- Additional features

- Heating boiler Navien: the best of its kind

- Inclusion problems

- Installation of the Navien floor standing boiler

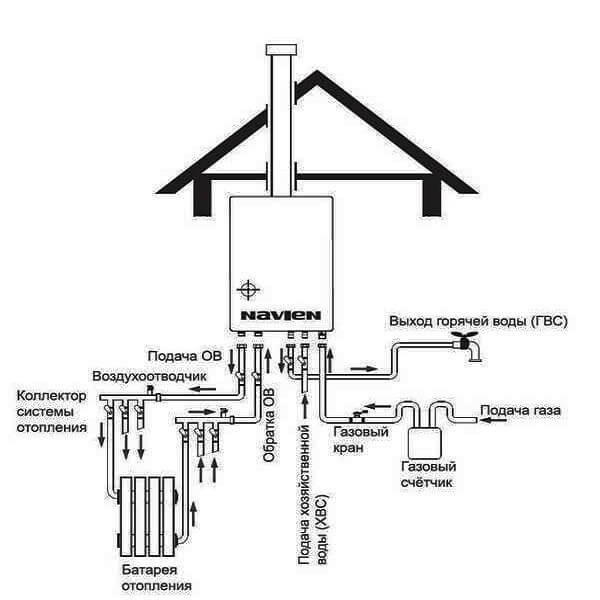

- Chimney connection

- Model range of boilers Navien (Navien) with characteristics

- Navien presents a versatile water heating system

- Frost protection system stability

- Operational safety with frequent voltage drops in the network

- Rational Design

- Fuel preheating (KR series)

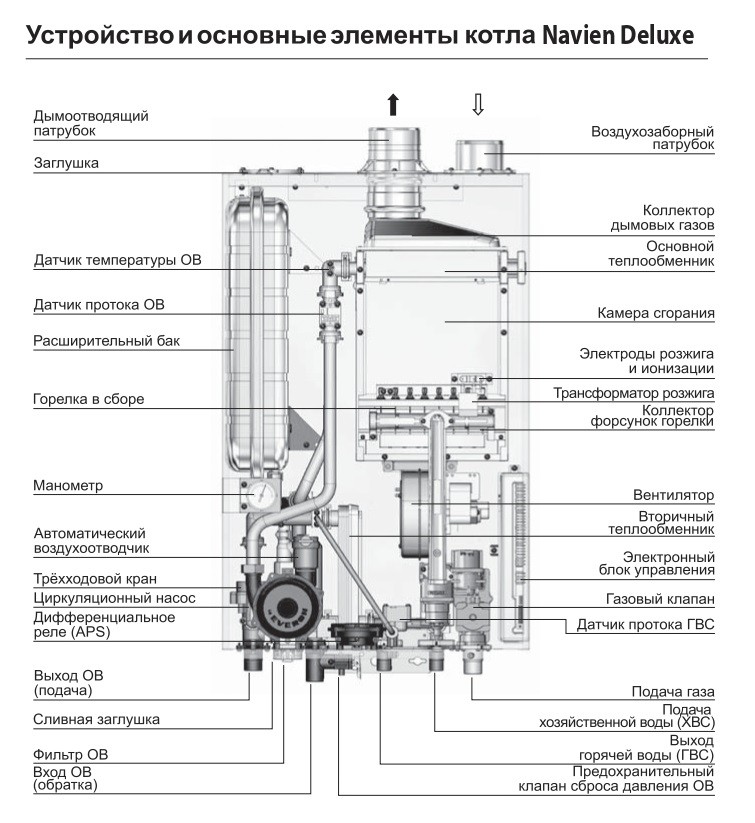

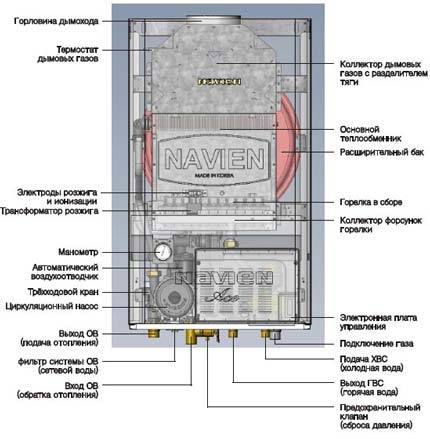

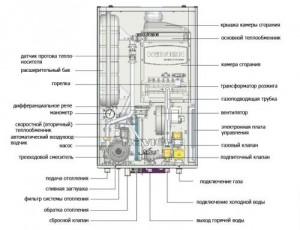

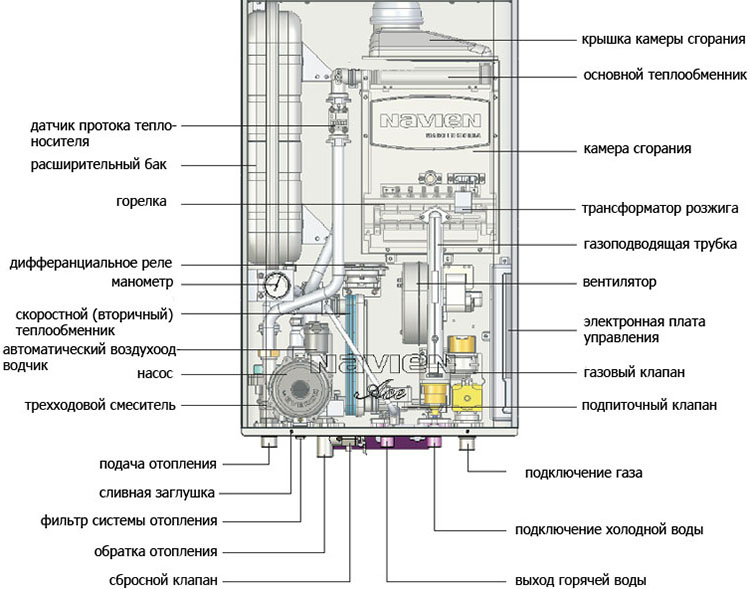

- Design

- Filling the boiler and heating system with water

- How to properly set up and run

- Elimination of some problems in the operation of the boiler

- Error 01e

- 02e

- 03e

- 05e

- 10th

- 11th

- Noise and hum

- No hot water

- Design features

- Tips and tricks for operating the Navien boiler

Additional features

The well-known problem associated with a voltage drop in the mains is solved in Navien devices, thanks to modern technological solutions - the SMPS chip.

In most cases, they are detrimental to heating equipment. However, due to the use of a unique SMPS chip, this problem is not such for Navien equipment.

The microprocessor of the boiler, paired with the Switched-Mode Power Suppl chip, allows you to equalize the voltage if its drop occurs within 30% of the nominal.This is true for Navien Ace 24k boilers (instructions for setting up this chip are presented in detail in the documentation accompanying the equipment), Navien Ace 16k and some other models.

What do equipment owners think about this technology?

I must say that the described technology regulates not only the voltage in the network, but also the pressure in the gas pipeline. The Navien Ace 24k boiler, the instruction of which determines the normal RH pressure of 0.6 - 3.0 bar, and the DHW pressure of 0.3 - 8.0 bar, is also equipped with a system to protect against pressure drops in the gas line. Thus, the control of gas pressure in this unit is controlled at two levels.

As for the Navien Ace 16k boiler, whose instructions require compliance with similar standards for pressure in the gas pipeline network, it is equipped with exactly the same security systems as its older brother.

Heating boiler Navien: the best of its kind

The Navien boiler is considered the most popular among heating and heating devices. The company presents only high-tech models for installation in various premises. On sale, everyone will be able to find for themselves the device that will serve him for the benefit of a very long time - and all this at a fairly attractive price. For heating apartments and small private houses, wall-mounted solutions are best suited.

Korean gas boilers Navien are double-circuit boilers that have an open and closed combustion chamber. They are used for heating and heating water for domestic and technical purposes.The entire automation system and documentation have been translated into Russian, so that everyone can easily study the existing instructions, as well as successfully save on heating, continuously maintaining the desired temperature in the premises. Uninterrupted and safe operation of the boiler is possible even in conditions of frequent power outages. In case of voltage fluctuations in the network, the SMPS protective system is activated, after which the boiler continues to work properly. In particular, thanks to this function, these double-circuit boilers have a long service life without breaking down and without requiring subsequent repairs.

Inclusion problems

There can be several reasons for such a malfunction:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by the protection system, which was activated due to the appearance of a critical error (overheating over 98 °).

There may be other reasons for failure. First of all, you should check the voltage in the network.

The boiler is able to compensate for fluctuations up to 30%, but, with more significant changes, it simply will not start. You can solve the problem by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, and the boiler continues to be silent, the wizard should be invited. Perhaps the cause was the failure of the control unit, breakdown or other serious problem.

Attempts to independently resolve the issue should not be made, this can cause the final destruction of the unit.

Installation of the Navien floor standing boiler

The floor-standing gas boiler is a potentially hazardous facility and, in accordance with the current requirements of SNiP, must be installed only in a special room - a furnace according to the project.These requirements cannot be neglected, since the user does not receive permission to operate the unit from the gas service.

The furnace must have a reliable ventilation system. For Navien gas boilers with a power of up to 150 kW, it can be installed on any floor, and more powerful equipment is only on the ground floor or in the basement.

Their installation in living quarters, bathrooms and toilets is prohibited. The furnace should not have cavities or niches, in order to avoid the accumulation of combustion products and the formation of explosive mixtures.

Typically, thermal insulation is carried out using a sheet roofing sheet laid on a refractory pad, for example, asbestos sheet with a thickness of more than 3 mm.

In front of the front of the device, a free passage is left for maintenance of at least 1.0 m. The space in front of the Navien boiler is covered with an iron sheet with an area of 1x1 m.

After installing the boiler, it is tied with auxiliary equipment and in-house engineering networks: a circulation pump, a fan, a security group, a drainage line, a make-up line, a heating and hot water system, a gas pipeline and a flue system.

Piping schemes are indicated in the design documentation for the boiler room and technical materials of the manufacturer. Installation and adjustment works are carried out by a specialized organization that has the right to conduct this type of operation. Works on gas equipment are carried out by Gorgaz specialists.

Chimney connection

The chimney ensures fire and sanitary safety in the house, and also contributes to the efficient operation of the unit with standard efficiency values.

The dimensions of the gas duct are set by the manufacturer of the boiler equipment in order to create the necessary vacuum in the combustion chamber to suck air into the combustion mouth. The exit point of the chimney is determined before the installation work is carried out so that it can be combined with the boiler flue pipe.

Closed-type Navien boilers are equipped with a coaxial chimney of the type that comes with the device or is specified by the manufacturer in the technical documentation.

When installing the boiler and its chimney system, it is important to withstand the slopes of the structural elements, carry out insulation at the points of its passage with the building structures, install a steam trap and a deflector. After tying the chimney elements into an integral structure, the natural draft in the boiler furnace is checked by bringing a lighted match to the viewing window of the ignition device

After tying the chimney elements into an integral structure, the natural draft in the boiler furnace is checked by bringing a lit match to the viewing window of the ignition device.

Model range of boilers Navien (Navien) with characteristics

Navien gas boilers are designed to organize heating and hot water supply of private houses ranging from 30 to 300 m2. The maximum water temperature is 80°, which meets the requirements of most plumbing fixtures. Navien devices compare favorably with similar samples from other manufacturers. Main advantages:

- Ability to operate at low gas pressure.

- Undemanding to the amount of pressure in water pipes.

- Increased circulation when the temperature drops to + 5 °, protecting the system from freezing.

- Built-in voltage regulator capable of correcting deviations up to 30%.

- Prices for Navien equipment are lower than for similar products from European companies.

There are wall-mounted and floor-mounted boilers, designed respectively for smaller or larger rooms. The design of different models provides for combustion with pressurization (turbocharged) or with natural air draft (atmospheric), which is provided by a closed or open type of combustion chamber. They are represented by the Navien Turbo and Navien Atmo series.

In addition, there are two- and single-circuit models designed to provide heating and hot water supply or only for space heating.

The Navien equipment line includes the following models:

- prime. This model range has the maximum configuration, the equipment fully complies with modern ideas about high technologies in any industry. Prime double-circuit boilers have all the innovative developments of today. The power range is within 13–35 kW. In total, the line includes 5 sizes, differing in power and, accordingly, in size. Devices have a full range of functions, operating parameters are displayed on a liquid crystal display. The price range is within 35-45 thousand rubles.

- Deluxe. The devices of this series have almost the same parameters as the Prime line. The only difference is the lack of an LCD display, but instead, an air pressure sensor is used in the circuit (indicated by APS in the diagrams). The presence of this device allows you to accurately dose the air jet, providing an optimal and economical combustion mode. There is a wide choice of models, from 10 to 40 kW.Prices for appliances are in the range of 23-35 thousand rubles.

- Ace. The most common and preferred line of heating devices Navien. It has an optimal ratio of price and functionality. Reliable and high-quality devices have several modes of operation (manual, automatic, timer). All installations are fully adapted to Russian conditions and have proven themselves in operation. Boilers with open and closed combustion chambers are available (Ace Ftmo and Ace Turbo), the connection of the boilers is simple and does not require significant labor costs. You can buy devices from this line for 20-30 thousand rubles.

- Steel (GA/GST). The ruler provides only space heating (single-circuit devices). There is a wide choice of power - from 11 to 40 kW, narrow functionality allows you to get a device that is most specialized for performing its tasks. Reliability increases, reduction in the number of structural elements makes it possible to increase strength, resistance to temperature and pressure drops. The construction uses durable materials, in particular stainless steel. Devices from the GA or GST lines can have a two-circuit design, they are made mainly in a floor version with high power. The price range depends on the configuration, power of the device and is in the range of 20-56 thousand rubles.

- SmartTok. A device that can be controlled remotely using a smartphone. This method of temperature control allows you to change the microclimate in the premises as comfortably as possible, without leaving them, to optimally adjust the operating mode according to your own feelings.There are three operating modes, an outside temperature sensor is used, which allows you to adjust the heating depending on weather changes. There is a voice control mode. The price for devices of this line ranges from 30 to 50 thousand rubles.

Please note that equipment prices vary by region and may increase.

Navien presents a versatile water heating system

Navien Ace gas boilers are not afraid low pressure gas and water, they are not afraid of voltage drops in the network. The operation of Navien gas boilers is characterized by a long period of operation and economical gas consumption. All Navien gas devices comply with the standards and norms of the Russian Federation and have the appropriate certificates.

Frost protection system stability

If the room temperature drops, the automatic frost protection system is activated. When the temperature of the heating water drops below 10 degrees Celsius, the circulation pump is automatically started, as a result of which the constant circulation of the coolant in the heating system is ensured. If the heating water temperature drops to 6 degrees Celsius, the burner automatically turns on and the coolant warms up to 21 degrees Celsius.

Operational safety with frequent voltage drops in the network

According to the instructions, the voltage can fluctuate within ± 30 percent, due to the operation of the Switched - Mode Power Supply (SMPS) protection chip on the microprocessor. At the same time, the operation of the boiler does not stop, which prolongs its period of operation and prevents breakdowns.

Operating conditions for heating and hot water:

- subject to low inlet pressure in the gas pipeline system - stable and safe operation of the Navien Ace gas boiler is possible at a gas pressure of four mbar (40 millimeters of water column);

- subject to low incoming water pressure in the water supply system - stable operation of the Navien Ace gas boiler is possible provided that the incoming water pressure drops to a value of 0.3 bar, which allows the use of this gas device in homes where there is a weak water pressure in the water supply system, including where frequent pressure drops in the water supply system.

Rational Design

Navien gas boilers are small in size and light in weight, they are convenient to transport, they are easy to install and there is the possibility of rational use of space. For ease of installation, the connecting pipes are located on both sides of the device, which greatly simplifies the piping and installation of the Navien Ace gas boiler.

Fuel preheating (KR series)

At low temperatures, the viscosity of the fuel increases, resulting in the effect of waxing, which significantly worsens the flammability of diesel fuel and the operation of the Navien gas boiler becomes unstable. This feature of operation is relevant for regions with a harsh climate, therefore, Arctic and winter diesel fuel has been created for these conditions.

Navien gas devices operate on any Russian-made diesel fuel, however, the cost of winter or arctic diesel fuel is much higher than summer fuel, and the use of summer fuel is impossible at low temperatures without preheating it.

The heating element, which is built into the burner of the Navien gas unit, before supplying fuel to the nozzle, preheats it, resulting in high-quality fuel atomization and uninterrupted ignitability. Due to the preheating in Navien Ace gas boilers, it is possible to use inexpensive summer diesel fuel, which leads to significant savings.

Design

1. The heat exchanger is made of stainless steel

For the production of the heat exchanger, stainless steel is used, so that it does not corrode, which significantly extends the life of the Navien Ace boiler.

2.  Modern diesel burner

Modern diesel burner

Due to the modern efficient diesel burner, quiet stable operation with minimal fuel consumption is ensured. According to the instructions, the burner can work with any diesel fuel, taking into account all types of fuel produced in the Russian Federation.

3. Fuel filter with replaceable cartridges

The fuel supply system is equipped with a filter to remove unwanted impurities, as a result of which the stable operation of the Navien Ace gas boiler is disrupted. Additional replacement cartridges are included with the Navien device.

4. Russified control panel

With the help of a fully Russified remote control panel equipped with a liquid crystal digital display, it is possible to save fuel and reduce heating costs, as well as constantly maintain a comfortable room temperature thanks to a room temperature sensor built into the control panel.

Filling the boiler and heating system with water

Error code 02 indicates that there was an attempt to start the boiler, but there is no water in the system, or it is not enough. What to do:

- The device is switched off from the socket and the gas supply is shut off.

- At the bottom of the boiler, among the many elements, you need to find a make-up tap. Turning it counterclockwise opens it, and turning it clockwise closes it.

- When the faucet is open, watch the pressure gauge. You need to close the tap when it shows 1.3 - 2 bar.

- Now the boiler is reconnected, gas is supplied and the start is made.

Don't worry if error 02 reappears. This can be caused by the fact that after bleeding (which is automatically performed at start-up), the water level is again insufficient. The filling operation must be repeated.

How to properly set up and run

Procedure:

- The procedure for starting the boiler begins with filling with water. Gas double-circuit units do not need to install additional devices, so you just need to open the make-up valve and bring the pressure up to 1.5-2 atm.

- After that, the valve closes, air plugs are removed in the system and on the unit itself, for which Mayevsky taps on the radiators and an air valve in the boiler are used.

- Then you need to bleed the air from the circulation pump. the casing is removed, the water heating regulators are turned on. There are specific sounds that indicate the operation of the system. On the pump, the screw in the middle is gradually unscrewed until water appears. This procedure must be done 2-3 times, after which the air from the pump will be completely removed.

- As soon as the circulation pump is put into operation, the burner will start electronically and the heating system will start to function.

This completes the initial start-up and adjustment procedure.

Elimination of some problems in the operation of the boiler

Like any, even the most reliable technique, some problems may occur in Navien boilers, some of which the owner of the device can fix on their own.

First of all, it is important to recognize the cause of the breakdown. So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code

So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code.

Here are the Navien boiler trouble codes:

- 01e - the equipment has overheated.

- 02e - there is little water in the heating / the circuit of the flow sensor has broken.

- 03e - there is no signal about the flame: it may not really exist, or there may be problems with the corresponding sensor.

- 04e - false data about the presence of a flame / short circuit in the flame sensor.

- 05e - problems with the heating water t sensor.

- 06e - short circuit in the heating water sensor t.

- 07e - problems with the hot water supply t sensor.

- 08e - short circuit in the hot water supply t sensor.

- 09e - a problem with the fan.

- 10e - problem with smoke removal.

- 12th - the flame went out during work.

- 13e - short circuit in the heating flow sensor.

- 14e - no gas supply.

- 15e - a problem with the control board.

- 16th - the boiler is overheated.

- 17e - error with the DIP switch.

- 18e - the smoke removal sensor is overheated.

- 27e - a problem with the air pressure sensor (open or short circuit).

Error 01e

Overheating of the equipment can happen due to the fact that the ducts have narrowed as a result of blockage, or the circulation pump has broken.

What you can do yourself:

- Examine the impeller of the circulation pump for damage to the impeller.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Check the heating system for air. If there is, it needs to be bled.

02e

An error that there is little coolant can be generated by the boiler if there is air in the system, little water, the impeller of the circulation pump is damaged, the distribution valve is closed, or the flow sensor is broken.

What can be done:

- Bleed the air.

- Adjust pressure.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Open distribution valve.

- Check the flow sensor - is there a short circuit in it, is there resistance.

- Open the sensor housing, clean the flag (moving mechanism with a magnet).

Most often, the problem is the presence of air in the hot water system.

03e

No flame signal. The reasons for this may be:

- Damage to the ionization sensor.

- No gas.

- No ignition.

- The faucet is closed.

- Faulty boiler grounding.

The blockage on the flame sensor must be cleaned. The gray coating on the electrode is cleaned off with fine sandpaper.

05e

What can be done:

- Check the resistance on the entire circuit from the controller to the sensor. Having found a malfunction, replace the sensor.

- Disconnect the controller and sensor connectors and reconnect.

10th

Smoke removal problems can occur due to fan failure, kinking, or improperly connecting sensor tubes to the fan. In addition, the chimney may be clogged, or there was simply a sharp and strong gust of wind.

What can be done:

- Repair the fan or replace it.

- Check the correct connection of the sensor tubes.

- Clean the chimney from blockages.

11th

A problem with the water filling sensor - this error is provided only for European-made boilers equipped with the appropriate sensors.

Noise and hum

It may happen that the error does not appear on the display, but an unnatural buzz or noise appears in the device. This happens when water hardly passes through the pipes due to scale, overheats and boils. The reason may be a bad coolant.

Coolant Navien

Troubleshooting procedure:

- You can fix the problem by disassembling the unit and cleaning the heat exchanger. If this fails, the part must be replaced.

- In addition, you need to check the taps - whether they are open to the maximum.

- Turn the water temperature down. It is possible that the boiler capacity is excessive for the pipeline to which it is connected.

No hot water

It happens that the heating boiler heats up as it should, but the water for hot water supply has stopped heating. This is a problem with the three way valve. Cleaning and repairs will not save - you need to change the part! The problem is not rare, the valves work normally for about 4 years.

So. Navien boilers are reliable and economical equipment. With proper operation and a competent approach to the difficulties that have arisen, problems can be eliminated even without the involvement of specialists from the service.

Design features

Absolutely all models of Navien boilers are controlled by Russified remote controls. Each boiler has a temperature sensor that allows you to maintain a comfortable temperature.

How the frost protection system works: when the coolant t drops to 10 C, the circulation pump turns on (it simply drives water through the pipes, preventing it from freezing). If t drops to 6 °C, the burner starts automatically.

Boiler design Navien Ace

The design of Navien boilers has two separate heat exchangers. Such a system has the following advantages:

- Resistant to clogging and scale from the central water supply.

- It is more convenient and cheaper to repair the heat exchanger.

- Greater productivity and quality of hot water supply.

There is a possibility of automatic or manual control. With manual control, you can change the heating water t from 40 to 80 C. At t 40 C and below, summer mode is activated. In this case, priority can be given to heating water for your needs. Automatic mode can maintain t in rooms from 10 to 40 C.

Boiler control panel Navien

The timer, which is also in NAVIEN boilers, allows you to set temporary work for half an hour at certain intervals.

Air-gas mixture preparation system. A powerful fan provides the optimal amount of oxygen. In flue gases - the minimum indicators of carbon dioxide and nitrogen oxide, which has a positive effect on fuel consumption.

Antifreeze cannot be used as a coolant in systems with Navien boilers.

Tips and tricks for operating the Navien boiler

The main advice of experts regarding the safe operation of the boiler:

- The room where the unit is located must be well ventilated.

- The unit must have a separate independent connection to the mains.

- The boiler must operate in a complete assembly and a protective case.

- It is forbidden for the user to independently repair the gas equipment of the boiler.

- The boiler must be subjected to an annual inspection by Gorgaz representatives.

- The owner of the boiler must periodically check the joints of the boiler and the gas pipeline for tightness with a soapy solution.

Additional Information.In the event of leaks, immediately close the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have long been used by Russian consumers. They quite rightly earned the trust of customers. Easy layout with the widest modern water heating functions allow you to choose these models from a large list of proposals on the heating market.

source