the tenants have the right to:

- Complain about the service organization to the supervisory authorities.

- File lawsuits in court, demanding the performance of their duties and compensation for harm.

- In the event of a breakdown, require replacement of pipes or equipment at the expense of the contractor.

Conscientious payers deprive contract violators of the opportunity to act first and justify their violations by non-fulfillment of obligations by tenants.

Process execution

In order not to harm the device, you need to know about the repair of its various parts. Routine maintenance includes several stages, which include checking, cleaning and adjusting. Before starting work, it is necessary to turn off the system and the source of gas supply. Then they wait for the system to cool down.

Inspection of important components

This step is required to diagnose the condition of the hardware. First, papers are checked and warranty sealing is carried out to determine whether the installation complies with SNiP and the rules of use. For the boiler to work, electricity and gas are required, so electrical parts are also inspected.

First, the protective case is removed from the unit and the elements and their level of deterioration are examined in turn.

The check is carried out to find out:

- proper operation of emergency machines;

- presence of pressure in the gas valve;

- the state of the ignition electrodes, if any;

- structural integrity;

- functioning of electronics;

- serviceability of connections in gas supply channels.

After that, the expansion tank is controlled and pumped up, protecting the system parts and compensating for the pressure that occurs during the expansion of the coolant. Special devices examine the unit, protective elements and gas communications. The pressure with cold water will average 1.1-1.3 bar. The exact figure depends on the type of equipment. After heating, the value should not be higher than the number indicated in the documents from the boiler.

Decontamination

First you need to empty the equipment and inspect the gas burner, determining the direction and quality of the flame.

The following parts must be removed and cleaned in turn:

- Support washer. A device that controls the position of the torch in relation to the installed heat exchanger.

- Air sensor that regulates the ratio of gas and air mixture.

- Flame detector, triggered by a decrease in thrust.

- The electrode responsible for igniting the air-gas mixture.

To prevent scale from clogging the burner, it must be cleaned in a timely manner using a special brush.

High temperatures and soot settling lead to deformation of metal structures. The burner is one of the important working elements of the device, so it should not be clogged with scale. The part is cleaned with special brushes. The burner operates normally when the flame is blue. If its color has turned yellow, then impurities must be removed from the element.

To evaluate the burner settings and check its operation, it is necessary to measure and analyze the exhaust gas in the boiler. Use a soft brush and a vacuum cleaner to clean the combustion chamber and all parts of the equipment that come into contact with the torch. Hard bristled metal is not suitable for cleaning nozzles. The branch pipe intended for supplying gas to the burner must be removed, disassembled and blown under pressure.

Functionality check

The operation of the unit without supervision is carried out using automatic control, which can have a different level of complexity. This technique often suffers from power surges. It is recommended to eliminate malfunctions in electronics immediately and adjust the system in time.

The boiler connected to the gas boiler, which supplies the DHW system, must be checked annually.

The boiler connected to the gas boiler and supplying the DHW equipment is subject to an annual check. In order to know the status of the safety node and identify vulnerable parts of the device, it is necessary to simulate an accident. After such a situation, the speed of the signaling devices, the tightness of the valve and other details are monitored.

If the unit does not work correctly, then it must be disassembled and the membranes replaced. The inlet of the gas pipe is also inspected.The entire gas pipeline is studied, in particular the junctions of the pipes from the outside, and the pressure level in it is determined. If there is a need to adjust the fittings, then it is performed. When the paint cracks on the pipes, the product is painted.

After the work done, you need to set the indicators that are indicated by the manufacturer in the documents, then check the equipment. The master must fill out papers in which he puts his signature and indicates the date of the next service.