- Performing a major overhaul

- What is included in the service? Gas workers opened and closed the gas boiler and that's it!

- Service types

- Maintenance (TO)

- Service maintenance

- How to conclude a maintenance contract?

- What is a contract?

- Rights and obligations of the parties

- Term of the conclusion of the contract

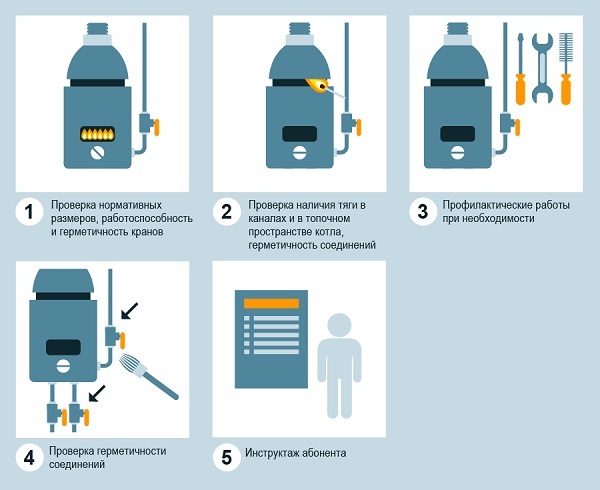

- Consider the diagnostic procedure in order.

- Gas pressure regulation

- What does the law say?

- What are the manufacturers saying?

- If we discard discontent, is THAT justified?

- When is maintenance carried out and how long does it take?

- How to save on maintenance?

- Performing a major overhaul

- The best price for the maintenance of gas boilers.

- Annual maintenance of gas boilers.

Performing a major overhaul

After the expiration of the operational period specified in the passport for the product, the gas boiler is subject to technical diagnostics. The main task of engineering and technical measures is to determine the possibility of further safe operation of the equipment.

Overhaul is carried out in order to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnosing as part of the capital service, they perform:

- Washing the heat exchanger.

- Comprehensive examination and cleaning of all closed boiler units.

A well-conducted set of measures is a guarantee of the correct operation of gas equipment during the subsequent service life.

Scale build-up in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

Cleaning of the heat exchanger from scale is carried out after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend preventive flushing every two years.

A simple procedure for flushing the boiler heat exchanger eliminates the problem at the stage of scale formation.

To carry out a major cleaning, remove the casing of the device and disassemble all removable parts of the unit. Separately, the heat exchanger is dismantled and thoroughly washed with chemical reagents using a pumping station.

Such washing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After that, the boiler is assembled and the system is filled with coolant.

In addition to servicing the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys

Cleaning of smoke channels, designed to divert combustion products from gas appliances and create traction, is not included in the list of measures necessary for the master to perform.

This work can be done for an additional fee. If desired, cleaning the chimney can be done on your own. It is advisable to flush it at least once a year.

What is included in the service? Gas workers opened and closed the gas boiler and that's it!

And in the past year, the last millennium, and the price of gas per person, even regardless of the number of burners, was 17 kopecks. And preventive work was carried out regularly with a mark in the gas book. When I was there, I remember that they did a free replacement of the old lubricant with fresh graphite.

Even the plates were changed for free. My mother had a taganok in Soviet times. So, during a comprehensive overhaul of the house, old toilet bowls with cast-iron cisterns and porcelain handles on chains were replaced with new compact systems and a taganok was changed to a 4-burner stove, which was later also replaced with a more modern one, but at its own expense.

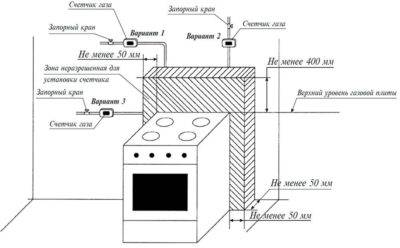

At that time, they were very jealous of the layout and installation of slabs. They walked with tape measures and measured the distance from walls and windows. Therefore, in typical houses, deviations from the project were punishable by fines. Previously, there were no flexible hoses and the stove stood as if rooted to the spot, there were no problems with distances.

There was no geyser, since during the overhaul a hot water main was brought up.

Service types

The company has been providing comprehensive gas equipment maintenance services for more than five years. The experience of our specialists allows us to offer not only technical (TO) or service (SO) maintenance, but also repair assistance. If a gas boiler from Baxi is installed in your house, then you can safely entrust its maintenance and repair to our qualified engineers.

Maintenance (TO)

Maintenance (TO, maintenance) of the Baxi gas boiler (Baxi) is carried out in accordance with the list of works specified in Government Decree No. 410 of 05/15/2013 and includes:

- Visual inspection of the integrity and compliance with regulatory requirements (inspection) of in-house and (or) in-house gas equipment.

- Visual check of the availability of free access (inspection) to the house and (or) house gas equipment.

- Adjustment of the gas combustion process in all modes of operation, cleaning of burners from contamination.

- Checking the presence of draft in the smoke and ventilation ducts, the condition of the connecting pipes with the smoke duct.

- Instructing gas consumers on the safe use of gas to meet household needs.

Installing a Baxi gas boiler in your home will definitely entail the need for its technical maintenance, which will ensure the safety of using gas equipment. All maintenance requirements are regulated by Government Decree No. 410 dated May 14, 2013.

Service maintenance

You can get acquainted with the list of works included in the basis of service maintenance (CO) of the Baxi gas boiler (Baksi), by opening those. manufacturer's certificate. It is the manufacturer who draws up a list of maintenance work, providing for certain operations for each type and model. The need for service maintenance is determined by the manufacturer's regulations, ensuring long-term operation of the gas boiler and prevention of breakdowns.

How to conclude a maintenance contract?

The basis for the conclusion of the contract is the citizen's appeal to the equipment maintenance organization. You have the right to choose a company yourself, the main thing is to check the availability of a license.

You need to take the following documents with you:

- Identity document.

- A paper confirming the ownership of housing.

- Application for a contract. It is filled in on the spot, each organization has its own form.

- It may also come in handy: documents confirming the composition of the VDGO, a copy of the act on determining the boundaries of the division of property on the gas distribution (attached) network, etc.

After providing the necessary papers, an agreement is signed and a subscription fee for the service is paid, according to the price list of the organization, at this the procedure is considered completed.

The cost of concluding a maintenance contract will vary by region of residence and equipment installed in the premises. For example, in Moscow, in 2020, the cost of maintenance from is from 300 rubles, more detailed prices indicating the name of the work are located on the website of the organizations.

We do not recommend that you complete the paperwork yourself. Save time - contact our lawyers by phone:

What is a contract?

After buying a unit, many are wondering if a gas boiler maintenance contract is needed. There is only one answer - remember that without registration of maintenance, the gas supply company can disconnect your house or apartment from gas supply at any time.

The service agreement for gas boilers is a standard document and includes the following information:

- Personal data of the owner and the address of the house or apartment.

- Name and details of the account of the service organization.

- List of equipment installed in the room.

- The list of works and services that are performed on the basis of the contract.

- Contract time.

- Service price.

The cost of the contract for services depends on the type of gas boiler and the total number of gas appliances. The conclusion of an official document will protect the user from poor-quality services. The contract clearly regulates the relationship between the owner of the apartment and the gas company that inspects and repairs the devices.

…

The gas boiler maintenance contract should include the following services:

- preparation and commissioning of a new boiler;

- preventive inspection and repair in a timely manner;

- replacement of defective parts;

- technical briefing;

- scheduled replacement of parts;

- carrying out current and major repairs;

- supply of spare parts.

To conclude a contract, the owner of an apartment or house must contact a local specialized organization. Her address and phone number can be obtained from your management company.

When concluding a contract, you must have the following documents with you:

- the passport;

- documents for an apartment;

- registration certificate for a gas boiler.

You can refuse to formalize a formal contract only in two cases:

- lack of gas supplies;

- in the presence of a common house contract.

Note! The management company can conclude a contract for the maintenance of gas appliances on behalf of the residents. Then the cost of services will be included in the bills.

Below is a sample service agreement for gas boilers.

Rights and obligations of the parties

The contract is concluded between the customer - the owner of the housing and the contractor - a specialized company providing services. According to the document, the customer undertakes:

- pay for services in the amount and terms stipulated by the contract;

- accept the services specified in the document;

- follow the recommendations for the operation and storage of equipment provided by the contractor;

- allow only persons with appropriate permits and permits to access the equipment;

- not transfer information on the provision of services received from the contractor to third parties and not use it in a way that could harm the interests of the contractor.

In turn, the performer is obliged:

- provide services in a quality and timely manner in accordance with the terms of the contract;

- perform all types of maintenance and repair of equipment at the request of the customer;

- carry out, at the request of the customer, the supply of spare parts and consumables necessary for repair and maintenance;

- not transfer or show to third parties the documentation provided by the customer;

- provide technical staff of the customer with consulting and practical assistance in the operation of equipment;

- restore the originals of the documents received from the customer in case of their loss.

The customer has the right:

- control the performance of services without interfering with the activities of the contractor;

- call the performer in case of any malfunction;

- refuse to perform the contract when paying for the services actually performed by the contractor.

The performer has the right:

- demand payment for services rendered;

- refuse to fulfill the contract subject to compensation for losses incurred by the customer;

- receive from the customer information that is necessary to fulfill obligations under the contract.

Term of the conclusion of the contract

Basically, the contract is concluded for a period of three years, but sometimes longer. During the validity period of the document, at least once a year, the service company conducts a control check and issues an act.

Gas appliances are a source of increased danger. Only after checking them by a specialist can it be argued that the device is safe. If the user of the gas boiler has not concluded an agreement for its maintenance, then the gas supply company will first send a warning letter about disconnecting the subscriber from the main. In this case, it is necessary to conclude an agreement as soon as possible so as not to be left without heat in the winter.

Consider the diagnostic procedure in order.

Firstly, before starting the gas boiler, it is necessary to analyze its appearance. Carefully inspect the outer casing, water, gas, see if there are any traces of splashes, stains, soot, burning around. The turned off boiler must be thoroughly cleaned from dirt, dust, cobwebs, scale, both inside and outside.

You should not turn a blind eye to minor flaws, in the future this can lead to major problems, up to completely changing gas equipment.

The next step is to pay attention to the smell of gas. If there is a suspicion of a gas leak, in no case do we independently ignite

We turn off the gas valve and call the specialists of the GorGaz service. They are quick to respond to emergency calls. Clearly explain to the visiting specialists the essence of the problem.

The gas equipment is visually in order, the smell of gas is completely absent. It remains to check the presence of traction in the exhaust system.

If possible, the exhaust system is checked visually. The next way is with a burning match, or a lighter

But, before that, it is important to make sure that there is no smell of gas, other extraneous odors. The air in the boiler room must be fresh

In modern two-loop boilers, there is a variant of their own wall hood. In this case, it is necessary to inspect the end of the exhaust pipe from the outside. There should be no ice, debris.

If you have a simple heating boiler with a manual ignition system, then before ignition, by cutting off the gas supply, using a torch, you can simply detect the presence of traction.

If the boiler is equipped with an auto-ignition system, then attention should be paid to the operation of the electronics system. If the boiler goes out after several ignition attempts, this is a lack of draft

There may be no draft if the upper casing of the boiler is not worn after repair. If the chimney is clogged, if it is mounted at an incorrect, negative slope, if the hood motor or sensor is out of order.

In modern gas boilers, an ignition error is necessarily confirmed by a digital error code.

If the error cannot be eliminated by elementary actions, then the boiler cannot be ignited.

It is also important to make sure that there is a coolant in the system. This can be checked with a manometer.

The minimum pressure should be about 0.5 atmospheres. If the system is electronic, then at a lower pressure the system turns off. If a simple mechanical system with manual control, then the boiler may fail - the heat exchanger will burn out. And this is one of the most important and expensive components of a gas heater. Replacement is carried out only by a specialist, and with an admission to this particular type of gas boilers.

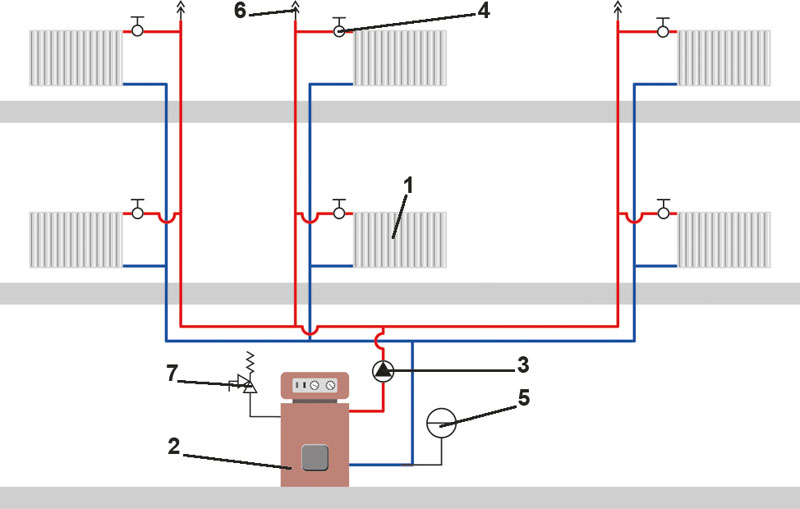

Most modern heating systems have a circulation pump. This pump makes the coolant circulate throughout the system, up to far points. It can be built-in or external. But his work is essential.You need to make sure it works. This can be tested by placing your hand on the pump housing and on the pipe that exits the pump. When the circulation pump fails, the system is able to work, but the heat supply parameters are reduced significantly.

In the first weeks of the heating season and in the most severe frosts, it is necessary to monitor the pressure of the coolant in the system, the readings on the boiler control panel. It is worth remembering that it is contraindicated for many gas boilers to add coolant to a hot system in order to increase pressure. This is fraught with a rupture of the heat exchanger housing, and even failure of all boiler mechanisms.

It is also worth remembering that the maximum temperature of the coolant in the system should not be more than 90 degrees Celsius. This can lead to the destruction of radiators and heating pipes, which, according to current regulations, are not designed for long-term operating temperatures of 90 degrees.

Competent regular maintenance, especially thorough at the first autumn start-up, is the key to the long-term operation of a gas boiler.

Gas pressure regulation

Measuring and adjusting the minimum and maximum gas pressure will allow not only to achieve the correct operation of the boiler, but also to save money. The exact pressure range is indicated in the instructions. For wall-mounted boilers, it is at least 2 mbar. The maximum pressure is 13 minibar.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the “chimney sweep” mode and check the pressure in this mode. If necessary, adjust the pressure to passport values.

What does the law say?

To date, all owners who have entered into a gas supply agreement are required to annually carry out maintenance of gas equipment. The consumer must provide the gas service with documents confirming the conclusion of a maintenance contract with the relevant company.

It is noteworthy that in Europe there is no practice of maintenance of boilers - this is an exclusively Russian norm.

Who can carry out maintenance?

Both legal entities and individual entrepreneurs can provide services. The list of approved organizations is published in the register of the State Housing Inspectorate for your region. Specialists of authorized companies and firms are trained at special plants, in our case - UKK Mosoblgaz.

What happens if maintenance is not carried out?

Everything that is in the apartment (house) is the responsibility of the consumer. That is, it is the consumer who is obliged to find an organization for maintenance, conclude an agreement with it and send the necessary documents to Mosoblgaz or Mosgaz.

If the regulatory authorities do not receive the necessary papers from you, then you may face a fine, and in the future - turning off the gas supply. Cut off the pipe and put a plug on it.

What are the manufacturers saying?

Some manufacturers recommend maintenance, others say nothing about it.

Will the boiler be removed from the warranty if a service company gets into it?

If the service is carried out by specialists, the guarantee will not be removed - according to the law. Moreover, some manufacturers can increase its duration if you carry out maintenance in a timely manner. Information about this is contained in the warranty card, carefully study it.

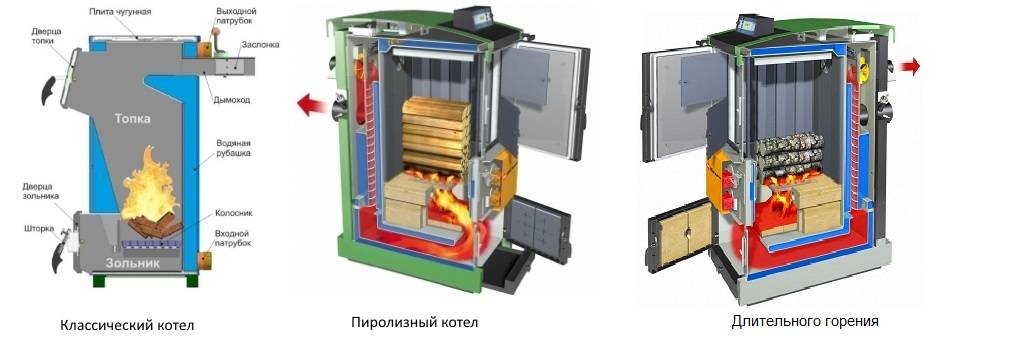

I want to install a new boiler in the house - which one to choose?

If we discard discontent, is THAT justified?

If the customer and contractor do not treat the need for service as a mere formality, then it definitely makes sense.

First of all, it is the diagnosis of possible problems. You can assess the condition of the boiler and other components before the heating season so that you do not find yourself without heat at an unexpected moment.

Over time, the operation of the heating system may deteriorate:

- The boiler often turns on and off.

- Everything works, but the batteries are cold.

- The pressure drops in the system.

- The extractor doesn't work.

During maintenance, the operation of all boiler components is checked and scheduled work is carried out:

- Testing the wiring.

- Clean internal parts, filter.

- Set up the burner.

- Check the pump.

Regular maintenance helps to play it safe and identify possible problems in advance.

If something happened to the boiler, then quickly replacing it during the heating season will be problematic.

If problems arise in the winter, you will have to urgently look for specialists. Winter is a “hot” season for companies, queues for orders are long and prices are high. The heating operation will stop until the boiler is repaired or replaced. If you have carried out maintenance, you are calm for the entire heating season.

The question is rather how you feel more comfortable: play it safe and feel calm, or hope that the boiler will work as long as possible without intervention, and the gas services will not remember you.

When is maintenance carried out and how long does it take?

By law, maintenance of a gas boiler is carried out at least once a year. In the contract with the contractor, a list of services is indicated, and after maintenance, an act is issued. The procedure lasts from 2 to 4 hours - everything is done within one working day. Work can be carried out at any time of the year, but it is better to do it in advance, before the start of the heating season.

During maintenance, the boiler is disassembled. If it is in operation, then it is advisable to turn it off a few hours before the arrival of the master - so that the system has time to cool down.

Energobyt Service → Services:Maintenance of boilers

How to save on maintenance?

It is best to wait for the period of special offers. From April to June, service companies have the lowest workload, so prices may be lower at this time.

Once again the most important:

Performing a major overhaul

After the expiration of the operational period specified in the passport for the product, the gas boiler is subject to technical diagnostics. The main task of engineering and technical measures is to determine the possibility of further safe operation of the equipment.

Overhaul is carried out in order to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnosing as part of the capital service, they perform:

- Washing the heat exchanger.

- Comprehensive examination and cleaning of all closed boiler units.

A well-conducted set of measures is a guarantee of the correct operation of gas equipment during the subsequent service life.

Scale build-up in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

Cleaning of the heat exchanger from scale is carried out after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend preventive flushing every two years.

A simple procedure for flushing the boiler heat exchanger eliminates the problem at the stage of scale formation.

To carry out a major cleaning, remove the casing of the device and disassemble all removable parts of the unit. Separately, the heat exchanger is dismantled and thoroughly washed with chemical reagents using a pumping station.

Such washing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After that, the boiler is assembled and the system is filled with coolant.

In addition to servicing the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys

Cleaning of smoke channels, designed to divert combustion products from gas appliances and create traction, is not included in the list of measures necessary for the master to perform.

This work can be done for an additional fee. If desired, cleaning the chimney can be done on your own. It is advisable to flush it at least once a year.

The best price for the maintenance of gas boilers.

100% guarantee of the best price for the annual maintenance of a gas boiler in the entire Moscow region.

For convenience, below is a table that shows the cost of maintaining gas equipment and a gas boiler, the price of servicing a gas boiler, as well as the total cost of work. An example is the standard set of process gas equipment and Buderus gas boilers.

Please note that the Energogaz company works with boilers of any technical type and all manufacturers, and the data in the tables are given solely as an example

| Service options | Cost taking into account the Buderus boiler model | |||

|---|---|---|---|---|

| U072 | U052/054/044 | GB062 | G124/234 | |

| Maintenance (including DRP, SACZ, meter, gas stove) | 10 500 rubles / year | 10 500 rubles / year | 11 500 rubles / year | 12 500 rubles / year |

| Service maintenance of a gas heating boiler | 5 000 rubles / year | 6 000 rubles / year | 8 000 rubles / year | 14 000 rubles / year |

| Comprehensive technical + service contract | 12 000 rubles / year | 12 500 rubles / year | 13 500 rubles / year | 18 500 rubles / year |

MINIMUM COST OF NECESSARY WORKS 8 500 RUB. WITH A CONTRACT FOR JSC MOSOBLGAZ

Annual maintenance of gas boilers.

By concluding an agreement for annual technical and service maintenance with the ENERGOGAZ group of companies, you are guaranteed to receive a discount on all work. Depending on the technological equipment and the boiler model, the discount on the annual maintenance of the gas boiler will be from 25 to 40%!

Given that annual maintenance is mandatory, for your convenience, we have developed a flexible service program for each gas boiler, which will allow you to ensure the safety and long-term operation of the entire gas system in the house.

A logical question arises - how much does it cost to maintain a gas boiler per year?

The cost of maintenance of a gas boiler consists of the minimum list of works approved by Government Decree No. 410:

- Visual inspection of the integrity and compliance with regulatory requirements (inspection) of in-house and (or) in-house gas equipment.

- Visual check of the availability of free access (inspection) to the house and (or) house gas equipment.

- Visual check of the state of painting and fastenings of the gas pipeline (inspection).

- Visual check of the presence and integrity of the cases in places where they are laid through the external and internal structures of apartment buildings and households (inspection).

- Checking the tightness of connections and disconnecting devices (instrument method, soaping).

- Functional check and lubrication of disconnecting devices.

- Dismantling and lubrication of cranes.

- Checking the operability of devices that allow you to automatically turn off the gas supply when the controlled parameters deviate beyond acceptable limits, its adjustment and adjustment.

- Adjustment of the gas combustion process in all modes of operation, cleaning of burners from contamination.

- Checking the gas pressure in front of gas-using equipment with all burners operating and after stopping the gas supply.

- Checking the presence of draft in the smoke and ventilation ducts, the condition of the connecting pipes with the smoke channel.

- Instructing gas consumers on the safe use of gas to meet household needs.

The cost of maintenance work is based on the requirements / recommendations of the manufacturer and is contained in the technical passport for the gas boiler.

- Recalling faults stored in the electronics/control unit/UBAH3

- Checking the strainer in the cold water pipe

- Checking the tightness of the water circuits

- Checking the heat exchanger

- Checking the electrodes

- Checking the pre-pressure of the expansion tank according to the static height of the heating system

- Checking the filling pressure of the heating system

- Checking for electrical wiring damage

- Checking the heating controller setting

- Checking appliances included in the heating system (DHW tank)

- Checking installed service functions